😁 Of course if the rivoting is significant, then you don't just blast it through the balance hub, that would me mindless. A degree of common sense gets applied. Do you think Bergeon would create such a tool if it was for hacking out the stem? Would Rolex accreditation want to test that a watchmaker is proficient in its use if they see it as hacking?

🤦. I can see snobbery runs high here. Not for me. Im off.

By all means, if you want to leave that's your choice. But if you are put off because some people on a forum give an opinion, you might be over reacting a bit. For the most part people here have tried to help you, putting their own time and effort into doing that.

To your arguments, Bergeon is in business to make money, and last time I checked, they were not the arbiters of what is a good method of removing a staff. There have been plenty of absolutely terrible watchmaking tools made over the years, so the fact that someone makes a tool for a particular purpose doesn't mean it's a good tool - that's just not logical.

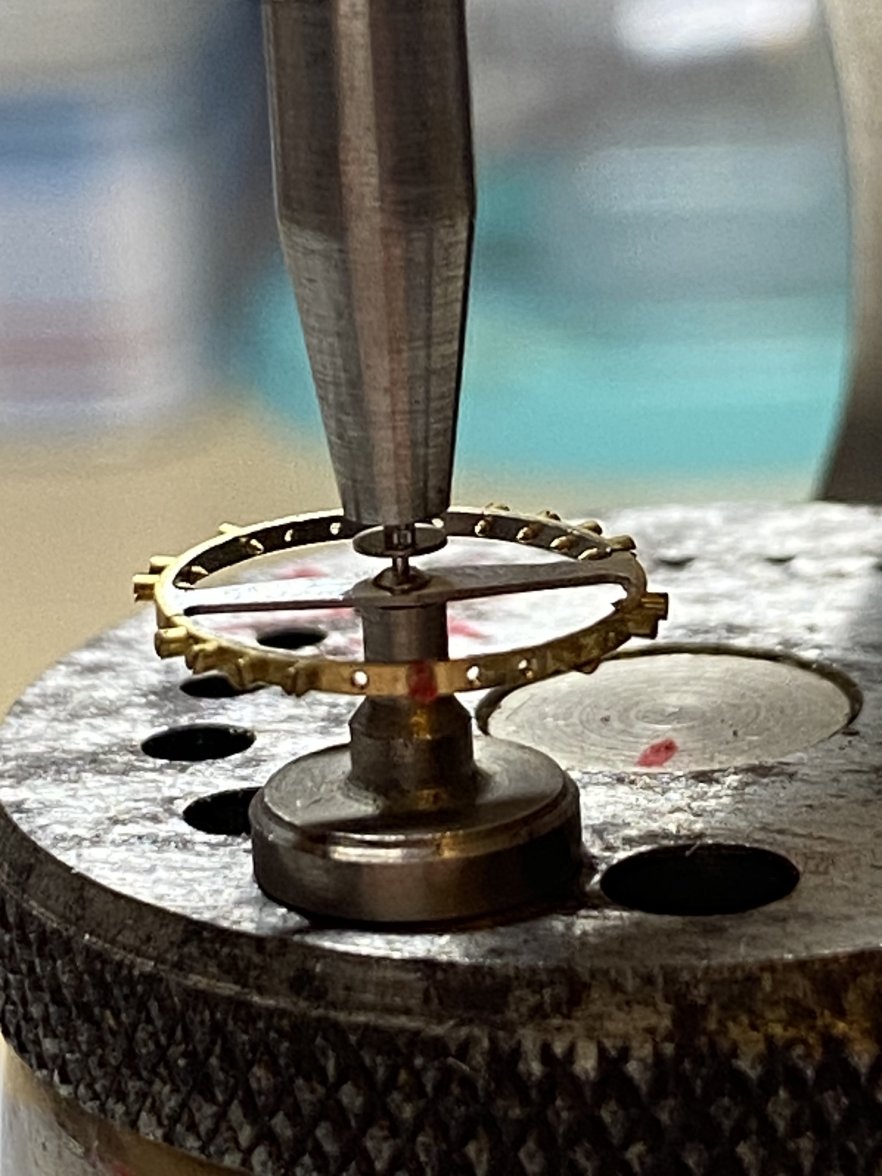

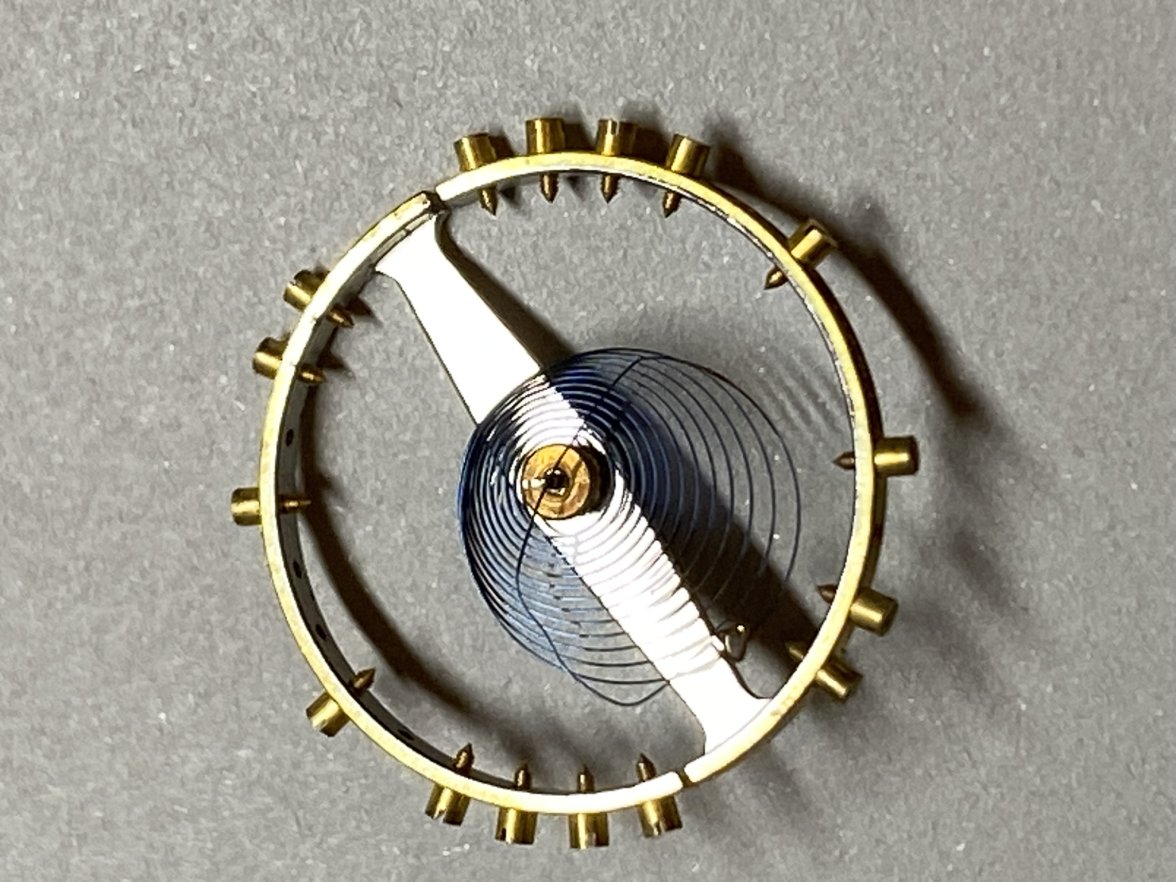

