1960s Geneve 565 (166.041)

sheepdoll

·You can post the video to You Tube and link it using the media shorcut in the ribbon.

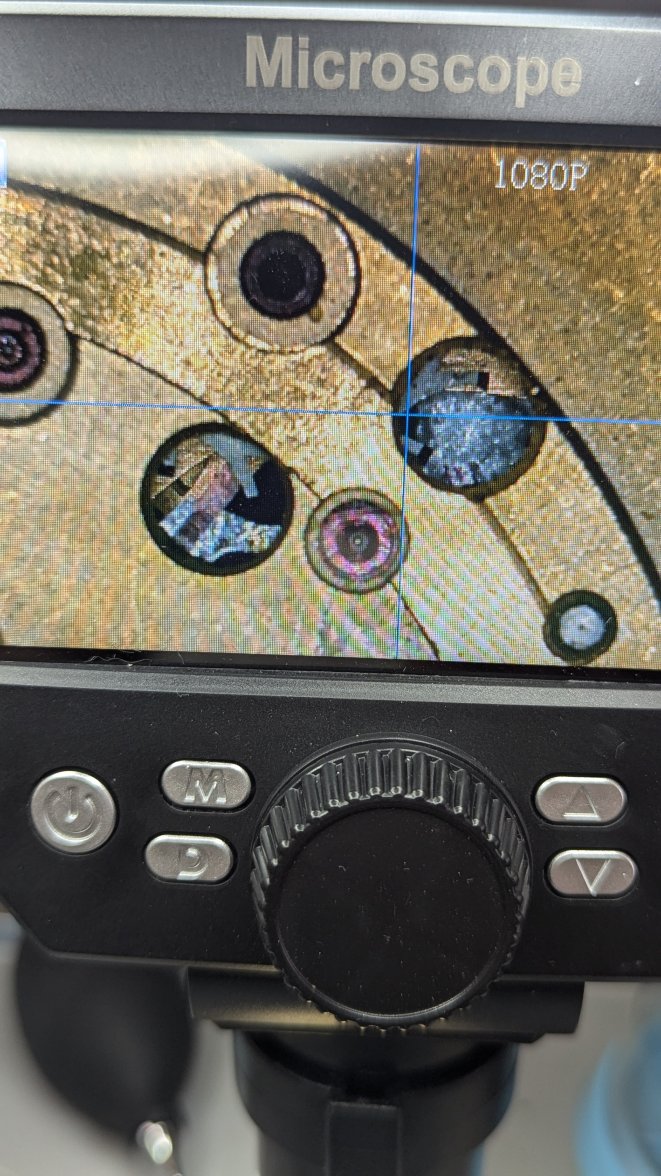

I am thinking about getting my USB microscope out. When OF goes all Brigadoon this afternoon at the time of this posting, and the dental numbing wears off I will be working with 4 or 5 pallet forks to see if anything can be saved. I only have one escape wheel (spare) which is missing (well it is folded over) pivot. The balance is pickling away in some alum. The spring has a few kinks in it. Still I went to the dentist this morning, and I always say I would rather untangle a hairspring. Now I get to put all that to the test.

I am having trouble visualizing the issue on your part. Did you just put together the escape wheel, pallet and balance? That is what I will be doing. As others said, you can turn the 'scape wheel with an artist brush. It does not take a lot of power, and sometimes the inertia will continue for about 5 ticks or so.

Each bit (subsection) of the watch gets taken apart over and over and over and over again. It is never one and done. Sort of like pedaling a bycycle, after a while one does not notice. Once the dial and hands go back on, I tend not to want to dissemble the plates as often.

Fiddeling with 5 incomplete watches is a bit like juggling. Not that I ever learned to juggle. The ones at the renfair jugglers never stopped, even backstage. Kinda like the method actors. They were serious when they would say "Do not do this at home."

