ChrisN

·Last year, I built my wife a Seamaster 60m for one Christmas present ( https://omegaforums.net/threads/chr...d-an-amateur-vintage-style-watch-build.18596/) so, having set a precedent, thought I should do another watch this year although this is a bit of a daft present. Should have stuck with Channel No. 5, much easier 😉. Well, times are hard (not really) so have invested $20 in this non runner. This is nothing special but interesting to see a different way of doing things. It's a bit of a Mickey Mouse design from the early Seventies though - ah, I remember it well: flares; T Rex; long hair; Slade; power cuts (in UK); blo#*y great!

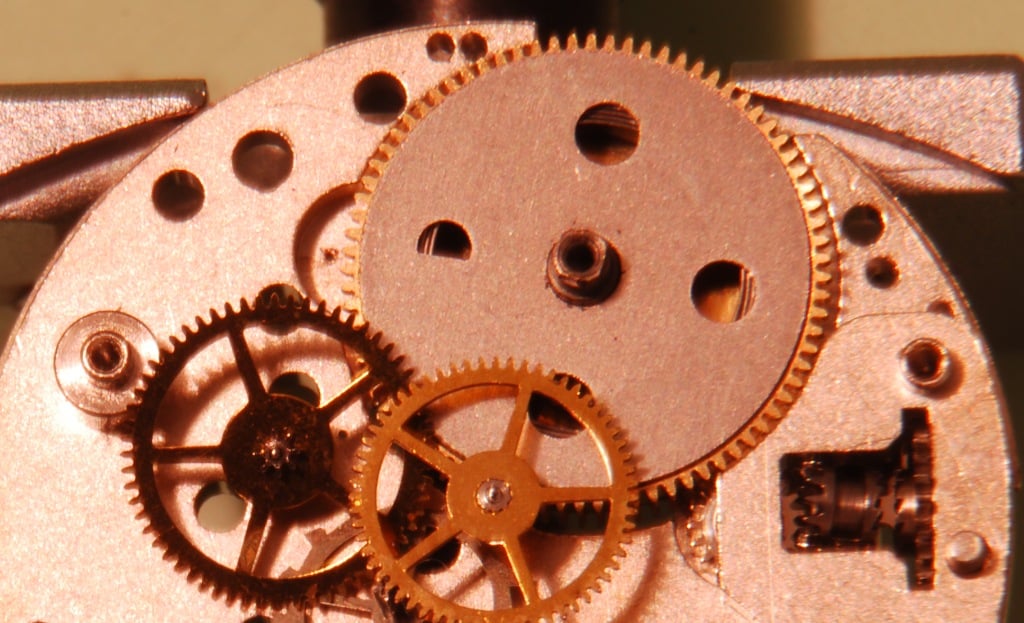

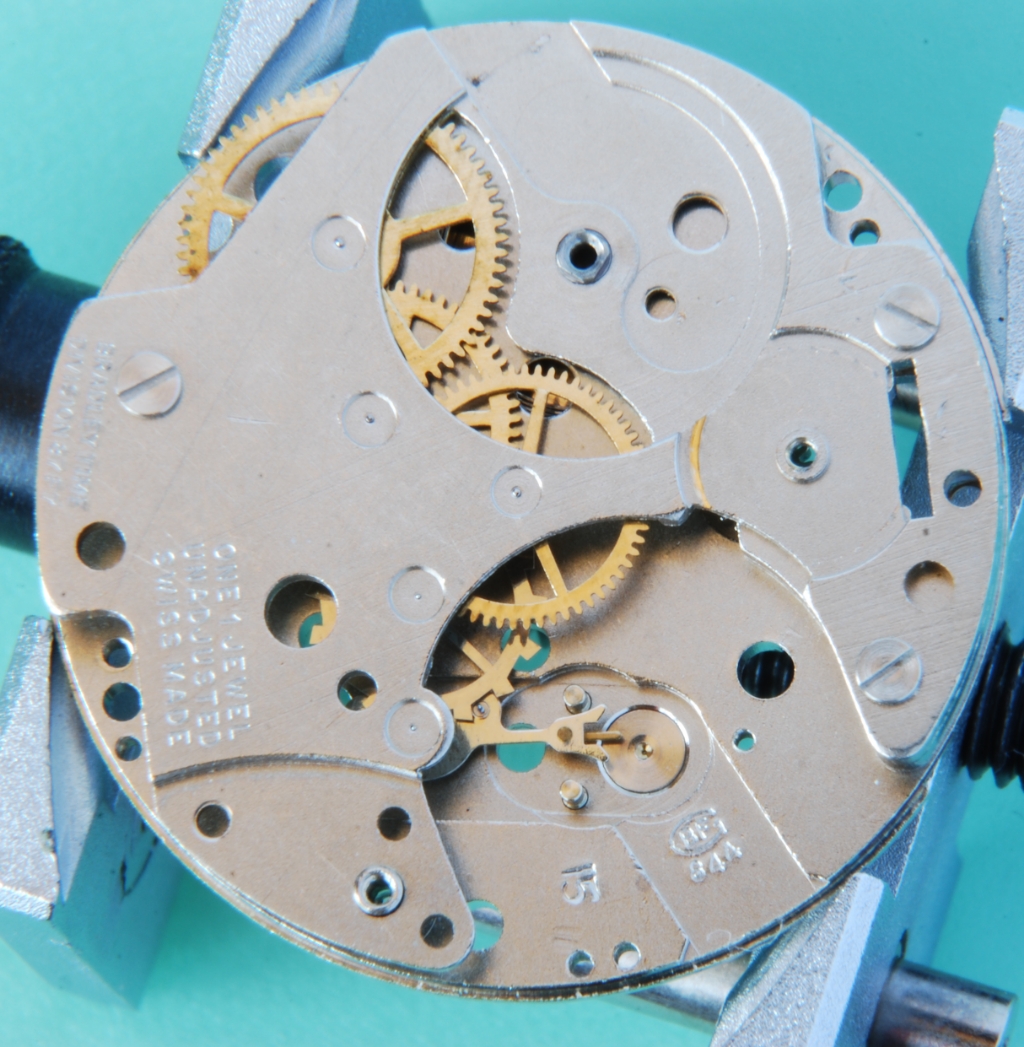

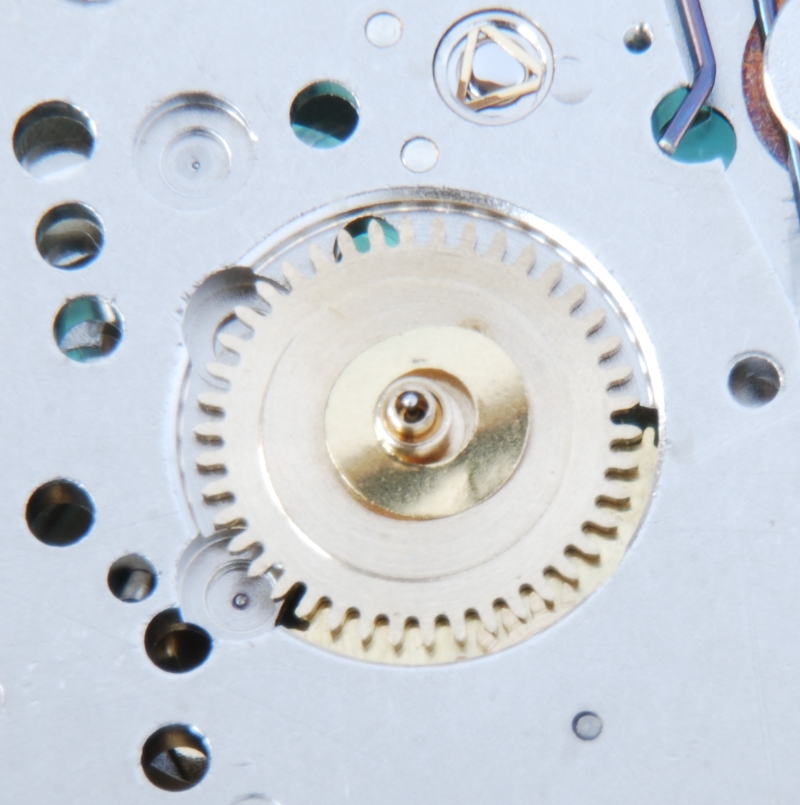

When I got this (advertised as not working), it would run for a few seconds and then stop so clearly not a broken balance staff. It was fully wound so some other problem. De-cased, it was apparent that the closing plate of the barrel was loose. These should be pressed on to the barrel to support the barrel on one side of the arbor. Might be visible here.

This is a Roskopf (I think) pin pallet escapement running at 18000 A/h and has a grand total of one jewel! I expected this to be the impulse jewel on the balance that contacts the fork but it isn't. Here's an Omega 565 balance with its ruby coloured impulse jewel (close to the pivot) and this balance on the left which uses a metal impulse.

Let the movement down, stripped it and it appeared to be all there. Cleaned and checked over and apart from the barrel issue, everything is fine. Little pivot wear so it likely has been a non runner for years. Parts for these cost buttons really, but nice to be able to re-use everything.

