ChrisN

·About 15 years ago I bought a B&M watch and I'm not sure why as it's not particularly attractive so it's been in a drawer for a long time...

Anyway, continuing with my watch experience, I thought it would be about time that it had a service. It's a BM13283 calibre which is a Lemania 283. This is actually an ETA 2892 (28800 A/h) with a Dubois Depraz 2000 (or 2020) module mounted on top. The 2892 also begat the Omega 1120 and so on but the DD module was used by a few manufacturers and is still in use by AP for some of their models - they don't mount it on a 2892 and they improve the finish a lot but it's the same basic module. Confused? Wait till you see inside it...

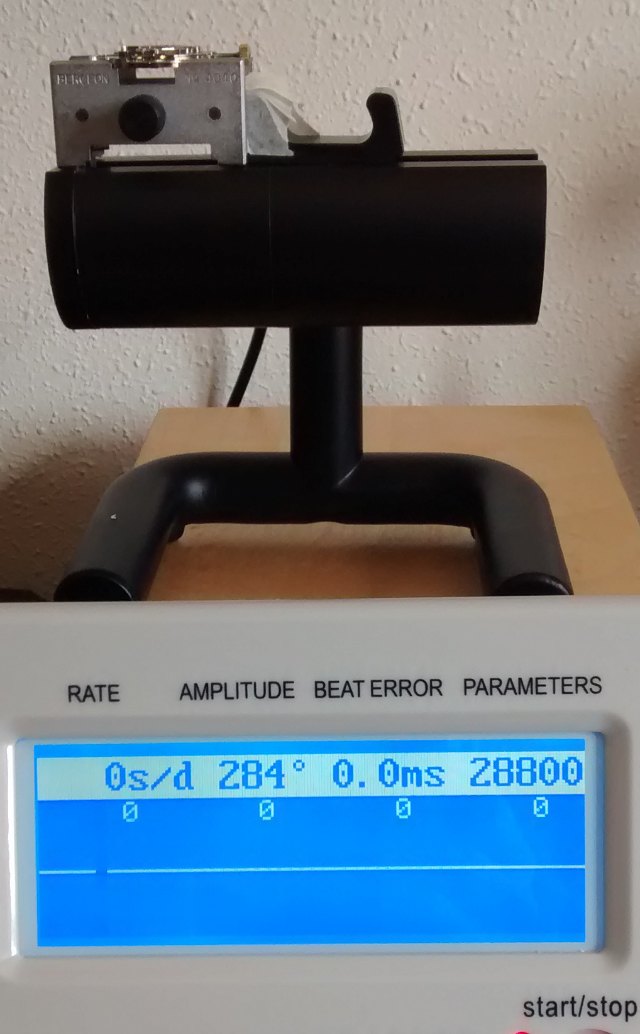

First step is to rebuild the 2892 and these are really nice - I can see why a lot of Watchmakers like them. Here it is in FH at full wind although it's now picked up to low 290s - dead flat. Six positions gave a rate variation of 8 seconds and that's pretty good. It is a TOP variant so, it should do that as that's within Omega 1120 spec. Of course, it didn't do that without a little work but these are nice to adjust.

