The 12 hour recorder on the Omega 321 and its problems

Eve

·Great thread!

I have a problem, maybe someone here can help.

The Problem: The reset of the chronograph is often very stiff, like if there is too much friction or if something is blocking/rubbing. Sometimes the pressure to reset the chronograph is normal (lightweight).

The Reset function:

As far as i understand there are basicaly 2 things affected when resetting the chronograph.

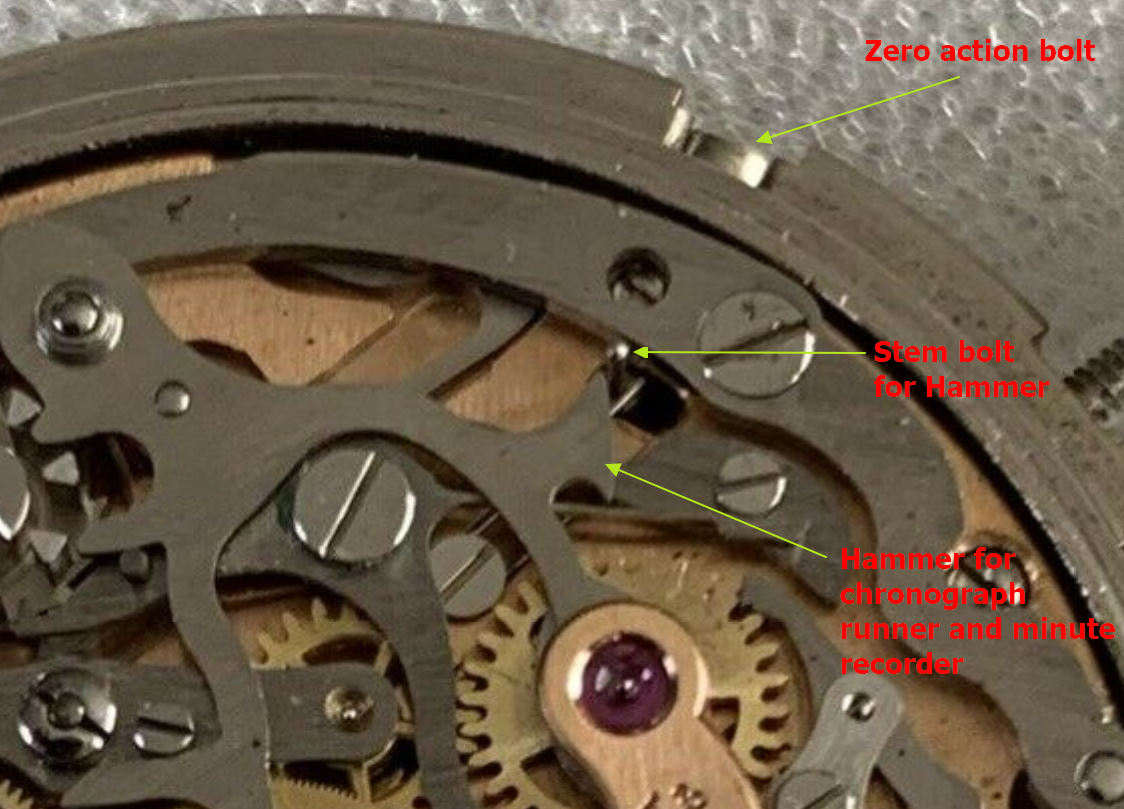

1) Caseback side: The pin (that holds back the hammer) slides out of the way and the hammer drops.