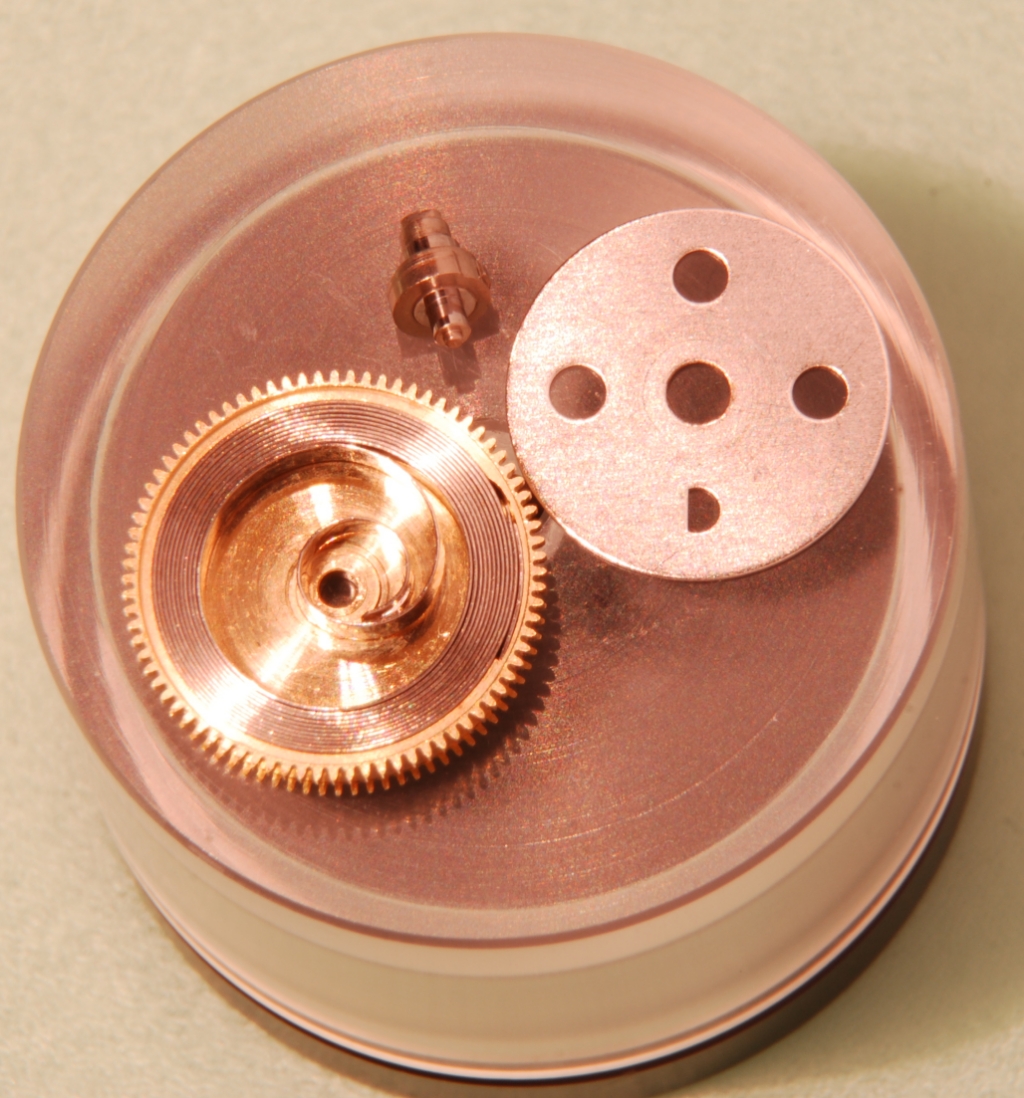

The mainspring goes in anti clockwise (most are clockwise) and as I wanted to re-use it and am too mean to buy left hand winders, had to wind it clockwise, press out of the winder into an mainspring ring, turn over and press into the barrel. Here, barrel with spring fitted, arbor and closing plate.

The closing plate snaps in fine so I can only assume it was badly fitted before. Other side of the barrel has another gear as well and directly drives both the minute and hour hand pipes. It becomes clear later.

This is unusual for me. In a more typical calibre, the barrel outer teeth drive the 2nd wheel which passes through the plate and has the cannon pinion attached to it onto which the minute hand is pressed. Then there's an intermediate pair of gears to drive the hour hand.