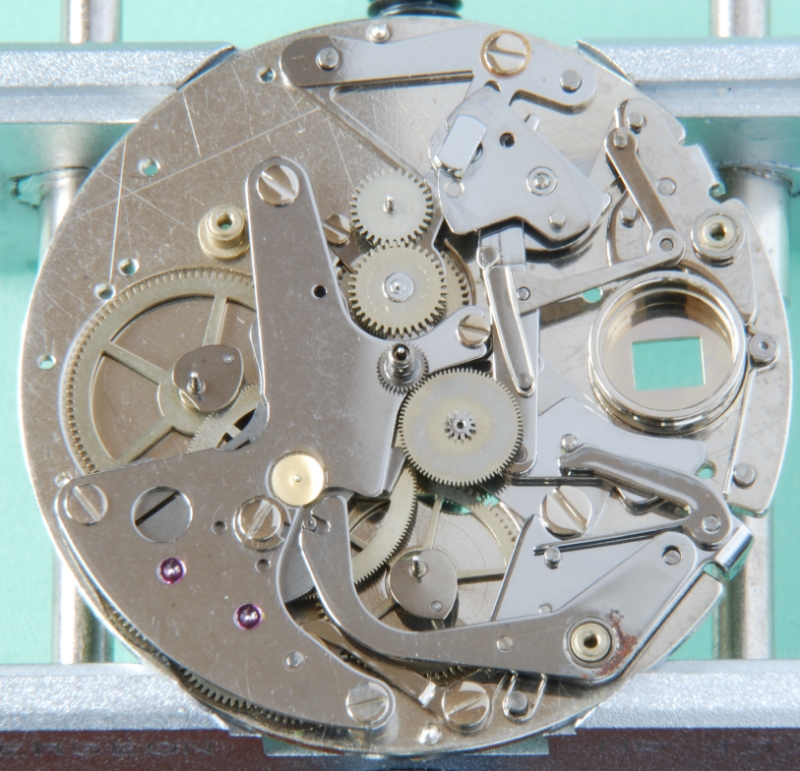

Here's the dial side of the movement showing that there's nowhere to mount the hands, just those gears showing through at the centre. That is the only link with the DD module and everything then happens away from the base movement.

The DD looked very dry and a little dirty but as these are usually exchange units, worth trying. Mounted and the amplitude plummeted by 30+ degrees without the chronograph running and a further 5-10 with it running. So, needs to be opened up. I've seen quotes where it's stated that opening these causes lots of springs to fly out and you're lost. Anyway, someone must service them and as long as all the parts are without significant wear, I'll be alright. Parts are not available...

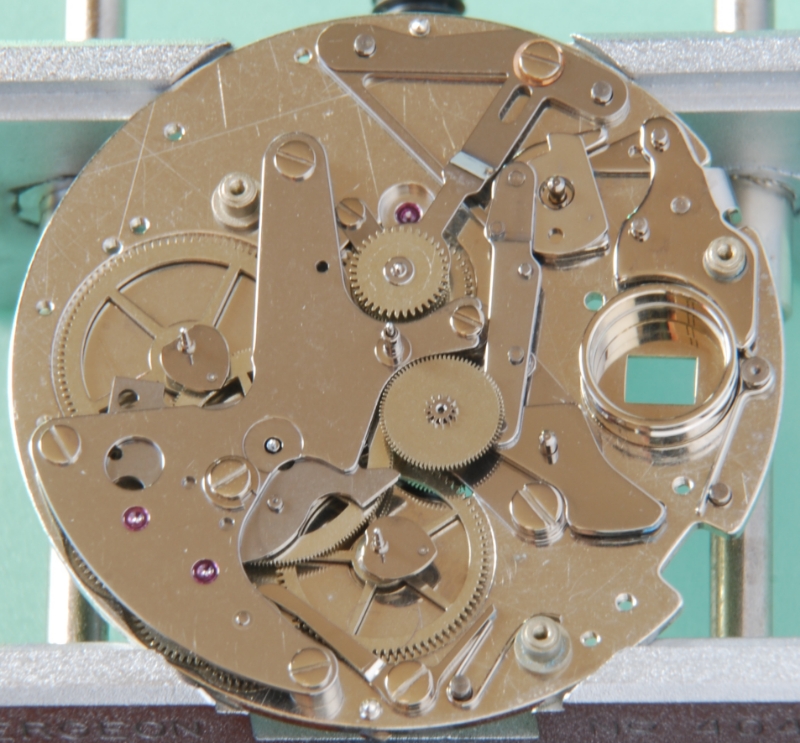

So, open it up from the dial side by removing three screws to get the front off and you're faced with this but at least no escaping springs. Looks a trivial job to strip and reassemble doesn't it.😉 Apart from the rust on that lower arm close to the reset pusher, it looks fairly clean.

I took it apart and these are the parts you're left with. Took an hour or two as I was trying to understand what each part did as it's not like anything I've ever worked on.

Luckily, Omega use a similar module in the 3220 calibres, mounted on an Omega 1120 so with that I've got some idea of how to oil this and how to test it. Unfortunately, it's only similar as about 50% of it is different. Ah well, don't want to make life too easy.

