Timing tolerances - a guide to understand how they work

Deafboy

··His Holiness Puer SurdusThat’s some fine circular logic...

😵💫

I guess you don't agree with my statement then.

😁

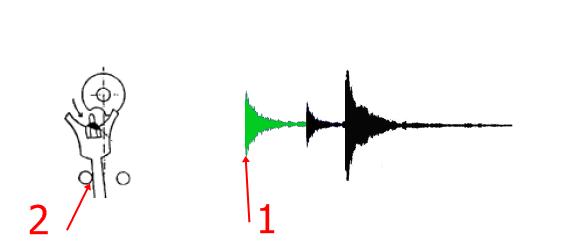

Here's my understanding of the use of lift angle to determine amplitude. Looking at the image below, the start of the acoustic pulse (1), which is used by timing machines to determine amplitude of the balance wheel, depends on the location of the banking pin (2). If the banking pin is moved closer or further from the vertical centerline it will affect the amplitude measurement. I hypothesized a watch model with fixed banking pins would have less sample-to-sample variation of lift angle than a model with adjustable pins.

lpestre

·Thank you Al!

Archer

··Omega Qualified WatchmakerI hypothesized a watch model with fixed banking pins would have less sample-to-sample variation of lift angle than a model with adjustable pins.

You have assumed that because the banking pins are adjustable, that they can't be adjusted consistently. There are always going to be variations (tolerances) even with the machining of fixed bankings, but in the context of the reason why lift angles weren't published, this explanation still seems quite a stretch to me.

Cheers, Al

Scooterino36

·Thanks for this Al, the exact explanation of tolerances I was looking for.

👍

👍

Professor

·When a movement is marked "unadjusted" I assume that means it was not adjusted to the various positions, but surely it was adjusted to keep good time in at least one position.

I've read that old time railroad approved pocket watches were usually carried in a pocket narrow enough the when the watch was inserted crown up it would stay that way, so these were adjusted for best accuracy in a crown up position. Accuracy in other positions, though tested, was secondary since even while sleeping the watch would be hung or stood in a crown up position.

I've seen unadjusted markings on movements of some high grade wrist watches. Did the movement manufacturer leave adjustment for positions up to the jewelers who sold their watches, or to whoever first cased the movement?

I've read that old time railroad approved pocket watches were usually carried in a pocket narrow enough the when the watch was inserted crown up it would stay that way, so these were adjusted for best accuracy in a crown up position. Accuracy in other positions, though tested, was secondary since even while sleeping the watch would be hung or stood in a crown up position.

I've seen unadjusted markings on movements of some high grade wrist watches. Did the movement manufacturer leave adjustment for positions up to the jewelers who sold their watches, or to whoever first cased the movement?

Archer

··Omega Qualified WatchmakerSometimes the amount of adjustment was downplayed in order to avoid duties when movements or watches were imported.

Dan S

·When a movement is marked "unadjusted" I assume that means it was not adjusted to the various positions, but surely it was adjusted to keep good time in at least one position.

I've read that old time railroad approved pocket watches were usually carried in a pocket narrow enough the when the watch was inserted crown up it would stay that way, so these were adjusted for best accuracy in a crown up position. Accuracy in other positions, though tested, was secondary since even while sleeping the watch would be hung or stood in a crown up position.

I've seen unadjusted markings on movements of some high grade wrist watches. Did the movement manufacturer leave adjustment for positions up to the jewelers who sold their watches, or to whoever first cased the movement?

It's probably true that PWs don't experience as much positional variation as WWs. But by definition, Railroad watches were adjusted in 6 (!) positions.

MtnMarine

·Thanks Archer! Great info

alikara

·Thanks Al for the writeup - this was really useful

KeyWestPaw

·Thanks for clarification. Been timing all my watches and wasn't sure how to average them.

Cheers!

Cheers!

D.D.

·Thank you Al 😀

- Posts

- 54

- Likes

- 40

jmnav

·Now you've got me wondering about the distribution of positions that my watch experiences during a typical day ... and how I could measure that. 😲

In practical terms, no need for it, as it can be implied. You know (or can get) what the tolerances and drifts are in the static positions. Now, you go to your watch expert of choice and tell him on my wrist, this watch goes 15s/day too fast (or whatever): he can (or should) be able to make an informed guesstimate between the static values and values on your wrist to further regulate your watch (that's what regulation is for, after all). Worst case scenario, it will take a few travels to the watch mechanic to properly regulate it.

Of course, the finer the adjustment, the finer (and more stable) the regulation.

Dan S

·J jmnavIn practical terms, no need for it, as it can be implied. You know (or can get) what the tolerances and drifts are in the static positions. Now, you go to your watch expert of choice and tell him on my wrist, this watch goes 15s/day too fast (or whatever): he can (or should) be able to make an informed guesstimate between the static values and values on your wrist to further regulate your watch (that's what regulation is for, after all). Worst case scenario, it will take a few travels to the watch mechanic to properly regulate it.

Talk about missing the point. 🙄

- Posts

- 54

- Likes

- 40

jmnav

·Talk about missing the point. 🙄

If so you say...

OK then: the way for you to know "about the distribution of positions that your watch experiences during a typical day ... and how you could measure that" is by adjusting a gyroscope to your watch capable to record which positions your watch has been along the day and for how long.

...which, in practical terms adds nothing of value, since they can be implied by knowing how the watch behaves in the static positions and solving the proportion of these static positions that render the observed result.