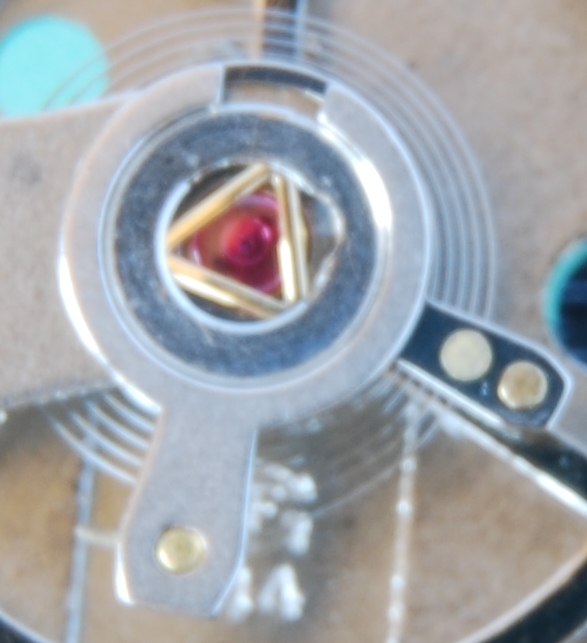

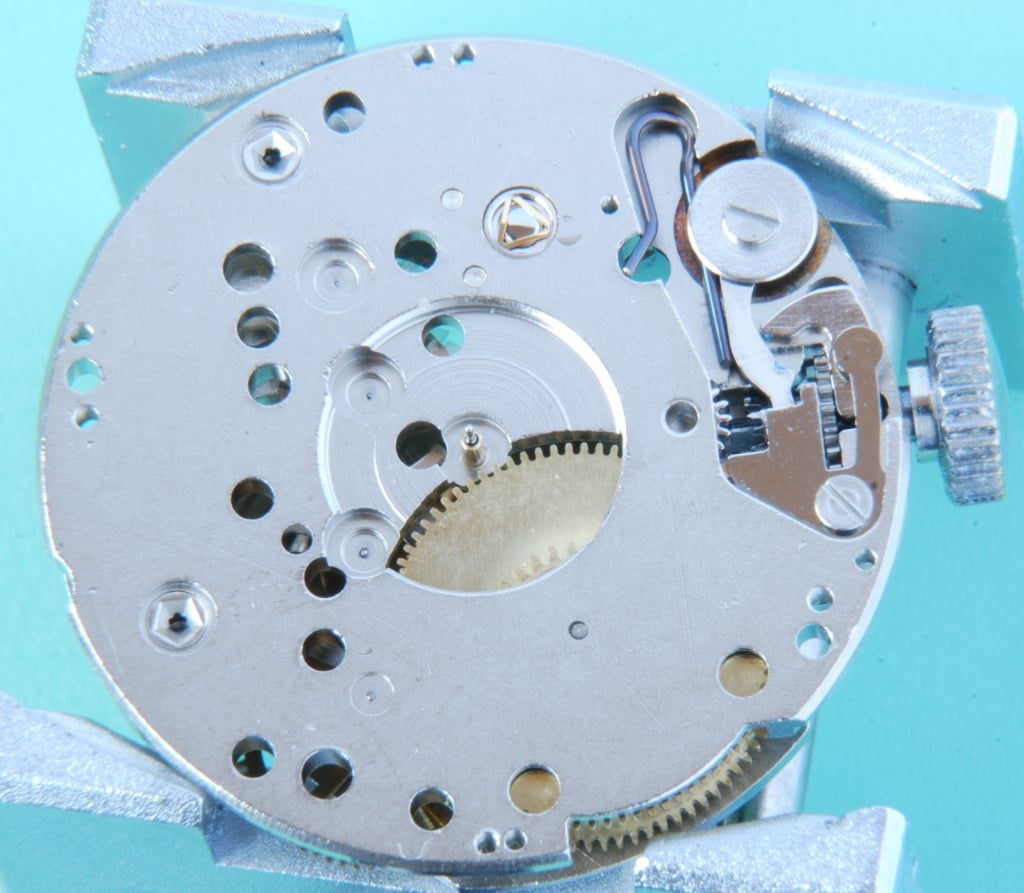

Here's the one jewel and it's the cap jewel on the balance cock so, on the wrist the balance will touch this side when the crystal is uppermost (arm rested on the table). It should run best in that position. It's a KIF shock protection system and those little triangular springs are rotated into the cut out to extract the jewel/holder. They can escape and end up anywhere so when working on them I keep a small oiler lightly pressed on the jewel so they go up the oiler rather than the nose...

Note above, adjustable stud carrier! Not too shabby.