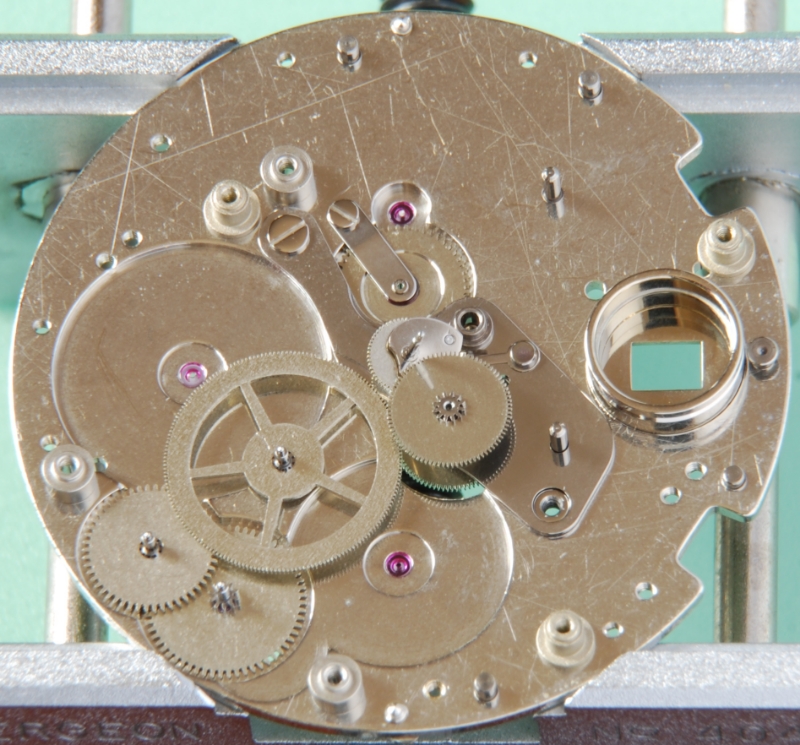

You build it on the rear plate which will contact the ETA. Here it is, cleaned, pegged etc.

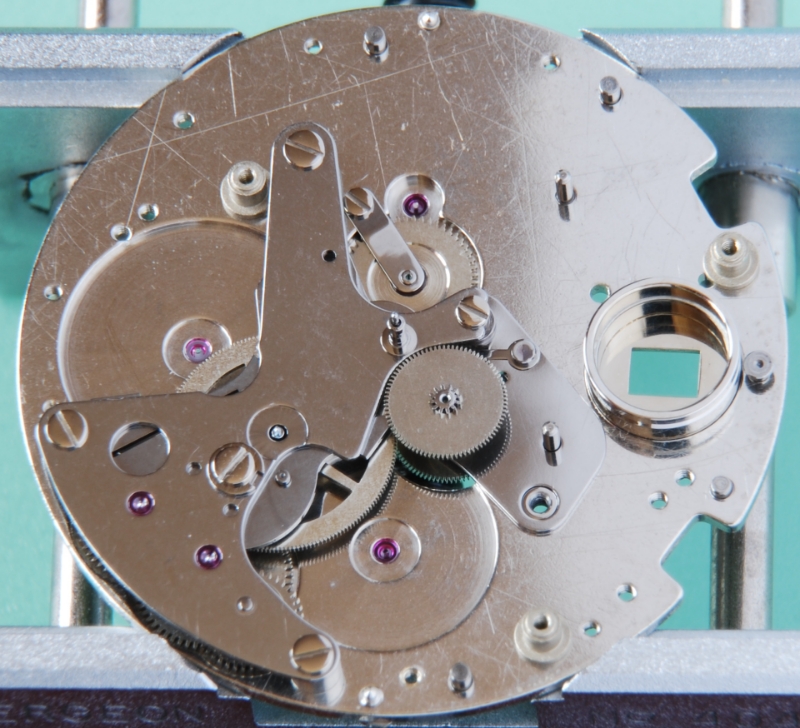

Second wheel added at the top and the minute bridge. The second wheel is the way into the movement for the permanent seconds counter and the whole chronograph train. The other wheel is just to drive the hour and minute hands.

Added part of the chrono train. The one in the centre with the heart will take the chrono second hand. It doesn't have a drive yet but will pass the drive in to the other wheels.

