1960s Geneve 565 (166.041)

UNLucky

·I'm waiting for a shipment to come with a new crown/stem seems I snapped mine at some point. Had not realized. So I've put this watch to the side and started in on a Seamaster Deville (166.020 / 552), That balance is messed up, so have one on order. I just attract silly issues.

sheepdoll

·Careful. It gets addictive.

Back in the day there were people who specialized in balance restoration only. I knew Henry quite well and traveled with him a few times.

Back in the day there were people who specialized in balance restoration only. I knew Henry quite well and traveled with him a few times.

UNLucky

·Ok. Got it all disassembled, and cleaned then reassembled and lubricated. Checking twice for which lube goes where. Now, after setting the balance (which took forever to get the impulse stone in right) it seems to be running really slow. putting it on the timegrapher and it goes for about 10 seconds before it says 'beat rate auto detect', it doesnt seem to be able to pick it up. What could i do to strengthen the balance? It is running visibly slower than the last time i had it assembled! go figure...

sheepdoll

·Still think you need to spend more time on the wheel train. If there is not enough energy going in, then there is no impulse to the balance. Check the pivots. The jewels. When it is correct, the wheels really spin with the least amount of nudging.

I just picked up another set of Mystery parts (Unknown caliber.) Included a balance, which is missing the roller jewel. I still have not toasted the pallet forks yet. Having too much fun with the fiber laser.

I just picked up another set of Mystery parts (Unknown caliber.) Included a balance, which is missing the roller jewel. I still have not toasted the pallet forks yet. Having too much fun with the fiber laser.

rendo

··faux legendOk. Got it all disassembled, and cleaned then reassembled and lubricated. Checking twice for which lube goes where. Now, after setting the balance (which took forever to get the impulse stone in right) it seems to be running really slow. putting it on the timegrapher and it goes for about 10 seconds before it says 'beat rate auto detect', it doesnt seem to be able to pick it up. What could i do to strengthen the balance? It is running visibly slower than the last time i had it assembled! go figure...

UNLucky

·I missed what you did differently this time. Did you install a new balance complete?

