- Posts

- 5

- Likes

- 0

Mgxr001

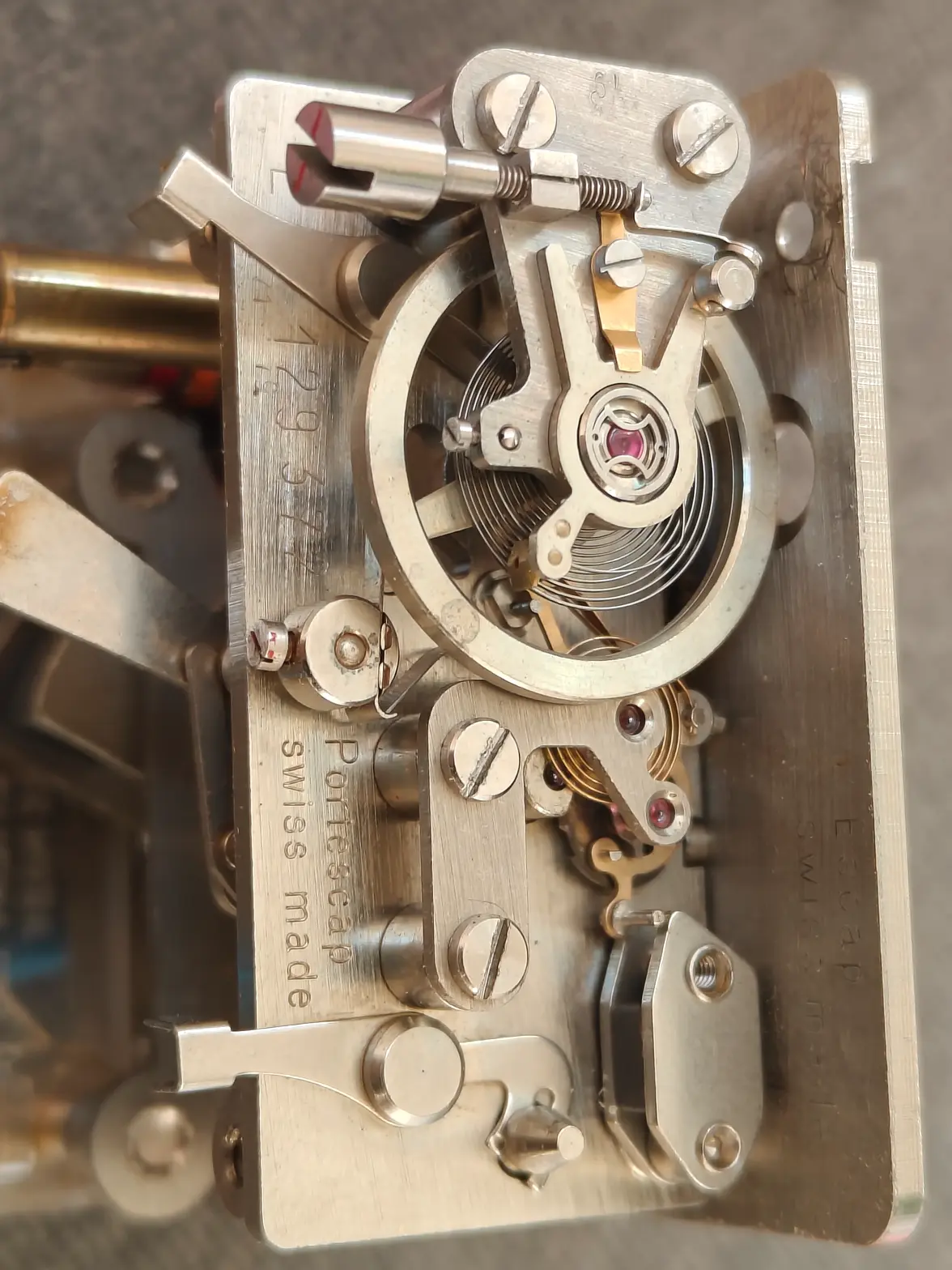

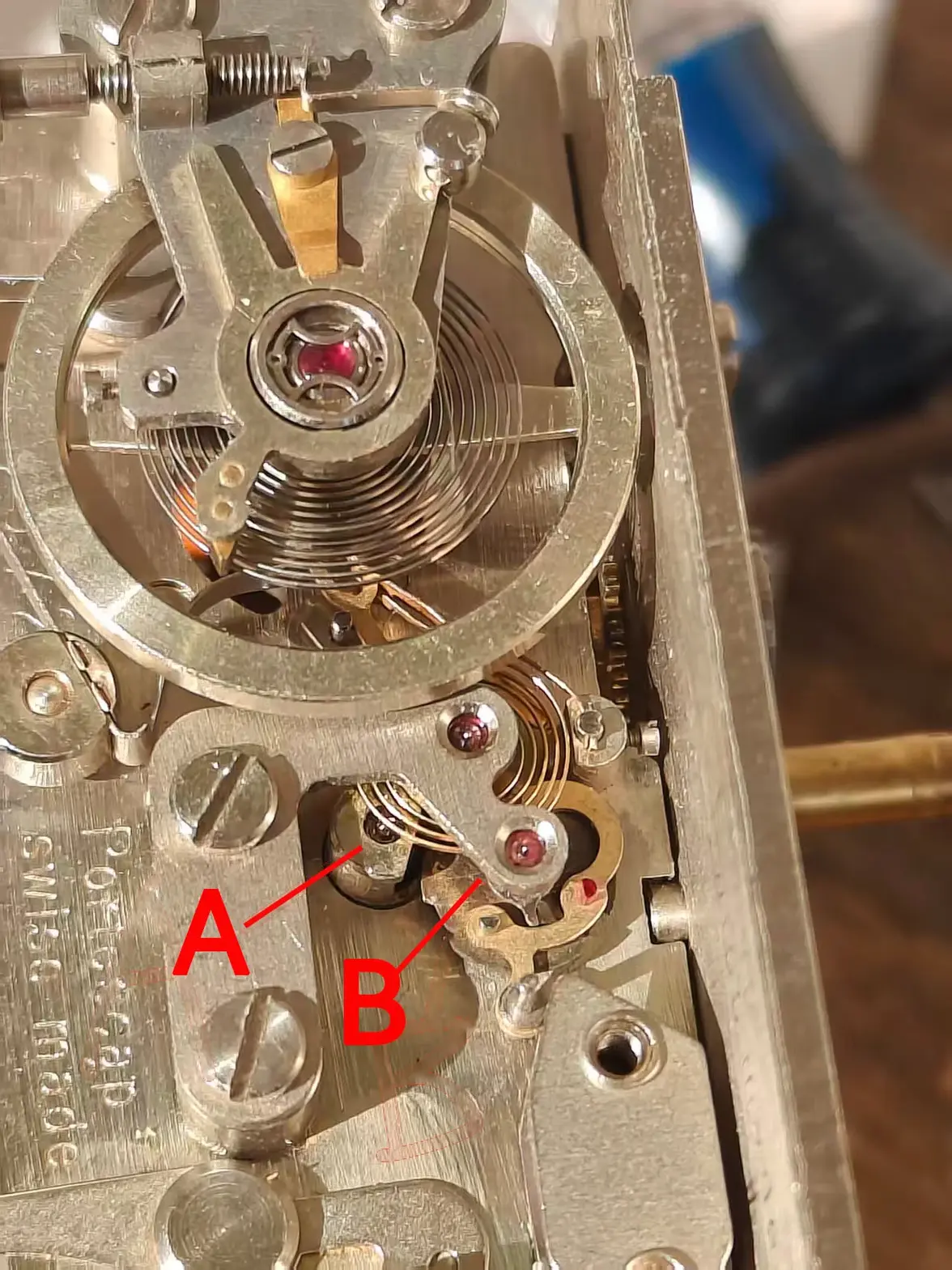

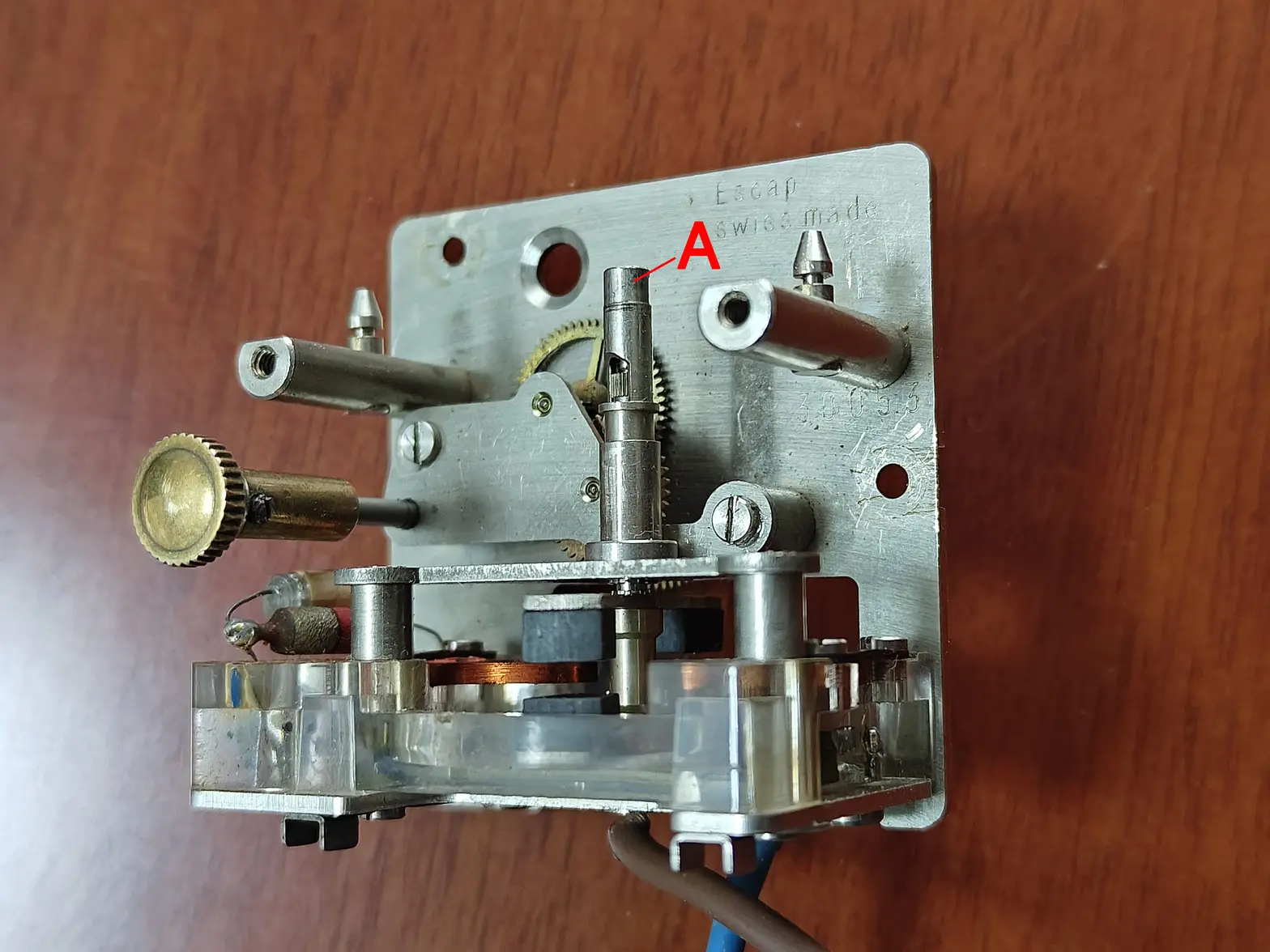

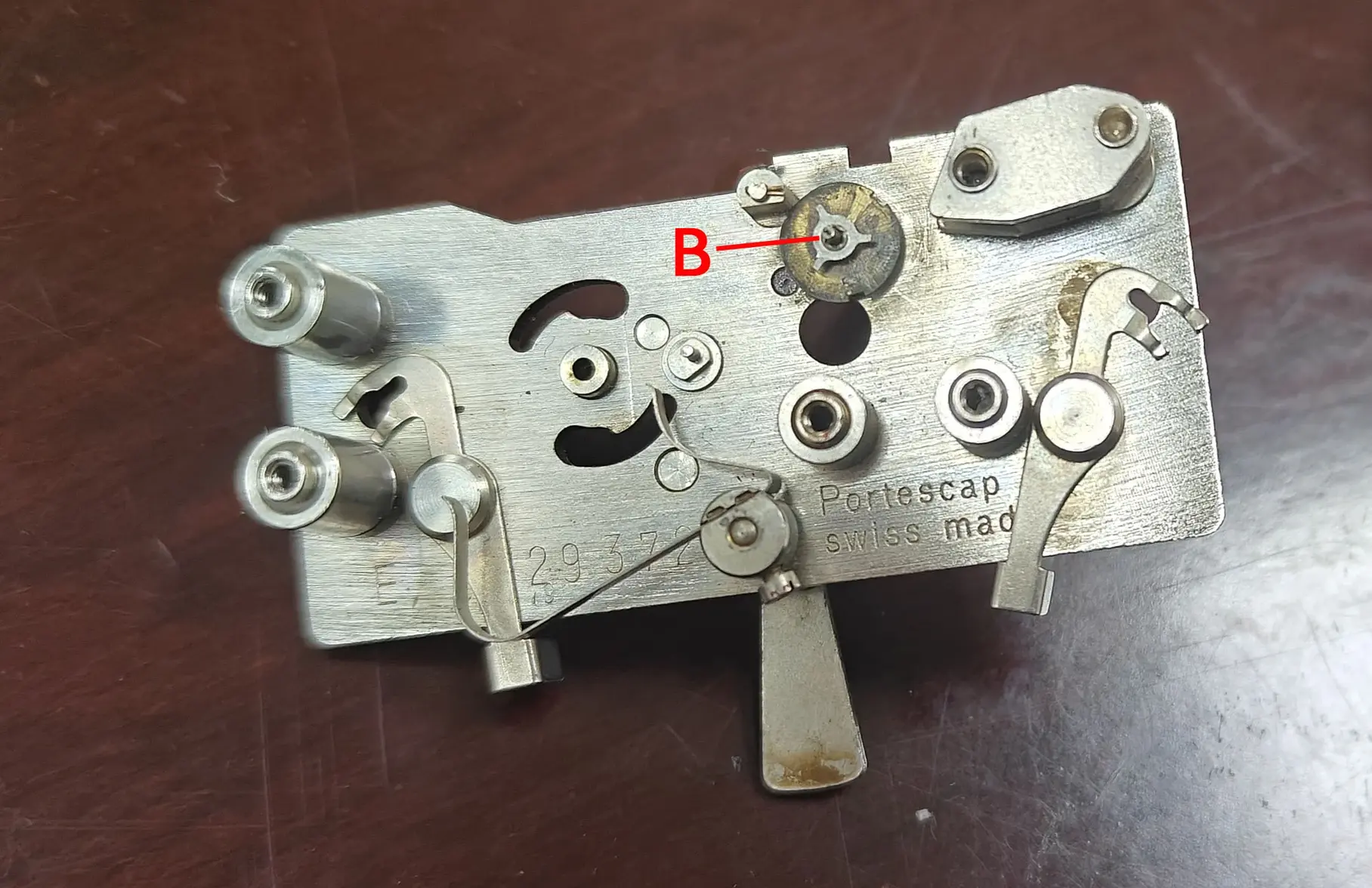

