Archer

··Omega Qualified WatchmakerOver the years there have been many conversations here and elsewhere regarding the reasoning behind Omega moving to the 861 from the 321. Many of these conversations make claims that the 861 was “cheaper” to produce, and the pillar wheel (known as column wheel by most, so that is the term I will use from here on) is often cited as the thing that caused the 321 to be so expensive relative to the 861.

Personally, I’ve never bought into this idea, and looking at what a column wheel costs as a spare part (the best indication we have about costs of production) my suspicions are borne out. The 321 column wheel is under $100 to purchase as a spare part. A column wheel for a 3313 is under $40, as is the column wheel for the 3300. The two parts of the cam (upper and lower) for the 861/1861 cost more than either of the column wheels for the 3313 or 3330, but are a little less than the column wheel for the 321.

On the new 3861, the two parts of the cam (what they for some reason call the upper and lower wig-wag on this movement) cost more than the column wheel for the Cal. 321.

So all in if we are talking about a part that ranges from less than $40 to a little more than double that, is this really a significant thing in the cost of making the movement?

Note that the remainder of the parts to make either system work is about the same in number...there's really nothing in it between the two.

So where are the supposed savings in the 861 design? There are a few things that would contribute to it certainly, and one is the balance wheel. They moved from an adjustable mass balance with an overcoil on the balance spring, to a smooth balance with a flat balance spring.

Here’s a 321 balance:

And an 861/1861 balance:

