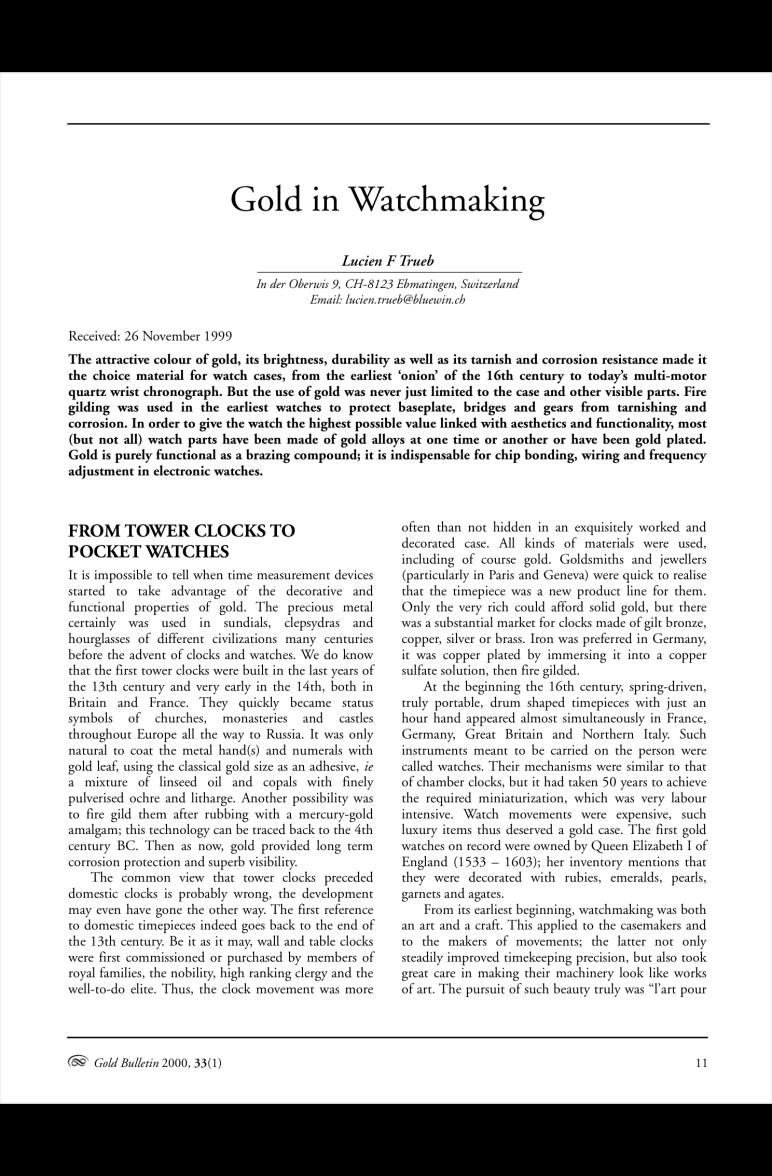

For those with an interest in gold alloys, the below is from a

1999 document titled “gold in watchmaking”