UNLucky

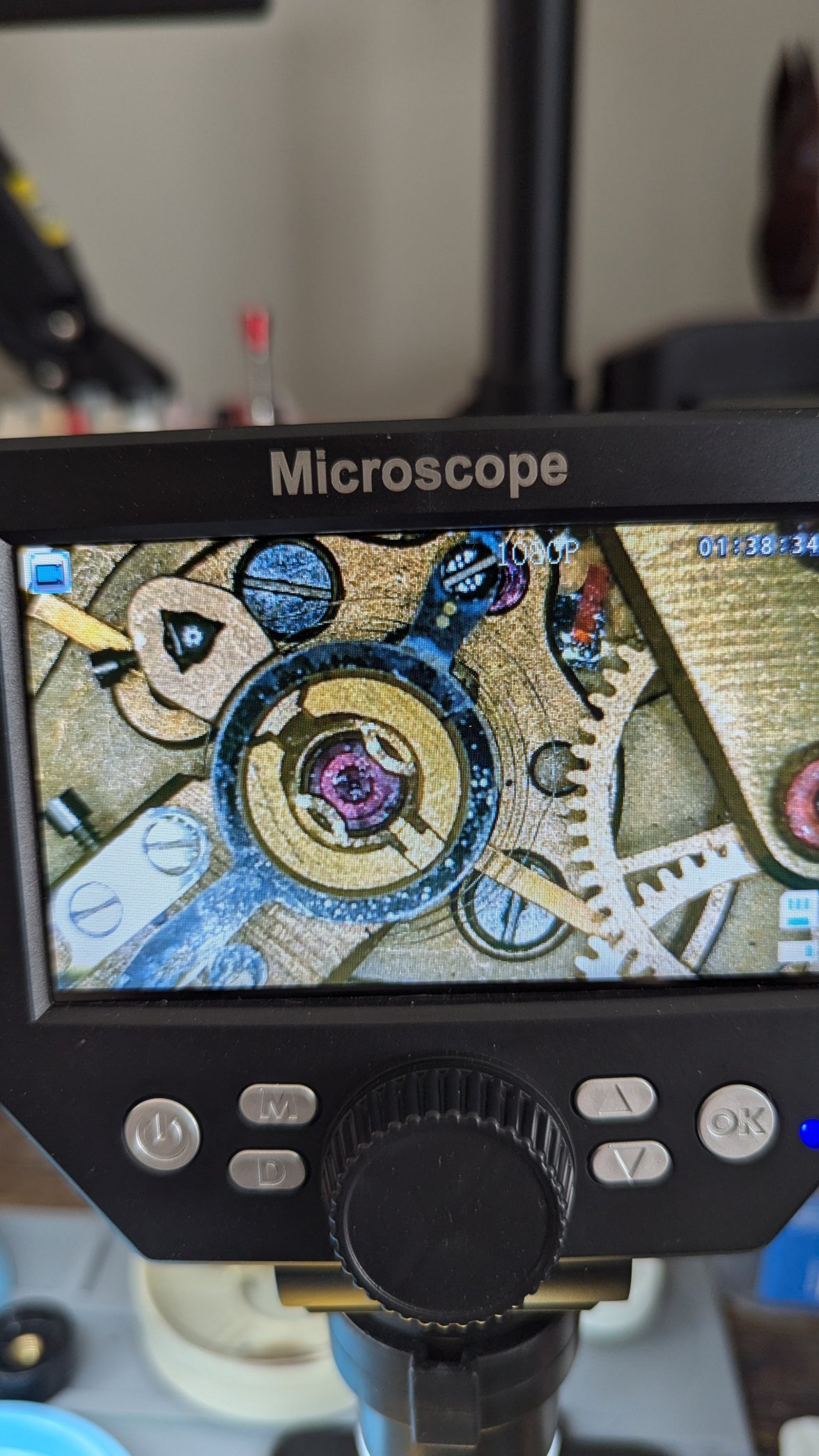

·I have a theory. I think where I'm picking it up to install it (the balance wheel) may be impacting the goose neck adjustment. I'm going to look at the balance under my microscope tonight and make sure I didnt mess it up. I've been picking it up and installing it with the (i think) the balance stud holder. I have not been grabbing it by the regulator, of that I'm sure. But I'm going to inspect everything tonight and also attempt to adjust the regulation of the wheel a tiny bit. I'm confident my power train is good, but to be safe, I'll re-check that too. Videos and pictures to follow when I get home.

rendo

··faux legendThe fact that you had so much difficulty installing the balance complete could be related to the problem you are having. I can see that happening if you have a very extensive beat error caused by the impulse jewel being way off compared to the mid-point of the banking pins.

Below is the best image I could find on the web to show you what I mean. Without the pallet fork installed and the balance at rest, you should see the impulse jewel somewhere in between the two banking pins. If it's slightly off centered, you would have some beat error. If it's off by a lot, you would have the issue you are describing and installing the balance would be hard like you experienced.

I'm not a watchmaker, so if any experts see an issue with what I'm saying, please chime in. I'm trying to help but I also wouldn't want to waste anybody's time.

Below is the best image I could find on the web to show you what I mean. Without the pallet fork installed and the balance at rest, you should see the impulse jewel somewhere in between the two banking pins. If it's slightly off centered, you would have some beat error. If it's off by a lot, you would have the issue you are describing and installing the balance would be hard like you experienced.

I'm not a watchmaker, so if any experts see an issue with what I'm saying, please chime in. I'm trying to help but I also wouldn't want to waste anybody's time.

UNLucky

·Ill

I'll give this a shot! Thank you! I also think my difficulty came from inexperience and trying to line up a small jewel into a small slot. I've nearly got it down to a science now, but I'll do this and take pictures.

The fact that you had so much difficulty installing the balance complete could be related to the problem you are having. I can see that happening if you have a very extensive beat error caused by the impulse jewel being way off compared to the mid-point of the banking pins.

