precisionhrlgy

·I recently had this lovely 14K Ross American cased De Ville come through the workshop. The good - it is a family heirloom that was looking to be restored so it could be worn again. It had been in eh family since new and the customer wanted it working once more. The bad - it was in rough shape and required quite a lot of work. The ugly - we will get to that.

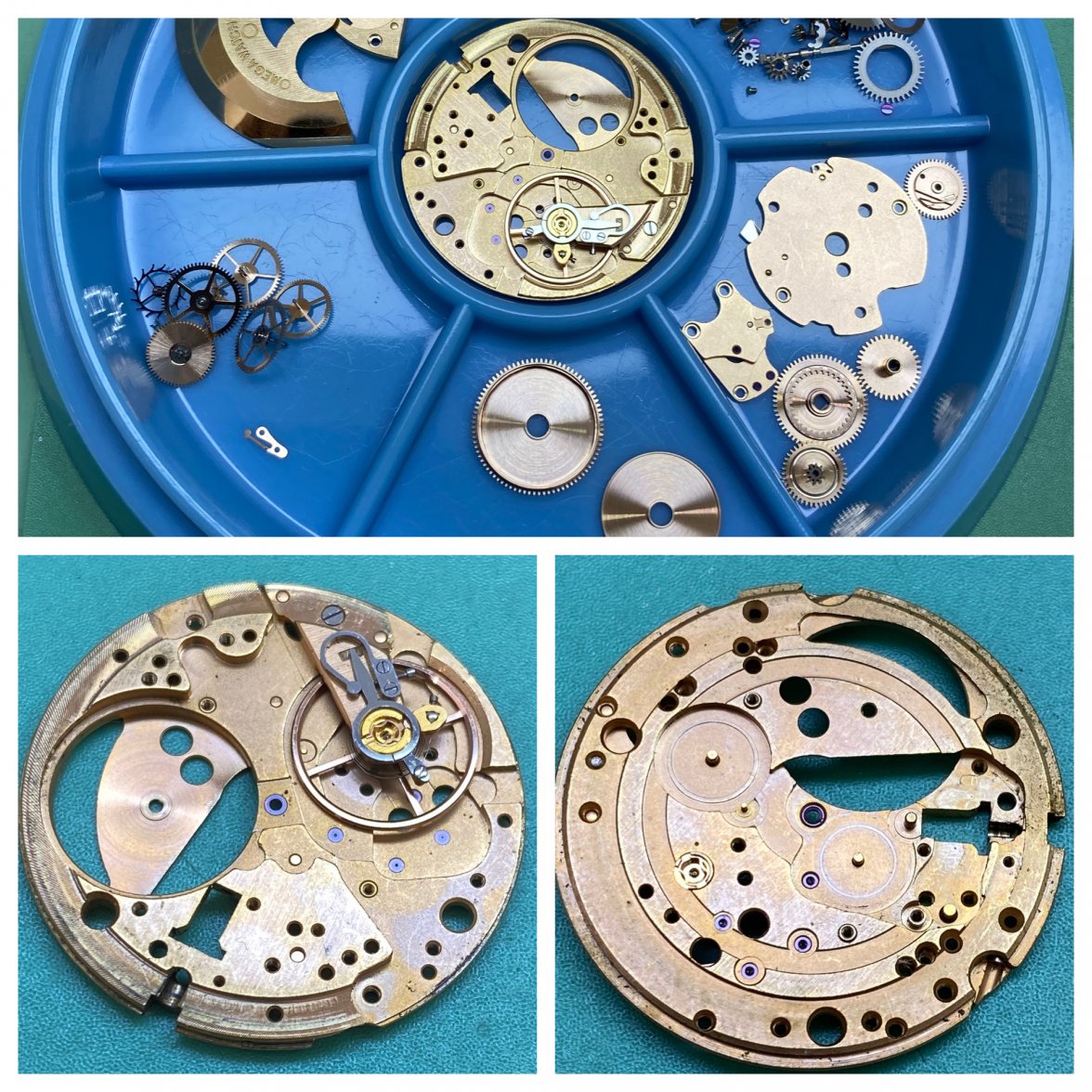

We can see from the beginning the watch has lived a relatively hard life. It's quite dirty and in need of a good overhaul.

The movement is generally dirty.