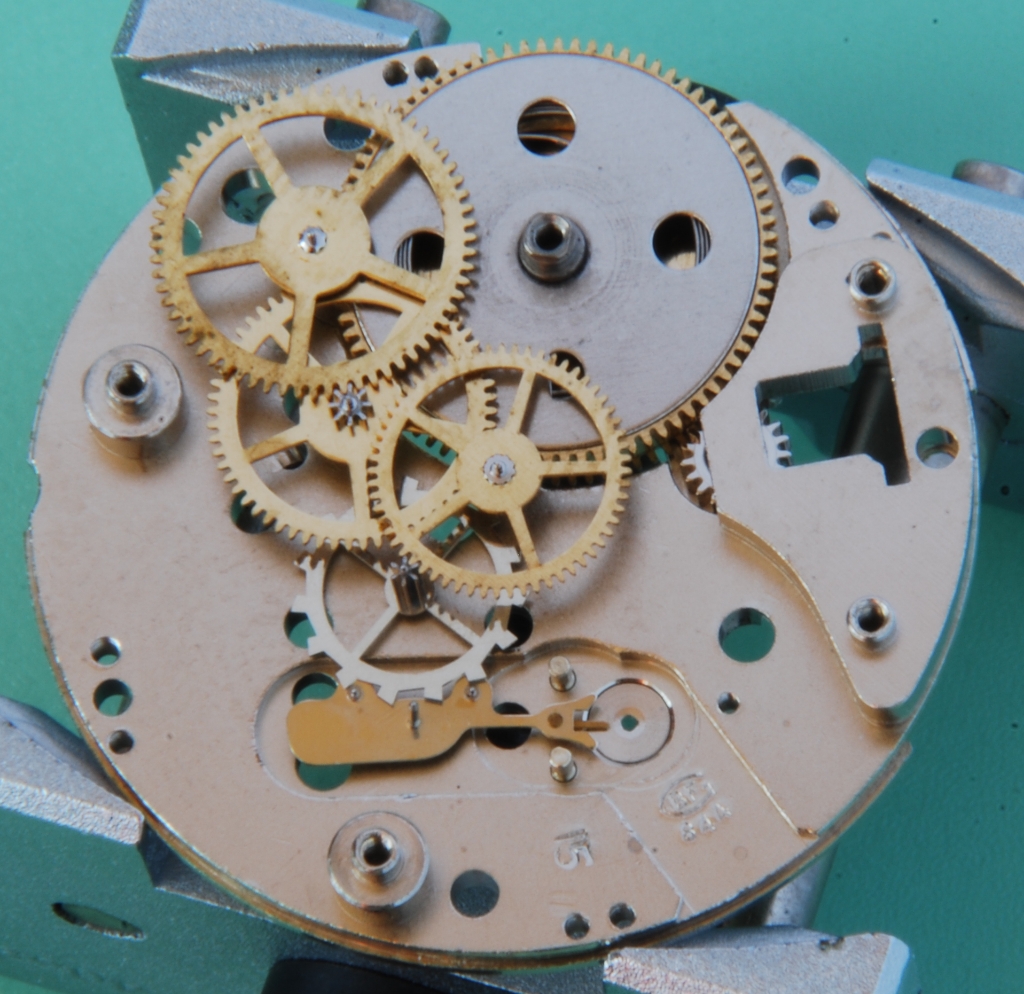

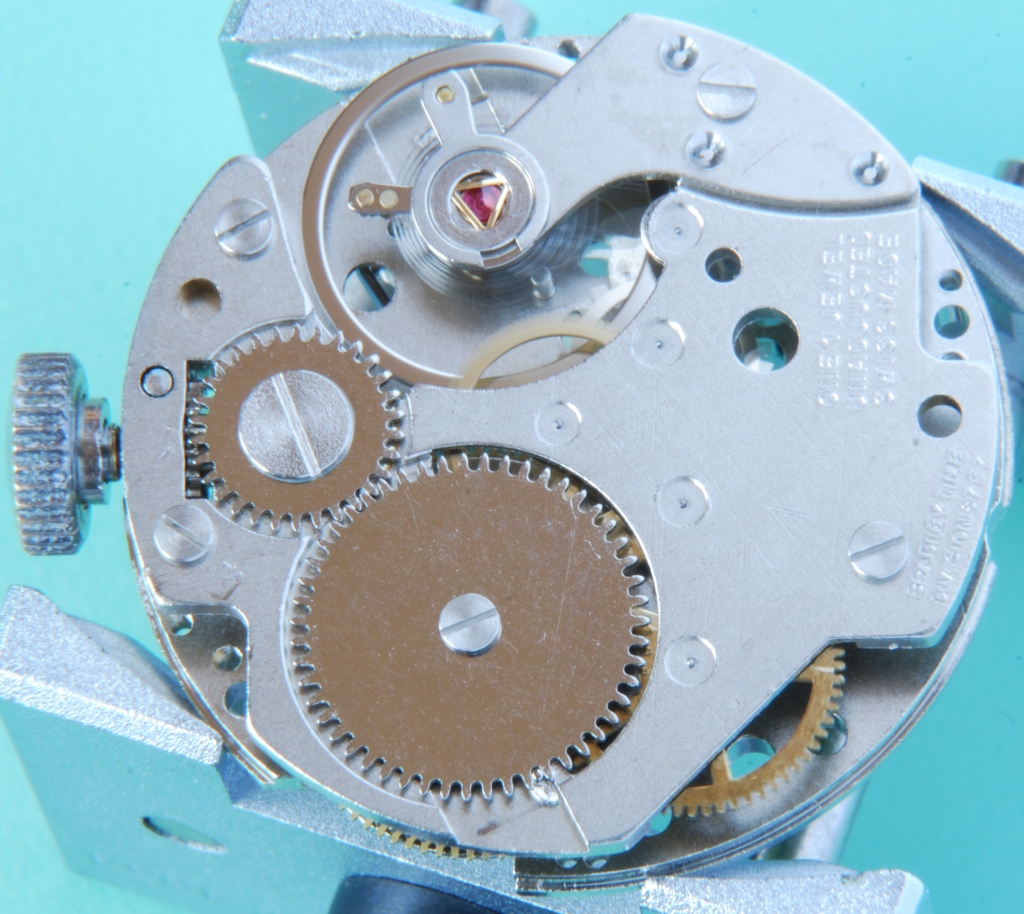

Here's the train from barrel (great wheel) and the teeth drive the 2nd wheel on the top left which drives the 3rd wheel below it, which drives the 4th wheel right in the centre of the movement. This rotates once a minute and extends through to the dial side and the second hand is pressed directly onto it. This drives the escape wheel (with the strange shaped teeth) whose movement is controlled by the pallet fork at the lower. There are two pins (hence pin pallet) on the left and right that contact the escape wheel teeth.

Now, all the above are under one plate which is a bl%#*y pain to fit as you're lining up six pivots and there are no jewels to give you visual clues. So, after a little time and a few choice words, it's fitted. Actually, I did this twice, the first time without the fork to check all rotate and have reasonable shakes. There is no adjustment anyway and no replaceable jewels so, luckily they were pretty good, a bit high on end shake but it's not an 861🙄

Very simple click and spring combined which rotates in the lower hole of the previous picture and is limited by a pin in the upper hole.