Below is the best image I could find on the web to show you what I mean. Without the pallet fork installed and the balance at rest, you should see the impulse jewel somewhere in between the two banking pins. If it's slightly off centered, you would have some beat error. If it's off by a lot, you would have the issue you are describing and installing the balance would be hard like you experienced.

I'm not a watchmaker, so if any experts see an issue with what I'm saying, please chime in. I'm trying to help but I also wouldn't want to waste anybody's time.

UNLucky

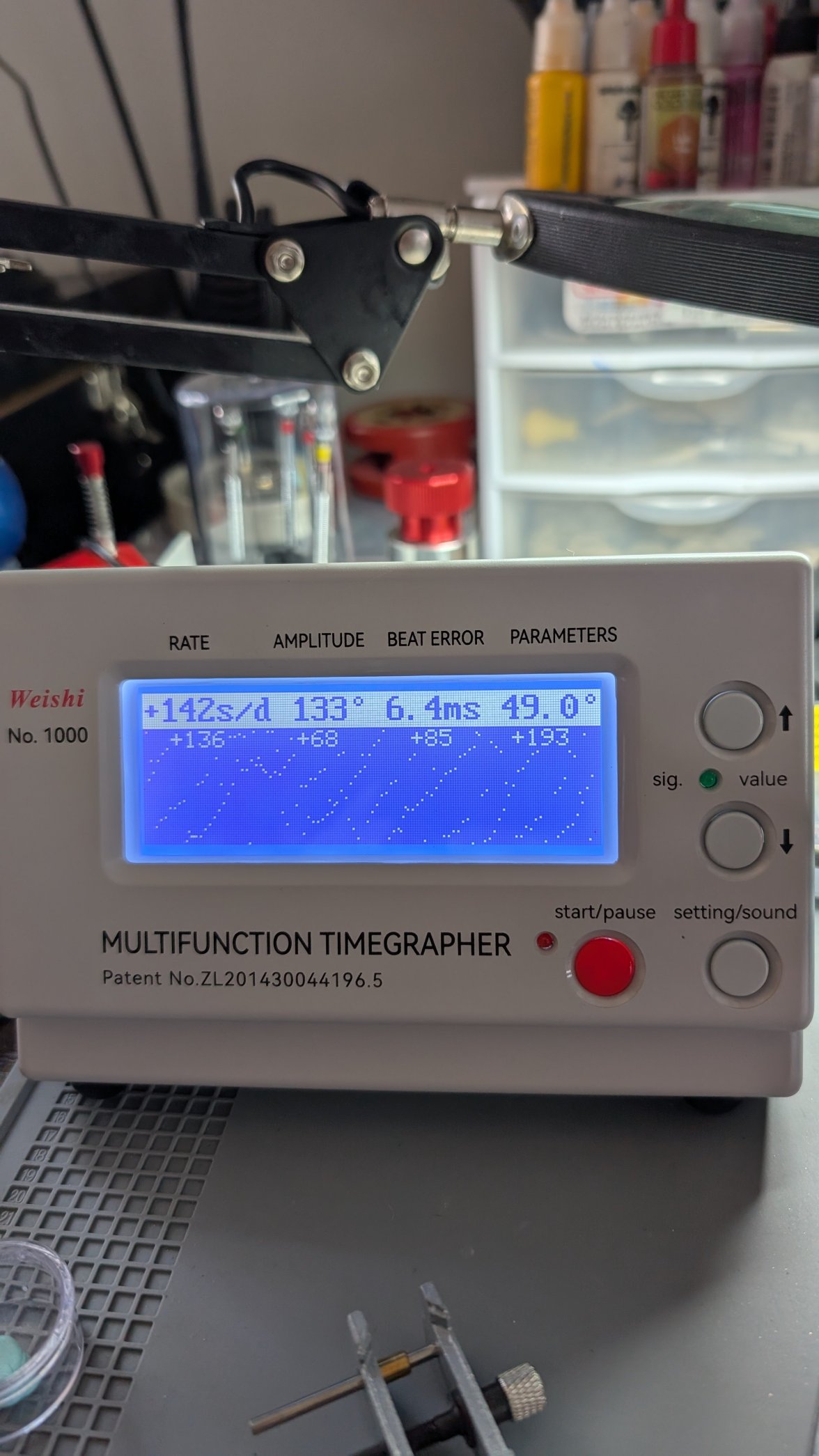

·UNLucky

·rendo

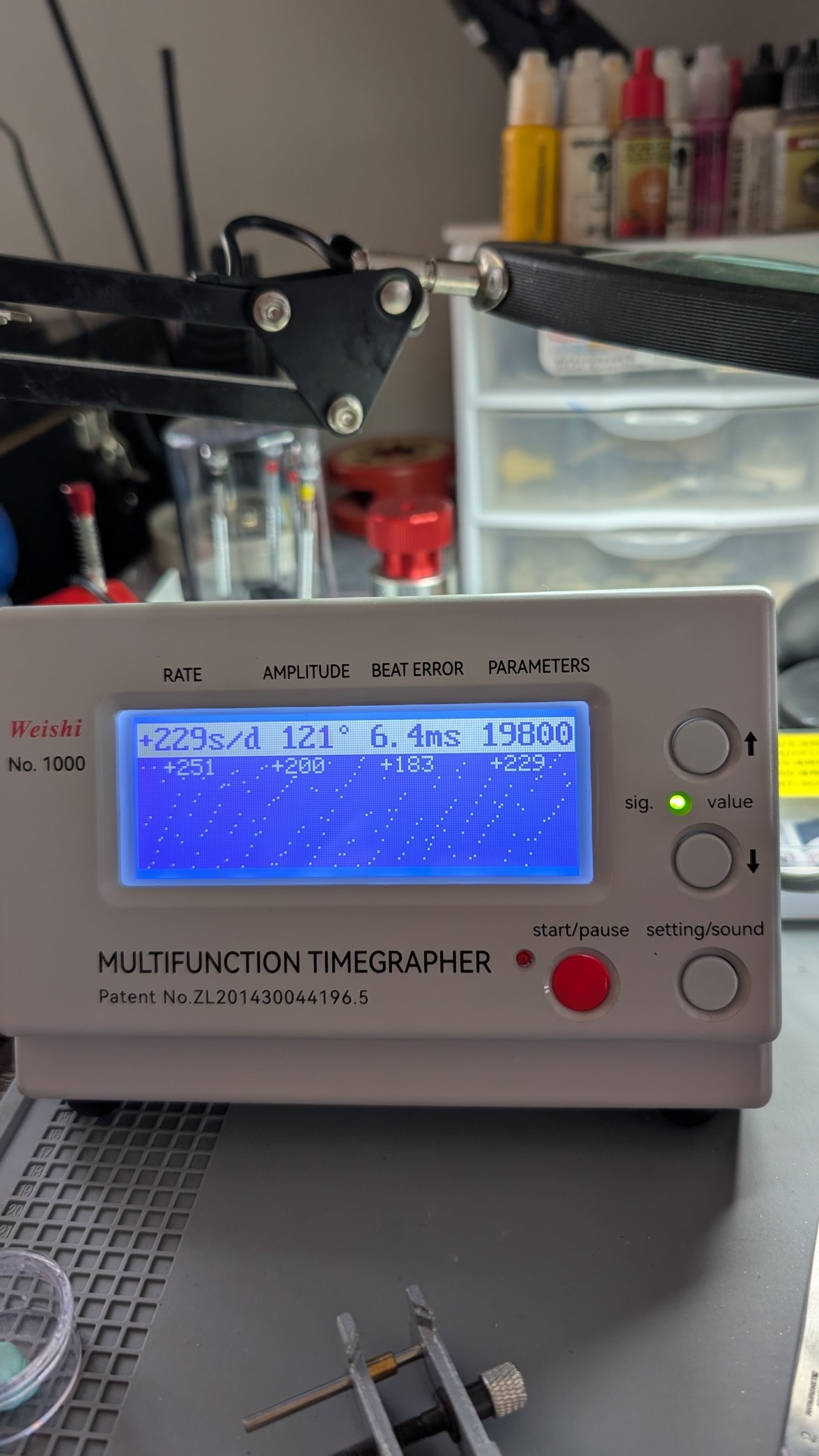

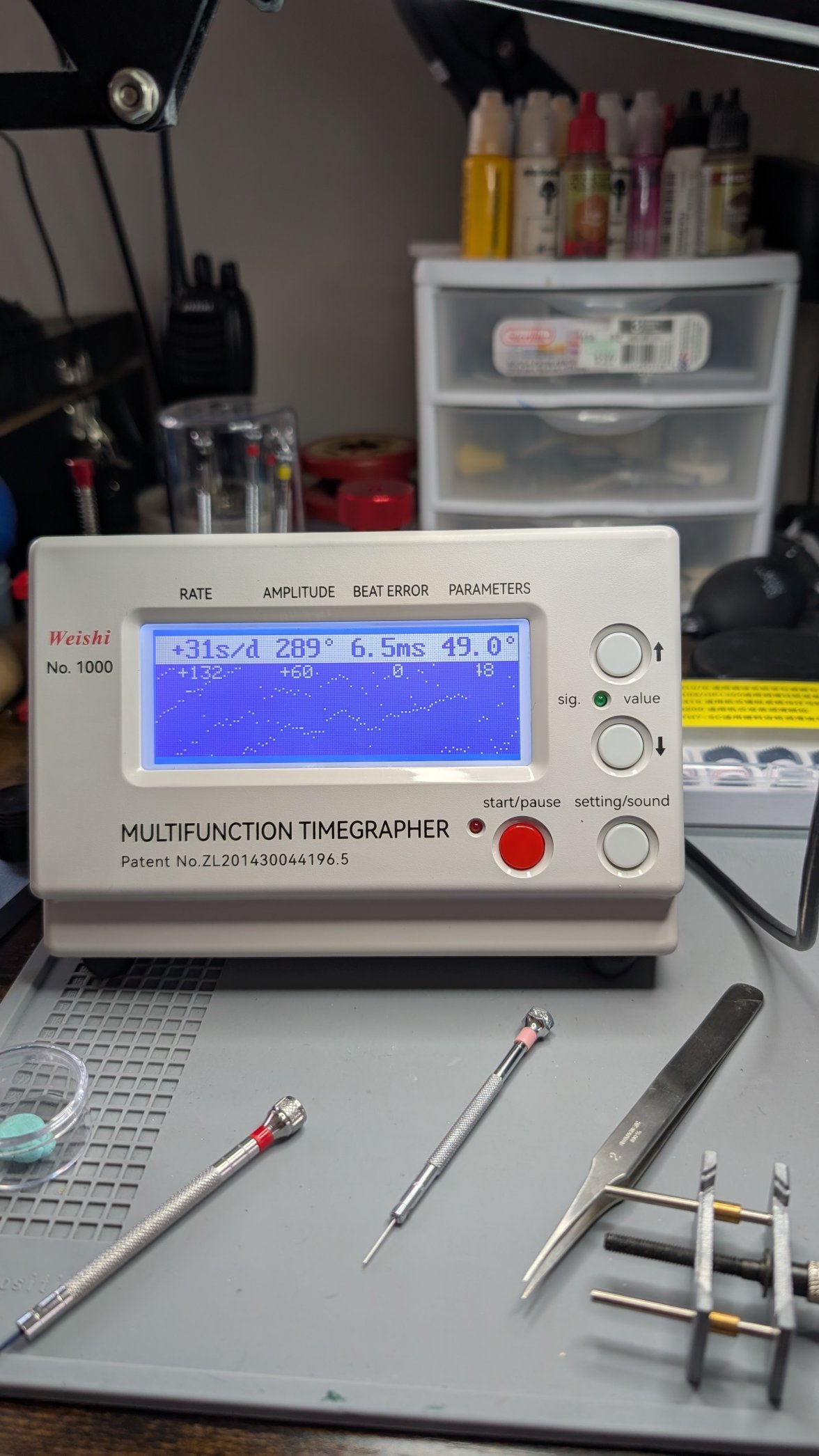