I am thinking about getting my USB microscope out. When OF goes all Brigadoon this afternoon at the time of this posting, and the dental numbing wears off I will be working with 4 or 5 pallet forks to see if anything can be saved. I only have one escape wheel (spare) which is missing (well it is folded over) pivot. The balance is pickling away in some alum. The spring has a few kinks in it. Still I went to the dentist this morning, and I always say I would rather untangle a hairspring. Now I get to put all that to the test.

I am having trouble visualizing the issue on your part. Did you just put together the escape wheel, pallet and balance? That is what I will be doing. As others said, you can turn the 'scape wheel with an artist brush. It does not take a lot of power, and sometimes the inertia will continue for about 5 ticks or so.

Each bit (subsection) of the watch gets taken apart over and over and over and over again. It is never one and done. Sort of like pedaling a bycycle, after a while one does not notice. Once the dial and hands go back on, I tend not to want to dissemble the plates as often.

Fiddeling with 5 incomplete watches is a bit like juggling. Not that I ever learned to juggle. The ones at the renfair jugglers never stopped, even backstage. Kinda like the method actors. They were serious when they would say "Do not do this at home."

noless

·i wanted to see the under side of the balance itself, so before installing the balance a photo of the roller table and roller jewel, well footage of how its moving might also reveal something.

it can be hard to troubleshoot over the internet.

it can be hard to troubleshoot over the internet.

noless

·UNLucky

·sheepdoll

·I would still just try the escapee wheel fork and balance. Leave the barrel bridge off. Then add the wheels one by one back.

I updated my similar thread https://omegaforums.net/threads/more-fun-sourcing-watch-parts-56x-and-75x.174686/post-2387350 yesterday just before the site went Brigadoon.

Have not yet tried the pallet warmer on the forks. I did get the Balance staff out of one of the balances. Had an old staff from decades ago, so I want to try that too.

I updated my similar thread https://omegaforums.net/threads/more-fun-sourcing-watch-parts-56x-and-75x.174686/post-2387350 yesterday just before the site went Brigadoon.

Have not yet tried the pallet warmer on the forks. I did get the Balance staff out of one of the balances. Had an old staff from decades ago, so I want to try that too.

UNLucky

·I would still just try the escapee wheel fork and balance. Leave the barrel bridge off. Then add the wheels one by one back.

I updated my similar thread https://omegaforums.net/threads/more-fun-sourcing-watch-parts-56x-and-75x.174686/post-2387350 yesterday just before the site went Brigadoon.

Have not yet tried the pallet warmer on the forks. I did get the Balance staff out of one of the balances. Had an old staff from decades ago, so I want to try that too.

Archer

··Omega Qualified WatchmakerThat's a lot. I'm not positive I know what exactly to do, I don't want to manipulate the fork, I'm not that level yet. I have a new fork coming that'll be here Weds I think. In the mean time I'll send pictures of the fork and bottom of the balance.

Have you checked all the pivots for wear?

Did you check them all for proper end shake?

Did you install a new mainspring and use the proper braking grease in the barrel?

Does the barrel arbor have proper end shake in the barrel, and the barrel have proper end shake in the movement?

Is there any wear in the main plate where the barrel arbor sits, or in the bushing on the barrel bridge?

Was there any damage inside the barrel where the arbor mounts, or any wear on the walls of the barrel drum?

Any corrosion in any of the pinions?