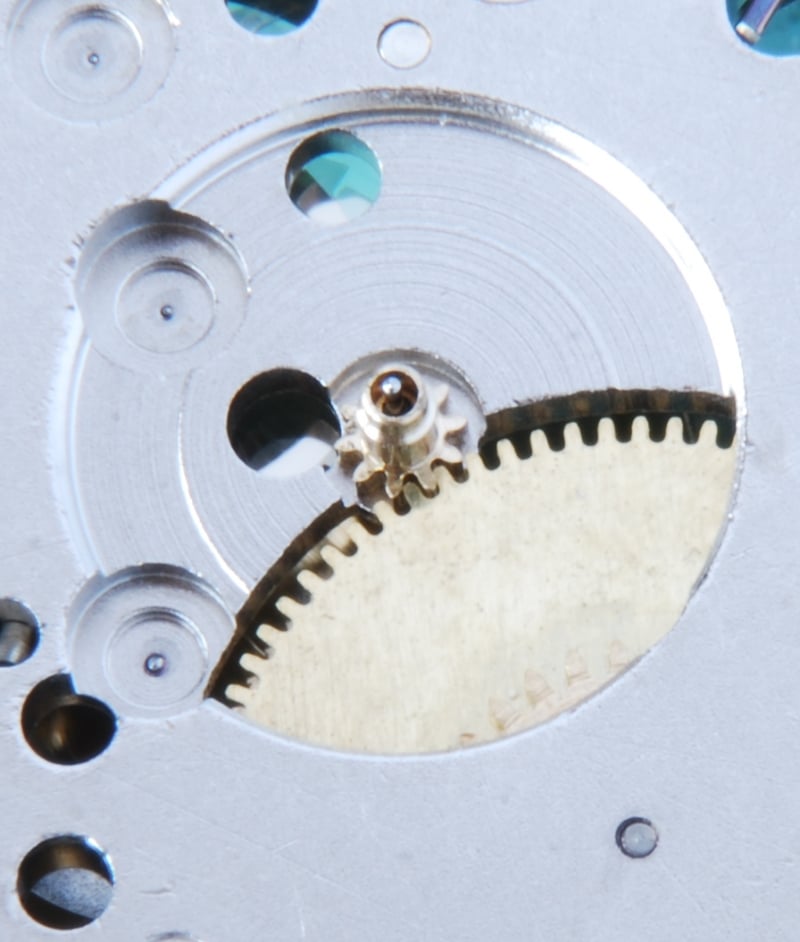

Nice arrangement for the keyless works on the dial side. The fourth wheel shaft for the second hand and other KIF can be seen here (it's not a ruby though) as well as the teeth on the barrel and it's secondary gear.

Cannon pinion fitted and meshed with the barrel gear outer teeth. So, as the 2nd wheel allows the barrel to rotate, the cannon pinion rotates. The minute hand is pressed on here.

The hour wheel (and dial washer) on top of the cannon pinion and meshed with the other gear on the barrel. The hour hand gets pressed on here.

That's it, turned over again, balance fitted and movement running.