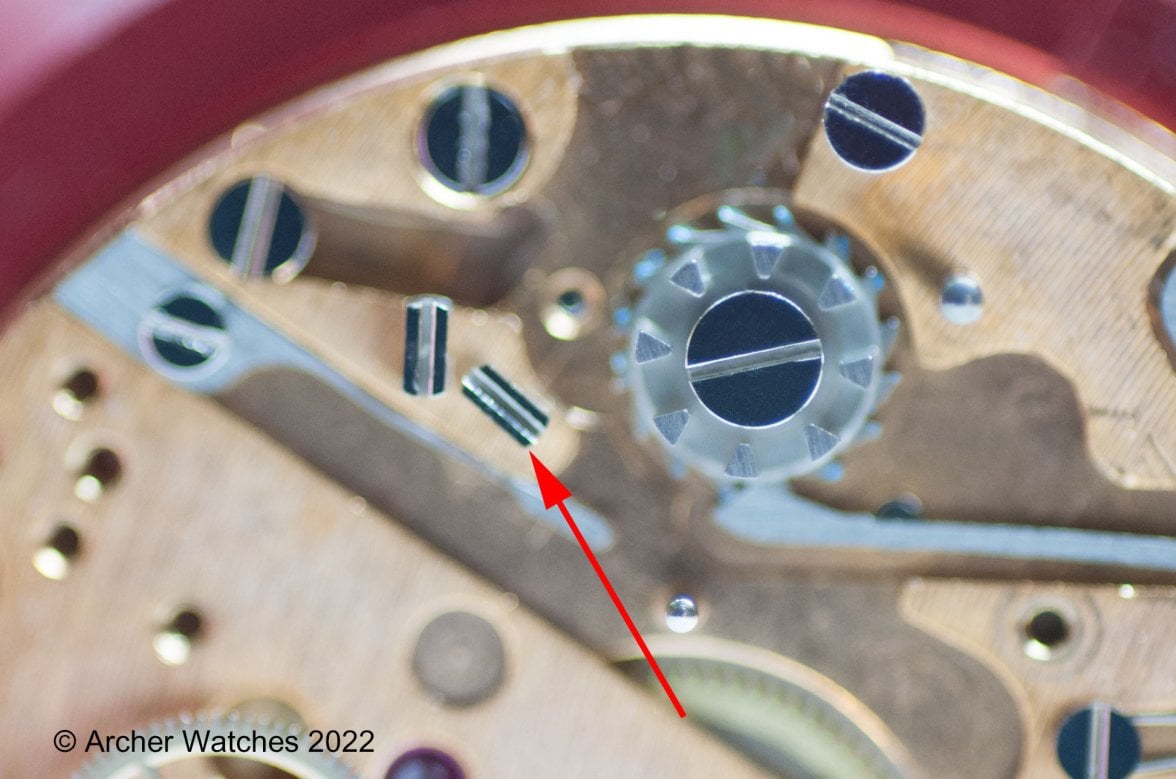

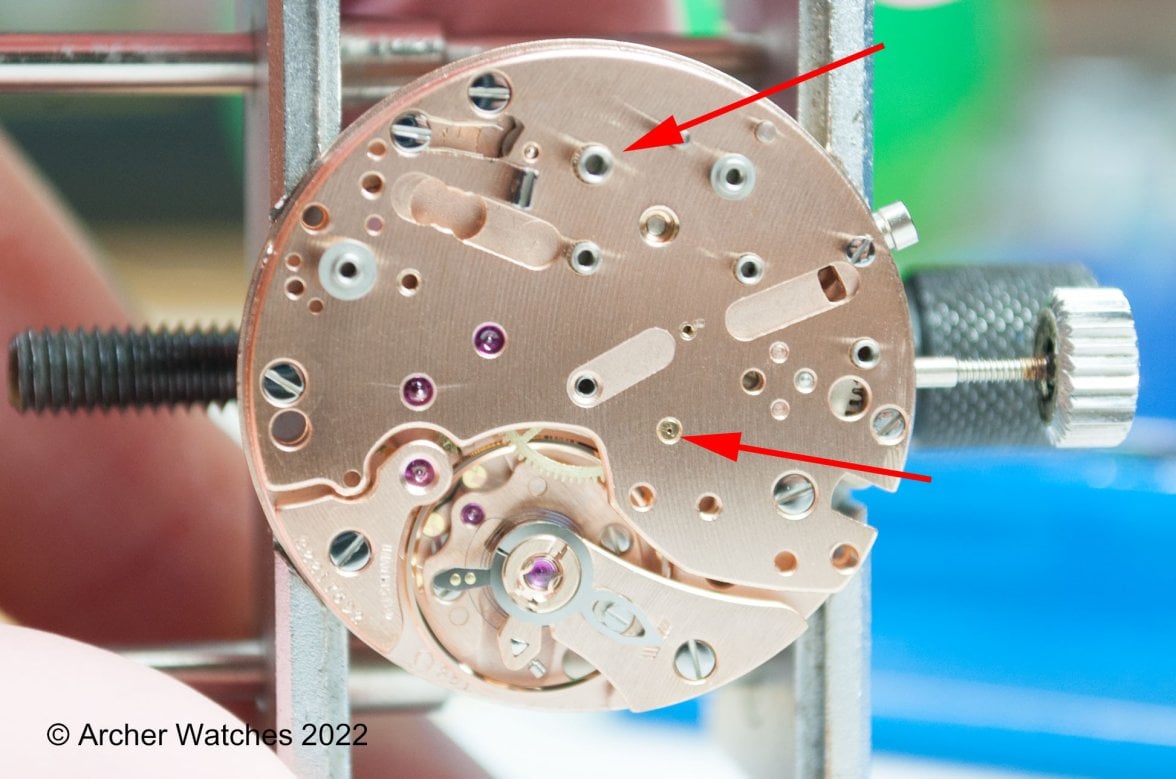

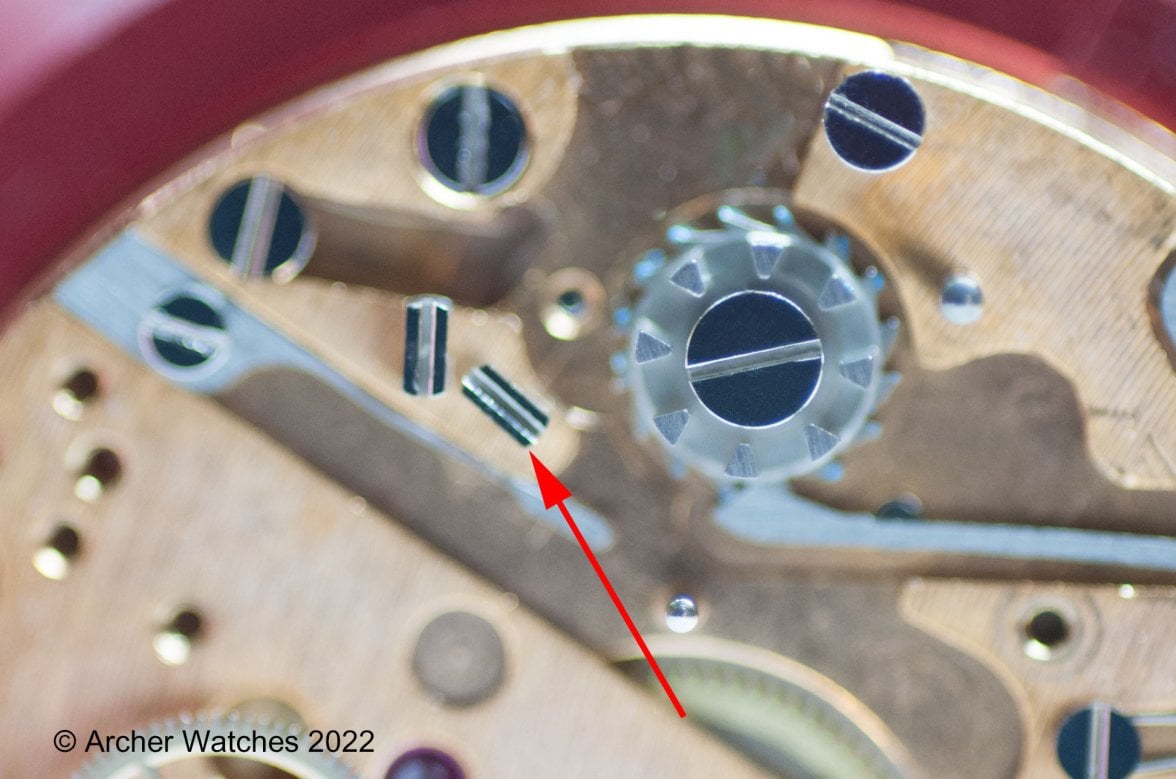

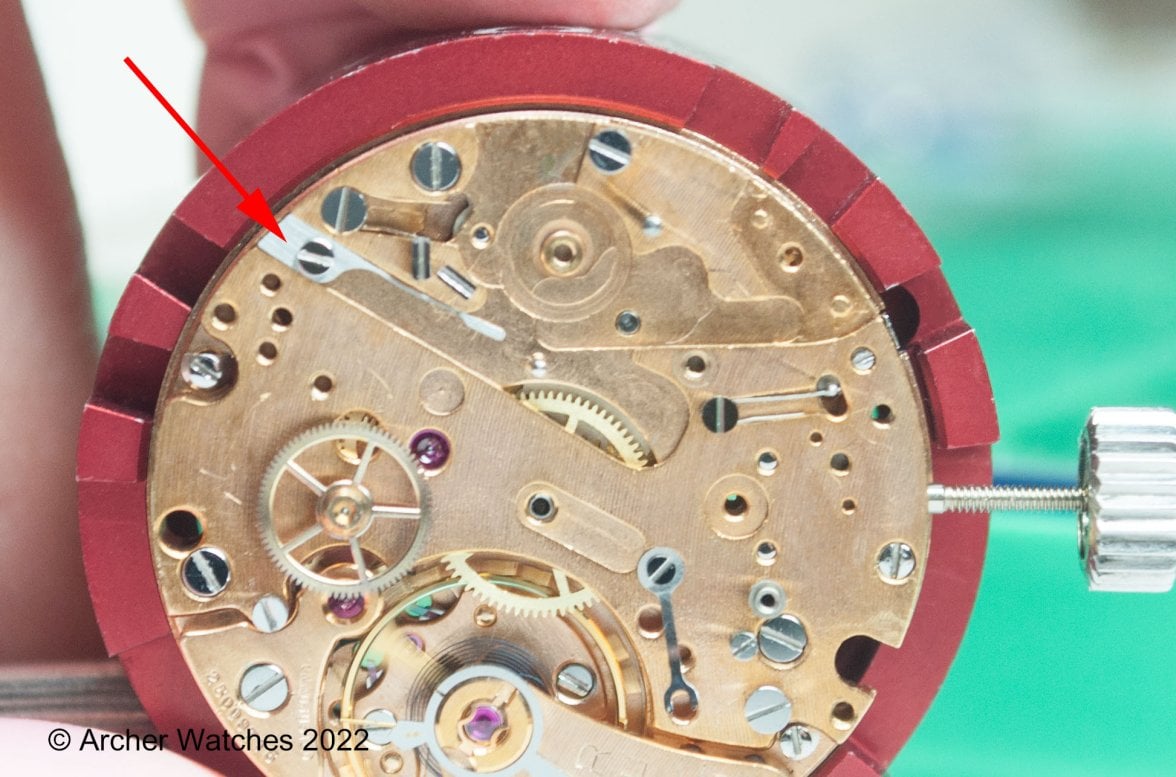

The main “wheel train and barrel bridge” is another area where changes were made, but these are less to do with the design of the movement and more do to do with streamlining manufacturability. An example is where the post for the column wheel was machined out of the brass plate on the 321 as you can see here:

It is a separate part made of steel that is pressed into the bridge on the 861, and I’ll show that later on. But in my view all these thing pale in comparison to the real savings in both manufacturing and servicing the 861, and the genius of the design of this movement.

The minute recorder.

