redpcar

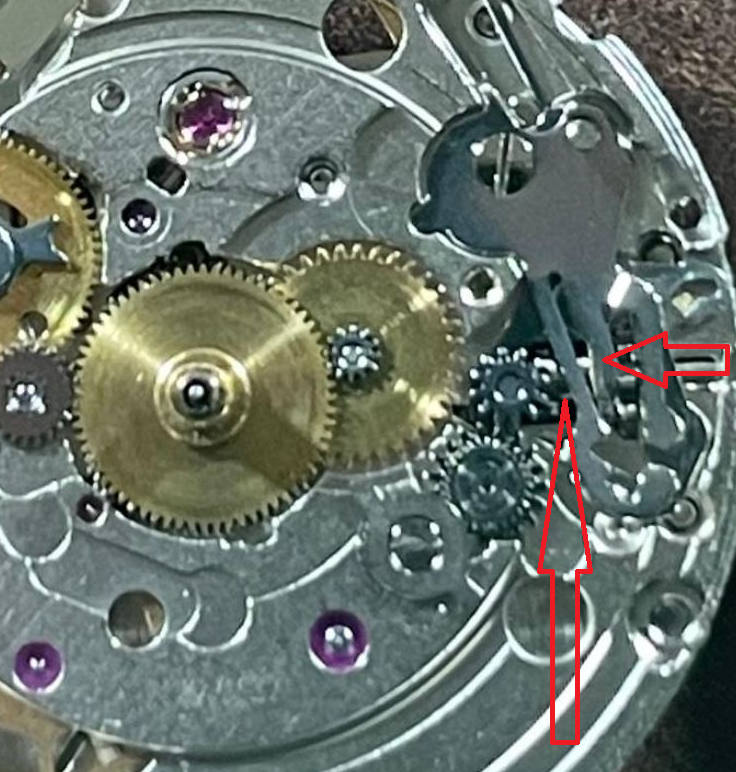

·I have a consistent dilemma when playing with the ETA 2836. When I re-install the stem, I always manage to kick the clutch wheel out from under the clutch lever. Very frustrating as I have to take everything back apart, lift the set bridge, push the wheel back in place and start over. As they say doing the same thing over and over and expecting a different result...

I always push the button to lift the set lever when installing the stem (very little pressure).

The question: should I be doing something different? Maybe I'm missing a worn piece. Maybe more lubrication on the stem. Or is it simply the nature of the beast.

Any help provided is greatly appreciated.

I always push the button to lift the set lever when installing the stem (very little pressure).

The question: should I be doing something different? Maybe I'm missing a worn piece. Maybe more lubrication on the stem. Or is it simply the nature of the beast.

Any help provided is greatly appreciated.