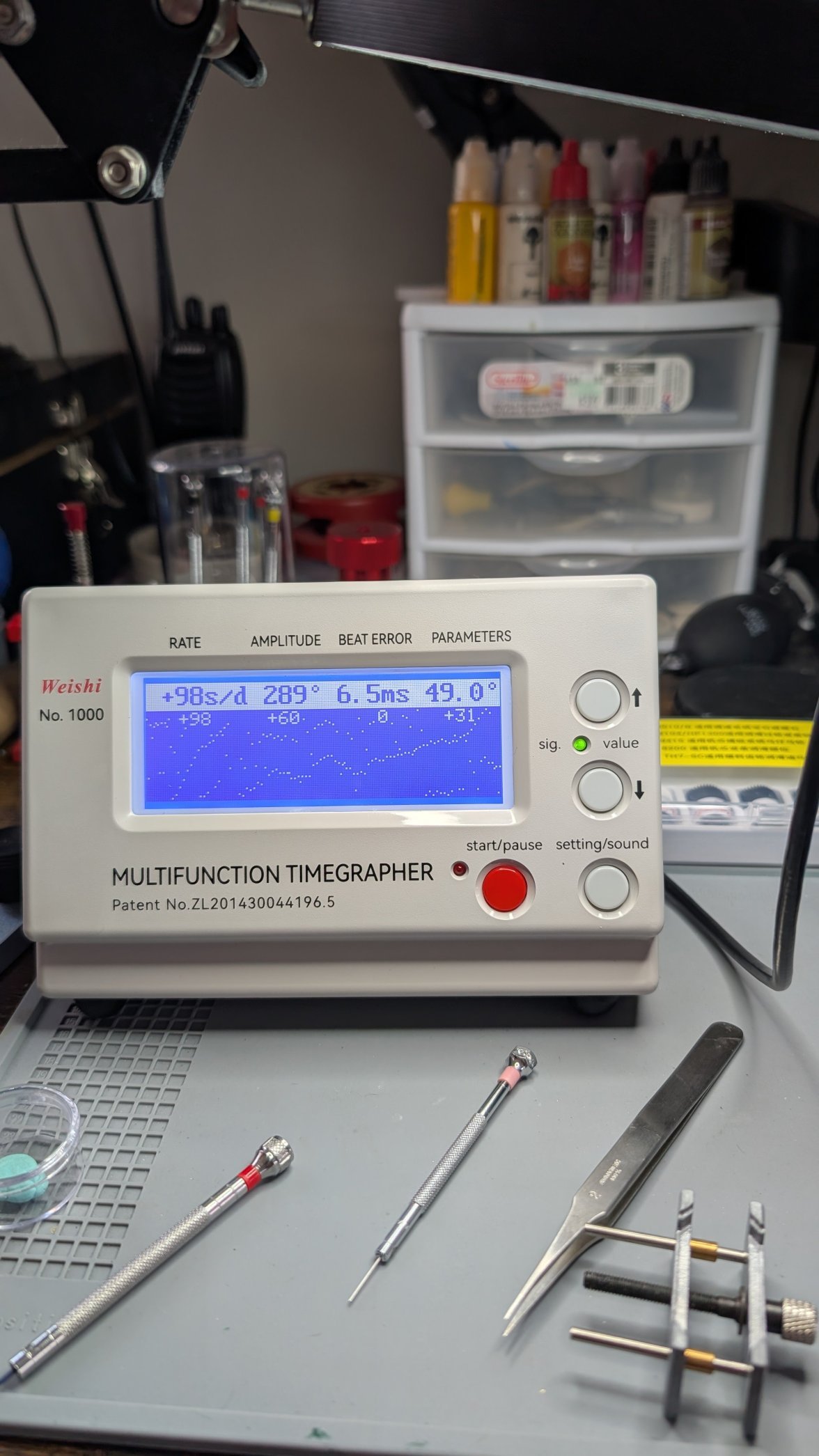

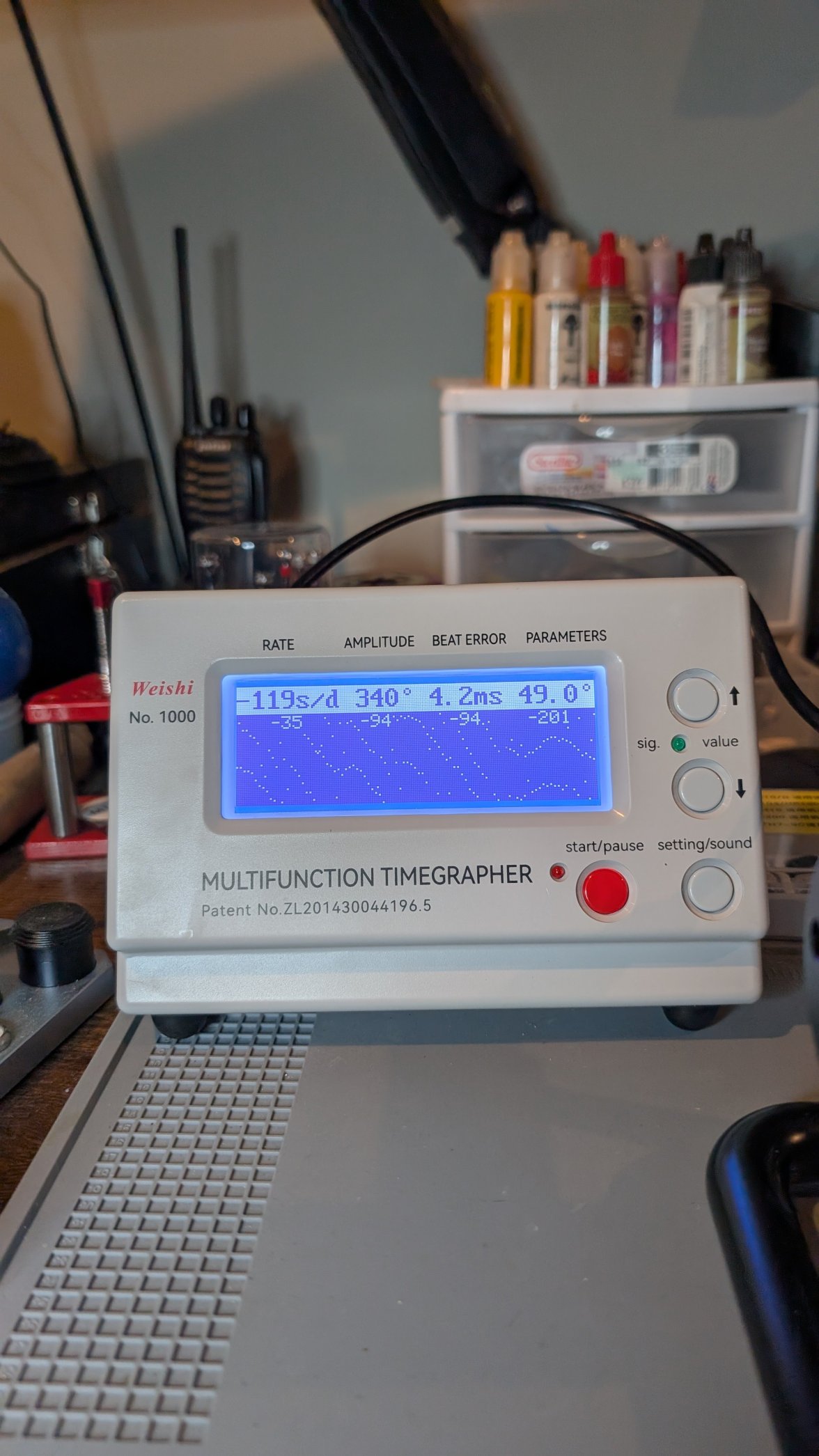

··faux legendIf the amplitude increased that much by just adjusting the regulator, you could be having an issue with the hairspring or the regulator pin. The amplitude looks good in the last photos. The beat error is high, but I’m hesitant to tell you to fix that as it’s a very delicate process on this movement. That still doesn’t explain the fluctuation in the amplitude. I’m assuming you demagnetized the movement.