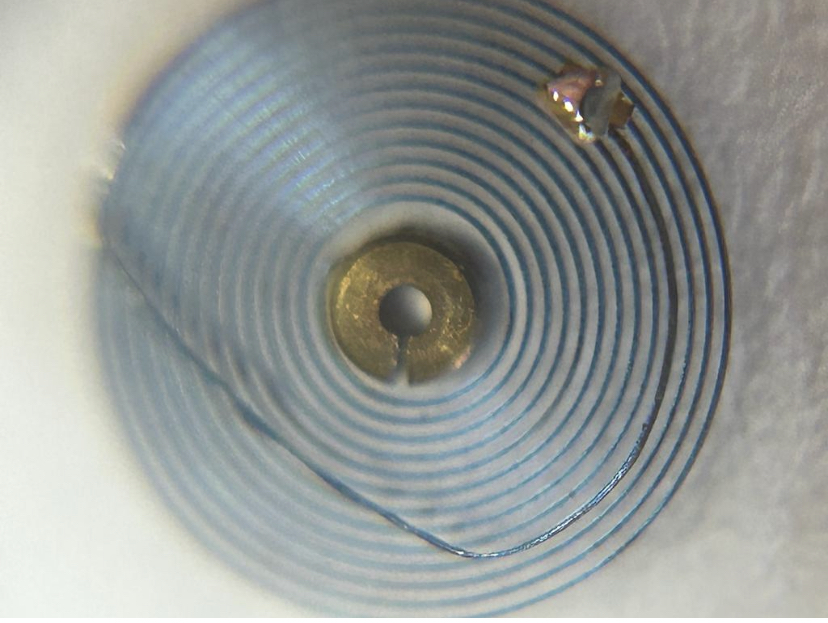

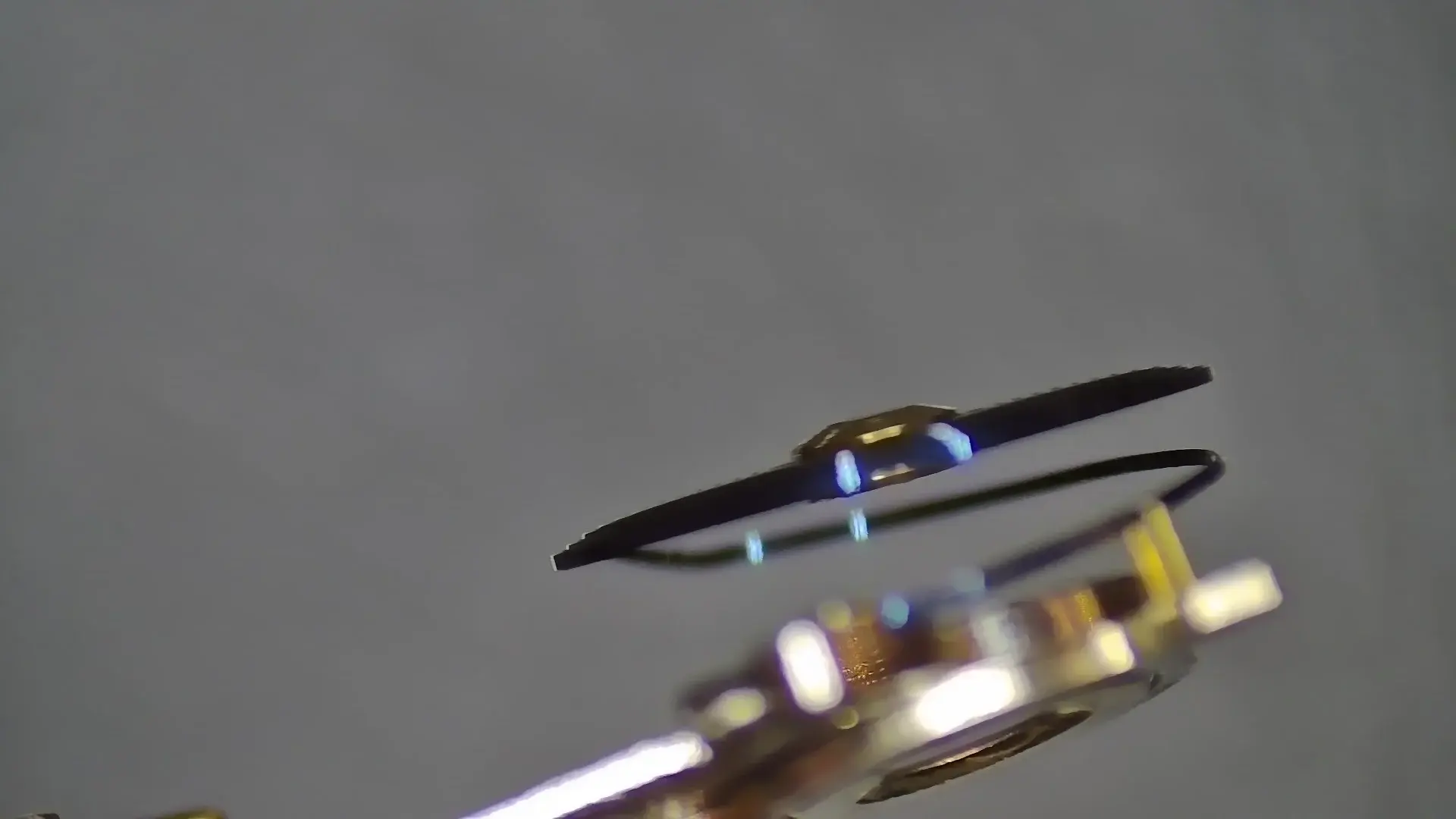

What is logical, is to look at evidence. These photos were taken by another watchmaker, but illustrate the issue with punching out the balance well. Here a balance staff has been removed with a Molfres, so the hub has been ground off. If you look at the rivet end, you can see how much of the flare there is that is well below the spot where the rivet typically breaks off when you punch it out. That is going to be forced through the hole in the balance - there's no doubt of that...

