rendo

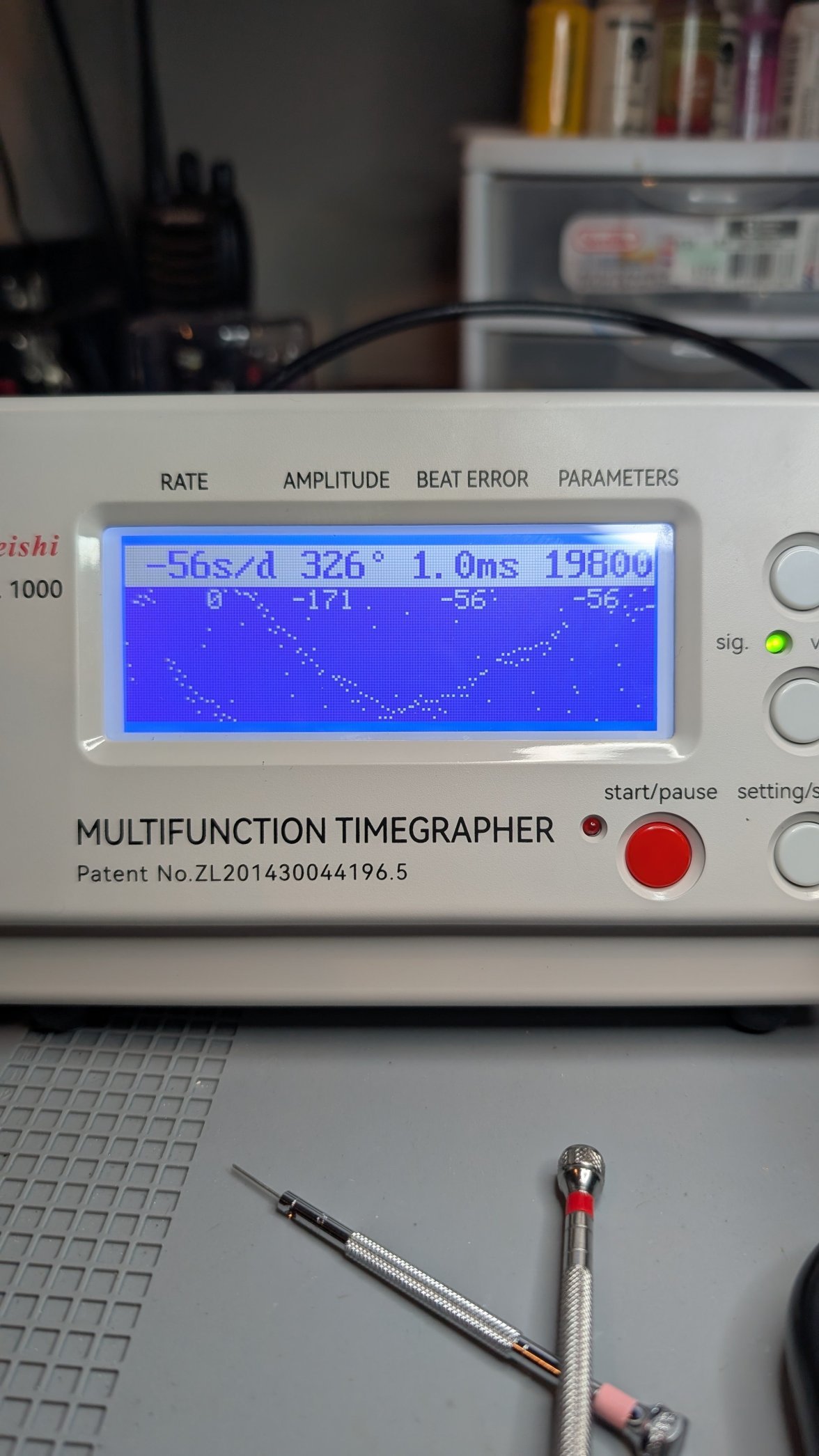

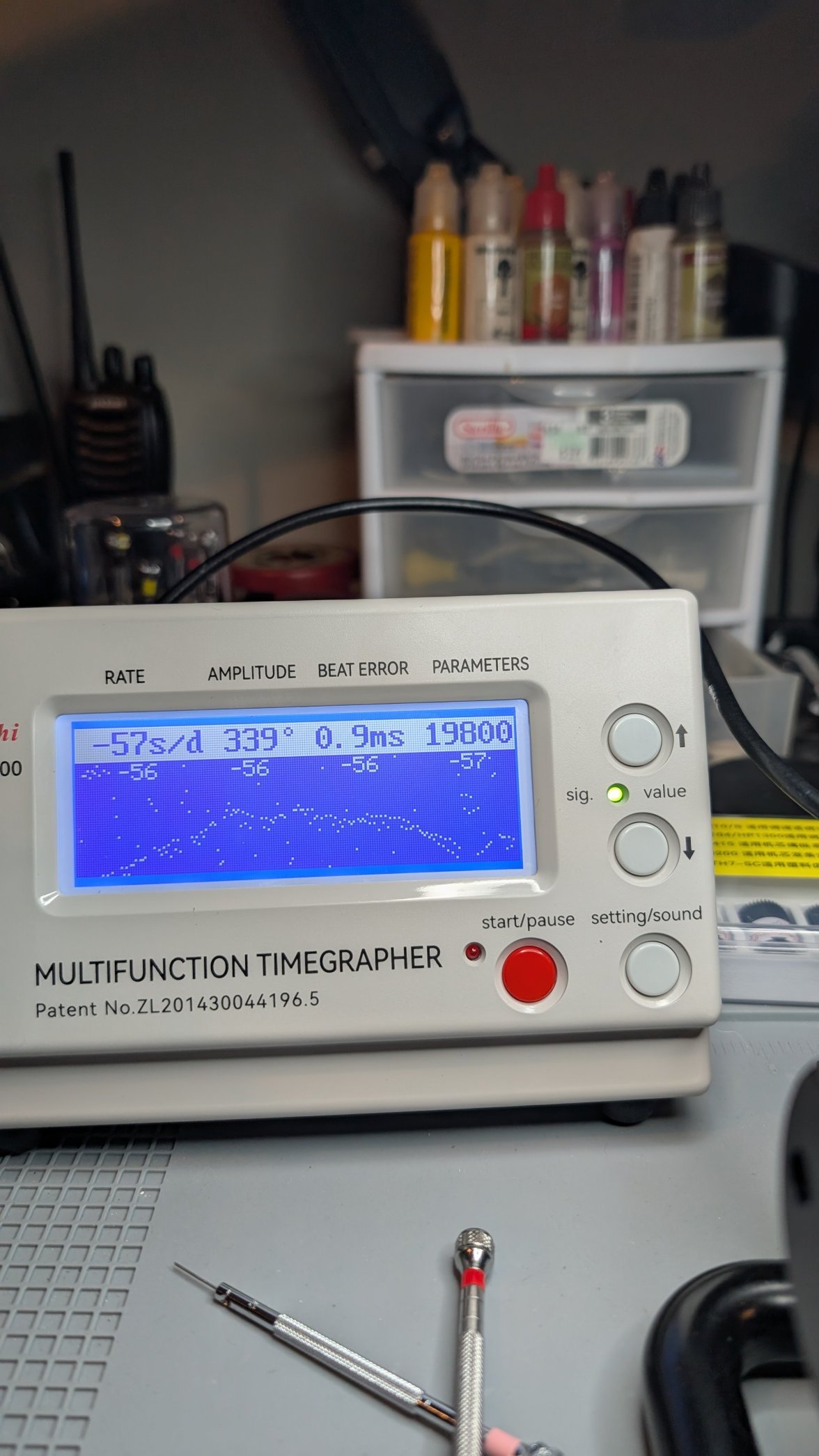

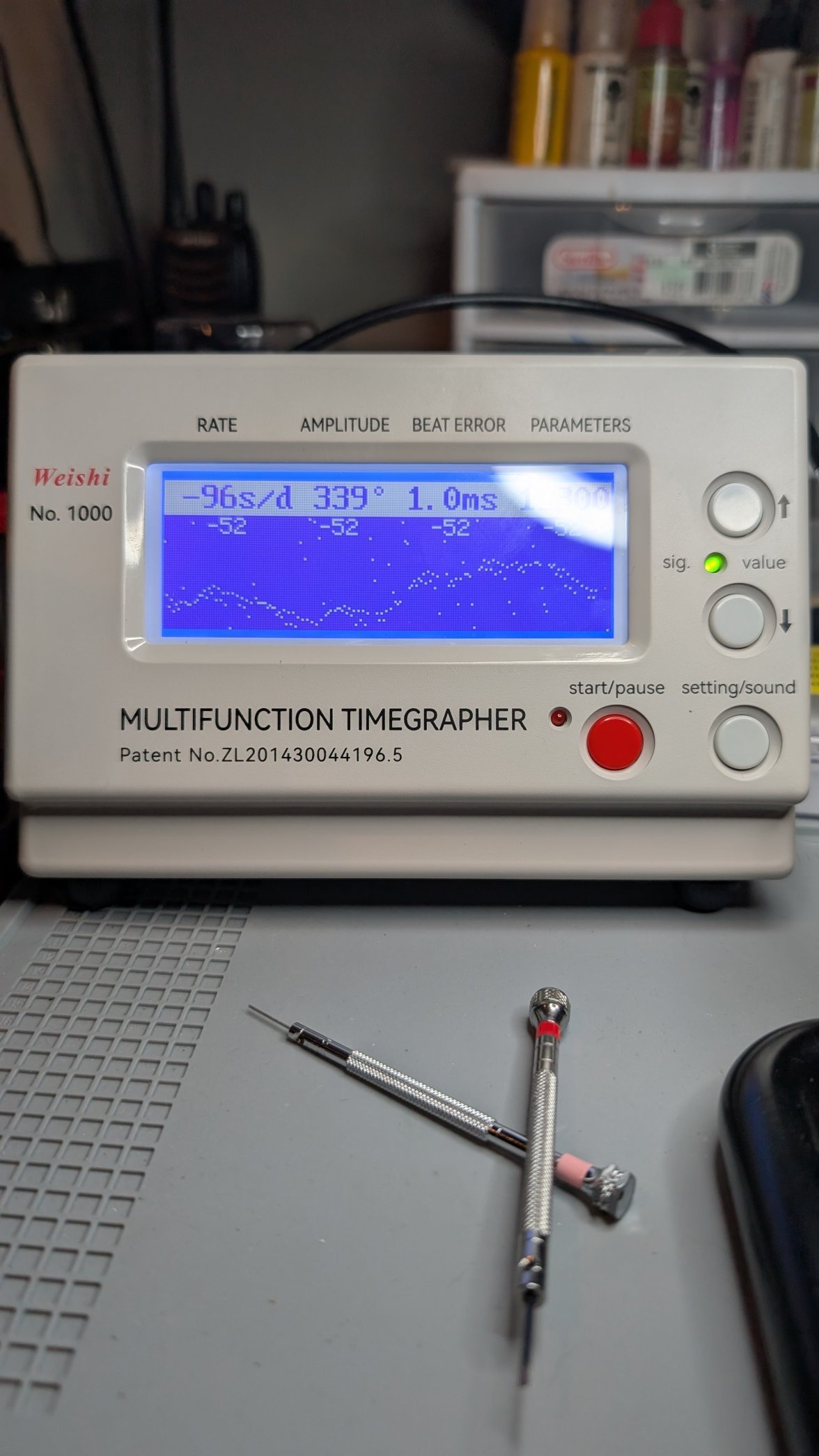

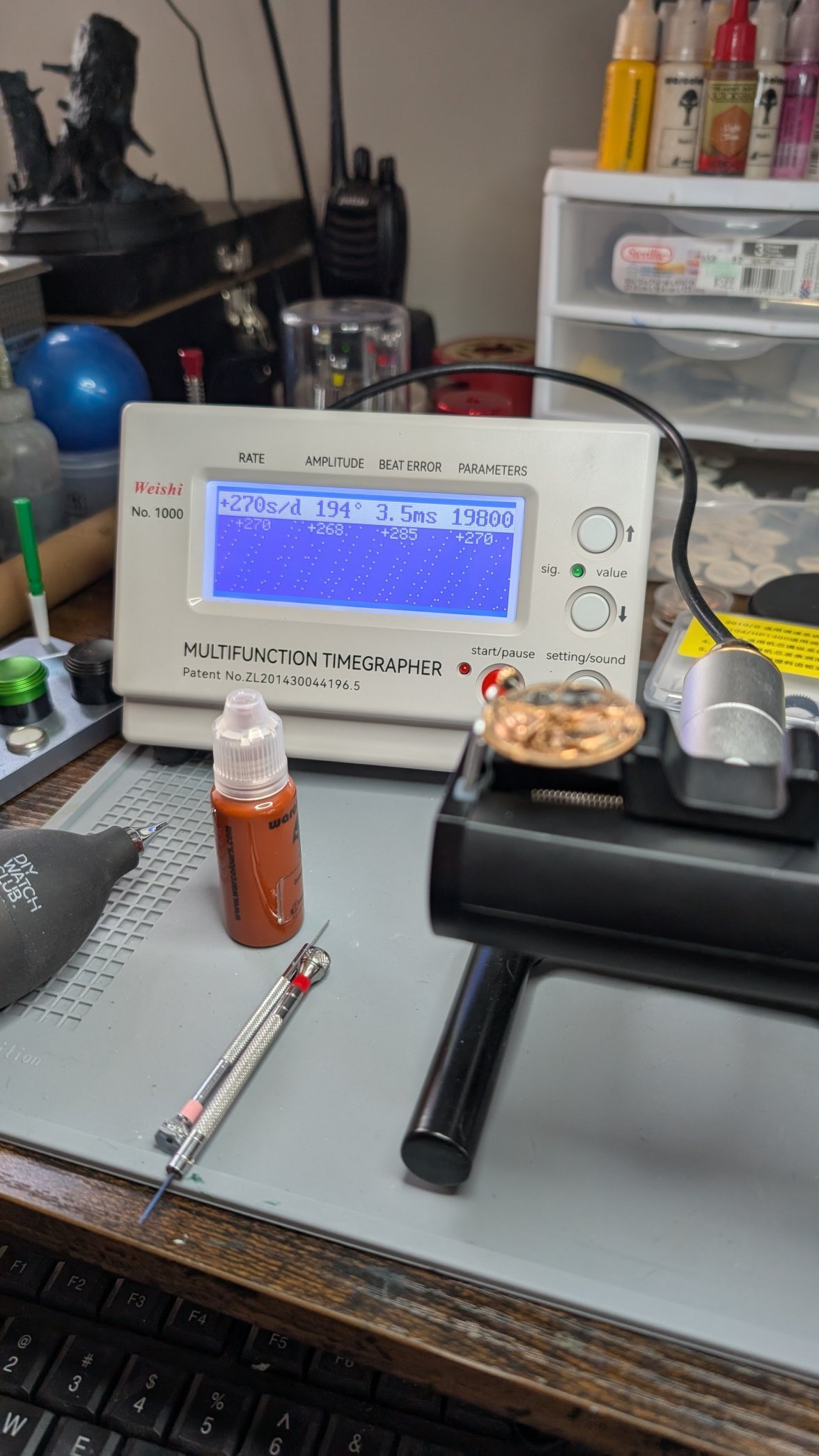

