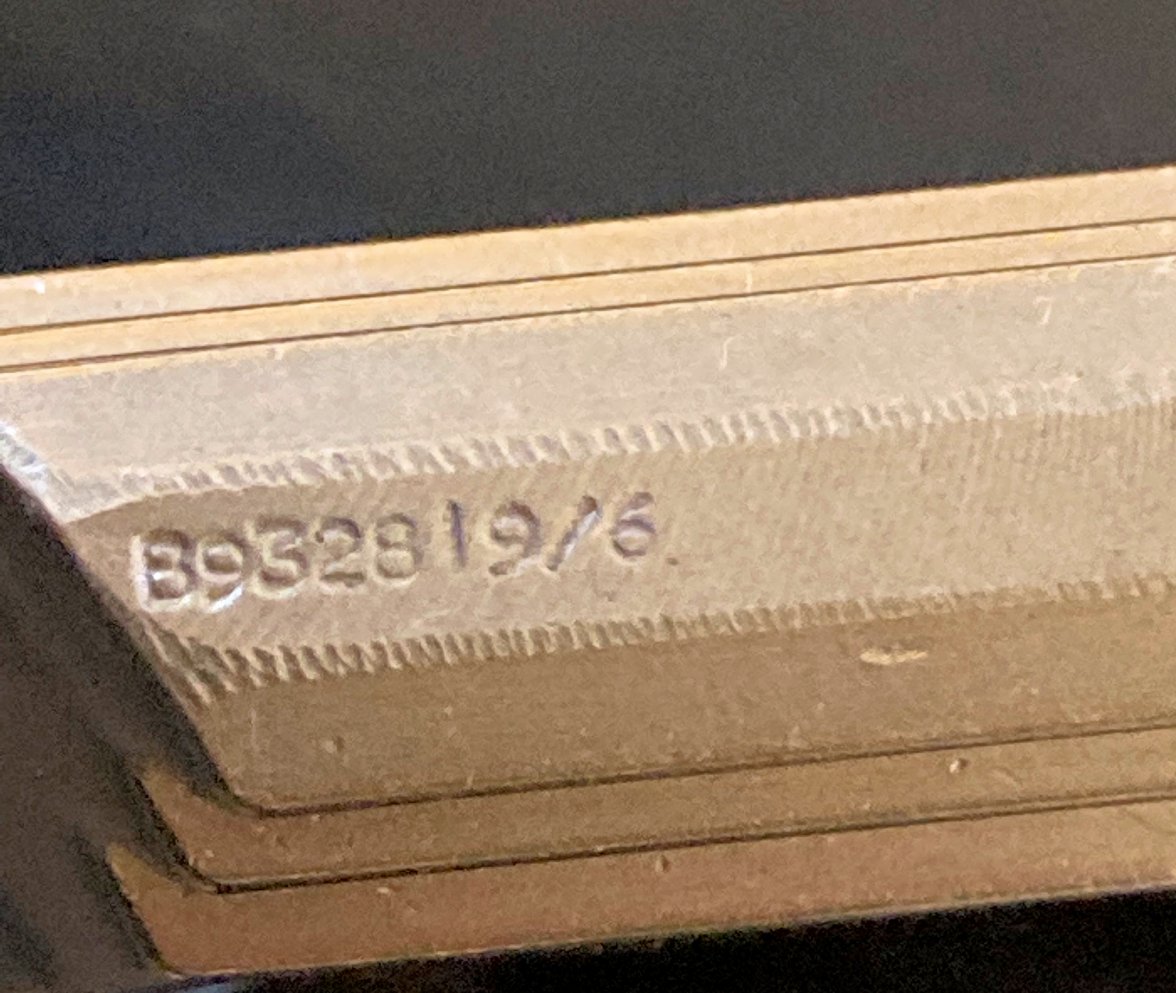

There will normally be an identifying part number either stamped or engraved somewhere on the root. Clean it with Jet A1 or petrol and a toothbrush and something will appear.

It actually looks like someone used an engraver to remove the numbers in the area between the root of the blade and the top of the fir tree. This area will normally never show signs of rubbing or wear so I am guessing in order to give then as gift or souvenirs the identifying number needed to be removed.

as

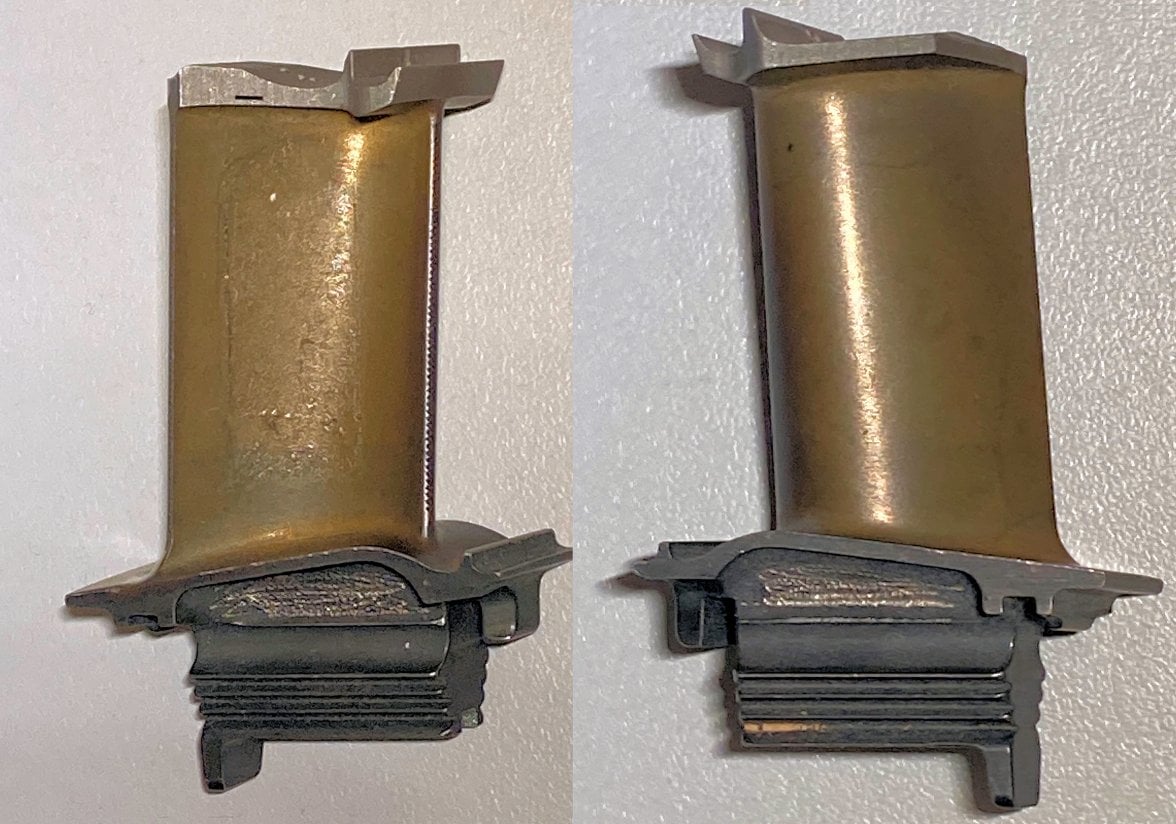

@Longbow mentions, the leading edge and training edge has cooling holes. On modern blades there are multiple cooling holes across both faces of the blade. the NGV (Nozzle Guide Vanes) are the fixed airfoil between the rotating airfoils who have similar holes and air is ducted from the engine and forced through the hollow center to cool the airfoils, normally the cooling air is about 250c temp.

A CFM56-7B (737-800) has 80 T1 blades and each blade in overhauled condition will set you back $10-14,000.00 per blade depending on market availability. Generally you will get 25000 hours and one overhaul before they scrap out, its an expensive business.