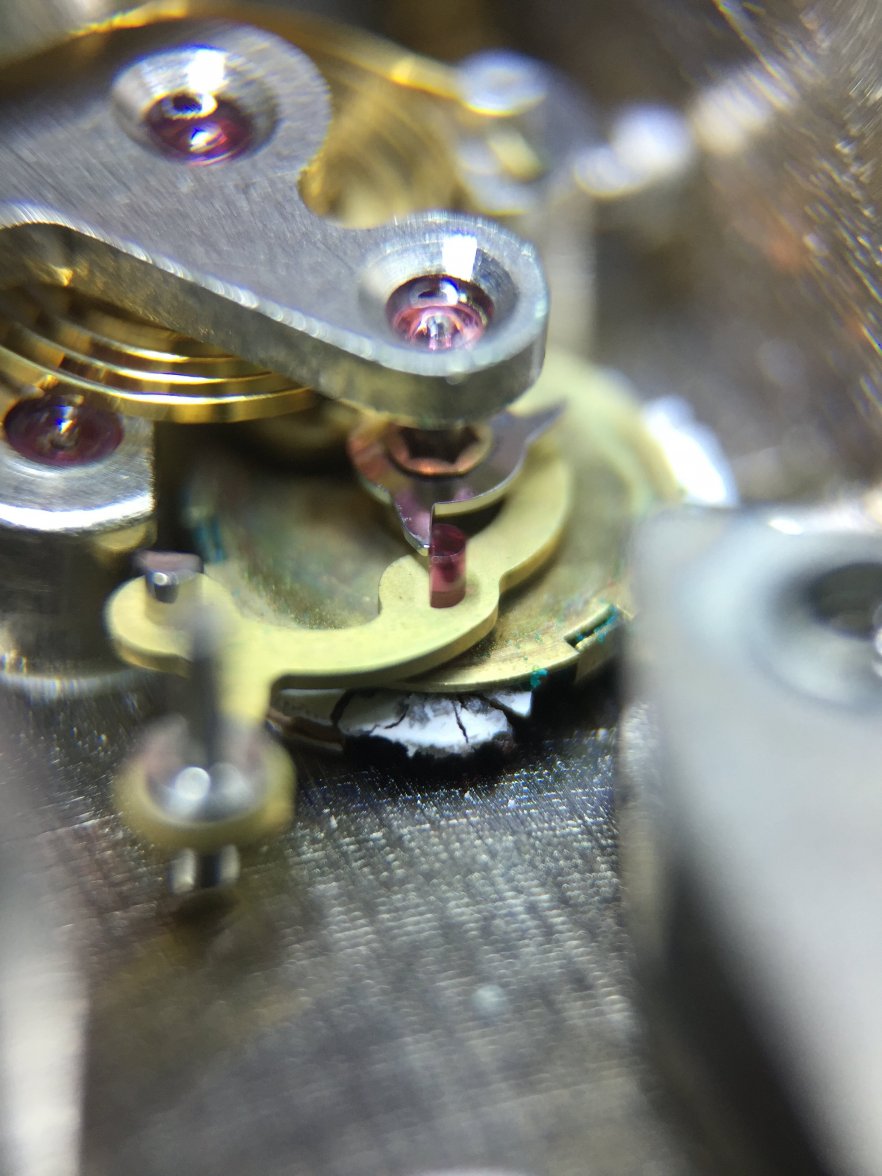

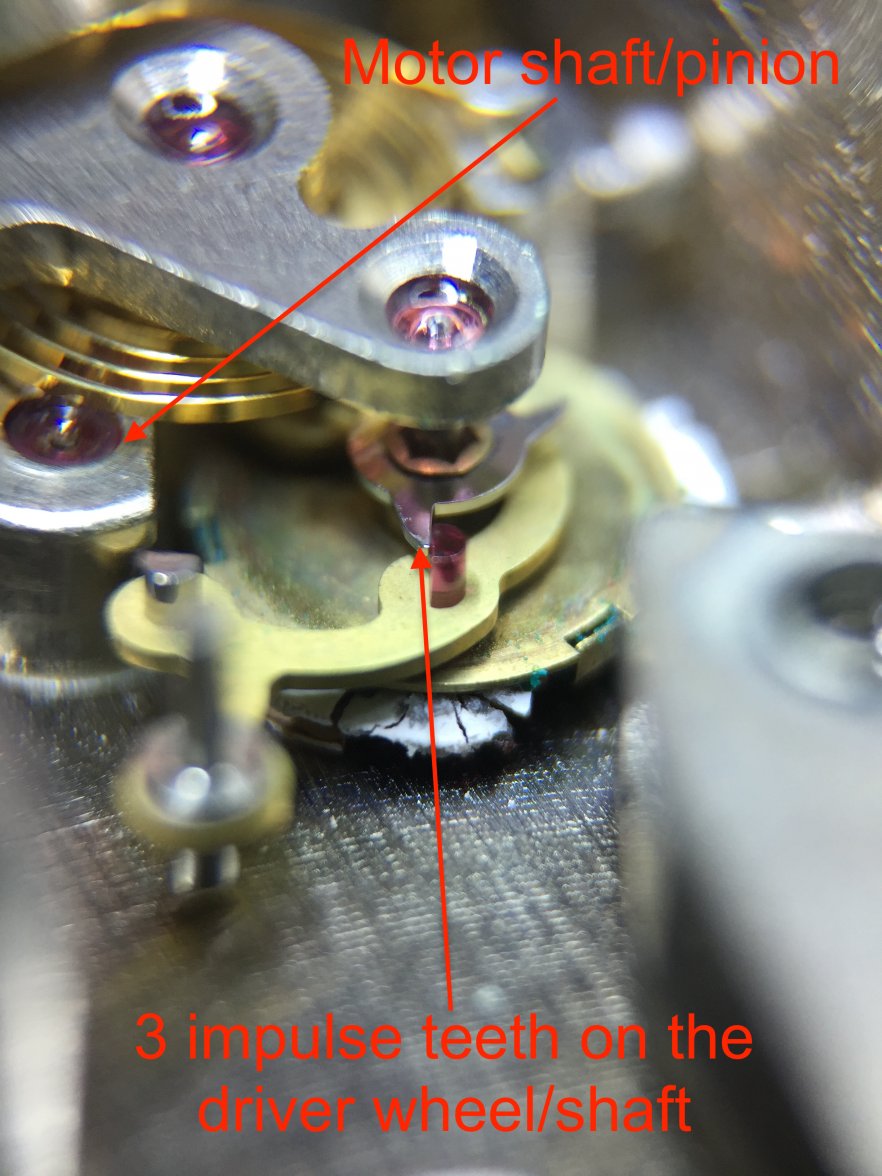

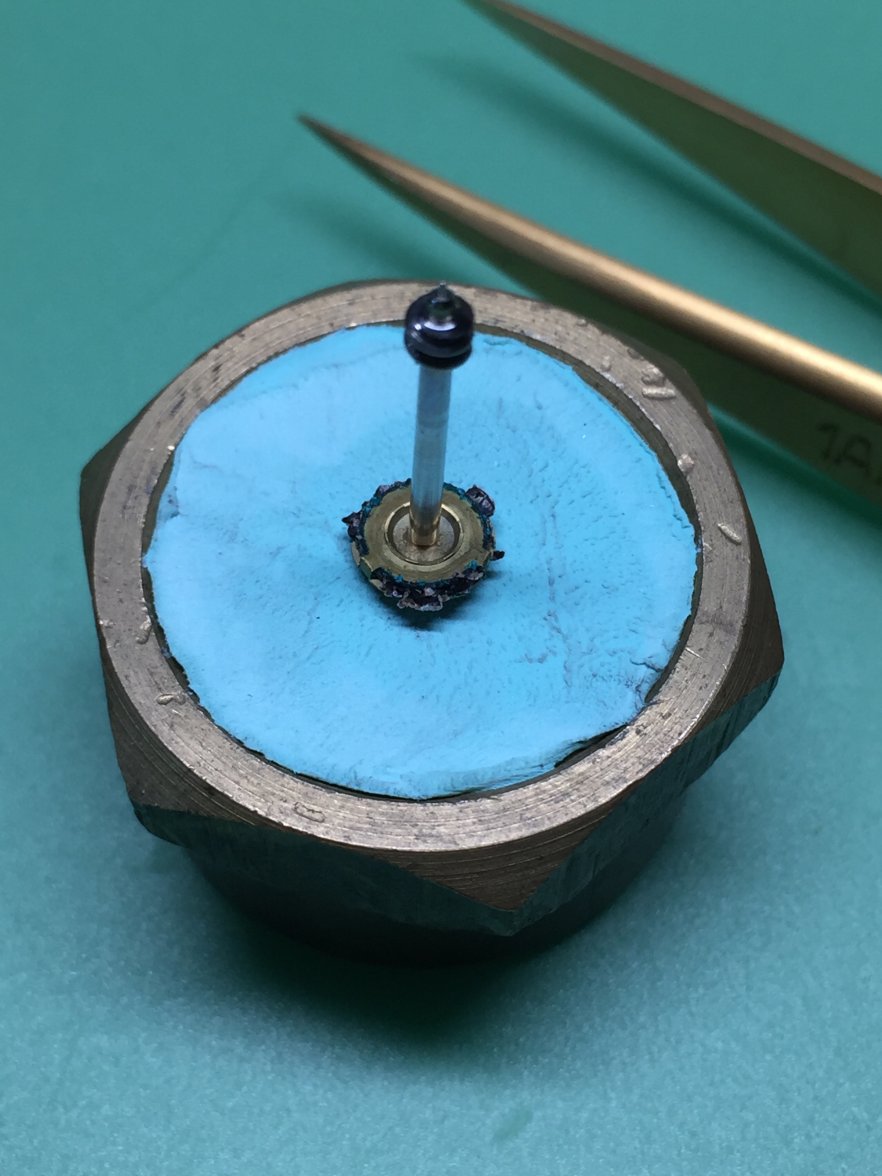

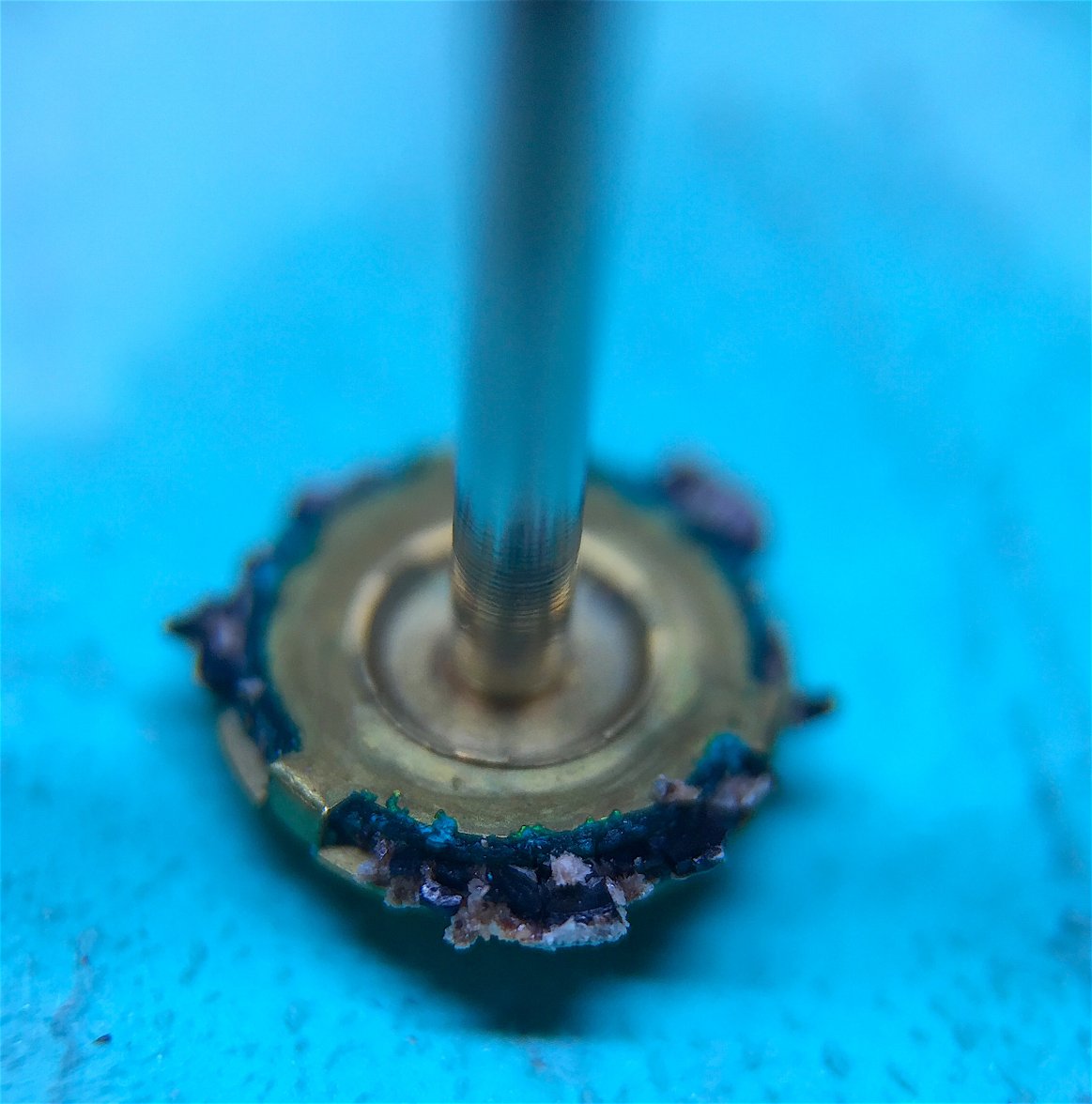

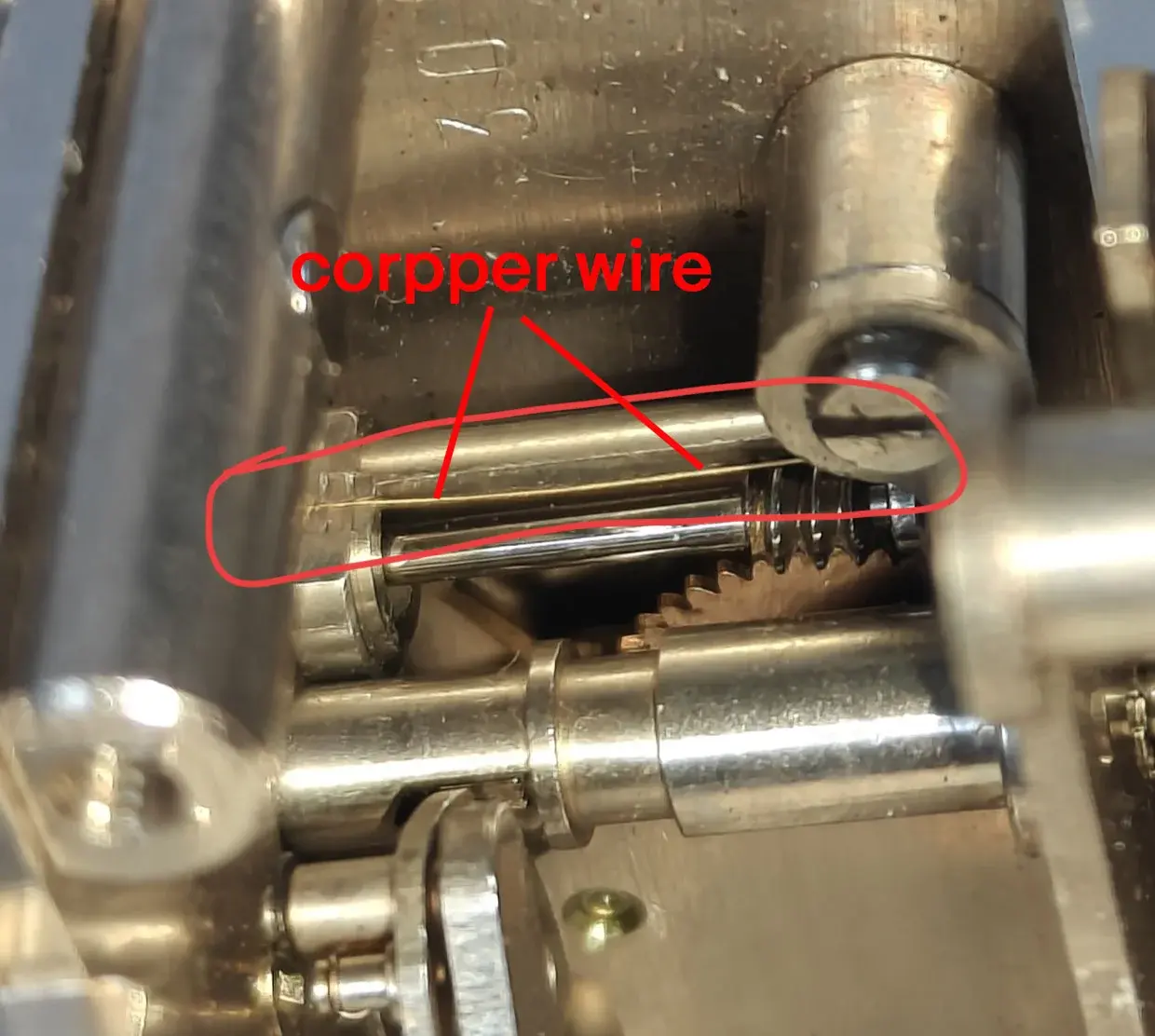