It’s hard for me to further troubleshoot this remotely. Let’s see if someone with more experience chimes in.

It’s hard for me to further troubleshoot this remotely. Let’s see if someone with more experience chimes in.

UNLucky

·If the amplitude increased that much by just adjusting the regulator, you could be having an issue with the hairspring or the regulator pin. The amplitude looks good in the last photos. The beat error is high, but I’m hesitant to tell you to fix that as it’s a very delicate process on this movement. That still doesn’t explain the fluctuation in the amplitude. I’m assuming you demagnetized the movement.

It’s hard for me to further troubleshoot this remotely. Let’s see if someone with more experience chimes in.

rendo

··faux legendYou would want to reduce the beat error to below 2.0, but you will need to do that by rotating the collet of the mainspring. This movement does not have a stud, which would make the adjustment a lot easier. I would watch some videos before attempting it. It’s very easy to damage the hairspring in the process.

Do a google search on timegrapher readings. You will see how it’s supposed to be a straight line unlike yours. This should give you an idea: https://www.beyondthedial.com/post/collector-guide-interpreting-timegrapher-results/

edit: correction, this movement does have an adjustable stud

Do a google search on timegrapher readings. You will see how it’s supposed to be a straight line unlike yours. This should give you an idea: https://www.beyondthedial.com/post/collector-guide-interpreting-timegrapher-results/

edit: correction, this movement does have an adjustable stud

Edited:

UNLucky

·You would want to reduce the beat error to below 2.0, but you will need to do that by rotating the collet of the mainspring. This movement does not have a stud, which would make the adjustment a lot easier. I would watch some videos before attempting it. It’s very easy to damage the hairspring in the process.

Do a google search on timegrapher readings. You will see how it’s supposed to be a straight line unlike yours. This should give you an idea: https://www.beyondthedial.com/post/collector-guide-interpreting-timegrapher-results/

UNLucky

·I feel like I'm right there. I'm going to let it run tonight and see how it goes. It'll bounce 4.2 to 5.6 beat error and jump 314 to 360 amplitude. So gonna just let it cook for a bit. Not sure what rhe next step is but reading and researching. I do need to oil the pallet gems anyway. Maybe that'll help. But it's getting there. Thank you all!

sheepdoll

·The 565 should have a movable stud. Which makes adjusting the beat a bit easier. The roller jewel does need to be aligned, which is tricky in these as they do not have banking pins. The banking stops are in the pallet fork bridge. I like to do this first as it is really risky, and I have managed to kack a few hairsprings in the process.

Usually the pallets are oiled. That seems to be a requirement which is a major factor in these needing regular service. There is also something called epilame[sp] which keeps the oil from spreading. That is pretty pricey stuff. I think this allows more time between service intervals as it keeps the oil on the pallets.

I think I heard here that the pallet pivots are best left to run dry since they do not rotate 360. I noticed that does seem to help the amplitude not oiling them.

You really need to get the beat error down to 1.5 or so.

Usually the pallets are oiled. That seems to be a requirement which is a major factor in these needing regular service. There is also something called epilame[sp] which keeps the oil from spreading. That is pretty pricey stuff. I think this allows more time between service intervals as it keeps the oil on the pallets.

I think I heard here that the pallet pivots are best left to run dry since they do not rotate 360. I noticed that does seem to help the amplitude not oiling them.

You really need to get the beat error down to 1.5 or so.

rendo

··faux legend@sheepdoll is correct that this movement has an adjustable stud carrier, so adjusting the beat error is a lot easier than what I described earlier.

UNLucky

·So I physically move the stud carrier? I've been slowly manipulating the fine regulation and coarse regulation screws. I'll try to find information on the stud carrier.

![wvusb37lnwjb1[1].jpg wvusb37lnwjb1[1].jpg](https://omegaforums.net/data/attachments/1838/1838726-f44b48dd367356c8d4f95ea4619346ac.jpg?hash=5KOUCmekVw)