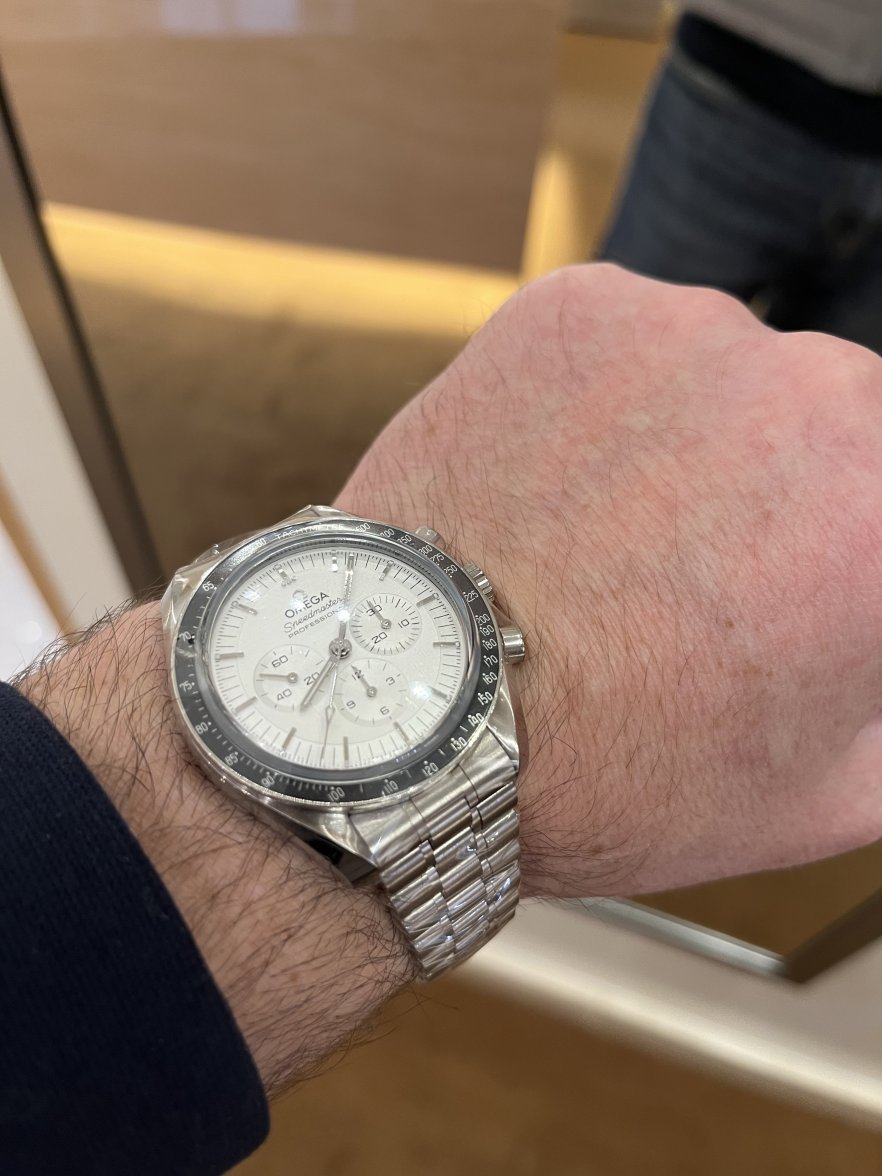

The buyer of an 18 ct yellow gold watch has a choice of half a dozen colours plus another good half dozen for white gold. There are distinct national preferences: German 18 ct gold is bright yellow (‘2N’) and contains 10% copper and 15% silver, while the Swiss variety is a darker yellow (‘3N’) and contains 12% copper and 13% silver. The latter colour is preferred in combination with steel for ‘bicolore’ cases and bracelets. Rosé gold (‘4N’) contains 16% copper and 9% silver, while red gold (‘5N’) contains 21% copper and only 4% silver. Watchcases are mostly made of the 2N type, as 95% of Swiss made gold watches are exported. However, certain manufacturers insist on rosé or red gold as their ‘trademark’ (4N and 5N colours). The 2N and 3N type alloys are available in fine grained varieties specifically for watchcases, as they are easier to polish to a high gloss; traces of iridium are added for grain growth inhibition.

As far as white gold is concerned, the 18 ct alloy with 16% palladium and 9% silver was quite widespread in the days of cheap palladium. Nickel white gold has totally fallen out of favour because of its allergenic potential. The law requires that no more than 0.5 micrograms of nickel are given off per square centimetre per week; this is easily achieved, but nobody wants to take a chance. White gold is presently very much in fashion, but it is expensive, as the palladium price has enormously increased in the past few years. This is mostly due to the uncertain supply situation (70% of that metal comes from Russia) and steadily increasing demand for automotive catalytic converters. White gold alloys with 12.5% or just 10% palladium (the latter need manganese or iron for strengthening) have been developed to save palladium. Some of the new white gold alloys can be hardened by heat treating, grain growth being inhibited with iridium. Other low palladium white gold alloys which do not need to be rhodium plated were recently introduced.

The alloys Gold 990 (23.76 ct) with 1% titanium and gold 986 (23.66 ct) with 1.4% titanium plus copper, never made the breakthrough that had been hoped for, despite their good mechanical properties and machinability. In the age-hardened condition, they are similar to 18 ct alloys. For one thing, gold 990 and 986 are about 30% more expensive than 18 ct gold, as they contain a lot more precious metal. Also, one must be aware of the fact that any price differential at the level of the case is multiplied eightfold by the time the complete watch makes it into the retail store display. Furthermore, recycling this type of alloy poses problems, both technical and economical, as gold refiners are not used to dealing with titanium. Only the Japanese owned American-Swiss Waltham Watch Company tried gold 990 in watch cases, but only with moderate success; there were no followers.

Bonus pictures so it’s not a just a wall of text! (Not all are mine)