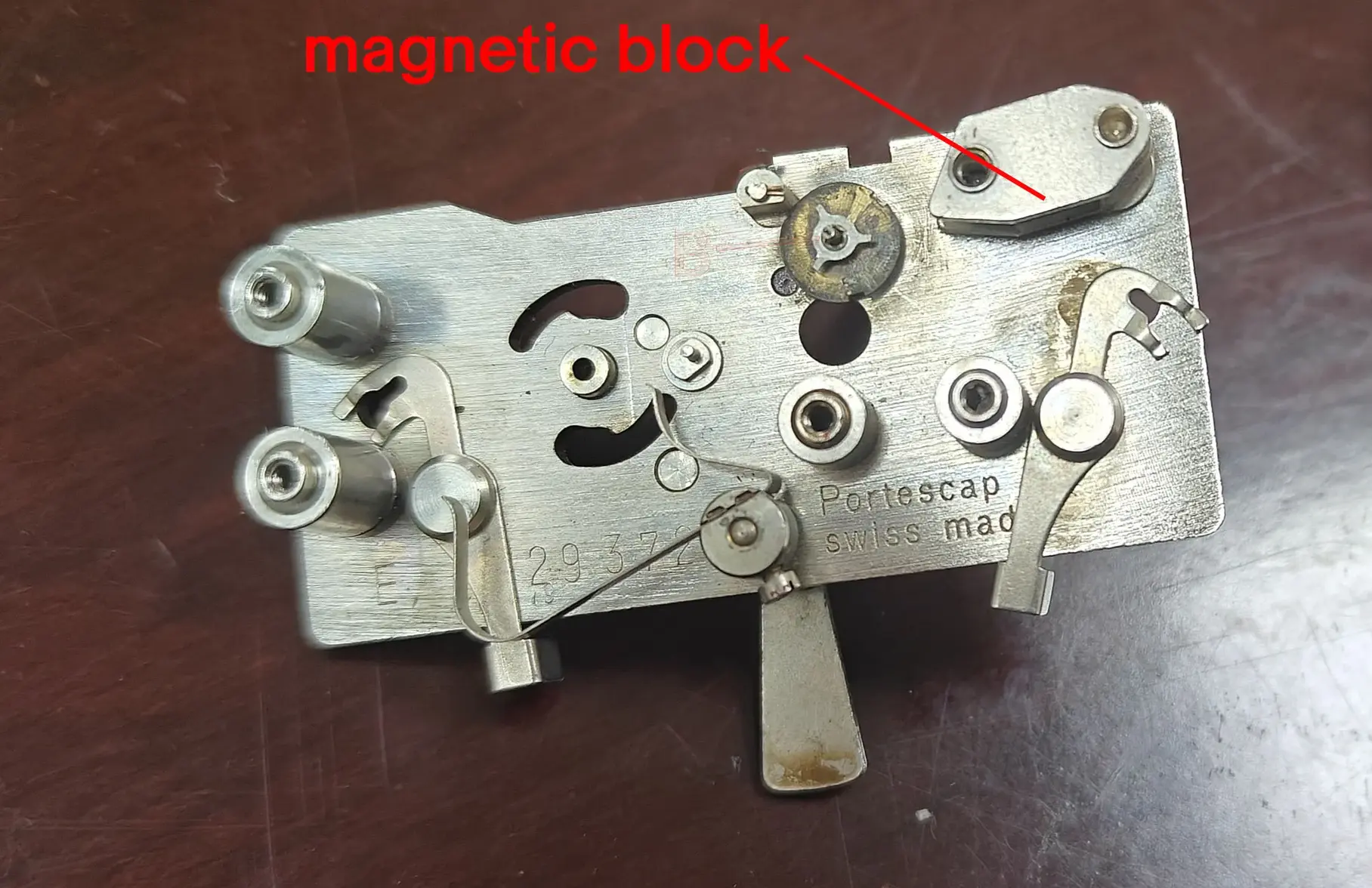

·I have a second-hand clock, as shown in Figure 1. It is battery-powered, and the movement has the number "129372" printed on it. After installing the battery, the power system works normally—I can see the A-axis rotating. The B-axis is connected to the transmission gears, which then drive the hands. The platform operates normally when manually adjusted. However, the clock does not run. I can see a small gear at the end of the A-axis, but there is no gear on the corresponding part of the B-axis. If there were a gear on the B-axis as well, everything would be easily understandable—the clock's failure to run would be due to a broken transmission. However, the B-axis does not appear to be missing any parts, and there doesn't seem to be space to install a gear. Please help me confirm:

1 Was there originally a gear on the B-axis? If so, could you provide a picture for reference?

2 If there was no gear on the B-axis originally, how does the transmission work? What is the reason the clock is not running?

1 Was there originally a gear on the B-axis? If so, could you provide a picture for reference?

2 If there was no gear on the B-axis originally, how does the transmission work? What is the reason the clock is not running?