ErichKeane

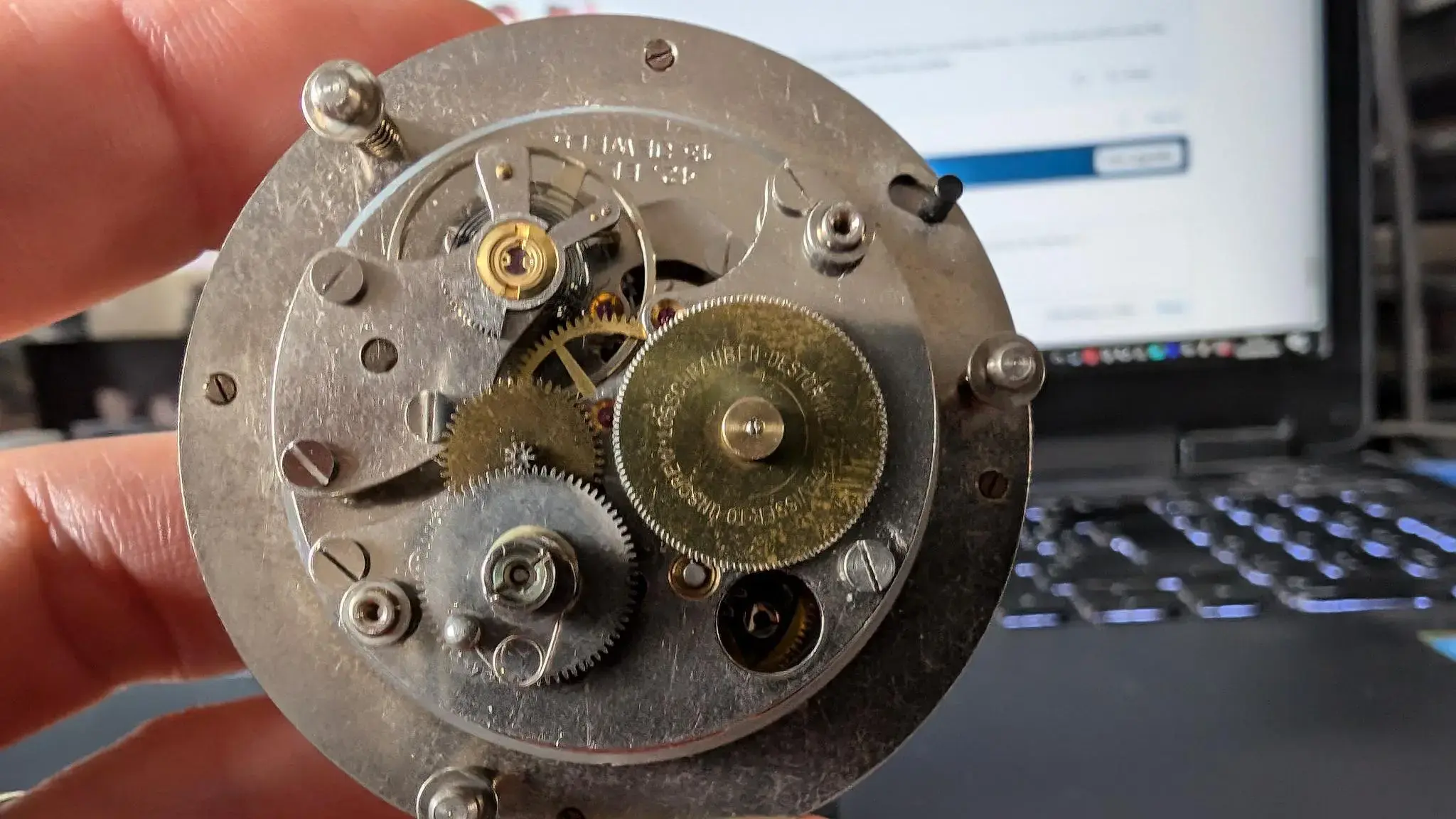

·The back side of the hole jewel is flat (in the image, and how it fits in that Chaton). The front has a bit of a profile. It is 'flat', except for about the center 1/3 has a bit of a 'olive' shape to it perhaps? Though it is REALLY hard to see the profile.

I see that OFrei (https://www.ofrei.com/page939.html) has the 30711 which MIGHT be right? But I can't really tell the profile even moving it around.

I DO see that the 30714 is the only one available in the size I need (64/200), but I can't tell if it is the right profile. I might have to order and just 'hope'. BUT now I see I can order THAT jewel via the hswalsh, but also OFrei and JBorel (https://www.julesborel.com/products/Seitz-Center-Jewels-30714/Seitz-Center-Jewel-30714-64-200).

So I might at least have a solution.

I see that OFrei (https://www.ofrei.com/page939.html) has the 30711 which MIGHT be right? But I can't really tell the profile even moving it around.

I DO see that the 30714 is the only one available in the size I need (64/200), but I can't tell if it is the right profile. I might have to order and just 'hope'. BUT now I see I can order THAT jewel via the hswalsh, but also OFrei and JBorel (https://www.julesborel.com/products/Seitz-Center-Jewels-30714/Seitz-Center-Jewel-30714-64-200).

So I might at least have a solution.