- Posts

- 26

- Likes

- 7

ansoa-66

·Hello

I am having a dilema.

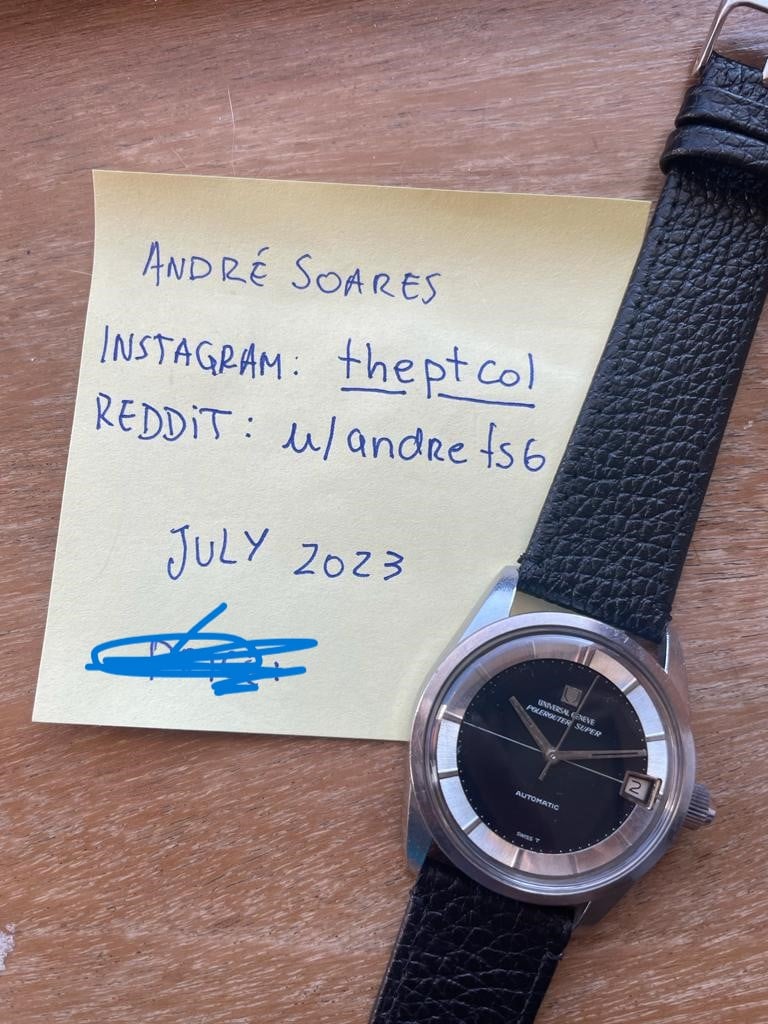

A few months ago I sent this Polerouter for service. The watch came back from service and in some positions I felt the rotor touching the case, very rarely but definetely happened.

I addressed this issue with my watchmaker. He said that it was normal for the watch with such age and advised me not to do anything.

Time passed, a few months, I haven't use the watch but I feel like now it is even worse. If the case is tightened closed, there's where you really hear the noise (facing up, off course).

What would you do? Take it to another watchmaker or go to the same and ask for a new "rubber" (sorry but don't know the exact word in english, the black rubber that isolated the case).

Thank you in advance

I am having a dilema.

A few months ago I sent this Polerouter for service. The watch came back from service and in some positions I felt the rotor touching the case, very rarely but definetely happened.

I addressed this issue with my watchmaker. He said that it was normal for the watch with such age and advised me not to do anything.

Time passed, a few months, I haven't use the watch but I feel like now it is even worse. If the case is tightened closed, there's where you really hear the noise (facing up, off course).

What would you do? Take it to another watchmaker or go to the same and ask for a new "rubber" (sorry but don't know the exact word in english, the black rubber that isolated the case).

Thank you in advance