rahul718

·Hello,

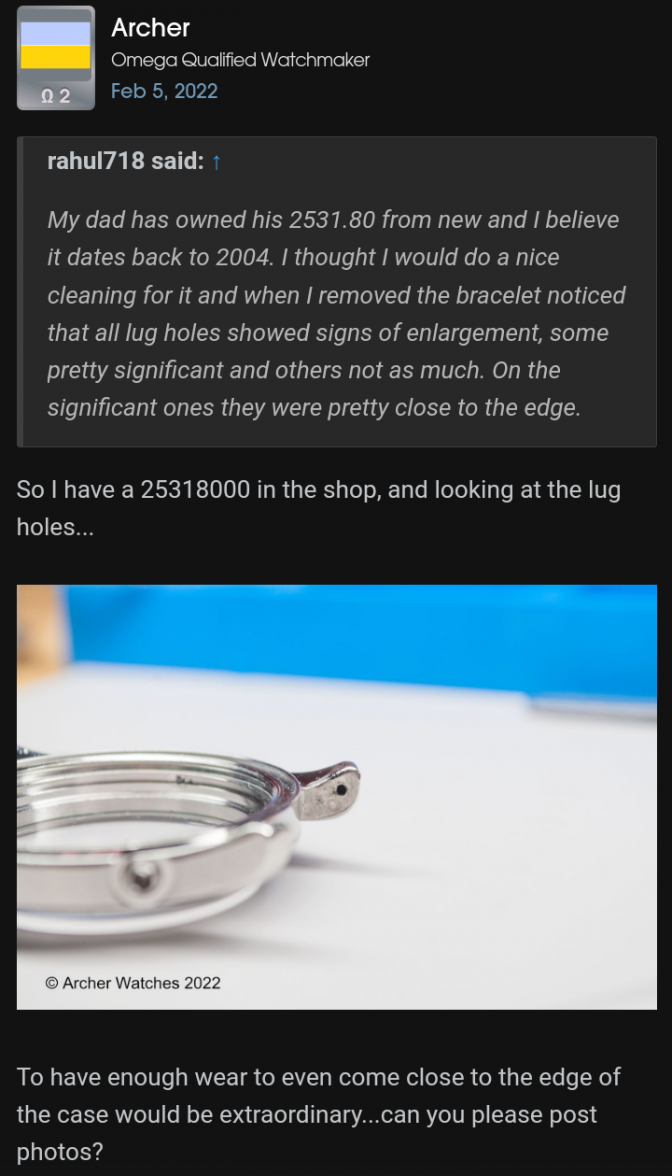

My dad has owned his 2531.80 from new and I believe it dates back to 2004. I thought I would do a nice cleaning for it and when I removed the bracelet noticed that all lug holes showed signs of enlargement, some pretty significant and others not as much. On the significant ones they were pretty close to the edge. It’s only stayed on the bracelet this whole time and he’s not one for swapping straps. My guess is time + dirt was the cause.

I didn’t take pictures but I’m wondering if laser welding would work in this case or should we just get a new case and send to Switzerland? I’ve seen some good laser weld repair on lug holes but just wondering if it actually lasts in the long run. Admittedly my knowledge on metals is minimal but wondering if the laser welding can stress the case and cause damage it? Would the repair be considered long lasting? How would the repair center or watchmaker make the lug hole in the same position and spec as it was originally? Any way to ensure the same kind of stainless steel is used to match the case?

sorry for all the questions. Just want to make sure we take the proper route.

Thanks

My dad has owned his 2531.80 from new and I believe it dates back to 2004. I thought I would do a nice cleaning for it and when I removed the bracelet noticed that all lug holes showed signs of enlargement, some pretty significant and others not as much. On the significant ones they were pretty close to the edge. It’s only stayed on the bracelet this whole time and he’s not one for swapping straps. My guess is time + dirt was the cause.

I didn’t take pictures but I’m wondering if laser welding would work in this case or should we just get a new case and send to Switzerland? I’ve seen some good laser weld repair on lug holes but just wondering if it actually lasts in the long run. Admittedly my knowledge on metals is minimal but wondering if the laser welding can stress the case and cause damage it? Would the repair be considered long lasting? How would the repair center or watchmaker make the lug hole in the same position and spec as it was originally? Any way to ensure the same kind of stainless steel is used to match the case?

sorry for all the questions. Just want to make sure we take the proper route.

Thanks