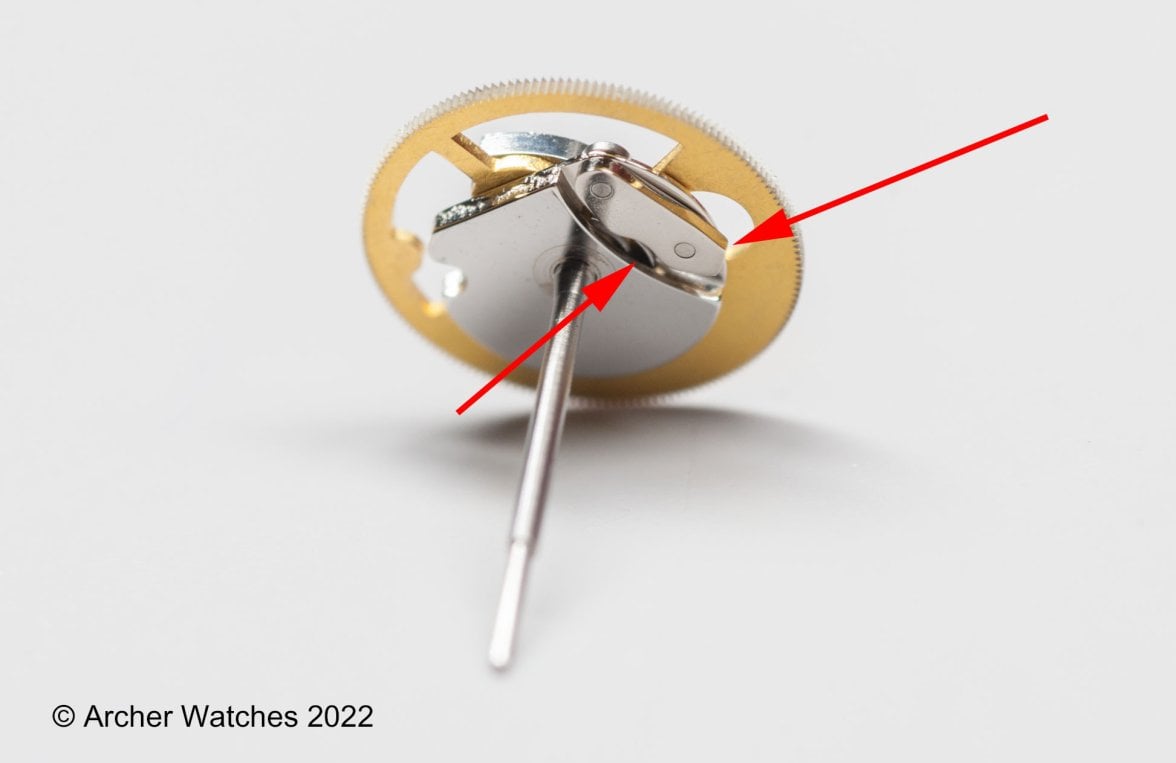

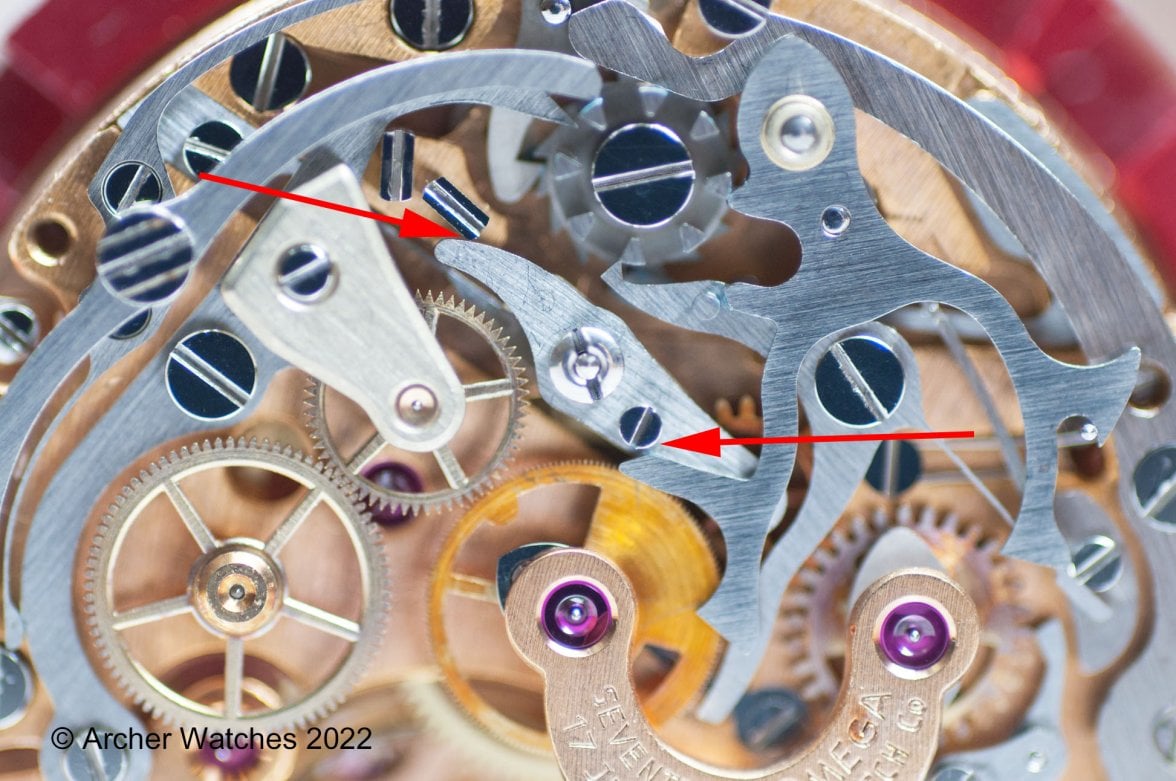

Let’s look at the 321’s minute recorder parts. It starts with the chronograph wheel, and on the underside of that wheel is a finger:

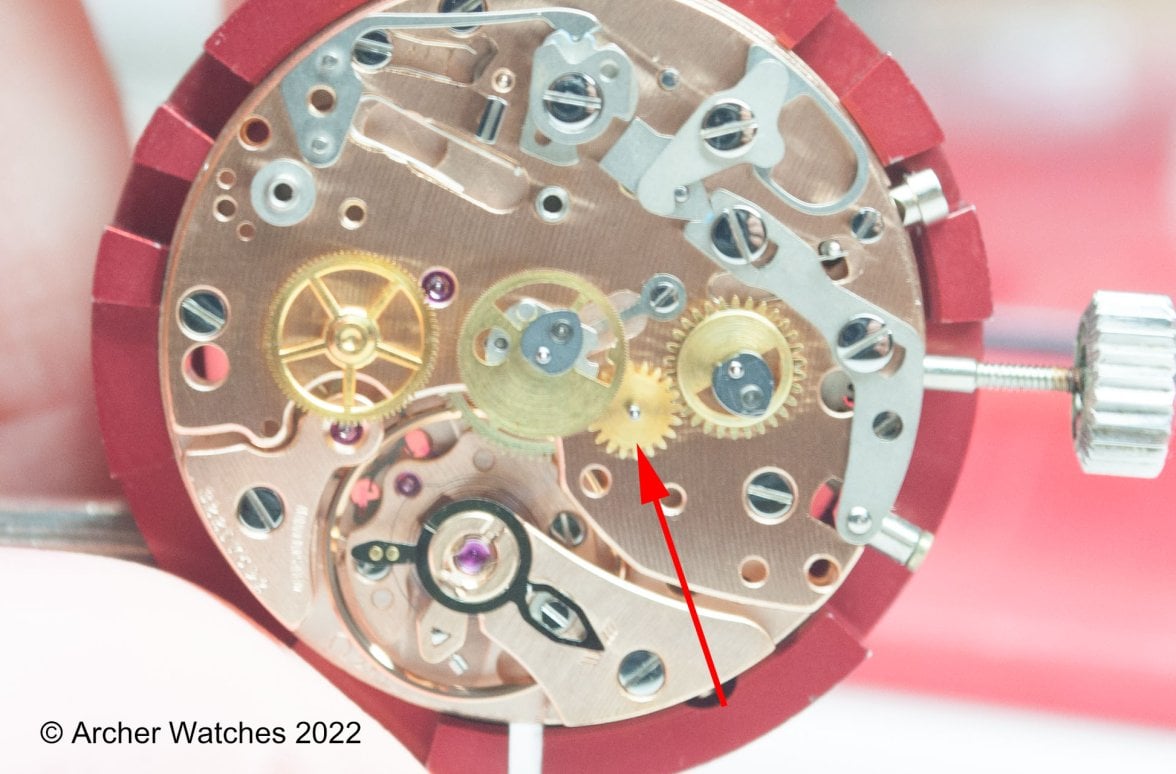

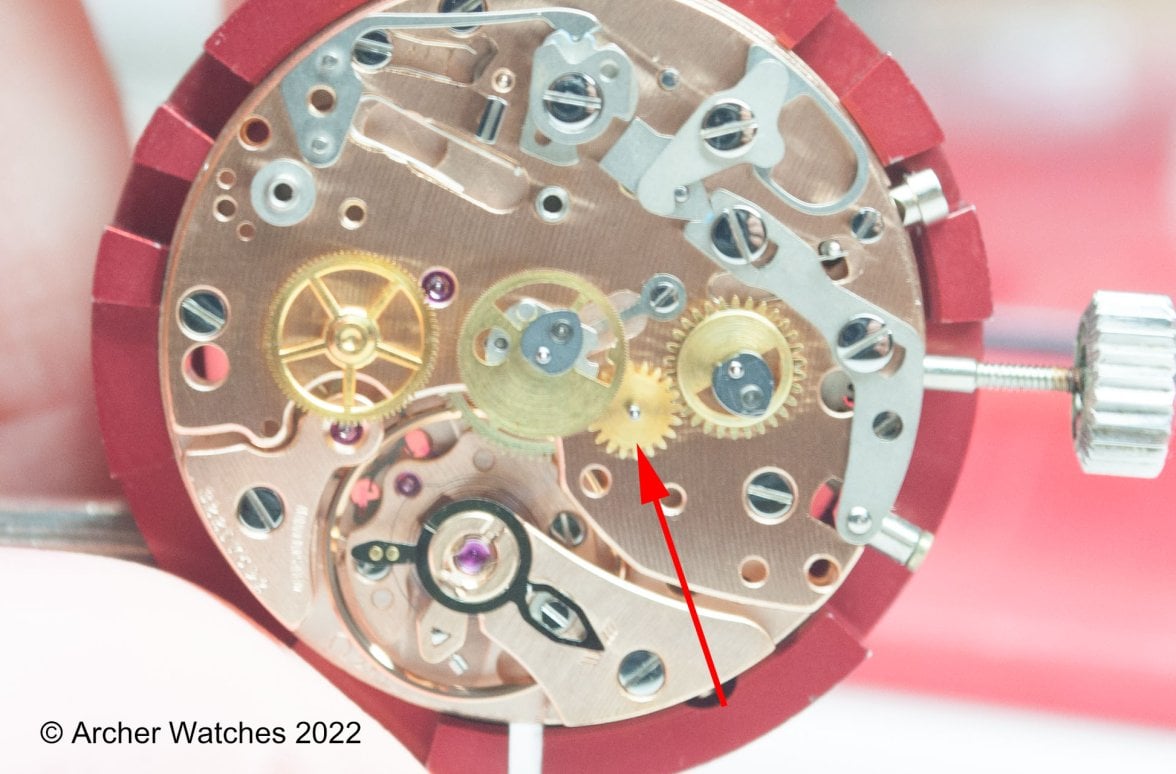

This wheel and finger rotates once per minute, and is what triggers the flip of the minute counter. Now that finger is rigid, but it can be rotated on the post of wheel, and this is one of the adjustments that the 321 has on the chronograph. Now this finger is quite short as you can see, so it clearly doesn’t reach all the way across to the minute recording wheel to trip it, so there’s an intermediate step. This is done via something called the sliding gear – this is actually a subassembly made up of several parts and here is the top view:

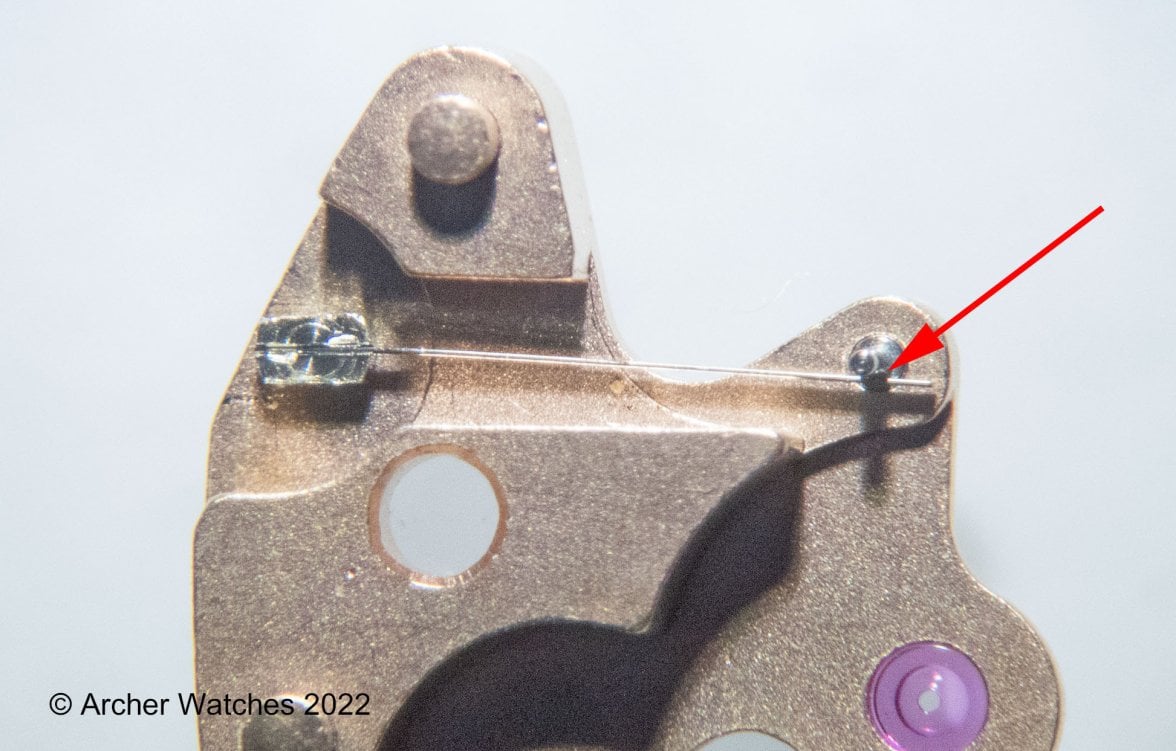

Bottom view:

Side view:

So there are several parts here – a wheel, top and bottom plates, two bushings, screw that holds it together, and a bushing that goes through it. This bushing slips over a post that is pressed into the wheel train and barrel bridge. But we aren’t done yet...there is also the minute counting wheel, and then the minute jumper assembly. The minute counting wheel itself is no different from the 861 version, so I won’t spend a lot of time on it. But the teeth of that wheel are located and held in place in their 1 minute increments by something called a jumper (sometimes a paperclip is used in place of it even!).

