Wibbles

·So if you could only have one tuning fork / hummer, what would it be?

A Longines Ultronic Diver only produced in 1972.

Speaking of Longines and transitional calibers and electrical stuff in general. Here's my contribution. The cybernetic Longines UltraQuartz(from 1971/2).

Longines as well as being part of the Swiss consortium developing the new tangled quartz movement which gave rise to the Beta 20 series, they also had their own project running concurrently in their own "Skunk works" and had a patent on it by 1968(which didn't exactly enamour them to the other participants). Unlike the Beta 20 project which used an integrated circuit processor to do the calculations reducing the quartz frequency to second impulses that then drove a tuning fork type motor to drive the hands, as it was the 60's it seems Longines smoked a few funny cigarettes 😗 😀 and came up with their "cybernetic" comparison circuit solution. Where the hands are driven by a tuning fork engine as a slave system, but the master quartz oscillator corrects any drift of the tuning fork against true via an electronic circuit(not unlike how atomic clocks work).

And what a truly mad movement it was.

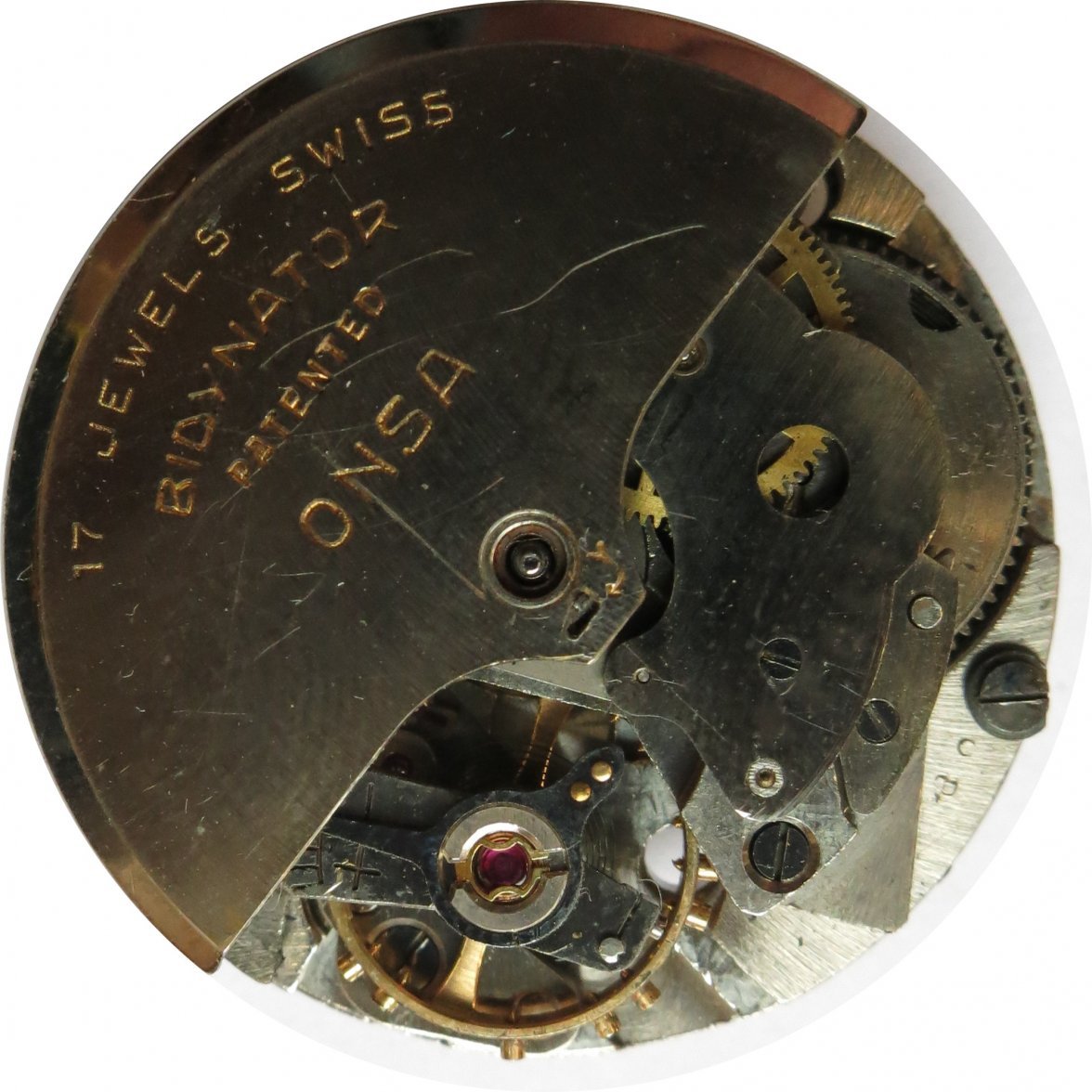

A veritable bird's nest of oddness. 🤨 Extremely handmade, almost a prototype that escaped the factory. Rather than use the very expensive at the time integrated circuits/chips, they used discrete components(from the hearing aid industry) hand soldered to the tiny board. The quartz oscillator itself(which is not far off an inch long) was hand cut from Brazilian crystal and hand tuned by adding minute coatings of gold leaf, using microscopes. The quartz can runs the length of the movement top to bottom on the right hand side under the circuit board. The big chunk of ironmongery top left is the tuning fork. This is what usually fails in these. And then we have the usual mechanical gears on top.

They're about as vulnerable as an ostrich egg in a cement mixer and when they go open circuit it's game over. In Longines service literature of the time the only part listed was the entire movement. I noted recently on Longines' website promoting their new VHP quartz their own example of the UltraQuartz they show has had a later movement transplant as it shows the one second/deadbeat seconds hand of the majority of quartz. In reality when working they have a very smooth seconds hand.

TBH I rarely wear mine as it is so delicate and was NOS. Though I did run an accuracy "trial" on it a couple of years ago and it was remarkably true to atomic time. Less than 20 seconds per year.

I didn't mention how energetic these watches are. They buzz. I don't mean the quiet Accutron buzz, I mean you can feel this watch vibrating on the wrist.