marcn

·Okay bear with me, I'm a guy who normally wears everything on natos...

Preamble:

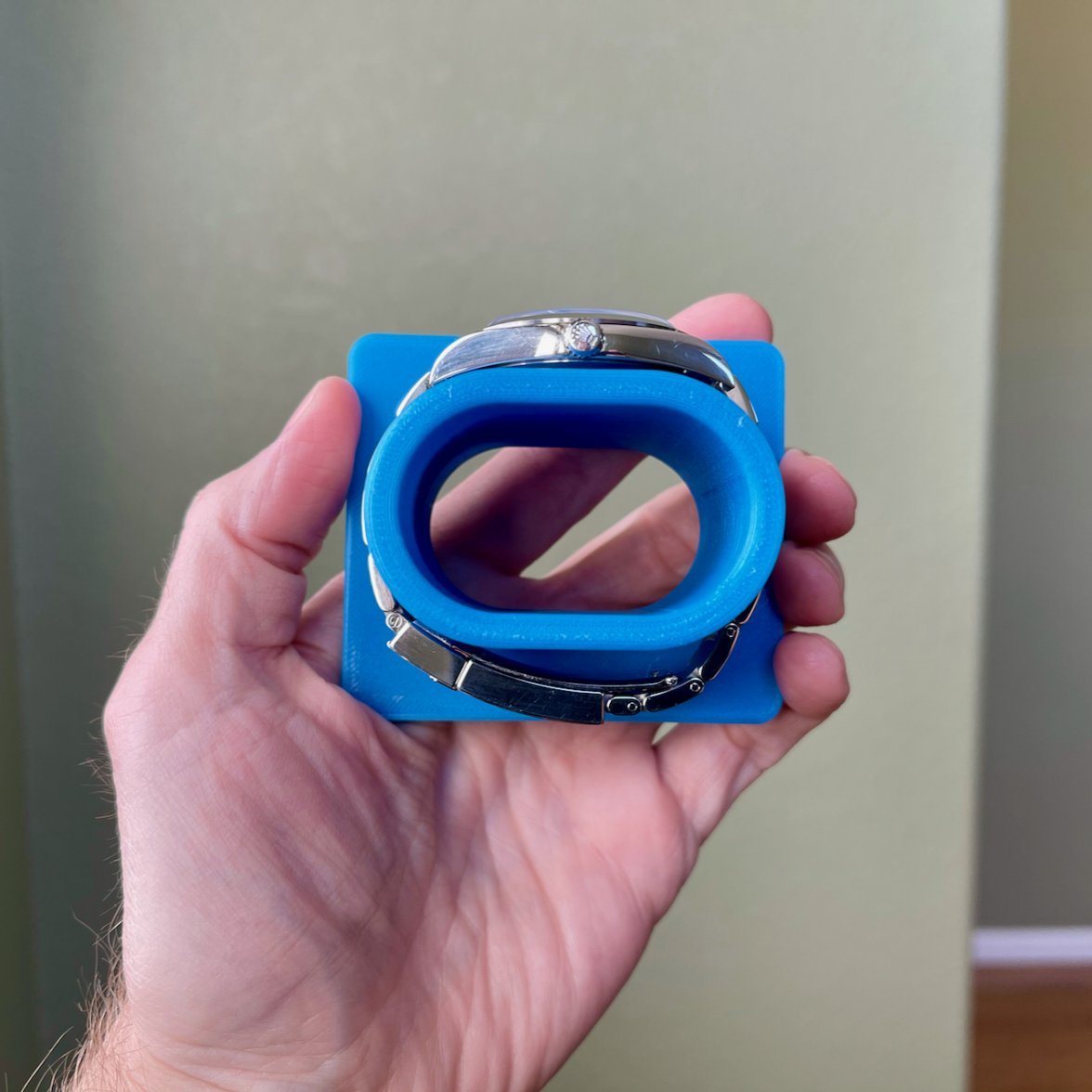

I'm starting to really love wearing my Explorer on the bracelet since it came back that way from service, and after the AD resized it. It's been reasonably cold, and on its current sizing, it's already fully extended, and does fit perfectly this way, but things are warming up.

I could bring it back to the AD for an adjustment (add a link but move everything back into the tightest fit, so I can then let it out when things warm up.)

Question:

Assuming I try this adjustment myself (The burgeon screwdriver I have appears to be the right size), is there a recommended place, given how things are currently looking, where I'd add that link? I'm thinking at the 6 o'clock side. But is that right/recommended? Want to do this once if I can, because I'm assuming I'm going to scratch the hell out of things! 😀

Thanks!

Preamble:

I'm starting to really love wearing my Explorer on the bracelet since it came back that way from service, and after the AD resized it. It's been reasonably cold, and on its current sizing, it's already fully extended, and does fit perfectly this way, but things are warming up.

I could bring it back to the AD for an adjustment (add a link but move everything back into the tightest fit, so I can then let it out when things warm up.)

Question:

Assuming I try this adjustment myself (The burgeon screwdriver I have appears to be the right size), is there a recommended place, given how things are currently looking, where I'd add that link? I'm thinking at the 6 o'clock side. But is that right/recommended? Want to do this once if I can, because I'm assuming I'm going to scratch the hell out of things! 😀

Thanks!