And What Did You Buy Today?(Not Watches or related)

JimInOz

··Melbourne AustraliaONEWATCH

·Didn't purchase, built it. Roughly 4' X 8' 6" table base. Octagonal tapered legs. Mortise and tenon joints. Red Oak with no stain and Old Master finish. Having the top made as it's size is beyond my capacity 9' 6" X 5' X 1 1/2" thick. The top will weigh around 275 pounds. And then the 12 chairs. Buying my mortise machine next week.

arturo7

·arturo7

·First step is to adjust OPV from 15bar factory set pressure to 9bar - the higher factory set is to accommodate inferior coffee pods.

Next step will be a PID temperature controller to replace the standard thermostat.

This forum is a great resource: https://coffeeforums.co.uk/forum.php

I've had a GC for about 5 years.

One of these days I'll do the OPV mod.

I temp surf, no plans for the PID.

jimmyd13

·I've spent hours digging deeper into this. Of late, I've developed quite a thing for radiator/hood ornaments. Strangely, when I saw this one I knew exactly what it was ... a Macchi 72. I ended up paying more for it than I thought I would have to ... but then found that Bonhams sold a similar one in 2012 for over $7000 ... so, yay me!

She's already at the carpenter's to have a mount made ... here's the auction photie ...

(Oh, and the props spin in opposite directions if you can blow hard enough)

She's already at the carpenter's to have a mount made ... here's the auction photie ...

(Oh, and the props spin in opposite directions if you can blow hard enough)

Wivac

·5starChad

·Bought some new running shoes. Plantar fasciitis is a real pain. Literally. Between running and muay thai my feet hate me.

ONEWATCH

·Swissmister

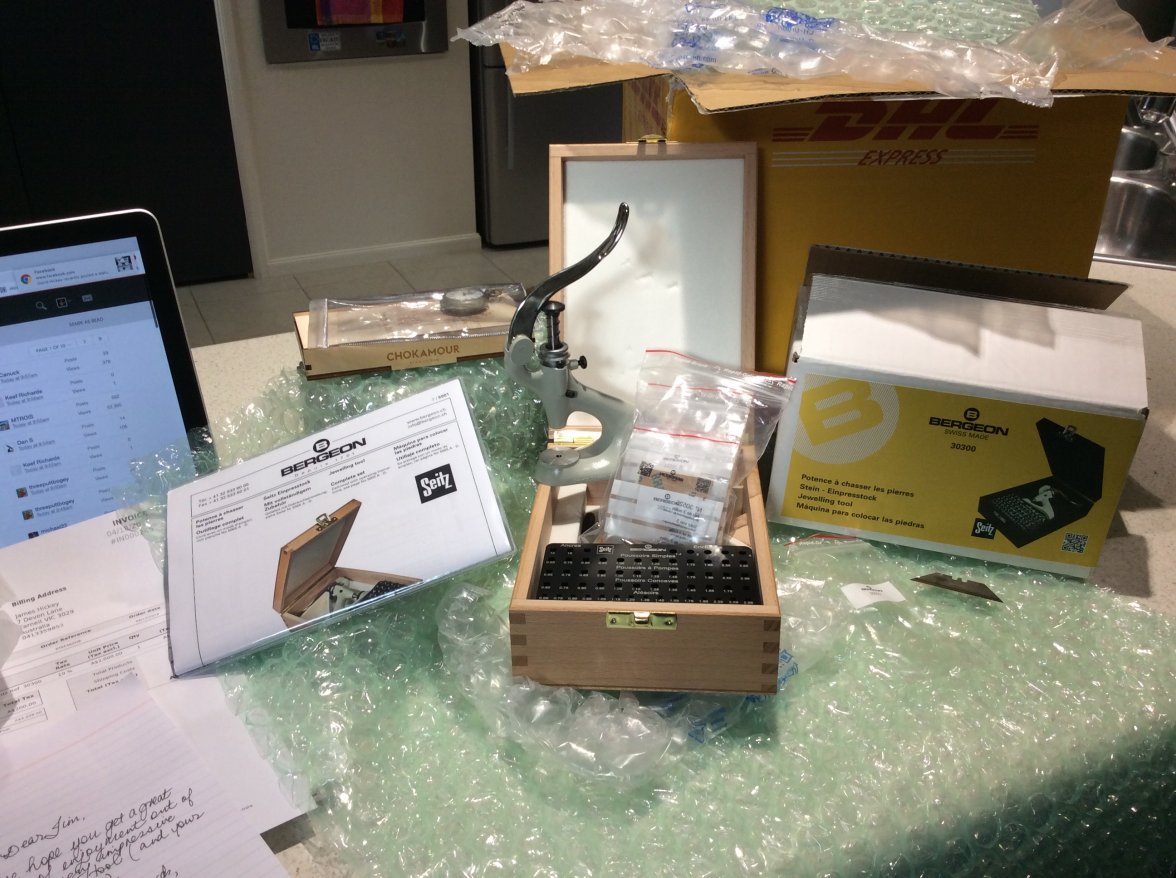

·A new mortise machine. For those who are wondering, it makes square holes in wood.

wagudc

·Are you making small wooden boxes? Furniture?

ONEWATCH

·Yes, I make square holes in wood. Then I make the tenon to go in the square hole in the wood. When I finish all 18 pieces and I put them together, hopefully I will have a chair. Above you can see the table base I built and the table top, 9.5' X 5', will arrive on the 25th. I only have 12 of the chairs to build. Having never built a chair I will be practicing with pine at $6.00 per chair as opposed to Red Oak at $45.00 per chair. It will be awhile but I will update.

Swissmister

·That's very cool. There's no better joint than mortise and tenon, and when the parts are relatively small, it's not easy to create strong joints, as in a chair. And chairs, of course, are subjected to a lot of strain and stress at various angles and from various directions. I've never been a chair-maker, while woodworking for decades, but it is an art form, really. Maybe you could move to poplar/tulip after spruce. It is excellent for working and quite hard, yet considerably less costly than oak or the higher end hardwoods like cherry, walnut, mahogany.

Did you make any mortises by hand before buying the tool? That is quite a process, like creating dovetails by hand. Have you ever used biscuits for joints? That's a very good system, too.

Sorry, I just looked back and saw the post with the table base. Great work. Tapered legs isn't a walk in the park. It will be a very fulfilling and functional project when finished. Something that will become a family heirloom, no doubt. Imagine your great, great grandchildren will one day be telling how you built that set way back in the early 2000s. It will be patinated with countless family memories. This is making me want to build a table (maybe buy the chairs.)😉

Did you make any mortises by hand before buying the tool? That is quite a process, like creating dovetails by hand. Have you ever used biscuits for joints? That's a very good system, too.

Sorry, I just looked back and saw the post with the table base. Great work. Tapered legs isn't a walk in the park. It will be a very fulfilling and functional project when finished. Something that will become a family heirloom, no doubt. Imagine your great, great grandchildren will one day be telling how you built that set way back in the early 2000s. It will be patinated with countless family memories. This is making me want to build a table (maybe buy the chairs.)😉

Edited:

ONEWATCH

·If you look above you can see the table base for the top. Those mortises were 2" X 1" X 2 1/2" deep and were done with a router. Since the skirt boars were so long I could not make the tenons on the table saw, so they were also routed. Lots of final chiseling, filing and sanding to get just the right fit. Usually use Titebond II but used hide glue for more time to get the table base square and the legs vertical. You can see on that photo the 4" square pieces of wood on the bottom of the legs to help make sure the legs are vertical. When I glue up tops I always put a 1/4" groove in each board and then a 1/4" piece to help get good alignment when gluing up. Helps keep the boards from racking out of horizontal.

I love poplar because it never moves. Usually only use it when I am going to paint it. Oak is a real pain to work with besides the cost. I made the octagonal tapered table legs. Set up a router jig on top of an old lathe I bought. ($20.00) It took 32 passes with the router to make one leg. Red oak requires multiple bit cleaning to keep the chatter down. Never gain will I make octagonal tapered legs.

I love poplar because it never moves. Usually only use it when I am going to paint it. Oak is a real pain to work with besides the cost. I made the octagonal tapered table legs. Set up a router jig on top of an old lathe I bought. ($20.00) It took 32 passes with the router to make one leg. Red oak requires multiple bit cleaning to keep the chatter down. Never gain will I make octagonal tapered legs.

Swissmister

·If you look above you can see the table base for the top. Those mortises were 2" X 1" X 2 1/2" deep and were done with a router. Since the skirt boars were so long I could not make the tenons on the table saw, so they were also routed. Lots of final chiseling, filing and sanding to get just the right fit. Usually use Titebond II but used hide glue for more time to get the table base square and the legs vertical. You can see on that photo the 4" square pieces of wood on the bottom of the legs to help make sure the legs are vertical. When I glue up tops I always put a 1/4" groove in each board and then a 1/4" piece to help get good alignment when gluing up. Helps keep the boards from racking out of horizontal.

I love poplar because it never moves. Usually only use it when I am going to paint it. Oak is a real pain to work with besides the cost. I made the octagonal tapered table legs. Set up a router jig on top of an old lathe I bought. ($20.00) It took 32 passes with the router to make one leg. Red oak requires multiple bit cleaning to keep the chatter down. Never gain will I make octagonal tapered legs.

ONEWATCH

·Something to be proud of.