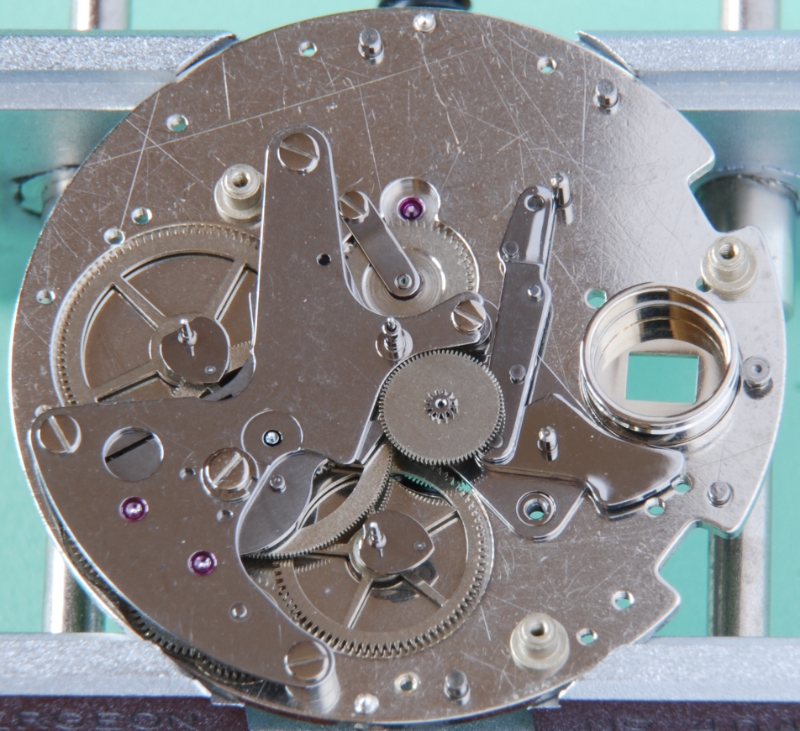

This is the chronograph bridge and underneath it is the hammer plate that will contact the hearts and reset the chrono function.

These are the minute (at 9 O'clock) and hour counter (at 6 O'clock) wheels of the chrono and they'll take the chrono hands. I've also added parts of the start/stop/reset mechanism on the right.

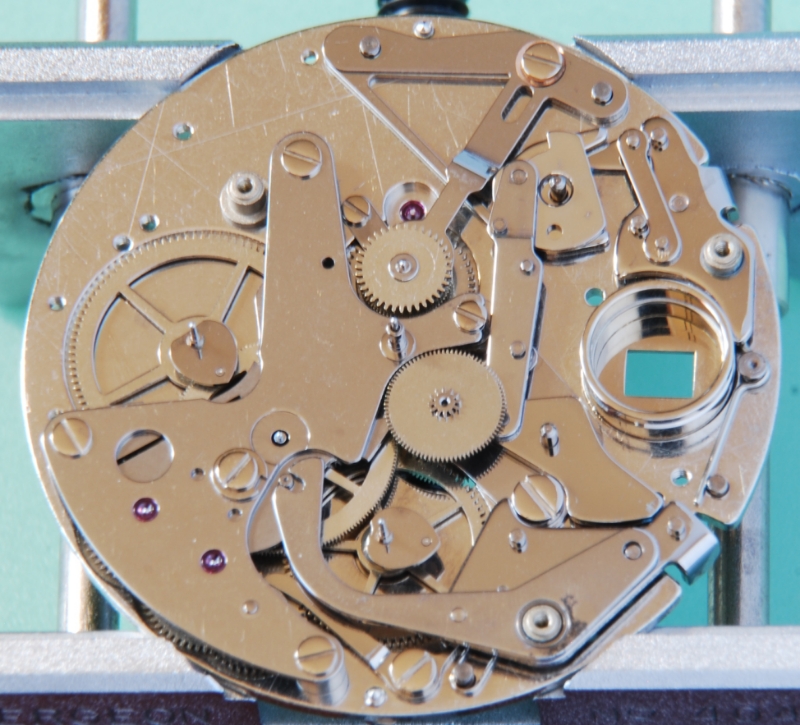

Added the clutch wheel just above the centre and this works when the upper T bar spring presses down onto it. When that happens it drives the centre part of the chrono and all the rest from that. Added some more parts of the mechanism at the upper which is the start/stop. Poorly applied grease on the triangular part so a bit of cleaning off needed.

