vadimo

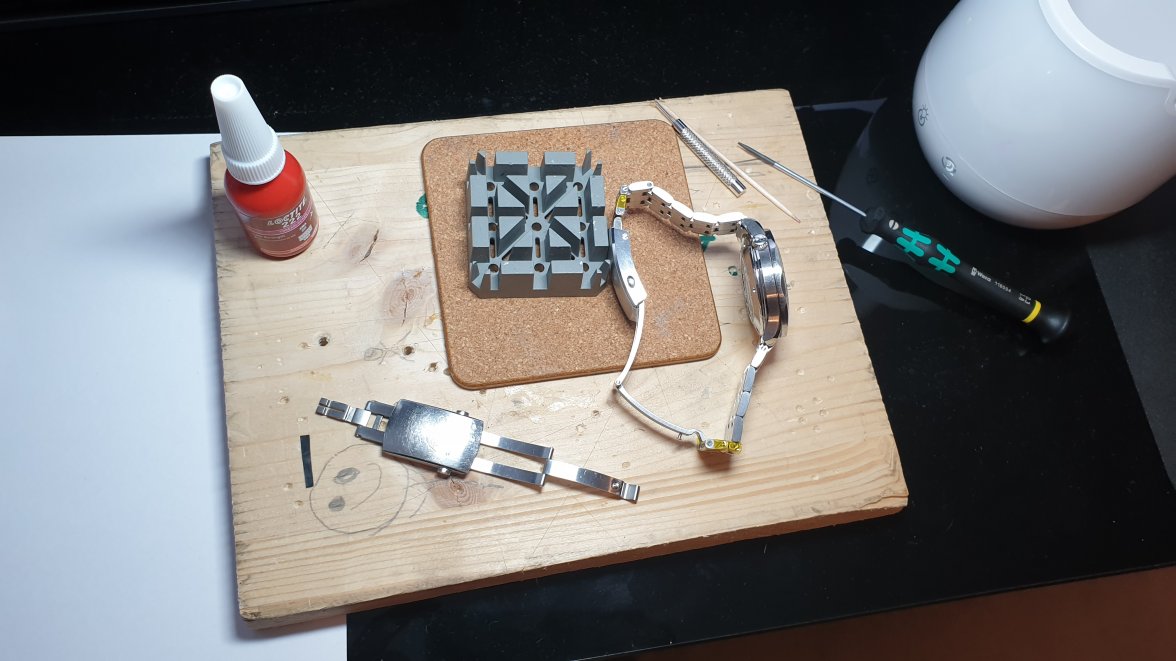

·I just got new 3 position micro adjustable clasp for previous generation Seamaster 300.

I am split between either do it myself and get the tools or got to a jeweller and pay them to do.

Any advice?

I am split between either do it myself and get the tools or got to a jeweller and pay them to do.

Any advice?