Anyone else collect knives?

Felice79

·It is a good piece of kit, and makes getting a decent edge, an easy operation. Being pretty foolproof helps.😁

Steve.

Having tried my luck with traditional Japanese water stones for some time (achieving rather mediocre results...😉 I can’t wait to try this thing out! Sal’s the man...😀

NOTSHARP

·Thanks! 😀

Having tried my luck with traditional Japanese water stones for some time (achieving rather mediocre results...😉 I can’t wait to try this thing out! Sal’s the man...😀

I have gone the opposite way, and have been using waterstones for the last six months, or so. Without doubt, I now get a better edge on my knives.

Steve.

MikiJ

·At least for me a better edge removes your fore-arm hair without any drag.

NOTSHARP

·Steve, could you tell me what exactly you mean by "better" edge? Just curious. Thanks! 😀

Maybe, "better for me", would have been more apt. 😉

I can certainly get a sharper, smoother, edge on all of my knives. I can determine, and control, the bevel angle that suits each knife.

Yes, it did take longer, initially, to get that edge, but, thereafter, maintaining the edge is very easy, often only needing a paddle strop.

I use a 1000/6000 combination stone, and a paddle strop loaded with chromium oxide paste.

Once the bevel is set, an occasional touch up on the 6000, gets the edge back in no time.

Sadly, no edge is "Wife Proof" 🙄

Steve.

STANDY

··schizophrenic pizza orderer and watch collectorPractice and a wet stone is all you need.

Being a butcher for many years I must say that people new to sharpening themselves tend to over sharpen a blade ( spend too long sharpening when it's not needed ) if it's not sharp in a few minutes and a few swipes your doing something wrong.

If I could give anyone a bit of advice it would be too steel your knife more which will mean sharpening less.

One of these is my secret ( and it's why ever butcher has a steel handling of his belt )

https://www.chefknivestogo.com/fdicfincutfl.html

Being a butcher for many years I must say that people new to sharpening themselves tend to over sharpen a blade ( spend too long sharpening when it's not needed ) if it's not sharp in a few minutes and a few swipes your doing something wrong.

If I could give anyone a bit of advice it would be too steel your knife more which will mean sharpening less.

One of these is my secret ( and it's why ever butcher has a steel handling of his belt )

https://www.chefknivestogo.com/fdicfincutfl.html

JonAsh6105

·This is part of my "collection". My dad picked these up in Thailand when he was stationed there '70-72. They are engraved with pictures of USAF and Army aircraft of the period: F4 Phantom, B-52, C-130, A4 Skyhawk, CH-47, Huey Cobra, and UH-1 Huey. I also have his old AF survival knife, as well as his 1960's Puma folding hunting knife.

