Breaking News: The New Steel Speedmaster With Caliber 321 “Ed White”

kelsey

·Sorry, what part if it?

Where to begin though.

I’ll give one example: production cost.

Getting a single watchmaker to assemble would slow production which in turn is costly, slowing production on any assembly line can be more costly then you can imagine.

BlackTalon

··This Space for RentGetting a single watchmaker to assemble would slow production which in turn is costly, slowing production on any assembly line can be more costly then you can imagine.

STANDY

··schizophrenic pizza orderer and watch collectorIt's funny you are saying that to someone who served as an industrial/ mechanical engineer for production lines.

Ohh boy...... I was only thinking the same thing 😉

kelsey

·It's funny you are saying that to someone who served as an industrial/ mechanical engineer for production lines.

STANDY

··schizophrenic pizza orderer and watch collectorAnd I’m a physicist and can give you real world examples from my work, kinda how I know. Equally I’m an investor in a lot of industry.

You do realise the parts are mass produced like other parts and not individually made by the watchmaker.

BlackTalon

··This Space for RentYou do realise the parts are mass produced like other parts and not individually made by the watchmaker.

Interesting that a physicist works a lot with assembly/ production lines. I am interested to hear more.

kelsey

·Exactly. Those mass-produced parts are simply assembled by a single watchmaker, versus getting passed through the hands of multiple people who each install just a couple/ few parts. So overall impact on production time would be pretty minimal. Definitely not $9k in additional timer needed.

Interesting that a physicist works a lot with assembly/ production lines. I am interested to hear more.

YY77

·I certainly (respectfully) disagree with you on that one.

kelsey

·I think there is so many angles too it that a broad statement that such aspects are overhyped is a massive over simplification of it.

One could argue either side that all Swiss mechanical watches are overhyped....yet here we all are 😉

One could argue either side that all Swiss mechanical watches are overhyped....yet here we all are 😉

Panjo

·Archer

··Omega Qualified WatchmakerI think there’s more too it then the “every watch that’s serviced is single watchmaker assembled”.

Where to begin though.

I’ll give one example: production cost.

Getting a single watchmaker to assemble would slow production which in turn is costly, slowing production on any assembly line can be more costly then you can imagine.

Let's look at the statement made again:

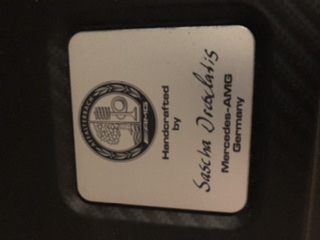

"One thing that I truly like about this watch - besides the incredible movement - is that it is not part of the industrialized way of producing a watch at Omega. One watchmaker is responsible for one entire watch, instead of parts going from workstation to workstation."

Bold emphasis is mine. It may be unusual at Omega, but it certainly isn't in the industry, in particular for premium products.

In terms of how much time this should take, let's look at Omega standards for servicing an existing watch (pretty sure I've done this before, but it seems worth repeating). Omega Work Instruction 48 outlines Omega's standards for the time it takes to service various watches. The Cal 321 falls into category WP8 in the latest version of this document. Other calibers that fall into this category are the 260 series (30T2's), the 330 bumper family, etc. I mention this because this are not nearly as complicated as a chronograph is, and yet Omega allows the same amount of time for servicing those. It might seem odd, but the reason is that these are used watches that typically have a lot of wear and problems, and all that needs to be addressed when servicing a vintage watch. Again assembling a movement using new parts that are all in perfect shape is an easy job for any watchmaker who is used to dealing with vintage.

So Omega allows 5 hours and 38 minutes for the complete service of the movement, then 1 hour and 52 minutes for installing the dial, hands, and final casing. Total of 7 hours and 30 minutes per watch. This is starting with an assembled watch, and ending with a serviced/repaired and assembled watch.