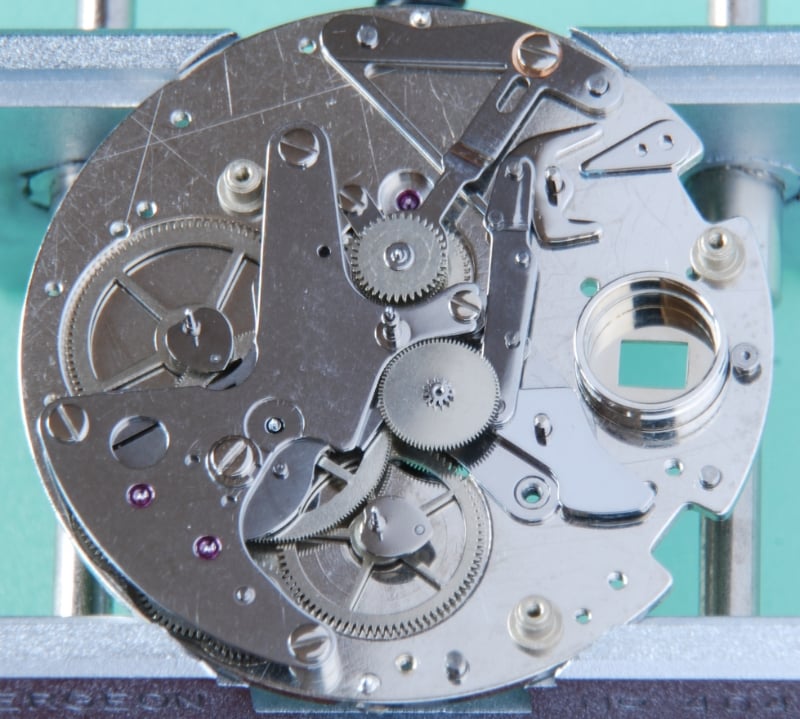

More parts of the stop/start and at the bottom, the lock which works to stop the whole chronograph part moving when not in use. It's a bit complicated all this.

This is the reset lever and the hammer operating lever (the rust is gone but it's still marked).

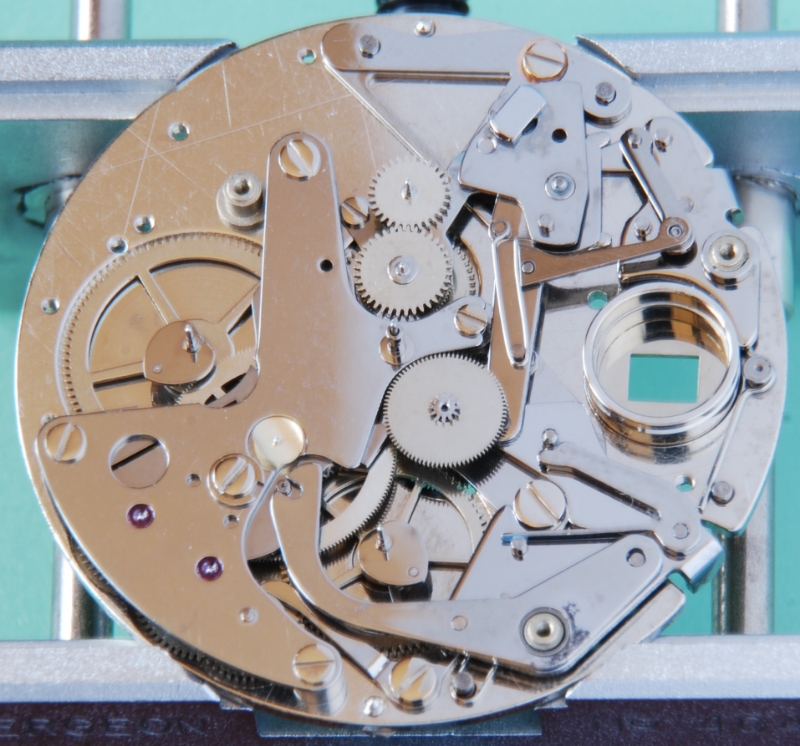

Few more springs and levers added and that should agree with the first picture.

Front plate fitted and it's complete. It is the first one I've done but I found this quite time consuming as it took at least twice the time of the base movement, probably three times. I can see the logic in sending them off to be rebuilt...