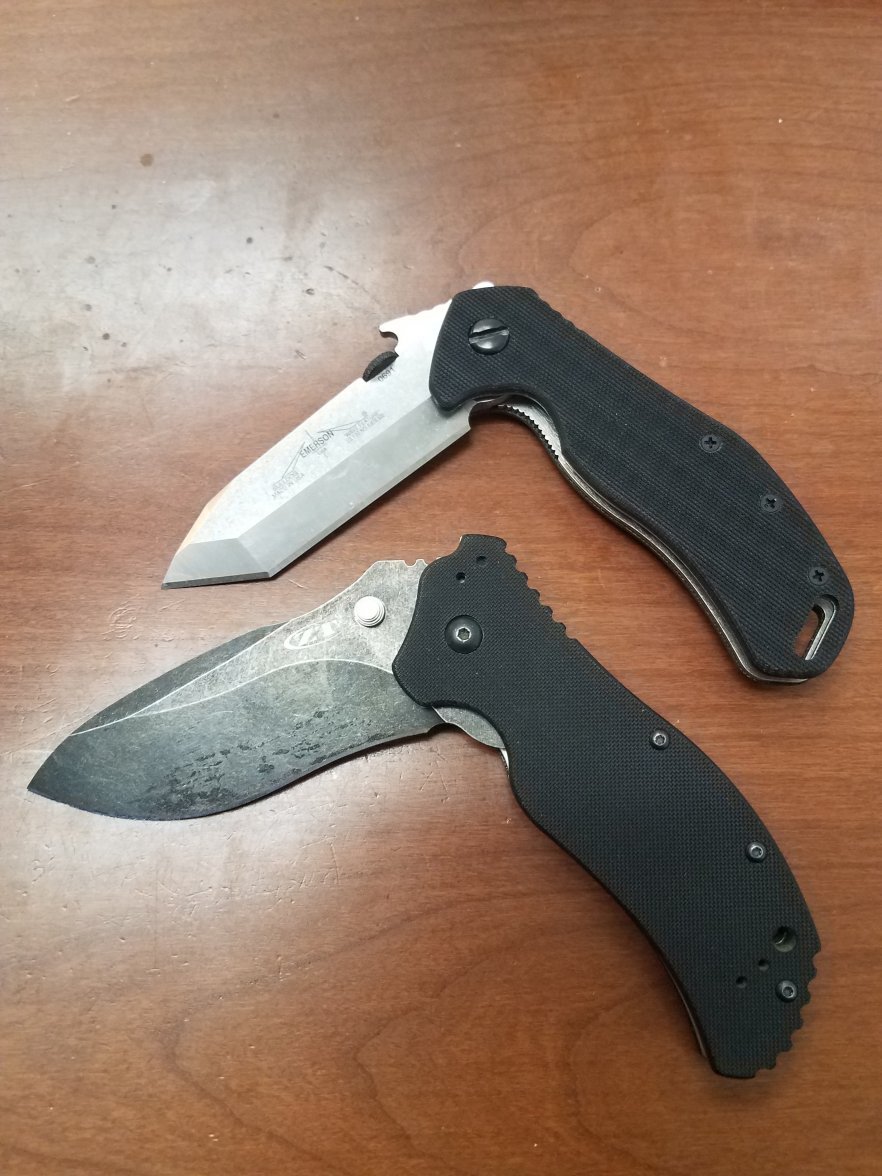

My two daily carry knives are a Zero Tolerance folder or an Emerson Mini Bulldog. The Emerson is possibly the highest quality knife I have ever seen. I also have numerous Benchmade folders and the Benchmade Adamas fixed blade I use for outdoors and camping. I also bought a TOPS Screaming Eagle after my time with the 101st Airborne Division. That one is far too large for any practical use, though.

*Pictures of the Benchmade and TOPS knives are not my own; pulled from google since I am currently at work.

My two daily carry knives are a Zero Tolerance folder or an Emerson Mini Bulldog. The Emerson is possibly the highest quality knife I have ever seen. I also have numerous Benchmade folders and the Benchmade Adamas fixed blade I use for outdoors and camping. I also bought a TOPS Screaming Eagle after my time with the 101st Airborne Division. That one is far too large for any practical use, though.

*Pictures of the Benchmade and TOPS knives are not my own; pulled from google since I am currently at work.

BlackTalon

··This Space for RentNOTSHARP

·Not me.

I used to be on BritishBlades, before it vanished into the ether.

Steve.

STANDY

··schizophrenic pizza orderer and watch collectorSpyderco forum is all now, others get a bit to full on with collectors and metal junkies.

I use knives

BlackTalon

··This Space for RentSpyderco forum is all now, others get a bit to full on with collectors and metal junkies.

I use knives

STANDY

··schizophrenic pizza orderer and watch collectorBeing a butcher when I left school and coming from a family in the meat game. I find it hard to play nice with chef,s and kitchen Cowboys with the whole Japanese steel is best and my knife is worth this much so it is better. ( usually No offence to anyone but think wearing out a few knives a year no matter what materials would mean I knew a bit about sharpening and what steel is best )

I think if you have more than 3 knives in the kitchen you have too many

There does not exist a good knife block set.

The biggest gimmick (I think rort) in the last 10-15 years is Damascus

My bread board 😉 ( full size butchers block )

I think if you have more than 3 knives in the kitchen you have too many

There does not exist a good knife block set.

The biggest gimmick (I think rort) in the last 10-15 years is Damascus

My bread board 😉 ( full size butchers block )

BlackTalon

··This Space for RentAs a butcher your view is definitely different then a typical cook's view, and for very good reasons. There is no question the high-hardness often associated with japanese kitchen knives is not desirable for butchering. You generally benefit from a softer, yet tougher blade steel/ heat treatment. Most of the japanese knives are geared towards vegetables, fish and poultry.

I am just a homer cook, and will admit to applying the same logic to kitchen knives that I apply to watches (i.e., I have more then three, and they generally cost a bit more then a basic Timex. 😁 ) I apply the same logic to cars as well; I have more then I need (2), and it is more expensive and has more crap on it then a car really needs to get from point A to point B.

There are a few knifemakers in the US who are making some 'real' butchering knives. I have very few japanese knives myself, but a decent enough collection of chef's knives, pettys, parings, etc. from knifemakers based in the US, Canada and the UK. I am a home cook, and I enjoy the benefit of knife edges staying sharp a lot longer, etc. It speeds up prep time when I get home from work, so we can eat dinner earlier.

No question a skilled butcher can break down a whole cow, pig, goat, etc. with a single 6 inch butchering knife; I had thew pleasure of watching a master butcher do just that at a butchering class last year. No need for an arsenal of knives for work like that -- just get 'er done. But sometimes it nice to have knife choices when the luxury of time allows for it.

As far as costs go, most of the knife forum members are happy to find the lastest budget performers, as they offer by far the most bang-for-the-buck. And while knives from custom makers can hold their value (and even go up in value for some), the pro cooks would rather have cheaper options that are easy to sharpen and hold the edge for a long time with minimal touch-up needed.