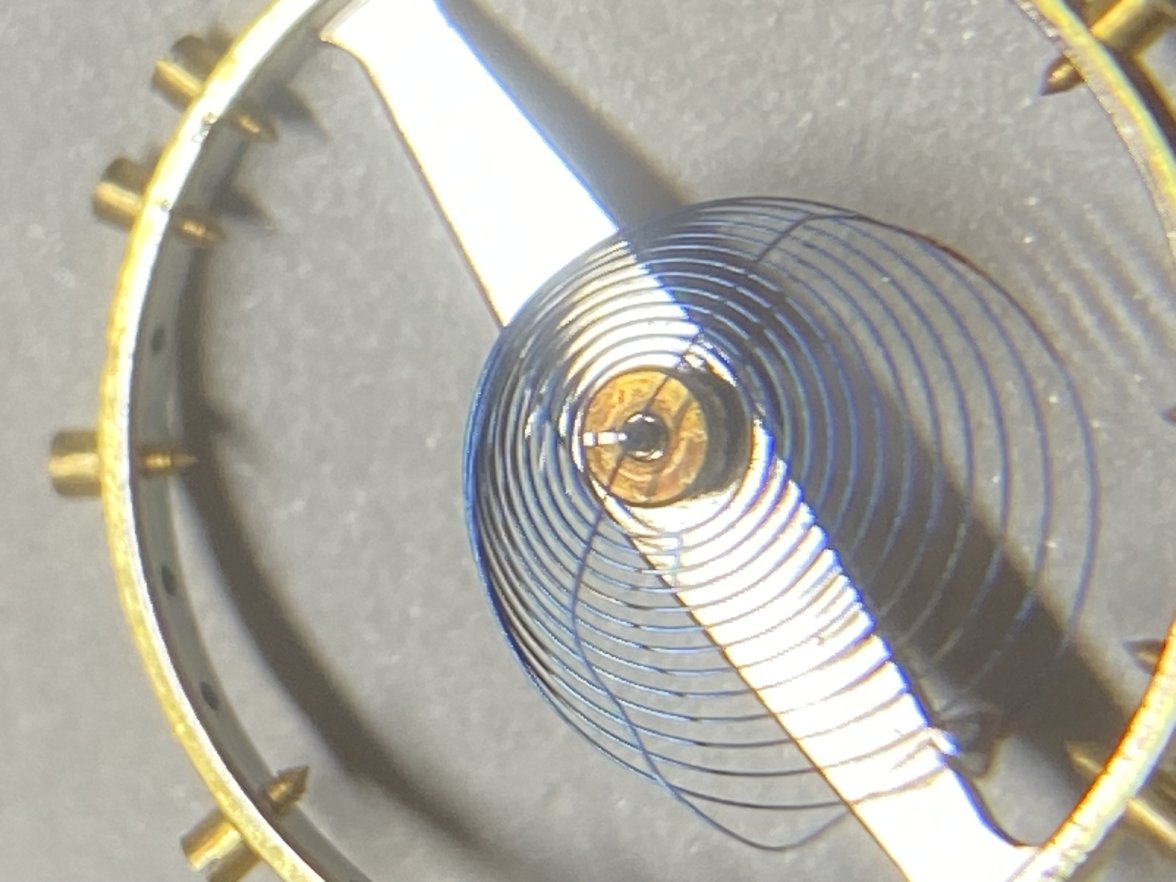

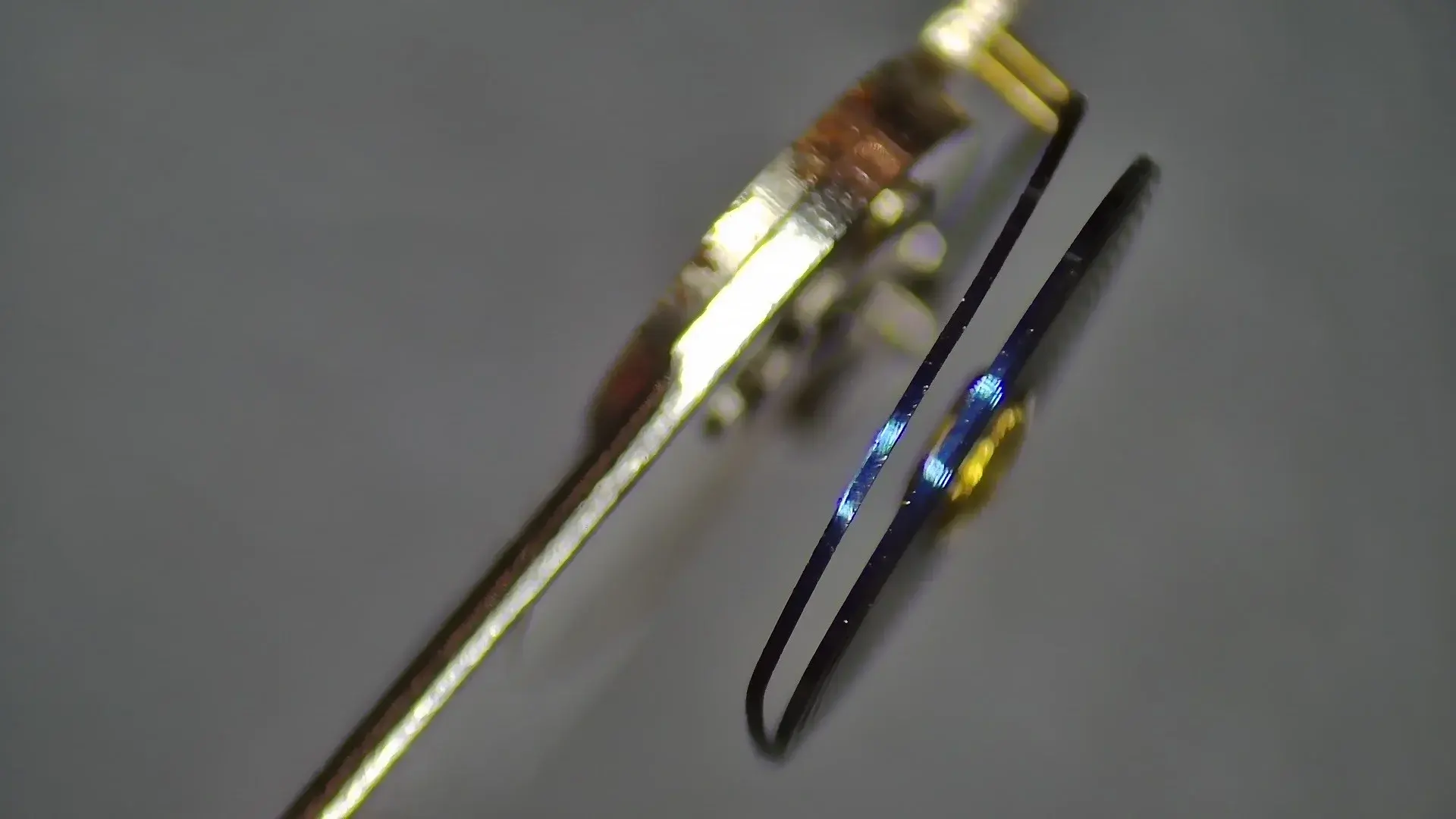

Here is another balance that the watchmaker removed by punching it out. You can see that the rivet didn't really break off cleanly...

You can see that the enlarged part of the rivet would be larger than the hole in the balance, and would be forced through it. The rivet has to be solid enough to ensure that it doesn't work loose, so therefore is going to be "significant" if the staff has been installed correctly.

You may be fine punching out a staff and fitting a new one once, but in the process you will likely enlarge the hole in the balance, and now the next staff replacement is going to be more difficult for the next guy. You mentioned Rolex and their approval of the Platax - Rolex wants watches repaired quickly, so like any brand they will do whatever takes the least amount of time. If they only get one restaffing from a balance using this method, then they don't really care - they just put a new balance in the watch next time or use a new wheel.