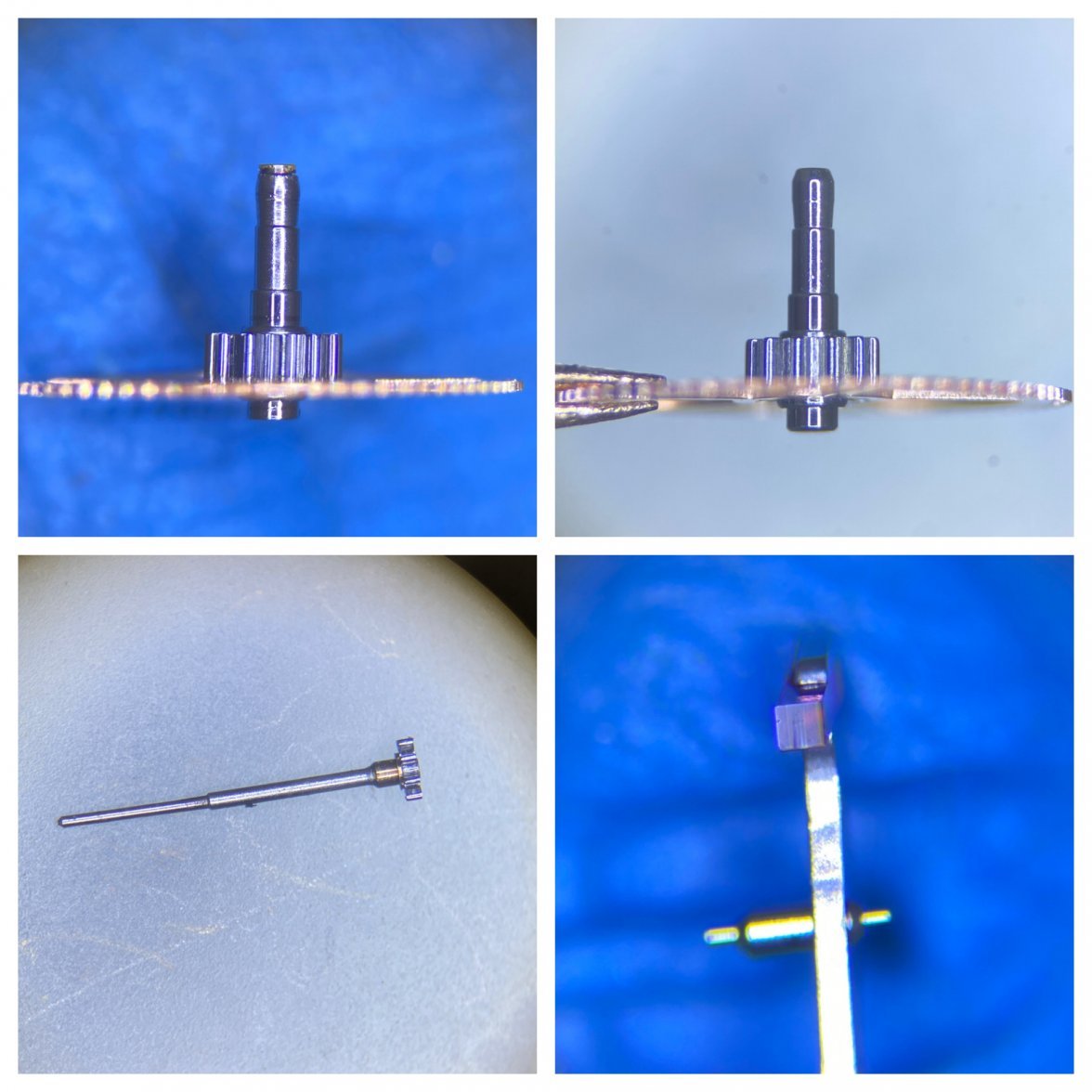

Upon close inspection of the components we can see the issues. The centre wheel is the old 55x series type with a separate bushing for the seconds pinion. The bushing has started to come out of the end - the reason that Omega upgraded this wheel to be one solid construction. The seconds pinion had some rust present on it so it was changed. You can also see the pallet fork stones have a groove carved out of them. This is the result of wear from lack of servicing over the years. A relatively common problem I see in these 55x series movements.

You can see just how filthy the automatic work was. The driving wheel fro the automatic work was so worn, you can see where it was rubbing on the plate. The barrel too was in bad condition. There were groves worn into the drum due to an out of flat mainspring. Also, the barrel wall was worn too. Once the mainspring was removed you can see the bad bend in the spring. Time for a new one. Finally, the clutch wheel (sliding pinion) had worn teeth and was ready to be changed.

New parts ordered and received and it's time to get to work.

The balance spring adjustments were made as it was out of flat and out of round. The rest of the movement was assembled and lubricated.

As we start to case up, we get to the ugly. It appears that someone has soldered in a new case tube at some point. However, the tube is too long. I didn't immediately pick up on this but when the watch was cased there was a clunking. This was strange as the oscillating weight pinion was changed due to excessive wear when it came in. It turns out the case tuber was left too long and that was rubbing on the oscillating weight. The funny thing is, this would have been happening ever since the new tube was installed. Sometimes I am just left shaking my head. I was able to file down the end of the tube and fix the problem in under 5 minutes - sometimes it really ins't hard.

The final result (except for the new crown that hasn't arrived yet)

We can see from the beginning the watch has lived a relatively hard life. It's quite dirty and in need of a good overhaul.

The movement is generally dirty.

Upon close inspection of the components we can see the issues. The centre wheel is the old 55x series type with a separate bushing for the seconds pinion. The bushing has started to come out of the end - the reason that Omega upgraded this wheel to be one solid construction. The seconds pinion had some rust present on it so it was changed. You can also see the pallet fork stones have a groove carved out of them. This is the result of wear from lack of servicing over the years. A relatively common problem I see in these 55x series movements.

You can see just how filthy the automatic work was. The driving wheel fro the automatic work was so worn, you can see where it was rubbing on the plate. The barrel too was in bad condition. There were groves worn into the drum due to an out of flat mainspring. Also, the barrel wall was worn too. Once the mainspring was removed you can see the bad bend in the spring. Time for a new one. Finally, the clutch wheel (sliding pinion) had worn teeth and was ready to be changed.

New parts ordered and received and it's time to get to work.

The balance spring adjustments were made as it was out of flat and out of round. The rest of the movement was assembled and lubricated.

As we start to case up, we get to the ugly. It appears that someone has soldered in a new case tube at some point. However, the tube is too long. I didn't immediately pick up on this but when the watch was cased there was a clunking. This was strange as the oscillating weight pinion was changed due to excessive wear when it came in. It turns out the case tuber was left too long and that was rubbing on the oscillating weight. The funny thing is, this would have been happening ever since the new tube was installed. Sometimes I am just left shaking my head. I was able to file down the end of the tube and fix the problem in under 5 minutes - sometimes it really ins't hard.

The final result (except for the new crown that hasn't arrived yet)