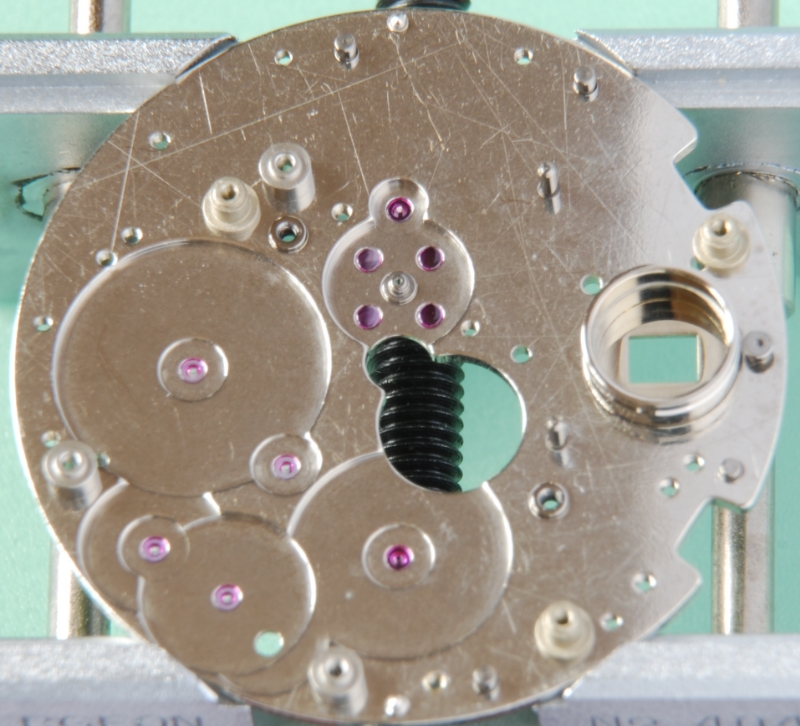

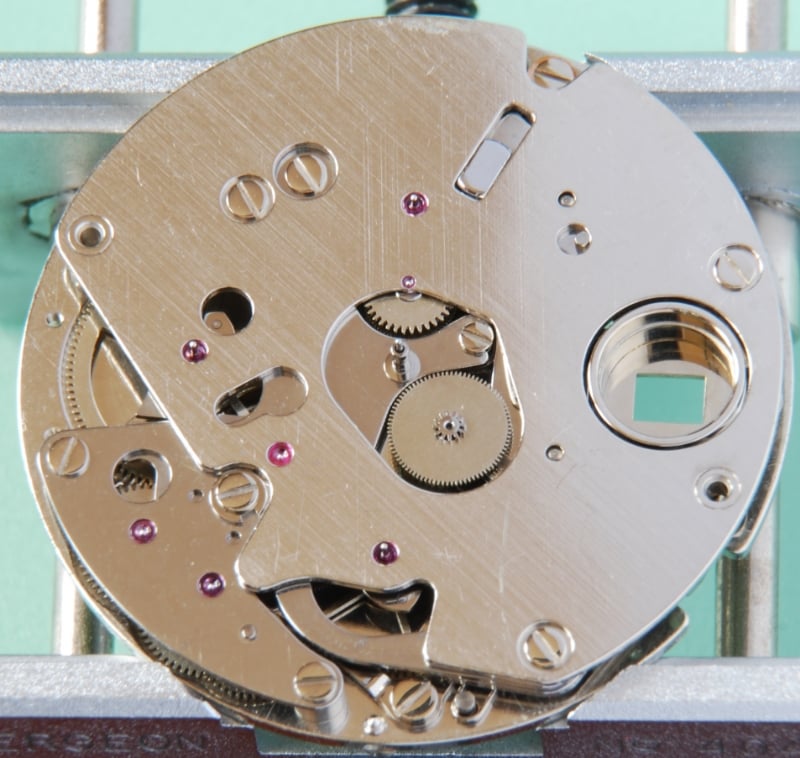

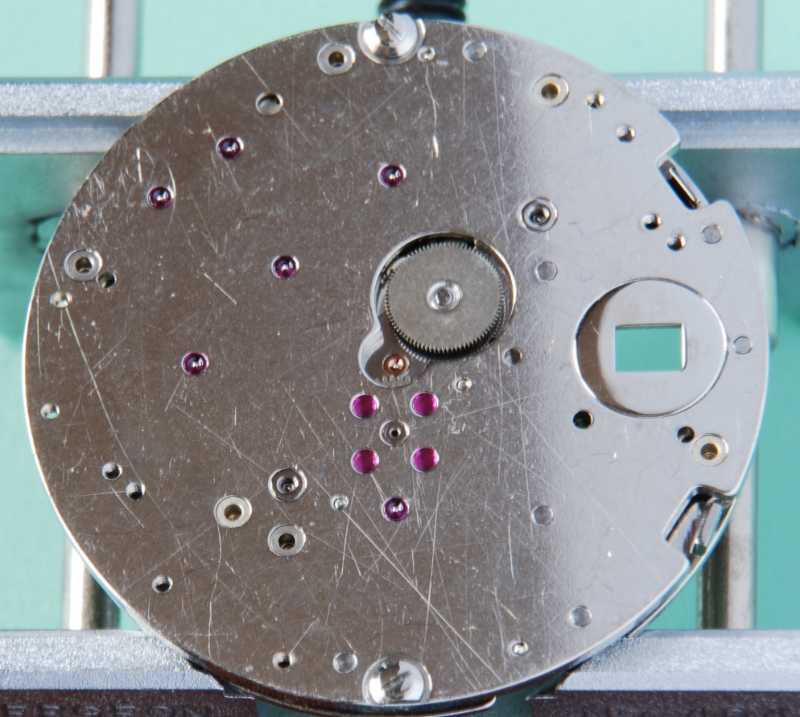

I'm surprised at how scratched these module plates