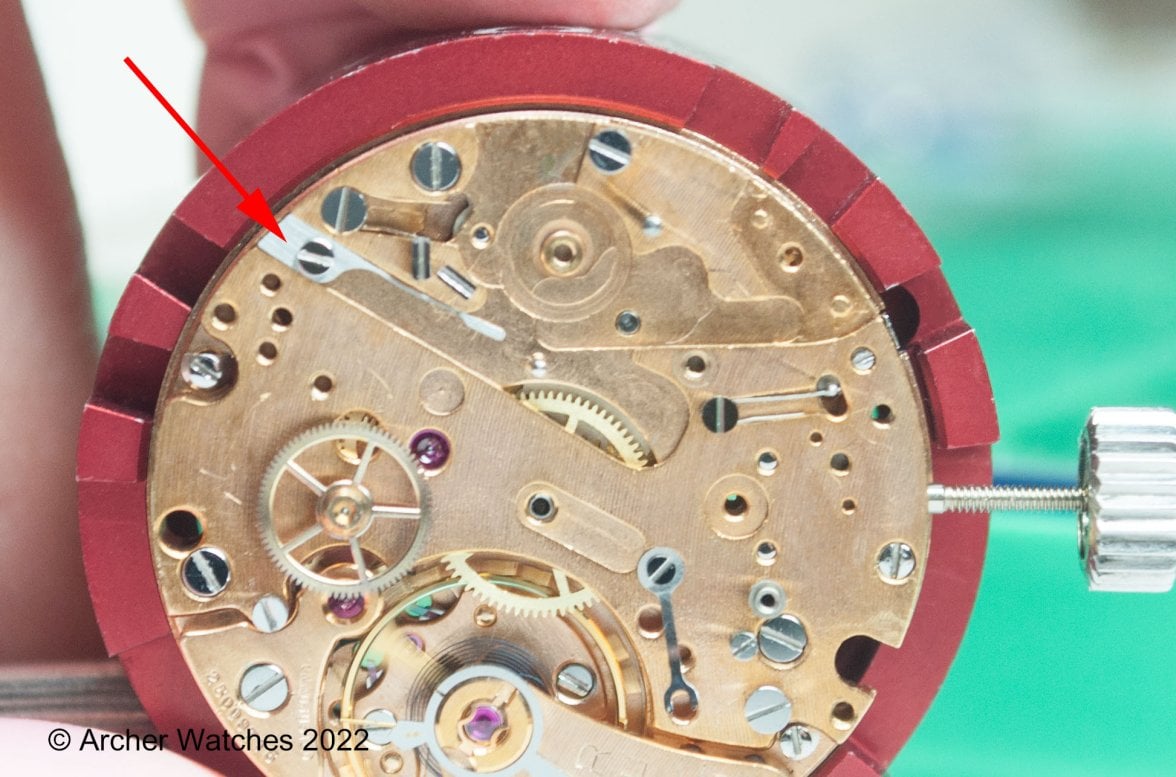

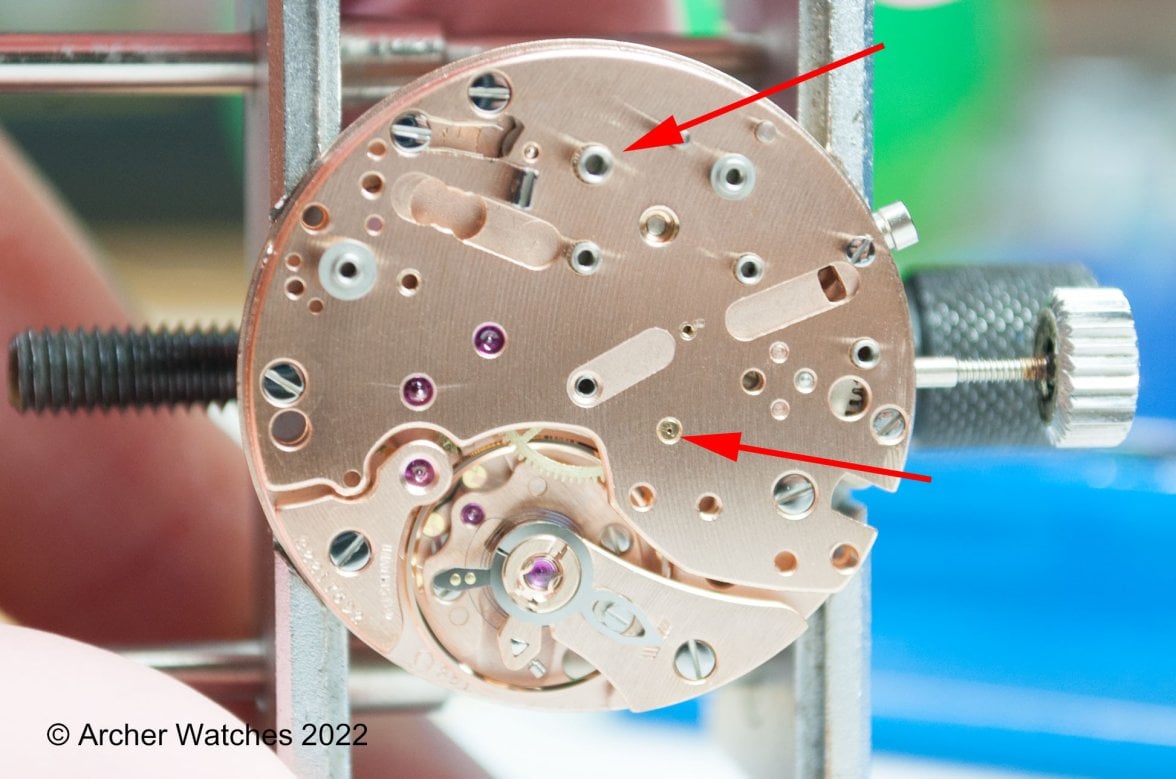

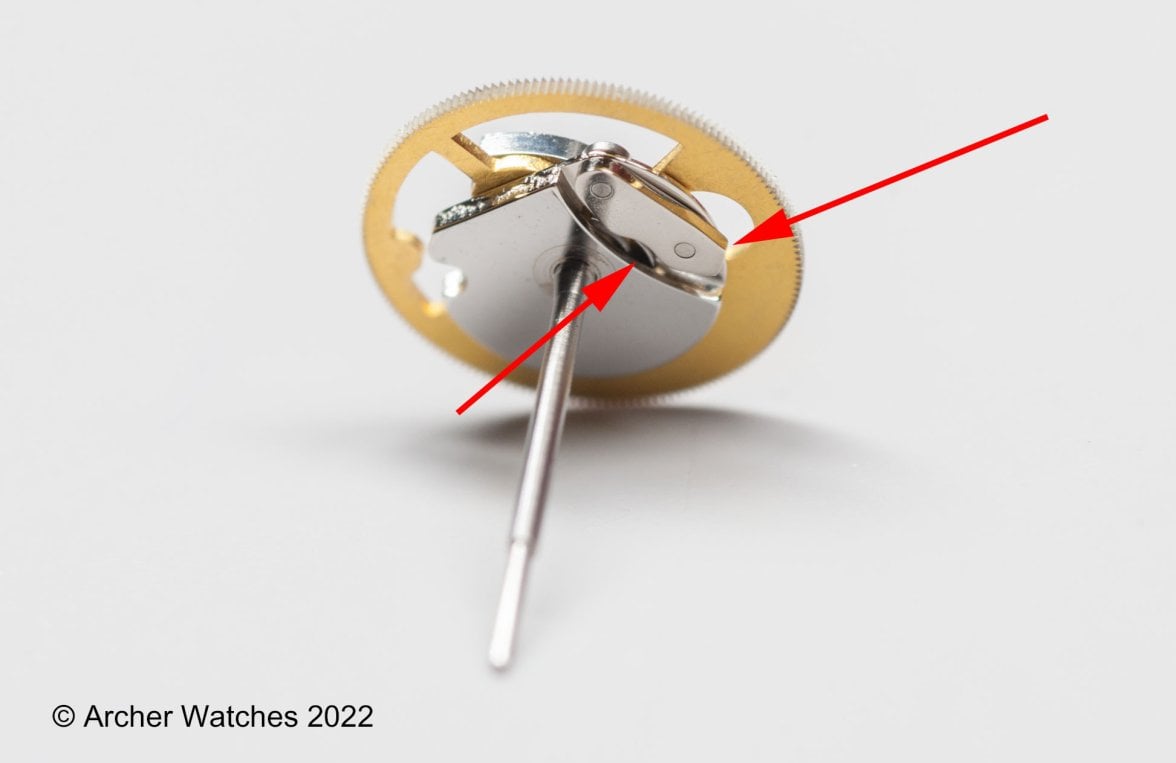

So here is the wheel train and barrel bridge where the jumper is located:

The upper arrow points to a slightly fuzzy part, and this is the post that the rest of the jumper mounts to. The lower arrow points to an eccentric screw – this is for adjusting the jumper, so by turning this the position that the wheel rotates it's position slightly.