The time for the movement service includes the initial disassembly of the watch, and cleaning, then checks for wear and gathering of replacement parts, repair of damaged parts, etc.. None of this would/should be included in the time required to assemble a watch using new parts. My guess would be that each watchmaker in this "new" system is presented with what could be described as a kit that they assemble - that would be the way to do it if anyone is paying attention to efficiencies at least.

So exactly how much time should be taken away because we are starting with an already disassembled watch, that has all new parts? That's a matter of speculation, but I would say you could pretty easily justify removing an hour from the 7' 30" total. So let's say that it takes 6 hours and 30 minutes per watch. What is the value of that time? Well we could assign an hourly rate, let's just be generous and say $300/hr. So to work in round numbers there's maybe $2k of direct labour costs here to assemble this watch, and I think if you were to compare this number to what Omega charges for a service of a vintage 321 watch, it's in the right ballpark.

How much more is that than if they had done this on an selective assembly (what you refer to as an assembly line) style system?

Difficult to say, but I'm guessing the savings in not having to set up a new line, or retool an old line is significant. It would require new fixturing for the various stages of assembly that the movement goes through as it moves down the line, and all the engineering time and manufacturing time required to produce all the tooling, then create new work procedures for all the workers, and then run them through the training on this "new" movement. Remember these are not skilled workers, but people who are hired "off the street" and trained on how to do one specific task, so emphasis on procedures and training needs to be significant to ensure quality standards are met. All of these costs are probably significant, because as you say, small changes on this kind of line can cost a lot (yes I know, as I've been there, done that).

In contrast setting up this "new" system is pretty easy - gather some watchmaking benches and the standard tools watchmakers already use or have, sit some watchmakers down at those stations, and you are done. If you pick those from the watchmakers that are already servicing 321 watches in the service center at Bienne, they need a total of zero training - they start producing at 100% immediately. Capital costs are much lower in this scenario, and training costs are zero because these are skilled trades who already have the knowledge and experience to do this job, just like all kinds of watchmakers all over the world do.

So is this more expensive? Maybe, but if so my feeling is it's not much based on what I know of watch manufacturing and assembly. I admit I've not been through the Omega factories, but I've been through enough other brands to understand in some detail how these things are set-up.

But in reality, all of this is a bit of a straw man. The price of a Veblen good doesn't have the sort of direct connection to production costs that you might be more familiar with in other goods.

Cheers, Al

kelsey

·Thanks for taking the time for such a comprehensive reply, it’s after 1am here now, I skimmed read but will read properly in the morning 😀

texasmade

·If given the choice between getting the new EW or a vintage 321, I'd rather go with new EW. I'm just not knowledgeable enough to properly value a vintage 321 or know if I'm getting a Franken watch.

Bp1000

·I always thought the 11k EW reissue would spark some interesting debate.

I’m mixed on what to think. I love the fact omega did this for the enthusiast. There would be no other logical reason to ramp up a production line of a fairly complex movement to assemble in terms of parts, investment in parts building, tooling and skill.

As I understand it Breguet are providing the stream or movements and yes there will be some margin in this but it’s hardly a hugely profitable move for omega.

Then you see that this is one alpha hand, 3 shades of off white and a bracelet away from a 3.5k FOIS

however, when you talk about steel chronographs and look at AP and even Rolex, what you get with the 321 movement and the finishing they’ve done is pretty special. Especially when you generally know AP sell steel chronographs purely on the finishing at the price they do.

still trying to figure out where I sit but I do love it.

I’m mixed on what to think. I love the fact omega did this for the enthusiast. There would be no other logical reason to ramp up a production line of a fairly complex movement to assemble in terms of parts, investment in parts building, tooling and skill.

As I understand it Breguet are providing the stream or movements and yes there will be some margin in this but it’s hardly a hugely profitable move for omega.

Then you see that this is one alpha hand, 3 shades of off white and a bracelet away from a 3.5k FOIS

however, when you talk about steel chronographs and look at AP and even Rolex, what you get with the 321 movement and the finishing they’ve done is pretty special. Especially when you generally know AP sell steel chronographs purely on the finishing at the price they do.

still trying to figure out where I sit but I do love it.