Esslinger has a good section of tech documents

https://drive.google.com/drive/fold...5azU2eFk?resourcekey=0-wkmwmF0oWowPqOMdm-03fA

WatchGuy is my goto place for searching datasheets

https://watchguy.co.uk/cgi-bin/files?subdir=Omega&dir=Technical Manuals&action=documents

The links above are pointed at the omega section. Use the back button to see other calibers.

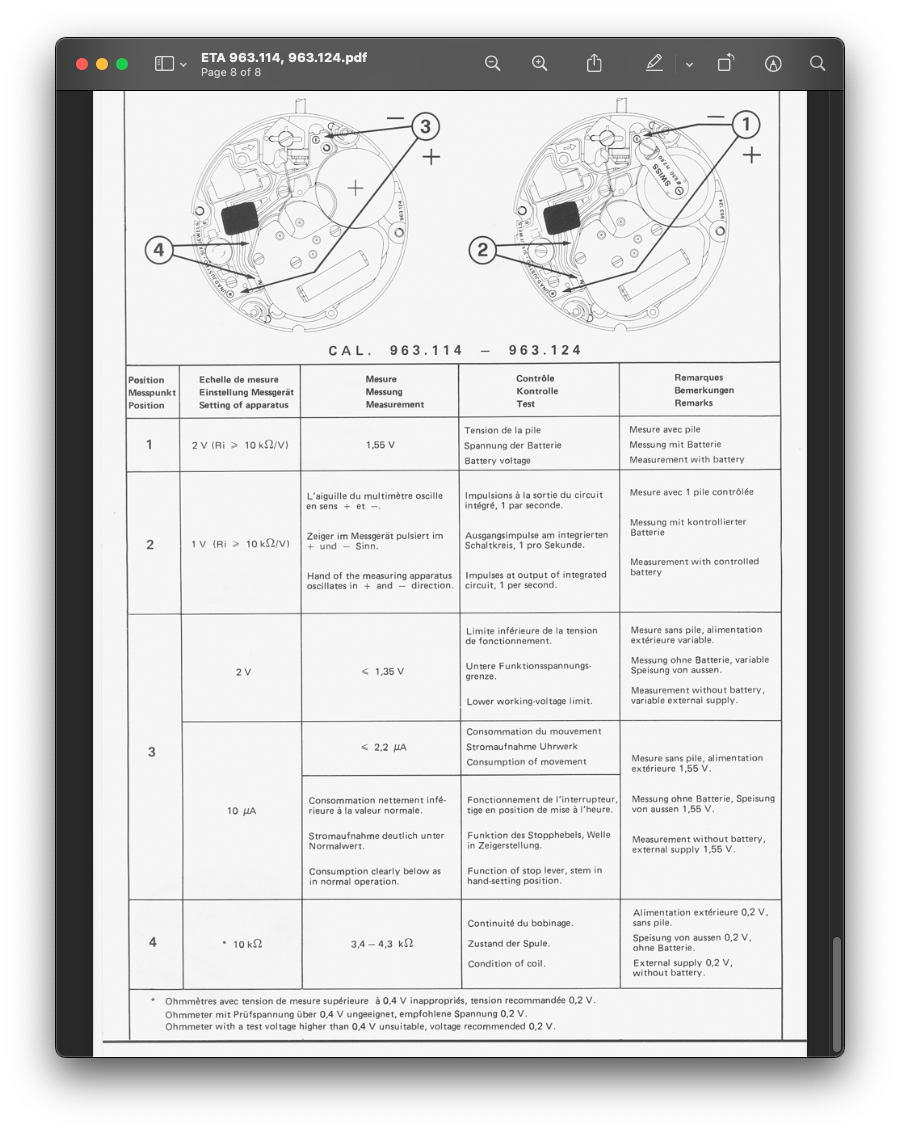

Here is a screenshot of an ETA datasheet with the voltage guides.

I am not sure where I saw the info on measuring the coil resistance. The last line may be what I was remembering. Somewhere I should have a guide to servicing Quartz watches. Might be in one of my books or magazines. Looks like I downloaded this back in January when I got the TAG/Heuer movements. (Where does the time go.) Addicted to information overload -- I tend to get distracted by what ever quickens me the most. Interruptions can cause delays of years or even decades of delay.

What I should be doing is troubleshooting some Ethernet interfaces on pipe organ boards. The modern NIC (Network interface controller) chips have built in diagnostics. When properly coded they can estimate where the break in the wires are by measuring the back reflections.

Something similar could be done with coils (which can act at anteni.) I have seen RF testers for Quartz watches. Not sure how often breaks in the coils occur. In motors these are usually close to one terminal or the other.

ESD (Electro Static Discharge.) is the bane of electronics. My first 'real.' job was repairing Apple /// computers. These were shipped almost 100% DOA. Amazing that Apple recovered. The Apple ][ did not use the CMOS SMT chips. Apple learned a lot about the issue. Why those blue grounding mats and wrist straps are now used. Most modern chips have protection diodes on the terminals.

Cold solder joins are also another issue. Might be interesting to reflow the chips on a defective module. Internally the wire die bonds can sometimes corrode. The packaging is to keep the light out. This can be hydroscopic. Early transistor suffered from and oxide called the purple peril after the oxide found. Lead free chips can suffer from something called tin whiskers. The best solder does remain lead which is exempt in life critical areas.

Most of this is academic. I doubt anyone outside of pure research is going to decap a watch chip and diagnose the failure or clone it. Much more profitable to do such with automotive or vintage game machines (Aka Jeri Ellsworth.)

Chips are basically stained glass precisely manufactured with a lithographic printing process. Quite simple, once one understands how they work. Tricky parts is working in a filtered environment with really pure materials.