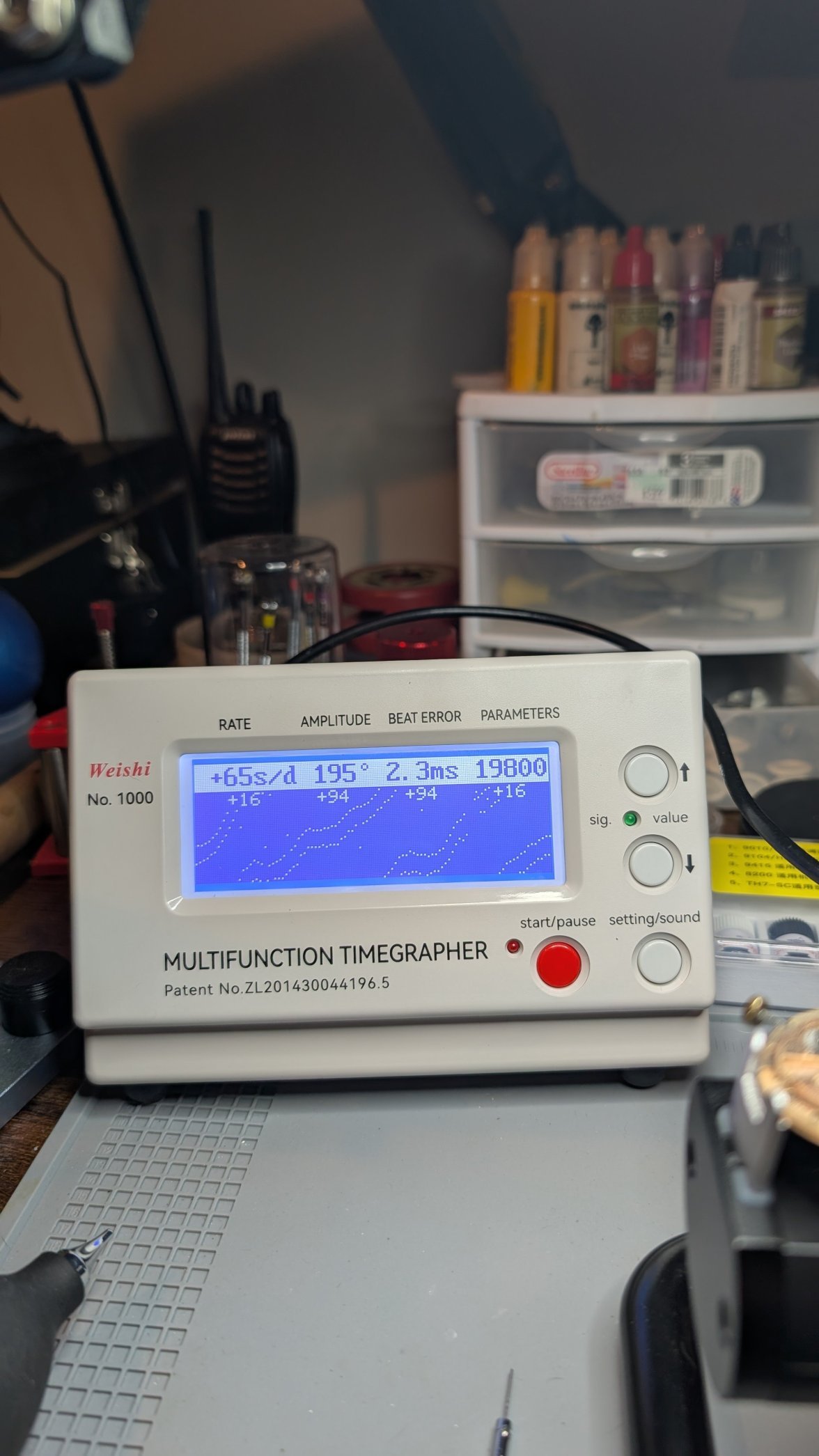

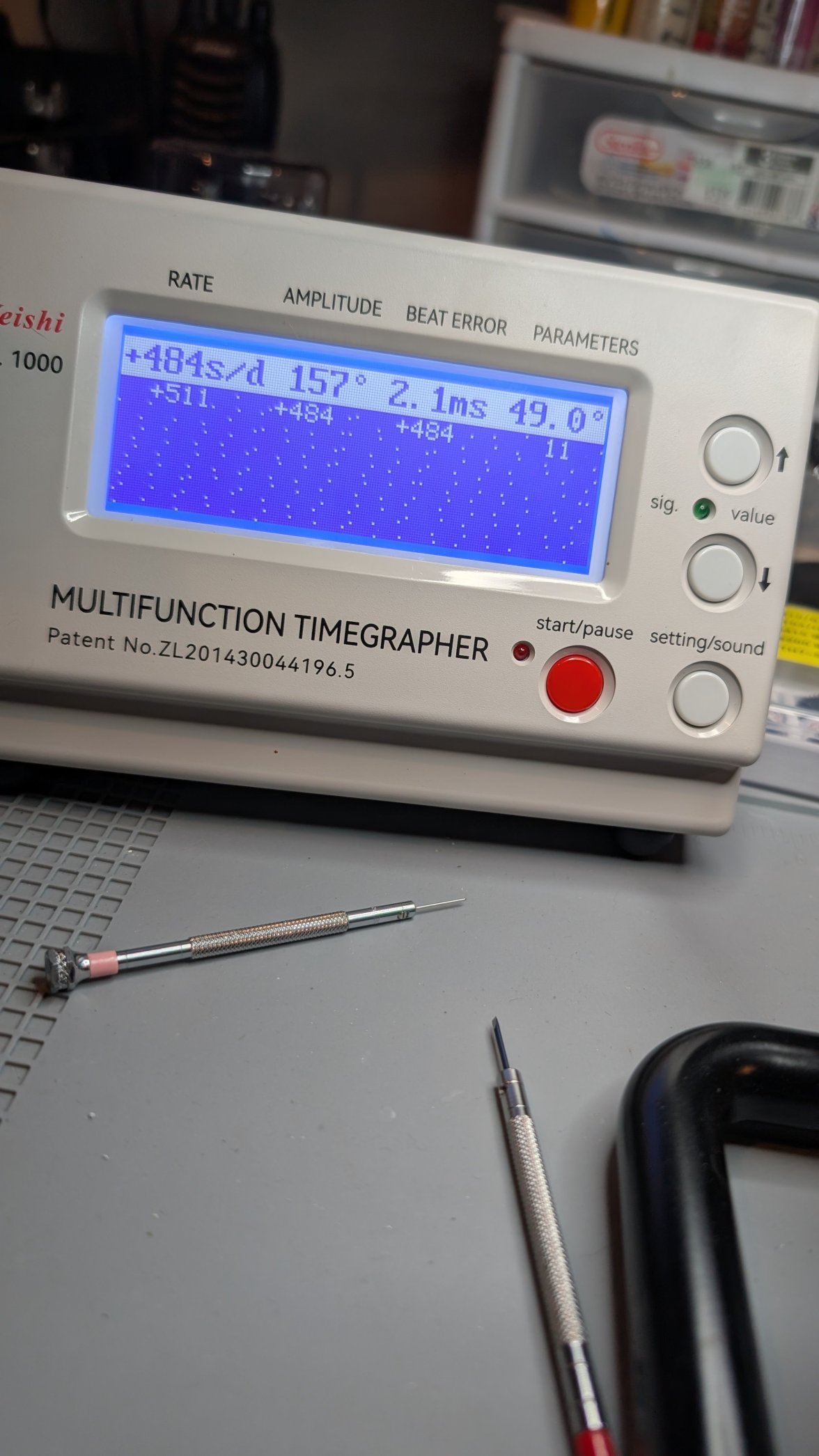

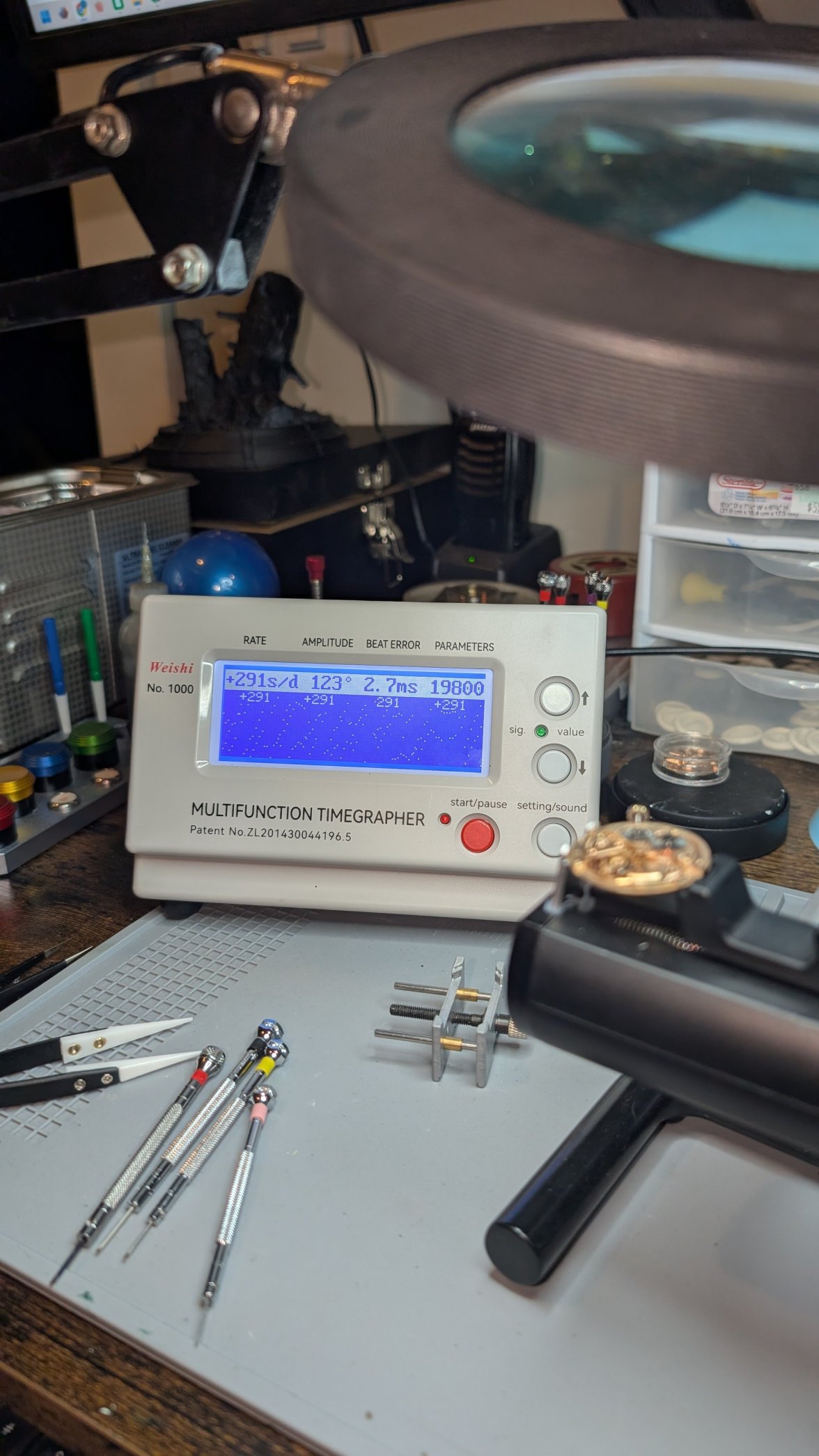

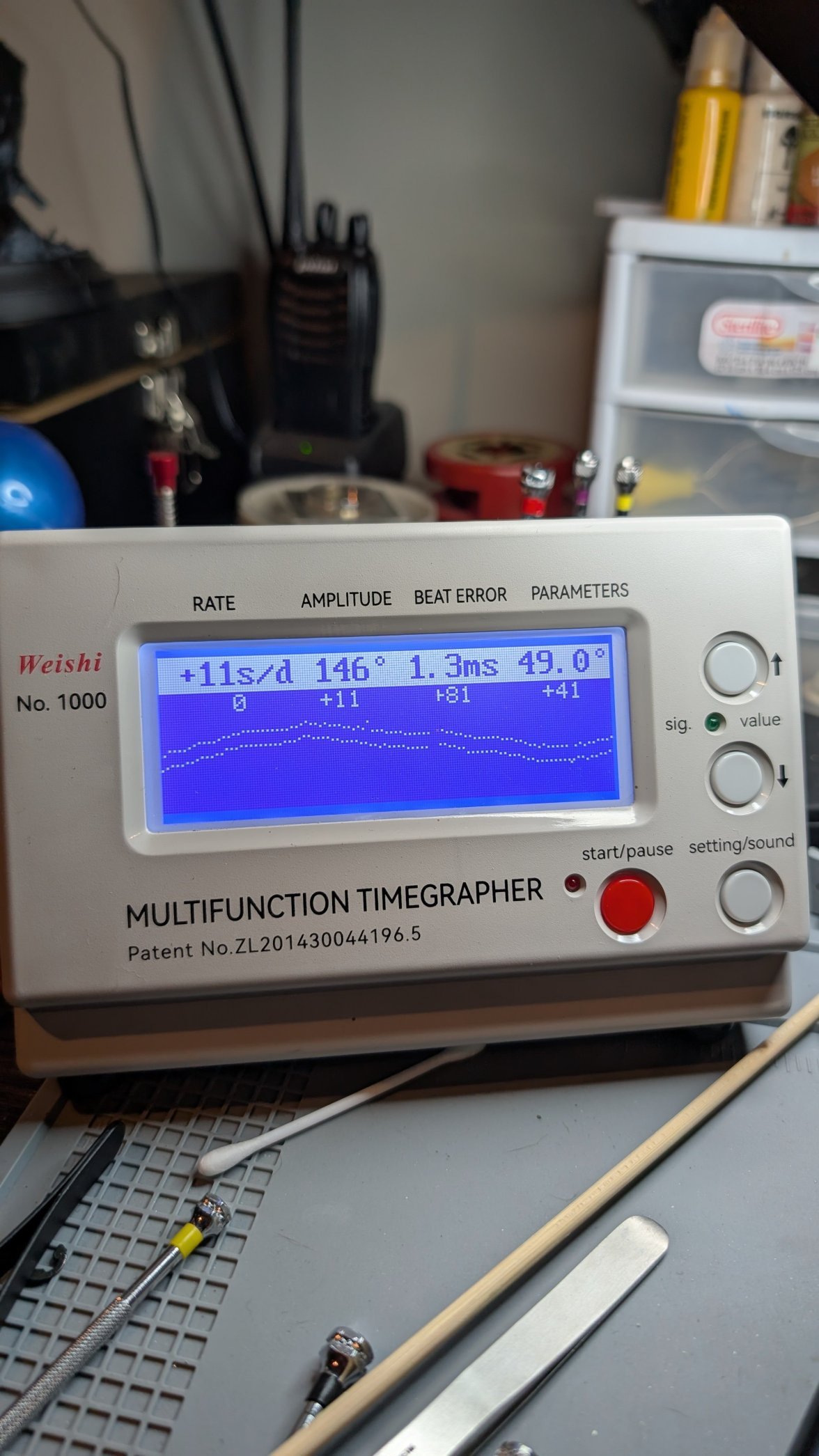

··faux legendYes, but try to make very small adjustments and give the movement some time until you see the new reading. Depending on your timegrapher settings, it should take around 10 seconds for it to calculate the new beat error.

Start by rotating the stud carrier either clockwise or counter-clockwise (pick one). If the beat error increases after the first adjustment, change your direction to the opposite of what you started with and keep going until you get as close as possible to zero. With experience, you can tell which way you should start adjusting it.

Ideally you want to measure beat error in different positions, but let's take one step at at time.

Start by rotating the stud carrier either clockwise or counter-clockwise (pick one). If the beat error increases after the first adjustment, change your direction to the opposite of what you started with and keep going until you get as close as possible to zero. With experience, you can tell which way you should start adjusting it.

Ideally you want to measure beat error in different positions, but let's take one step at at time.