sheepdoll

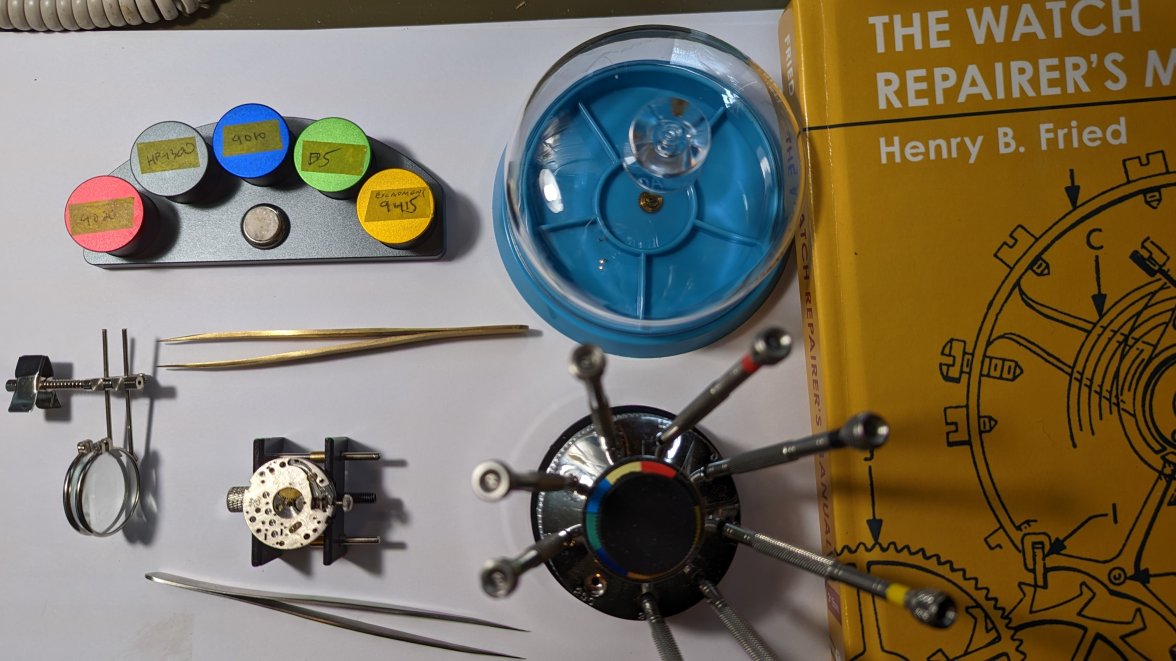

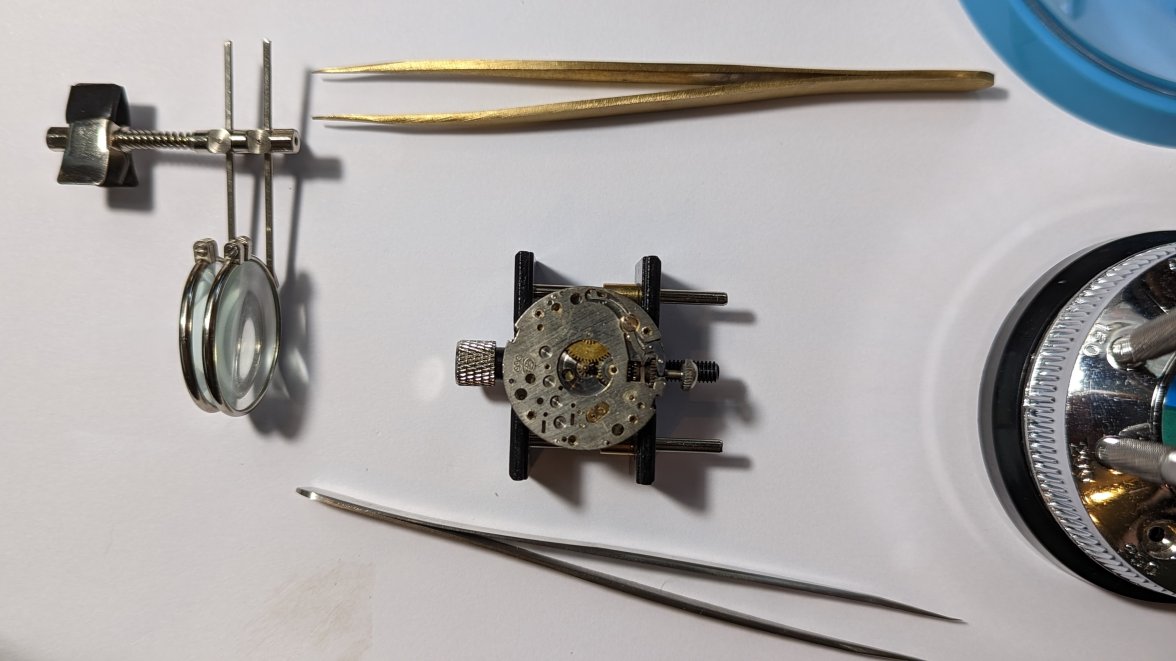

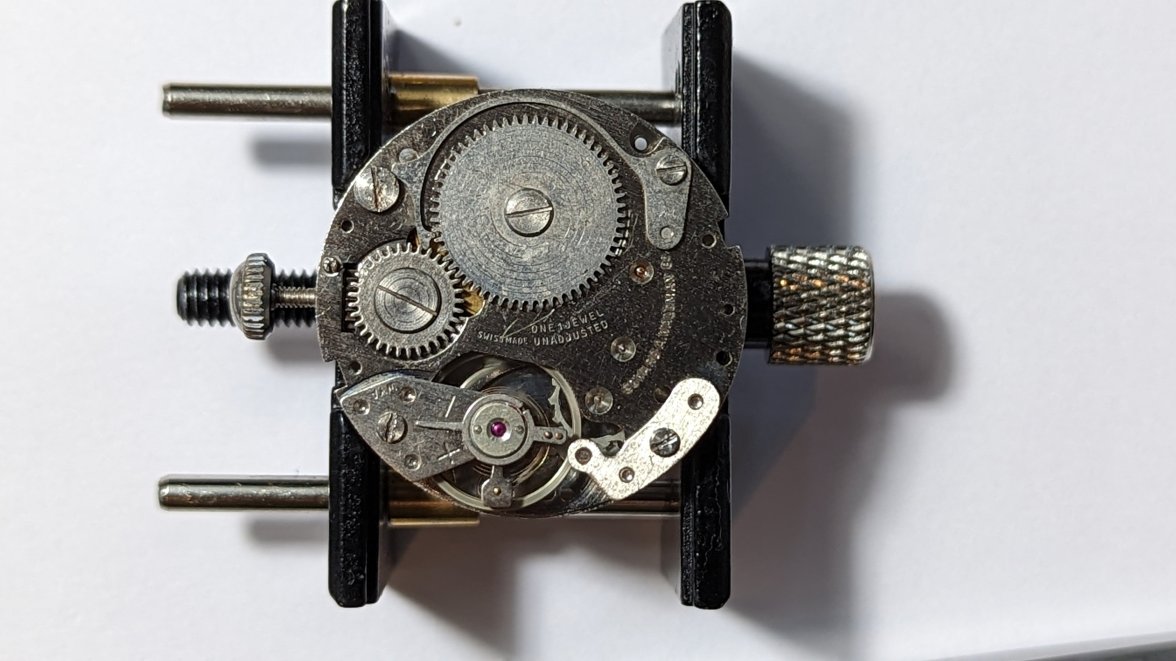

·The guide to practical watchmaking says to use cyanide of potassium at one point. Says to use benzine and a brush. Or says to use "cleaning solution" then "rinse solution" without ever explains what those solutions are. It's always something.

But yeah I think machines and chemicals go hand in hand at this point in my startup phase.

)

)Also look closely at the spelling of benzine as I and @Dan S said the spelling can make a difference benzine is not benzene. When in doubt always look up the MSDS. A lot of chemicals which are branded are 'trade secrets.' as the right blend of chemicals can be worth a fortune. Cola is a mixture of Citric acid, vanilla, and sugar. This creates a fantasia of taste which are like a musical chord. Back in the days of custom drug store soda fountains phosphate drinks were popular as in cherry or strawberry phosphates. Cola is effectively vanilla phosphate. It is said that the difference between coke and pepsi was whether lemons or limes were used. Pepsi also used corn sugars, Coke used cane sugars (rum) In our era the formulas are pretty much the same. Also note that how these mix is not linear. Mixing stuff in a cup verses mixing stuff in a vat produces different results.

The old guys had to get their stuff from nature. Cyanide comes from the seeds of stone fruits like apricots peaches or seeds like apple seeds. Ammonia comes from pee or piss. Which is basically what watch cleaner is synthetic pee. In the old days the poor would save their piss and sell it to the fullers who would use it for cleaning cloth (and other things.) If one could not afford a pot, then they "Would not have a pot to piss in" and be piss poor. Pee is also considered to be sterile and has been used as an antiseptic.

You really do not want to know what is in the stuff you consume.

-j

Edited: