HiBoost

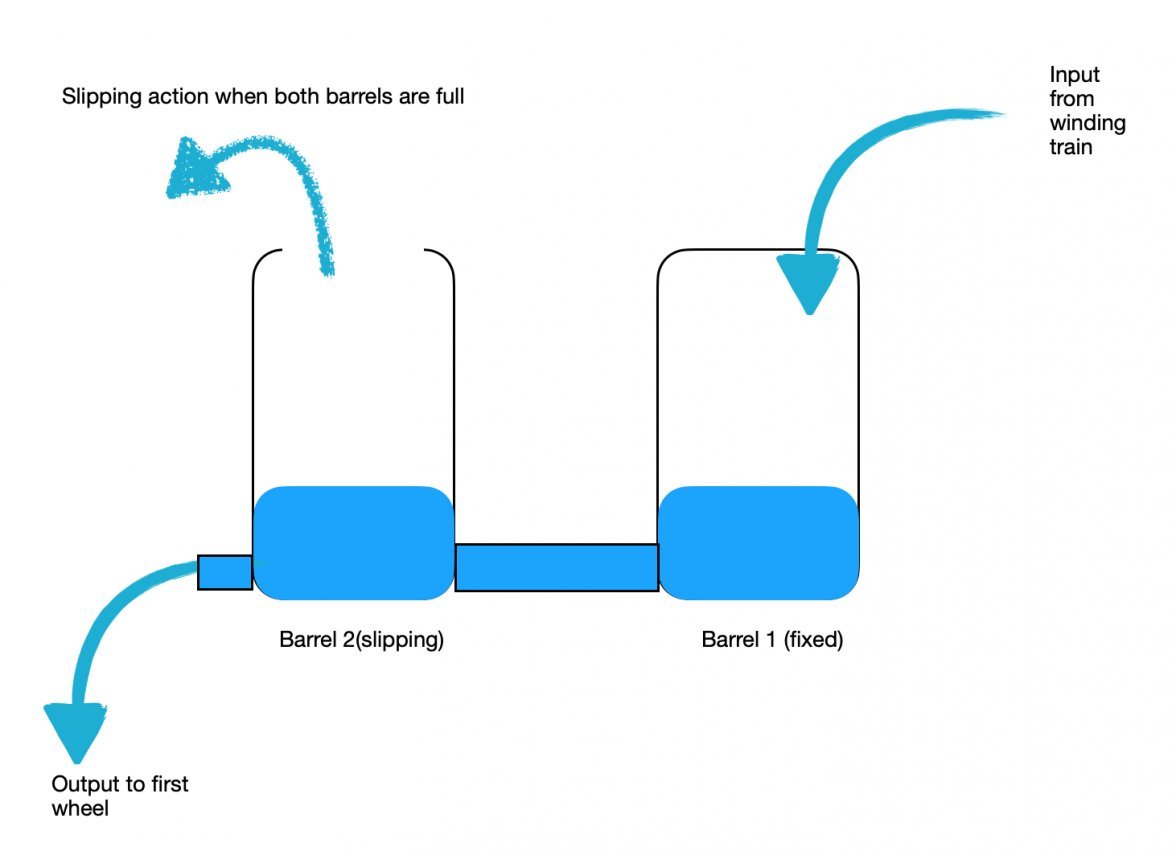

·There were a series of interesting comments in this 2015 thread but my overall takeaway was that one barrel has a fixed spring and the other has a slipping spring to deal with the rotor's never-ending input. On my new SM300 if the rotor swings around to the right position I can see the toothed edges of both barrels. They are even labeled 😀 Given the description, I was expecting that if I hand wound the movement I would eventually see one of the two barrels stop turning while the other would continue to turn. The watch was already wound and running after a week of wearing but I did another 40 winds and both kept turning in unison. Do I have the wrong expectation/understanding, or did I simply not wind long enough?

I know hand winding is not necessary, I just thought this would be a neat visual indicator of full wind if in fact one barrel does stop turning at some point.

I know hand winding is not necessary, I just thought this would be a neat visual indicator of full wind if in fact one barrel does stop turning at some point.