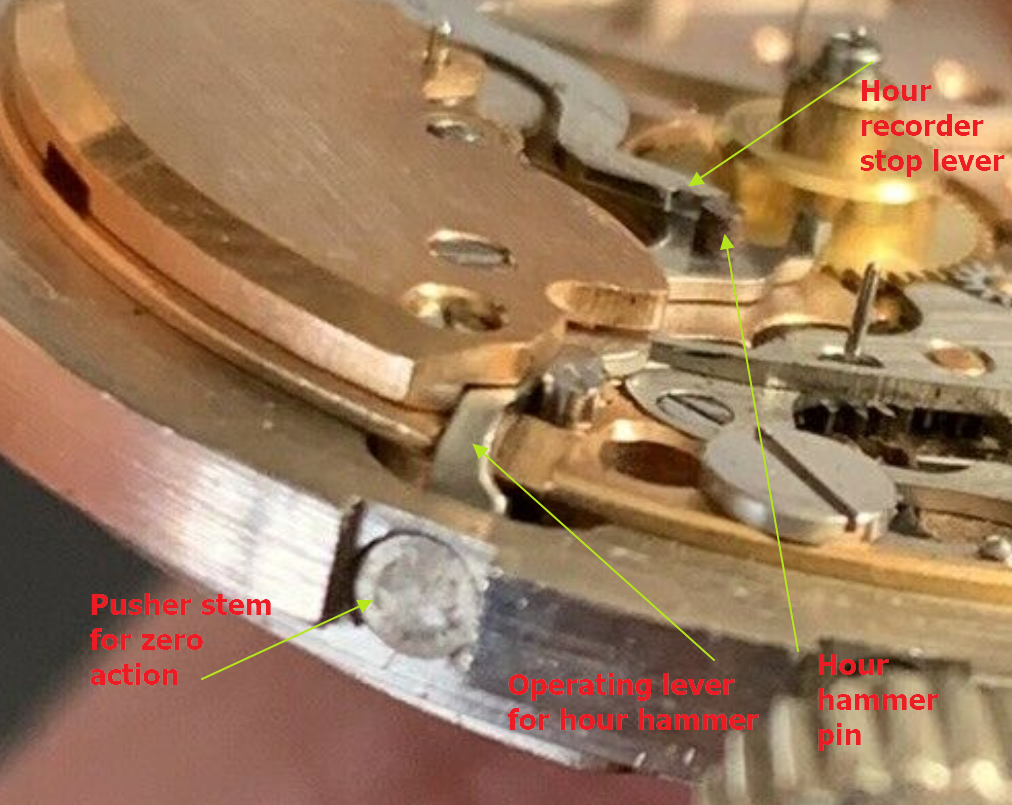

2) Dial side: the pusher stem for zero action is pushing the operating lever to the hour hammer, the pin slides by the hour recorder stop lever, pushing it out of the way and resetting the hour recording runner.

1)

2)

As far as i undersand, worn out hour recorder stop lever or the hour hammer pin woud cause the "lazy reset", so those would be not the reason for a stiff reset. Somhow doubt that the friction is cause by the sliding action from stem bolt releasing the chronograph runner (caseback side).

Here was mentioned that the cause could be worn movement holder ring like in the post above (which is not the case here).

So my guess would be, the problem is somewhere around the operating lever for the hour hammer. Like here mentioned: worn at either interface, slightly bent, chipped or the wrong type for the case.

Or like Archer wrote somewhere: "burr on the movement spacer making the operating lever difficult to move, or a bent stem bolt for hammer".

Would this be a correct assumption? Does anybody have any additional thoughts?

Thank you!

I have a problem, maybe someone here can help.

The Problem: The reset of the chronograph is often very stiff, like if there is too much friction or if something is blocking/rubbing. Sometimes the pressure to reset the chronograph is normal (lightweight).

The Reset function:

As far as i understand there are basicaly 2 things affected when resetting the chronograph.

1) Caseback side: The pin (that holds back the hammer) slides out of the way and the hammer drops.

2) Dial side: the pusher stem for zero action is pushing the operating lever to the hour hammer, the pin slides by the hour recorder stop lever, pushing it out of the way and resetting the hour recording runner.

1)

2)

As far as i undersand, worn out hour recorder stop lever or the hour hammer pin woud cause the "lazy reset", so those would be not the reason for a stiff reset. Somhow doubt that the friction is cause by the sliding action from stem bolt releasing the chronograph runner (caseback side).

Here was mentioned that the cause could be worn movement holder ring like in the post above (which is not the case here).

So my guess would be, the problem is somewhere around the operating lever for the hour hammer. Like here mentioned: worn at either interface, slightly bent, chipped or the wrong type for the case.

Or like Archer wrote somewhere: "burr on the movement spacer making the operating lever difficult to move, or a bent stem bolt for hammer".

Would this be a correct assumption? Does anybody have any additional thoughts?

Thank you!

Edited:

Eve

·ok, while writing a long question, i think i might have found a few informations during research here, so i guesss no more answers are needed.

OF is full of info, one just has to dig deep enough. 👍

OF is full of info, one just has to dig deep enough. 👍

- Posts

- 20

- Likes

- 9

yyau

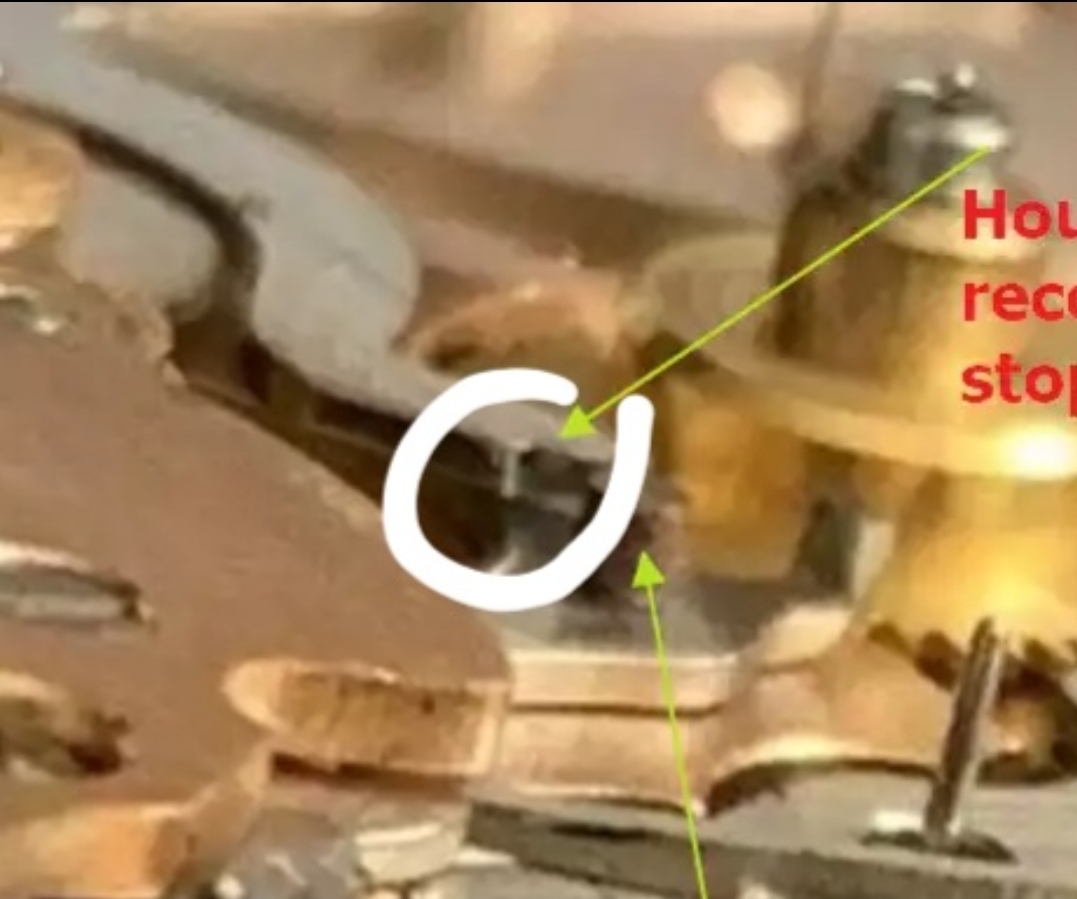

·This is an 861, but the same issues with the hole in the main plate where the hour recorder wheel locates is common on 321's also - you can see there is a burr there and the hole is slightly oval:

I have disturbed you many times recently because I am very interested in the restoration of these movements.

When you encounter a problem with the hole in this position, what approach do you take? It seems to me that it cannot be repaired

SpeedTar

·Hi!

When a reset is too hard I usually slight polish the angle if the stop lever which is in contact with the pin of the hammer. Then with a proper lubrification everything get smooth.

If the movement holder holes are ovalized there is only 2 options : repair by bushing or replacing by a new one (the 861's holder are compatible).

When a reset is too hard I usually slight polish the angle if the stop lever which is in contact with the pin of the hammer. Then with a proper lubrification everything get smooth.

If the movement holder holes are ovalized there is only 2 options : repair by bushing or replacing by a new one (the 861's holder are compatible).

- Posts

- 20

- Likes

- 9

yyau

·Hi!

When a reset is too hard I usually slight polish the angle if the stop lever which is in contact with the pin of the hammer. Then with a proper lubrification everything get smooth.

If the movement holder holes are ovalized there is only 2 options : repair by bushing or replacing by a new one (the 861's holder are compatible).

Are you sure it can be repair by bushing? There is almost no space in this hole. For watchmakers, this accuracy may not reach their limit.😀

- Posts

- 20

- Likes

- 9

Archer

··Omega Qualified WatchmakerY yyauHi Archer

I have disturbed you many times recently because I am very interested in the restoration of these movements.

When you encounter a problem with the hole in this position, what approach do you take? It seems to me that it cannot be repaired

Other than to remove any burrs, there’s not much else you can do. Not enough room to install a bushing. Fortunately it’s rare that it gets to that stage.

- Posts

- 20

- Likes

- 9

TimtimeIntl

·I really enjoyed the info in these posts. Thx

Archer

··Omega Qualified WatchmakerI really enjoyed the info in these posts. Thx

If you want a slightly more in depth review of the hour recorder, you might want to look at this one:

The mysterious Speedmaster hour counter | Omega Forums

TimtimeIntl

·Thx. I grabbed 5 chronographs out of the safety dep box yesterday. 3 Speedies. One a -67 (321) and the 12 hour recorder does not move. I knew that when I purchased it a few years ago and have never chased the problem myself. I like knowing the ins and outs of chronographs but have learned they have so much more going on with them than I know how to repair. You guys who do work on them have studied them, and more importantly, have gone down all the dark alleys that repairing them leads you down and I appreciate threads like these where you share those learned lessons.