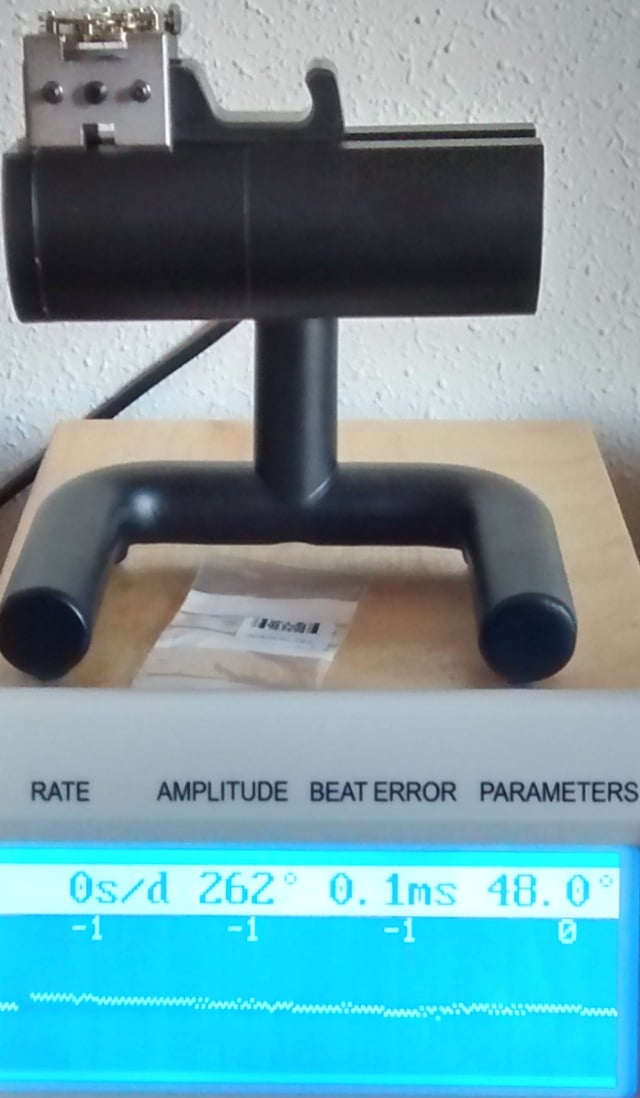

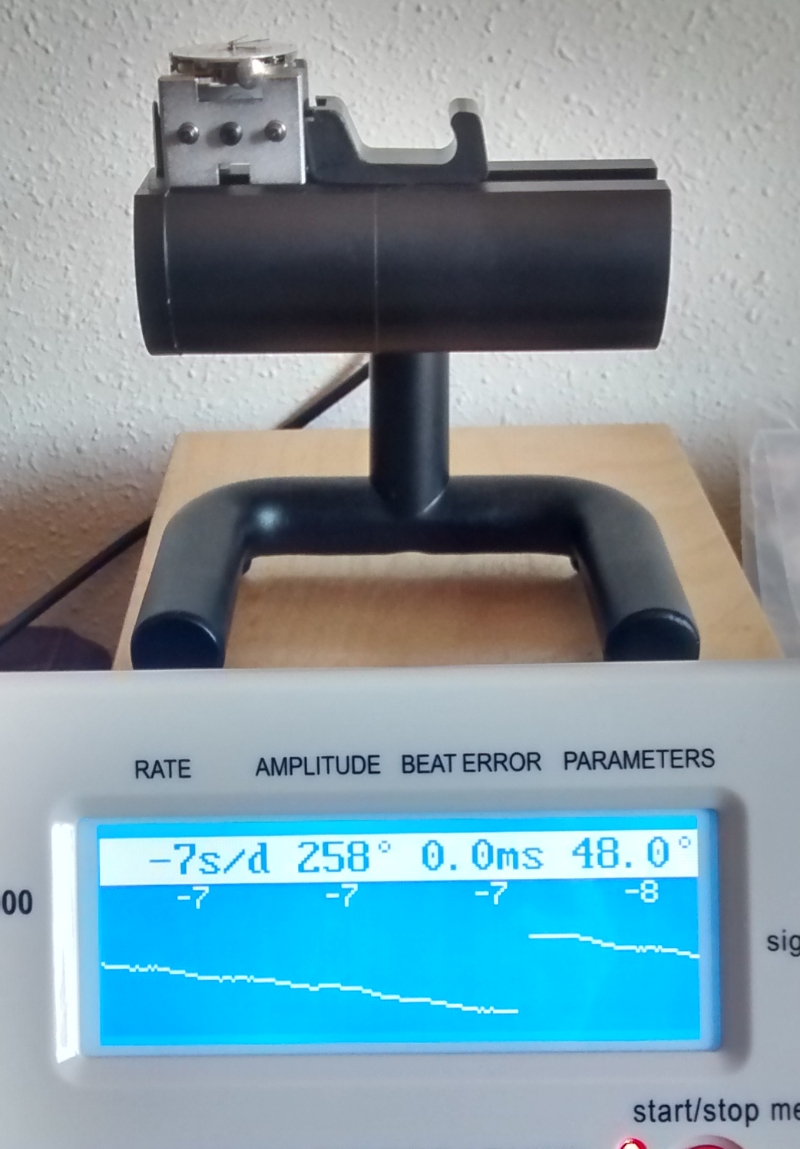

Added a little oil to the sinks and used 9415 on the pallet pins and here it is running in FH. I know I shouldn't oil the fork pivots but a tiny amount of 9010 seemed sensible as it's metal in metal. I don't think this is a bad result for a pin pallet but this is only the second I've done...

Will leave it for a few days and add the dial, hands and case. Need to order a crystal but this year I have lots of time unlike last when I finished for Epiphany

So, how much oil in those sinks? These are not like jewels so I'm not sure, just wetted the pivots so far. Happy to take advice here.

More next week. By the way, I do have Omegas so must show one of those next but I like to ramble...

Cheers, Chris

When I got this (advertised as not working), it would run for a few seconds and then stop so clearly not a broken balance staff. It was fully wound so some other problem. De-cased, it was apparent that the closing plate of the barrel was loose. These should be pressed on to the barrel to support the barrel on one side of the arbor. Might be visible here.

This is a Roskopf (I think) pin pallet escapement running at 18000 A/h and has a grand total of one jewel! I expected this to be the impulse jewel on the balance that contacts the fork but it isn't. Here's an Omega 565 balance with its ruby coloured impulse jewel (close to the pivot) and this balance on the left which uses a metal impulse.

Let the movement down, stripped it and it appeared to be all there. Cleaned and checked over and apart from the barrel issue, everything is fine. Little pivot wear so it likely has been a non runner for years. Parts for these cost buttons really, but nice to be able to re-use everything.

The mainspring goes in anti clockwise (most are clockwise) and as I wanted to re-use it and am too mean to buy left hand winders, had to wind it clockwise, press out of the winder into an mainspring ring, turn over and press into the barrel. Here, barrel with spring fitted, arbor and closing plate.

The closing plate snaps in fine so I can only assume it was badly fitted before. Other side of the barrel has another gear as well and directly drives both the minute and hour hand pipes. It becomes clear later.

This is unusual for me. In a more typical calibre, the barrel outer teeth drive the 2nd wheel which passes through the plate and has the cannon pinion attached to it onto which the minute hand is pressed. Then there's an intermediate pair of gears to drive the hour hand.