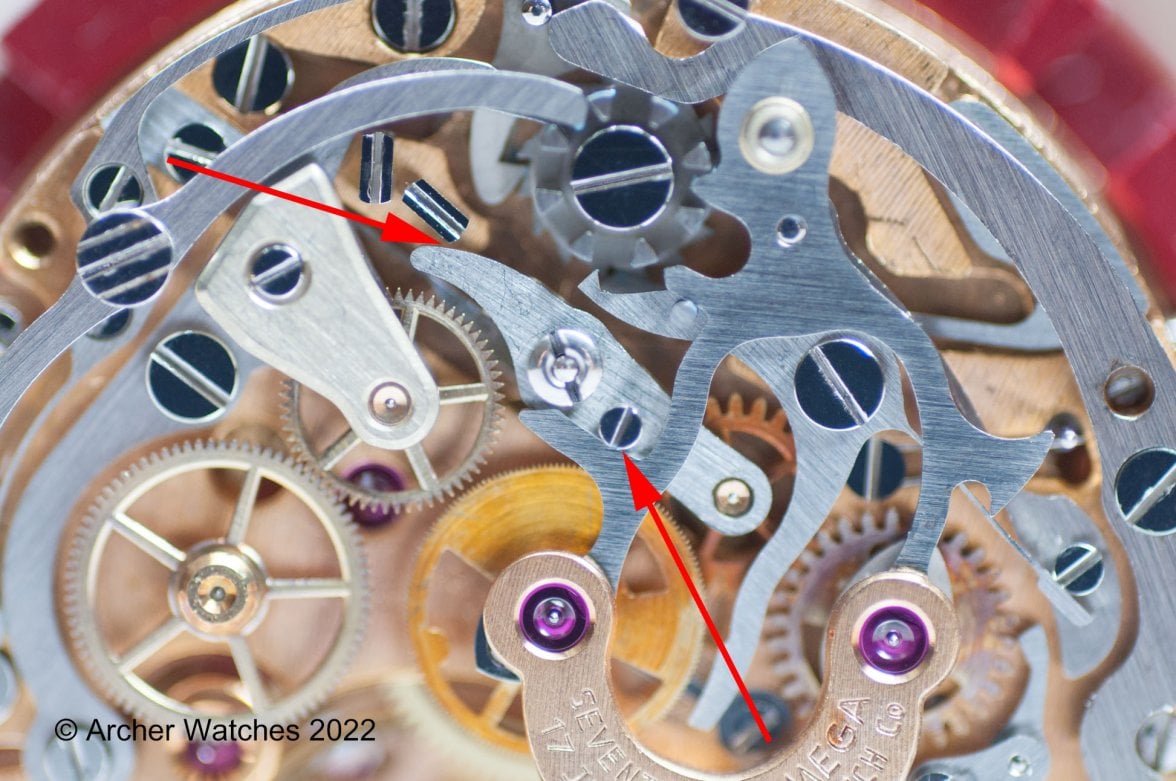

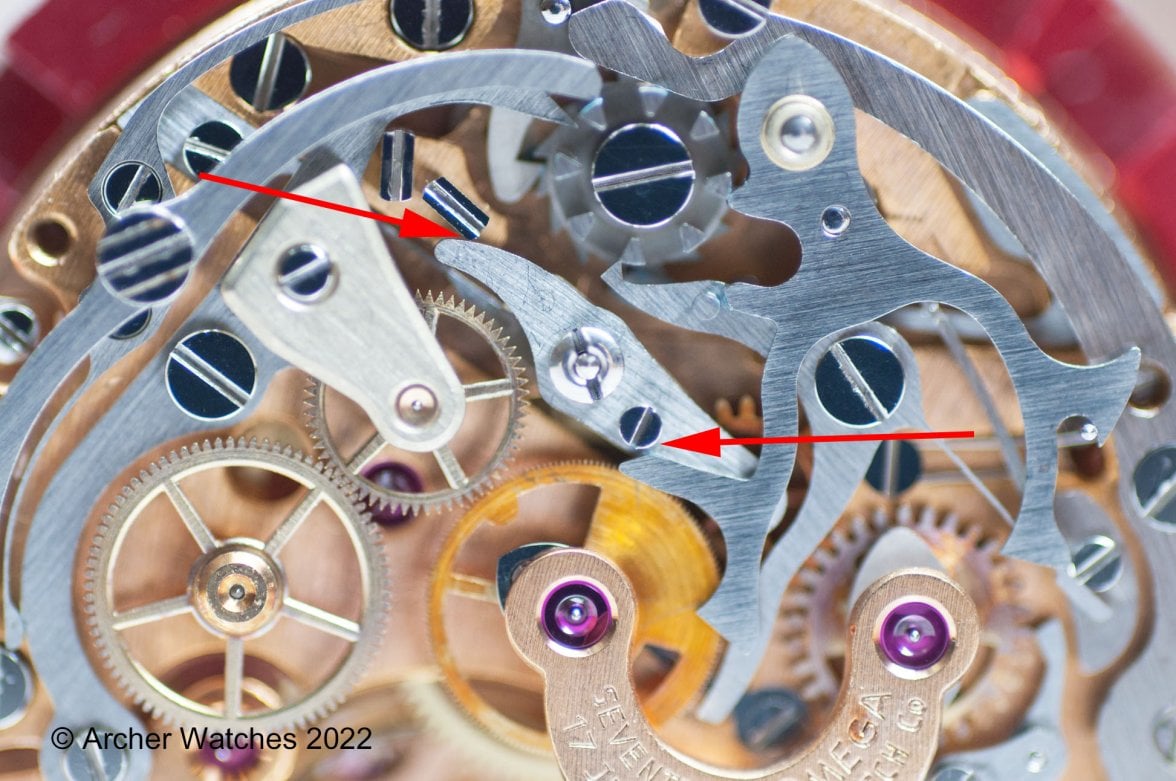

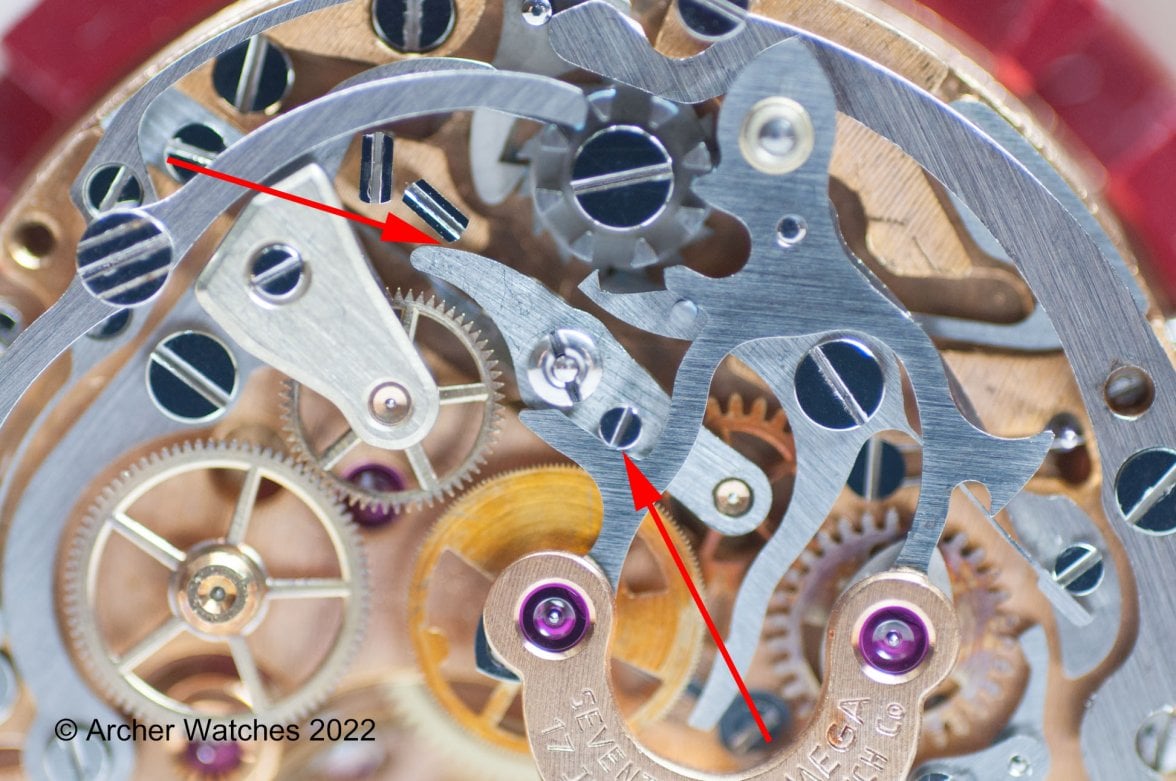

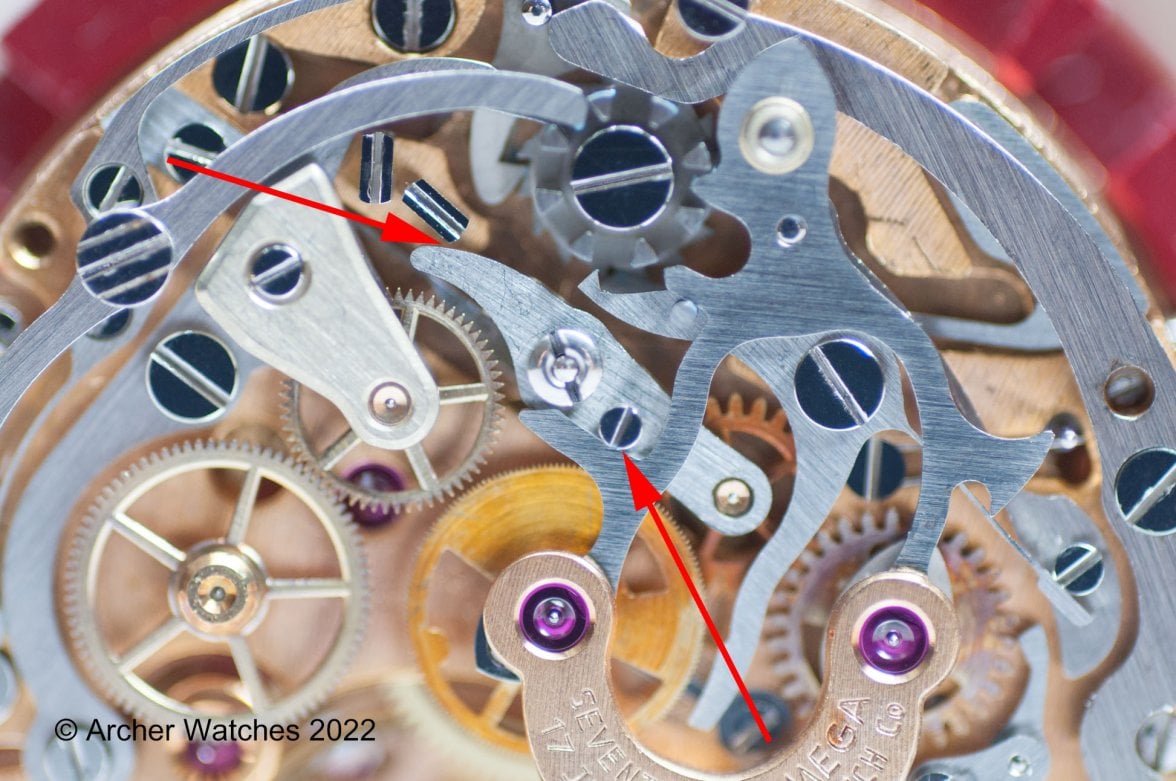

Now the parts that mount in this area:

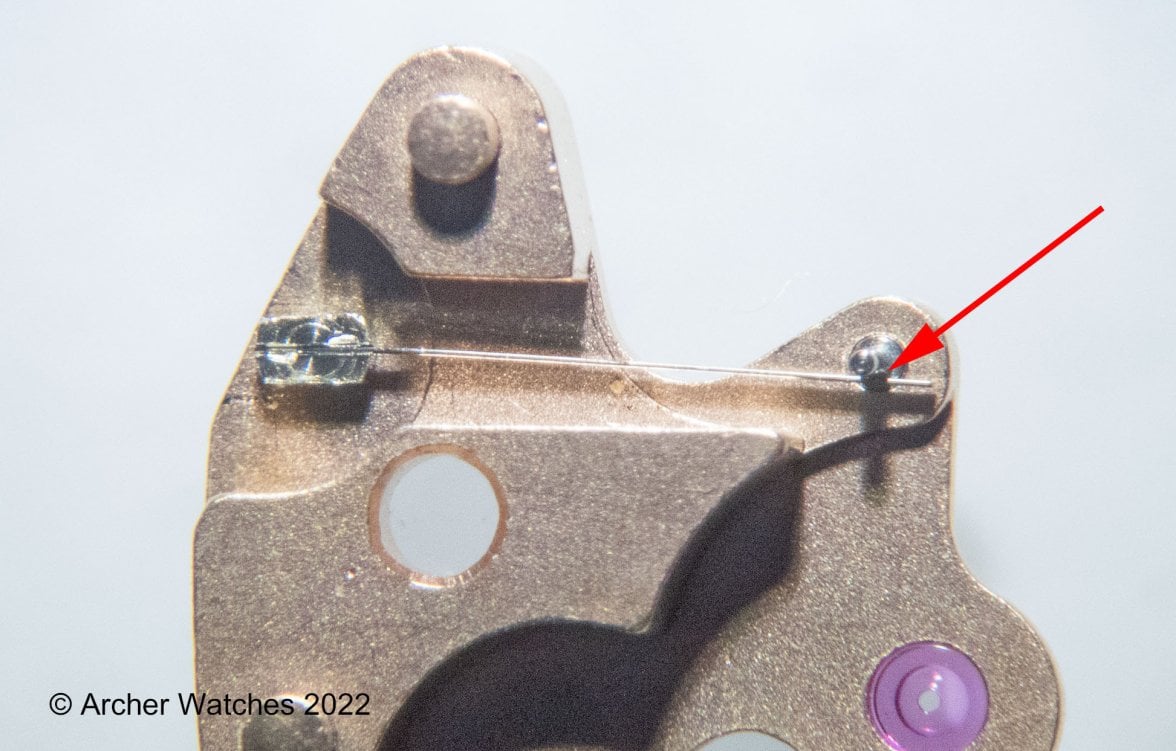

The upper part is the minute counter jumper bridge, then the minute counter jumper, and then the screw that mounts the bridge to the post. There’s one last part – the minute jumper spring:

This spring wraps around a screw that sticks up from the bridge, and is what provides tension on the minute recorder jumper. So this spring helps keep the minute counter hand from moving as you are timing an event. The tension here is important, because too little will allow it to move around, and too much will add too much drag to the movement. In my experience, this spring is very fragile, and I’ve had many 321’s come in with the spring missing, and something else stuck in there.

More in part 2...

Personally, I’ve never bought into this idea, and looking at what a column wheel costs as a spare part (the best indication we have about costs of production) my suspicions are borne out. The 321 column wheel is under $100 to purchase as a spare part. A column wheel for a 3313 is under $40, as is the column wheel for the 3300. The two parts of the cam (upper and lower) for the 861/1861 cost more than either of the column wheels for the 3313 or 3330, but are a little less than the column wheel for the 321.

On the new 3861, the two parts of the cam (what they for some reason call the upper and lower wig-wag on this movement) cost more than the column wheel for the Cal. 321.

So all in if we are talking about a part that ranges from less than $40 to a little more than double that, is this really a significant thing in the cost of making the movement?

Note that the remainder of the parts to make either system work is about the same in number...there's really nothing in it between the two.

So where are the supposed savings in the 861 design? There are a few things that would contribute to it certainly, and one is the balance wheel. They moved from an adjustable mass balance with an overcoil on the balance spring, to a smooth balance with a flat balance spring.

Here’s a 321 balance:

And an 861/1861 balance:

The main “wheel train and barrel bridge” is another area where changes were made, but these are less to do with the design of the movement and more do to do with streamlining manufacturability. An example is where the post for the column wheel was machined out of the brass plate on the 321 as you can see here:

It is a separate part made of steel that is pressed into the bridge on the 861, and I’ll show that later on. But in my view all these thing pale in comparison to the real savings in both manufacturing and servicing the 861, and the genius of the design of this movement.

The minute recorder.

Let’s look at the 321’s minute recorder parts. It starts with the chronograph wheel, and on the underside of that wheel is a finger:

This wheel and finger rotates once per minute, and is what triggers the flip of the minute counter. Now that finger is rigid, but it can be rotated on the post of wheel, and this is one of the adjustments that the 321 has on the chronograph. Now this finger is quite short as you can see, so it clearly doesn’t reach all the way across to the minute recording wheel to trip it, so there’s an intermediate step. This is done via something called the sliding gear – this is actually a subassembly made up of several parts and here is the top view:

Bottom view:

Side view:

So there are several parts here – a wheel, top and bottom plates, two bushings, screw that holds it together, and a bushing that goes through it. This bushing slips over a post that is pressed into the wheel train and barrel bridge. But we aren’t done yet...there is also the minute counting wheel, and then the minute jumper assembly. The minute counting wheel itself is no different from the 861 version, so I won’t spend a lot of time on it. But the teeth of that wheel are located and held in place in their 1 minute increments by something called a jumper (sometimes a paperclip is used in place of it even!).

So here is the wheel train and barrel bridge where the jumper is located:

The upper arrow points to a slightly fuzzy part, and this is the post that the rest of the jumper mounts to. The lower arrow points to an eccentric screw – this is for adjusting the jumper, so by turning this the position that the wheel rotates it's position slightly.

Now the parts that mount in this area:

The upper part is the minute counter jumper bridge, then the minute counter jumper, and then the screw that mounts the bridge to the post. There’s one last part – the minute jumper spring:

This spring wraps around a screw that sticks up from the bridge, and is what provides tension on the minute recorder jumper. So this spring helps keep the minute counter hand from moving as you are timing an event. The tension here is important, because too little will allow it to move around, and too much will add too much drag to the movement. In my experience, this spring is very fragile, and I’ve had many 321’s come in with the spring missing, and something else stuck in there.

More in part 2...