Damascus is definitely window dressing, and anyone who claims it makes for a better performing knife generally has drank the Kool-Aid. It is similar to the finish work that goes into some watch movements, or a waffle patterns carved into some dials (or a meteorite dial); it offers zero performance gain. And while I have no interest in owning a mass-market damascus knife, or anything made from factory-produced damascus, I have a couple damascus knives from custom makers that are highly-functional art. No real reason for commissioning them other then the custom makers are phenomenal bladesmiths, and I wanted something that represented the height of their steel-forging skills. One such knife is a scimitar made by a maker who worked as a butcher for several years, and was eager to make some butchering knives instead of the more pedestrian gyutos. It is definitely not an everyday knife for me, but I sure as heck smile whenever I break it out to portion steaks.

Before I got drawn into the world of watches, kitchen knives represented my most frivolous purchases. I definitely got a few duds over the years, but there are quite a few in my knife blocks that remind me why I gave up on the soft stainless steel knives made by Wusthoff, Henkels, etc. The speed in which I can go through a pile of onions, bell peppers, etc. is substantially higher then with those german-branded knives that I had always been led to believe were the 'best' kitchen knives you could get. Thankfully one cooking forum educated me a bit on the wonders old european carbon knives, which then led into the world of japanese-style knives. For many stopping at the old european carbons is as far as they need/ want to go, and that is still a big step up.

I am just a homer cook, and will admit to applying the same logic to kitchen knives that I apply to watches (i.e., I have more then three, and they generally cost a bit more then a basic Timex. 😁 ) I apply the same logic to cars as well; I have more then I need (2), and it is more expensive and has more crap on it then a car really needs to get from point A to point B.

There are a few knifemakers in the US who are making some 'real' butchering knives. I have very few japanese knives myself, but a decent enough collection of chef's knives, pettys, parings, etc. from knifemakers based in the US, Canada and the UK. I am a home cook, and I enjoy the benefit of knife edges staying sharp a lot longer, etc. It speeds up prep time when I get home from work, so we can eat dinner earlier.

No question a skilled butcher can break down a whole cow, pig, goat, etc. with a single 6 inch butchering knife; I had thew pleasure of watching a master butcher do just that at a butchering class last year. No need for an arsenal of knives for work like that -- just get 'er done. But sometimes it nice to have knife choices when the luxury of time allows for it.

As far as costs go, most of the knife forum members are happy to find the lastest budget performers, as they offer by far the most bang-for-the-buck. And while knives from custom makers can hold their value (and even go up in value for some), the pro cooks would rather have cheaper options that are easy to sharpen and hold the edge for a long time with minimal touch-up needed.

Damascus is definitely window dressing, and anyone who claims it makes for a better performing knife generally has drank the Kool-Aid. It is similar to the finish work that goes into some watch movements, or a waffle patterns carved into some dials (or a meteorite dial); it offers zero performance gain. And while I have no interest in owning a mass-market damascus knife, or anything made from factory-produced damascus, I have a couple damascus knives from custom makers that are highly-functional art. No real reason for commissioning them other then the custom makers are phenomenal bladesmiths, and I wanted something that represented the height of their steel-forging skills. One such knife is a scimitar made by a maker who worked as a butcher for several years, and was eager to make some butchering knives instead of the more pedestrian gyutos. It is definitely not an everyday knife for me, but I sure as heck smile whenever I break it out to portion steaks.

Before I got drawn into the world of watches, kitchen knives represented my most frivolous purchases. I definitely got a few duds over the years, but there are quite a few in my knife blocks that remind me why I gave up on the soft stainless steel knives made by Wusthoff, Henkels, etc. The speed in which I can go through a pile of onions, bell peppers, etc. is substantially higher then with those german-branded knives that I had always been led to believe were the 'best' kitchen knives you could get. Thankfully one cooking forum educated me a bit on the wonders old european carbon knives, which then led into the world of japanese-style knives. For many stopping at the old european carbons is as far as they need/ want to go, and that is still a big step up.

STANDY

··schizophrenic pizza orderer and watch collectorBurt Foster is one of my favourite knife makers in the US have a few and use them hard hunting and dressing buffalo in the bush.

Old European carbon is where it's at, refurbishing a few Gustav Emil Ern,s at the moment knife and chopper. Plenty of carbon in these two look at that patina 😉

Larger chopper is a Sheffield Ox head chopper

And for a pairing knife you can not go past a Le Morta

http://couteaux-morta.com/couteau-morta-fixe-inox-en-us/

( mammoth Ivory inlay, 5000 year old bog wood handle )

Old European carbon is where it's at, refurbishing a few Gustav Emil Ern,s at the moment knife and chopper. Plenty of carbon in these two look at that patina 😉

Larger chopper is a Sheffield Ox head chopper

And for a pairing knife you can not go past a Le Morta

http://couteaux-morta.com/couteau-morta-fixe-inox-en-us/

( mammoth Ivory inlay, 5000 year old bog wood handle )

Edited:

JimInOz

··Melbourne Australia..........

And for a pairing knife you can not go past a Le Morta

http://couteaux-morta.com/couteau-morta-fixe-inox-en-us/

( mammoth Ivory inlay, 5000th year old bog wood handle )

That's a nice little knife 👍.

But what are all of those strange looking coloured things on the chopping board?

😁