Here's the one jewel and it's the cap jewel on the balance cock so, on the wrist the balance will touch this side when the crystal is uppermost (arm rested on the table). It should run best in that position. It's a KIF shock protection system and those little triangular springs are rotated into the cut out to extract the jewel/holder. They can escape and end up anywhere so when working on them I keep a small oiler lightly pressed on the jewel so they go up the oiler rather than the nose...

Note above, adjustable stud carrier! Not too shabby.

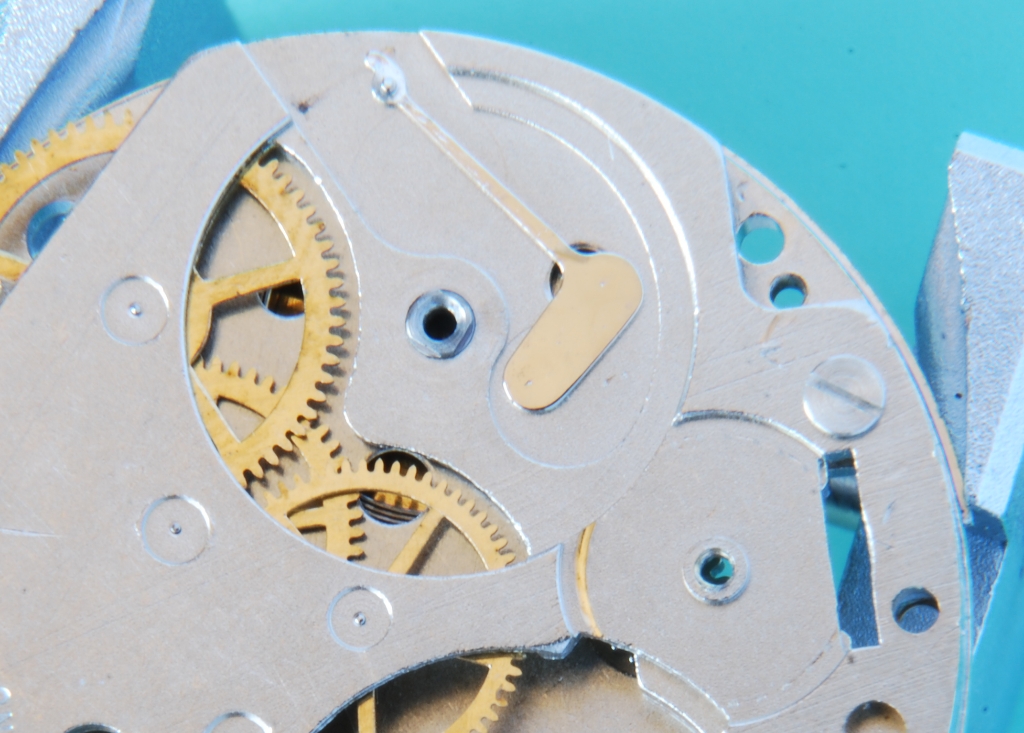

Here's the train from barrel (great wheel) and the teeth drive the 2nd wheel on the top left which drives the 3rd wheel below it, which drives the 4th wheel right in the centre of the movement. This rotates once a minute and extends through to the dial side and the second hand is pressed directly onto it. This drives the escape wheel (with the strange shaped teeth) whose movement is controlled by the pallet fork at the lower. There are two pins (hence pin pallet) on the left and right that contact the escape wheel teeth.

Now, all the above are under one plate which is a bl%#*y pain to fit as you're lining up six pivots and there are no jewels to give you visual clues. So, after a little time and a few choice words, it's fitted. Actually, I did this twice, the first time without the fork to check all rotate and have reasonable shakes. There is no adjustment anyway and no replaceable jewels so, luckily they were pretty good, a bit high on end shake but it's not an 861🙄

Very simple click and spring combined which rotates in the lower hole of the previous picture and is limited by a pin in the upper hole.

Nice arrangement for the keyless works on the dial side. The fourth wheel shaft for the second hand and other KIF can be seen here (it's not a ruby though) as well as the teeth on the barrel and it's secondary gear.

Cannon pinion fitted and meshed with the barrel gear outer teeth. So, as the 2nd wheel allows the barrel to rotate, the cannon pinion rotates. The minute hand is pressed on here.

The hour wheel (and dial washer) on top of the cannon pinion and meshed with the other gear on the barrel. The hour hand gets pressed on here.

That's it, turned over again, balance fitted and movement running.

Added a little oil to the sinks and used 9415 on the pallet pins and here it is running in FH. I know I shouldn't oil the fork pivots but a tiny amount of 9010 seemed sensible as it's metal in metal. I don't think this is a bad result for a pin pallet but this is only the second I've done...

Will leave it for a few days and add the dial, hands and case. Need to order a crystal but this year I have lots of time unlike last when I finished for Epiphany

So, how much oil in those sinks? These are not like jewels so I'm not sure, just wetted the pivots so far. Happy to take advice here.

More next week. By the way, I do have Omegas so must show one of those next but I like to ramble...

Cheers, Chris

Edited: