Most of those videos are clickbait. Still they are entertaining. And can be somewhat inspiring in a warped sort of way.

I have probably been guilty of most of those practices. Apart from the oil. I was taught if one could see it oil was probably too much. Lifting bridges with screwdrivers is probably more common than not. There are those little slots there after all. The little plastic spludgers were not so common in the older days. I have taken to using pegwood which can be sharpened to fit into these little spaces. I do not know if this is frowned upon or not.

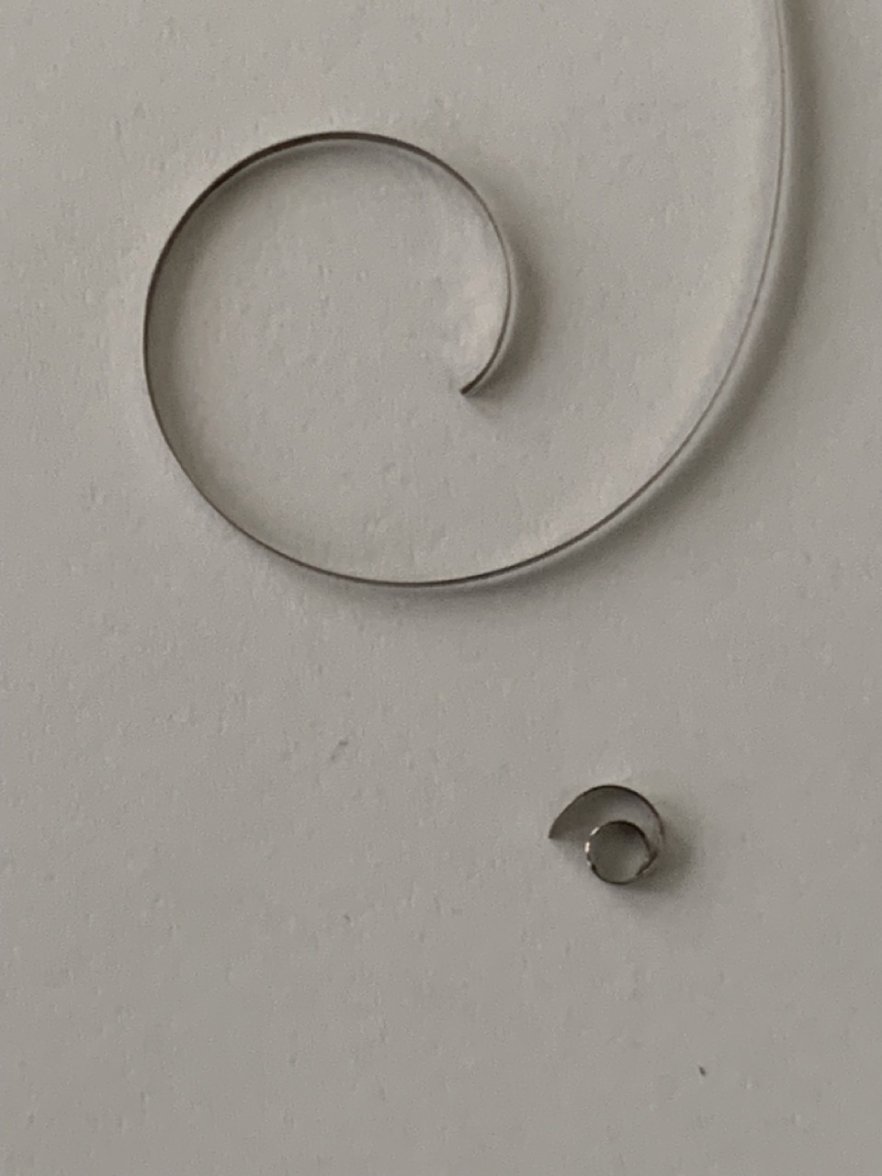

The order of bridge placement is an interesting one. Most instruction has the train installed before the escapement. I think the idea is to make sure the train is not binding. I found this can sometime cause problems when the balance slips putting sliding under the center wheel kinking the hairspring. What happened with my Val-72. In the cheaper watches balance wheels seem to be built with the train going in last. Most likely these were assembled with jigs and automation. This is probably another case where one really needs to have in person instruction.

I have taken to working on the watch in sections. With many repeated assembly steps. I have no deadline so I may assemble something like the escapement first where I can see it clearly. If this does not work, then the watch will not. A lot of instructional vids show the balance being cleaned mounted onto the plate with it's bridge.

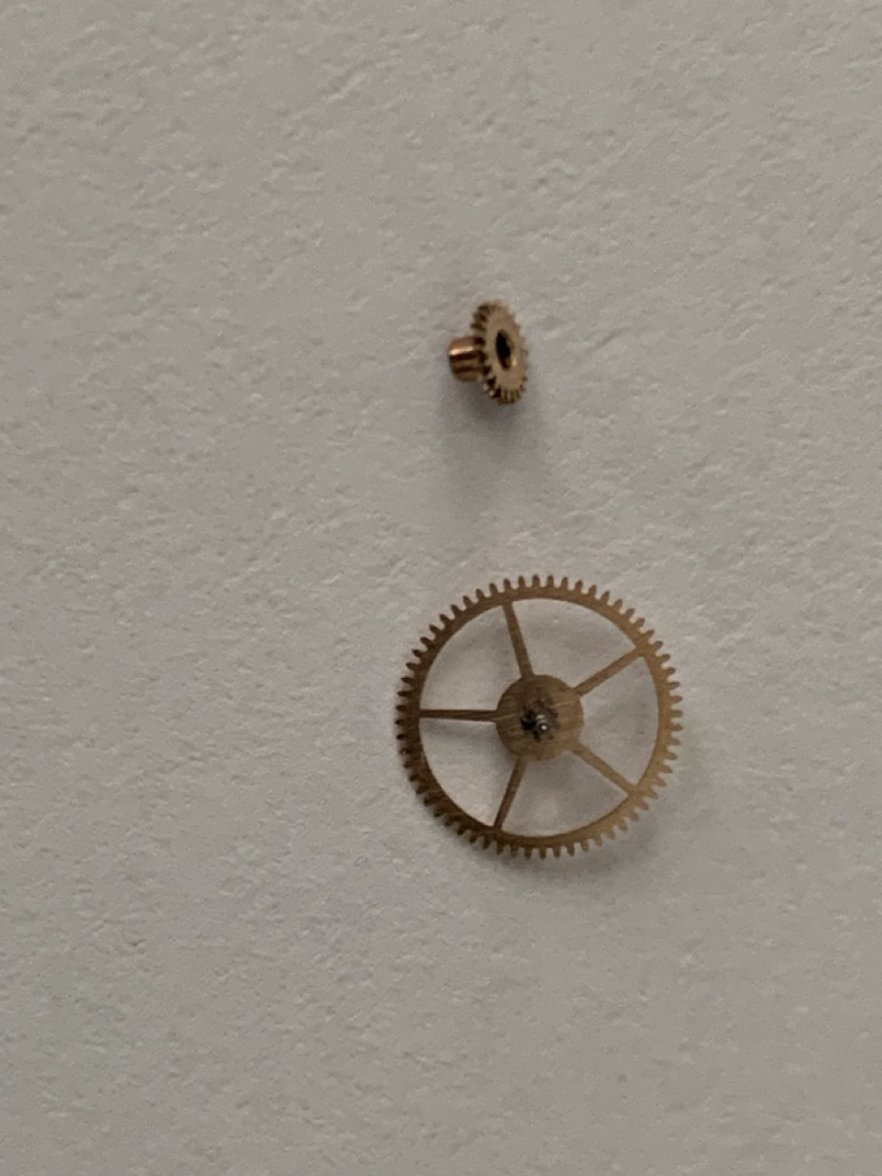

I like to check the train as standalone. Such requires many steps of assembly and disassembly. Even more than one cleaning/oiling cycle. I have taken to assembling the barrel first, then the escapement, then the train.

For chronographs, I have taken to setting up the chronograph without the timeworks. Just the minimal wheels. This way I can see what may be binding. I like watch puzzles, so the parts may not be all from the same watch. Or I got a replacement part online, which may be cast off from something else. A problem when such are restricted.

Rodico was seen as a panacea. I always thought Rodico was my friend. Now I see how re using it can collect contaminates.

I suspect many of these practices date from when every shop had a watchmaker and many had service departments. The idea being to get through as many as one could in a day.

I have also noticed that watchmakers are highly competitive. Somewhat secretive and quick to dis the competition. And fiercely territorial. Even when the competition is not local. Such probably made sense in small communities as a survival skill.

Now we have the net, which can show us the good as well as the bad. I think it great

@Archer is willing to take the time and point out these foibles.

30 years ago I was told I was too old for WOSTEP. I did get to visit and even attend some sample lectures. Even buy some textbooks. I was working in high tech at the time. I suspect had I done the that program I would have eventually found my way into training others. I did however take to getting things like USB microscopes, and CAD programs for creating virtual models of parts. Henry wanted me to make a Cad Model of a Tourbilon. He died and then there was no need to do so. I did however make models of things like the Antikeythera mechanism, Babbage's computer, and the Jaquet-Droz pipe organ playing doll that inspired all this. I also used the CAD program to model pipe organs.

It is easy to drift about using such things. A repeater watch missing parts and I got lost in the world of computer vision, 3D modeling and photogrameritry. (Some of what I used on the doll.)

I think I am really addicted to information overload. So am glad there are quazi instructional videos out there for inspiration.

Now if Clickspring would just post more progress on the Antikeythera ...