are. Can't see why. Anyway, here's the back of the module.

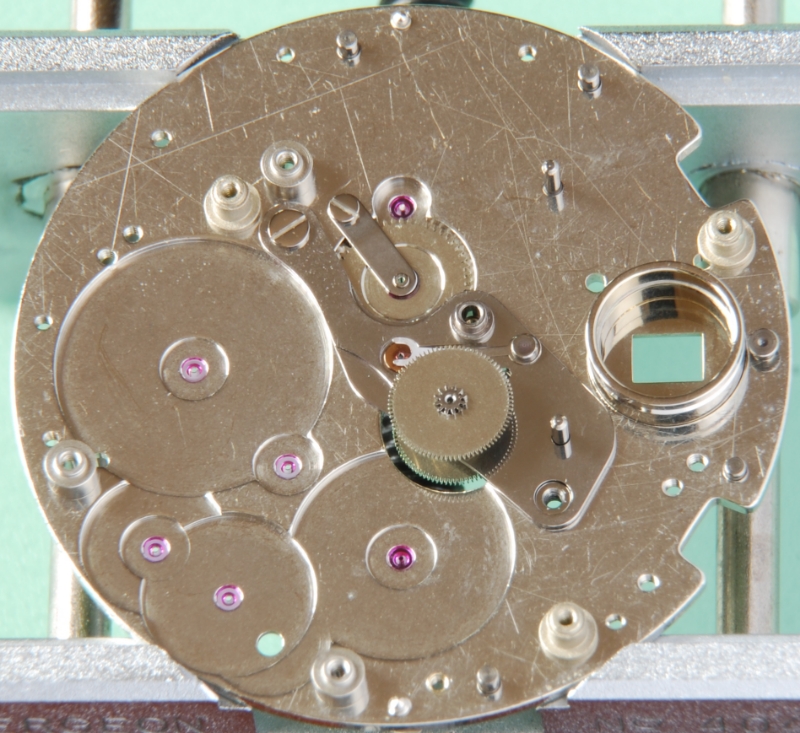

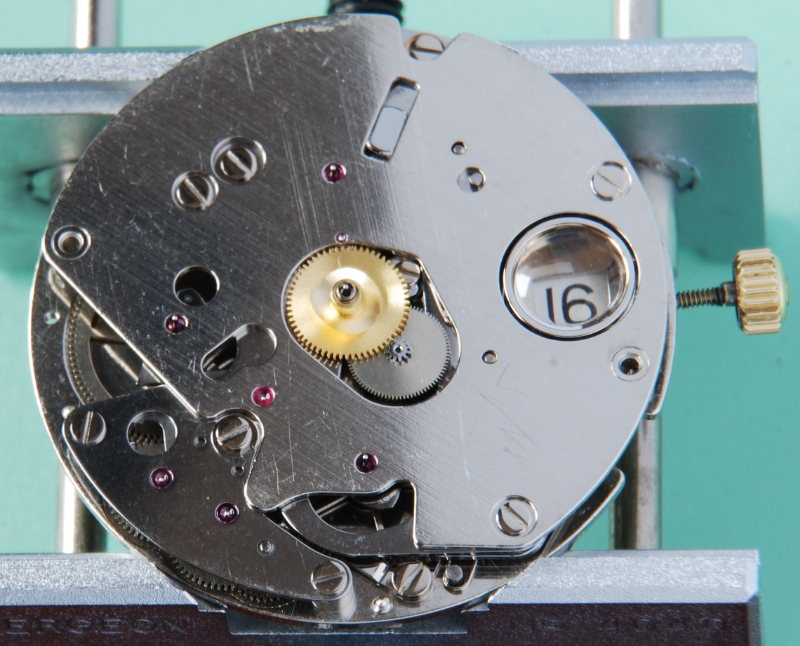

And now with the 2892 mounted and running.