Such appeals to authority as Bergeon or Rolex are not sound arguments, really.

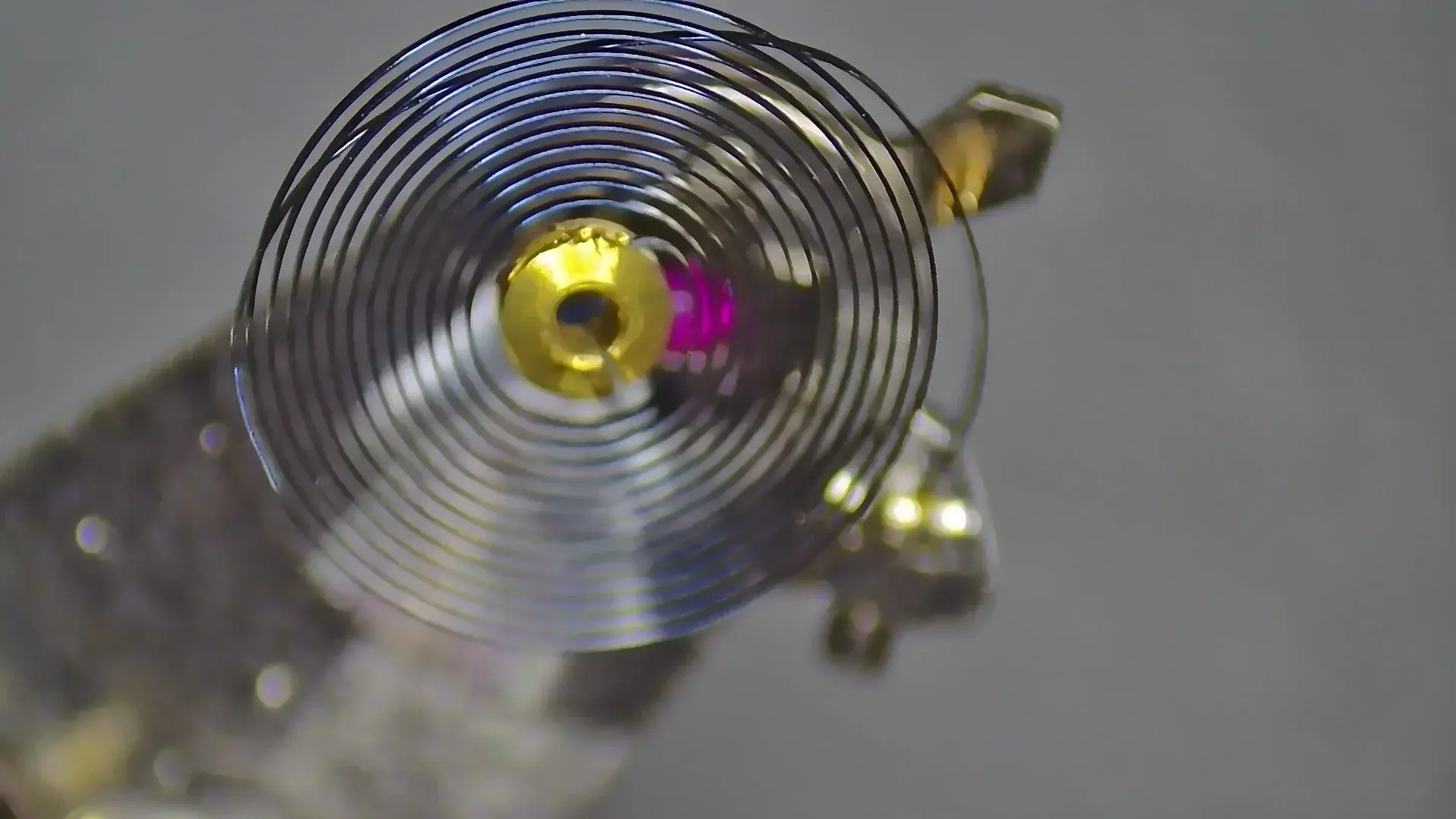

Now when you are working on a watch like this one, where parts have been discontinued for a long time, and new balances are not readily available, using the least risky method would be wise. My approach personally is to use methods that have the least potential for damage. On a balance like this, it would be a Molfres, or the lathe, and on any that I'm able to, alum is used.