Jerseyhammer

·Before it was called OMEGA, the company’s first workshop opened in 1848. Then, in 1894, they created the revolutionary 19-ligne “OMEGA” calibre - which changed the watch industry forever and gave them their famous name. This year, they are celebrating the 125th anniversary of that iconic moment.

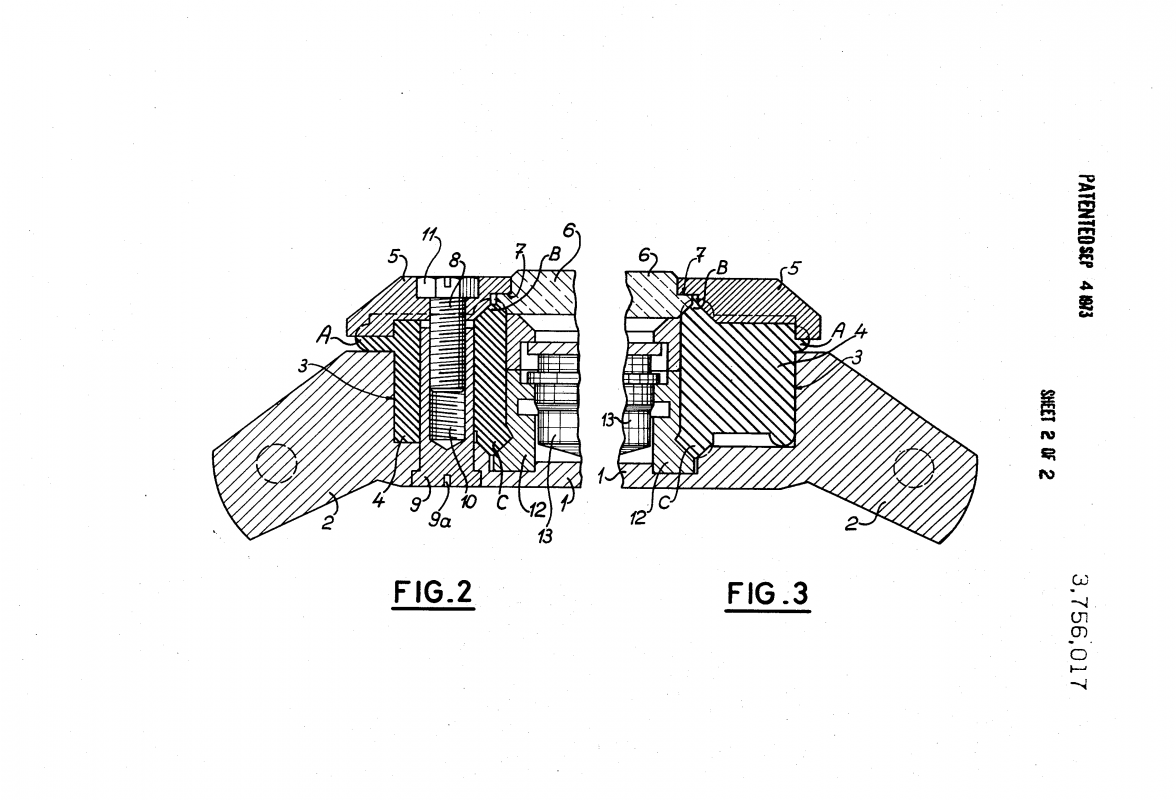

To celebrate this milestone they are producing a De Ville Tresor exquisite timepiece, crafted from 18K yellow gold with a burgundy leather strap and a red enamel dial. The caseback includes an anniversary medallion, as well as a decorative j,engraving known as "damaskeening".

To celebrate this milestone they are producing a De Ville Tresor exquisite timepiece, crafted from 18K yellow gold with a burgundy leather strap and a red enamel dial. The caseback includes an anniversary medallion, as well as a decorative j,engraving known as "damaskeening".