Turned over and the front plate is running ready for the dial.

Am leaving it to settle down but first indication is that the amplitude drop has halved so all good. Interesting to do anyway.

Cheers, Chris

Anyway, continuing with my watch experience, I thought it would be about time that it had a service. It's a BM13283 calibre which is a Lemania 283. This is actually an ETA 2892 (28800 A/h) with a Dubois Depraz 2000 (or 2020) module mounted on top. The 2892 also begat the Omega 1120 and so on but the DD module was used by a few manufacturers and is still in use by AP for some of their models - they don't mount it on a 2892 and they improve the finish a lot but it's the same basic module. Confused? Wait till you see inside it...

First step is to rebuild the 2892 and these are really nice - I can see why a lot of Watchmakers like them. Here it is in FH at full wind although it's now picked up to low 290s - dead flat. Six positions gave a rate variation of 8 seconds and that's pretty good. It is a TOP variant so, it should do that as that's within Omega 1120 spec. Of course, it didn't do that without a little work but these are nice to adjust.

Here's the dial side of the movement showing that there's nowhere to mount the hands, just those gears showing through at the centre. That is the only link with the DD module and everything then happens away from the base movement.

The DD looked very dry and a little dirty but as these are usually exchange units, worth trying. Mounted and the amplitude plummeted by 30+ degrees without the chronograph running and a further 5-10 with it running. So, needs to be opened up. I've seen quotes where it's stated that opening these causes lots of springs to fly out and you're lost. Anyway, someone must service them and as long as all the parts are without significant wear, I'll be alright. Parts are not available...

So, open it up from the dial side by removing three screws to get the front off and you're faced with this but at least no escaping springs. Looks a trivial job to strip and reassemble doesn't it.😉 Apart from the rust on that lower arm close to the reset pusher, it looks fairly clean.

I took it apart and these are the parts you're left with. Took an hour or two as I was trying to understand what each part did as it's not like anything I've ever worked on.

Luckily, Omega use a similar module in the 3220 calibres, mounted on an Omega 1120 so with that I've got some idea of how to oil this and how to test it. Unfortunately, it's only similar as about 50% of it is different. Ah well, don't want to make life too easy.

You build it on the rear plate which will contact the ETA. Here it is, cleaned, pegged etc.

Second wheel added at the top and the minute bridge. The second wheel is the way into the movement for the permanent seconds counter and the whole chronograph train. The other wheel is just to drive the hour and minute hands.

Added part of the chrono train. The one in the centre with the heart will take the chrono second hand. It doesn't have a drive yet but will pass the drive in to the other wheels.

This is the chronograph bridge and underneath it is the hammer plate that will contact the hearts and reset the chrono function.

These are the minute (at 9 O'clock) and hour counter (at 6 O'clock) wheels of the chrono and they'll take the chrono hands. I've also added parts of the start/stop/reset mechanism on the right.

Added the clutch wheel just above the centre and this works when the upper T bar spring presses down onto it. When that happens it drives the centre part of the chrono and all the rest from that. Added some more parts of the mechanism at the upper which is the start/stop. Poorly applied grease on the triangular part so a bit of cleaning off needed.

More parts of the stop/start and at the bottom, the lock which works to stop the whole chronograph part moving when not in use. It's a bit complicated all this.

This is the reset lever and the hammer operating lever (the rust is gone but it's still marked).

Few more springs and levers added and that should agree with the first picture.

Front plate fitted and it's complete. It is the first one I've done but I found this quite time consuming as it took at least twice the time of the base movement, probably three times. I can see the logic in sending them off to be rebuilt...

I'm surprised at how scratched these module plates are. Can't see why. Anyway, here's the back of the module.

And now with the 2892 mounted and running.

Turned over and the front plate is running ready for the dial.

Am leaving it to settle down but first indication is that the amplitude drop has halved so all good. Interesting to do anyway.

Cheers, Chris