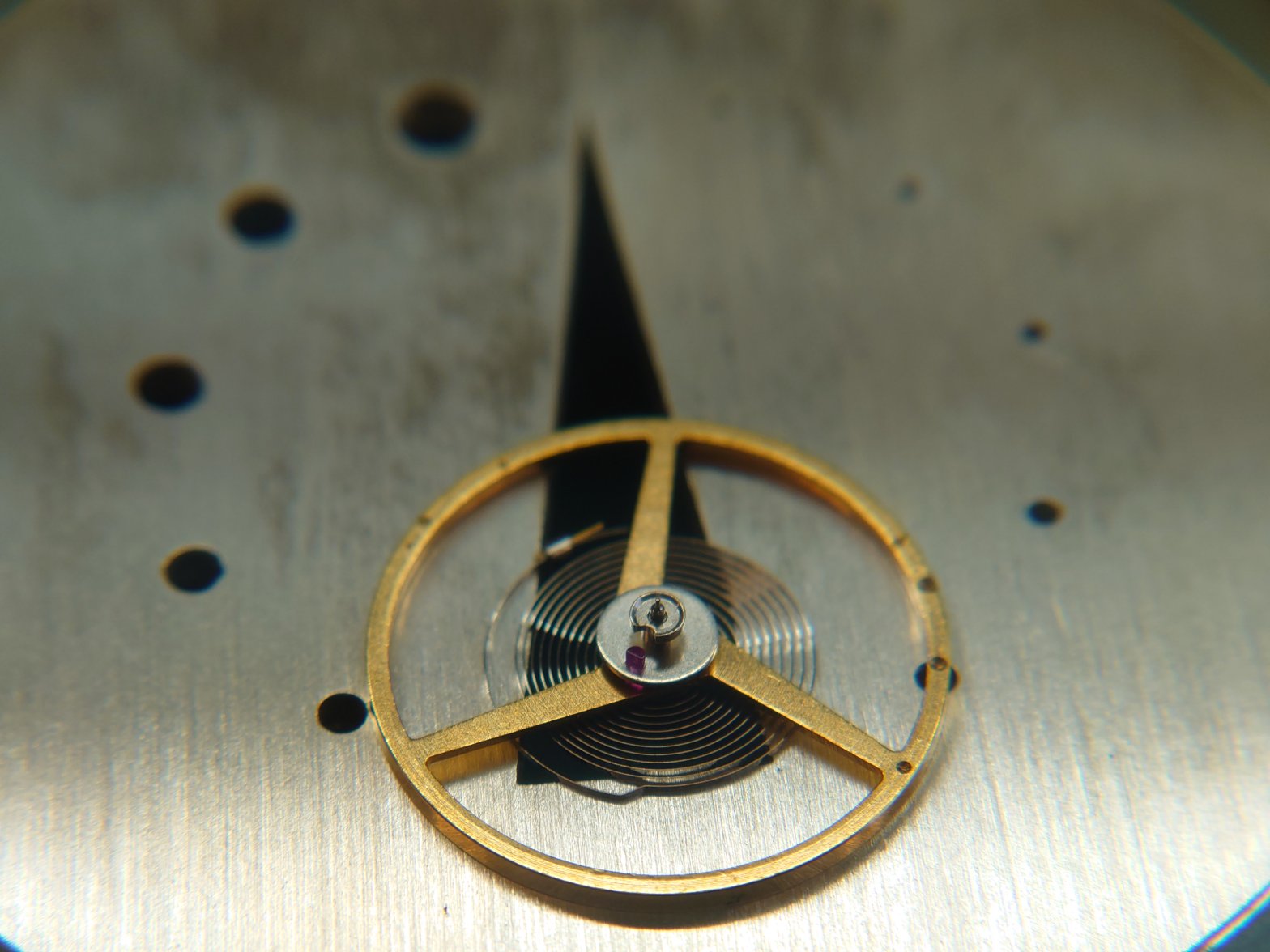

Is the balance spring flat, and not dished or angled up on one side?

These are all very basic things that need to be checked and any issues rectified before you start any work on pallet forks or changing balance staffs, etc.. When this sort of issue happens, people tend to focus on the escapement and balance, but the fact that the rest of train spins without the pallet fork in place doesn't really confirm that all the other important things have been dealt with properly.

sheepdoll

·I don't want to manipulate the fork, I'm not that level yet.

The SS is a bit tricky on these watches as there is no back pressure on this pinion. It pops out easy. There is just the thin piece of foil. Last night on the laser I made my first attempt at a movement holder what can back this up. I forgot to bring a spare watch plate. The winding gears also need a recess for something to allow back pressure. I suspect there is a proper movement holder for these what has a set screw under the center pivot.

The setworks can also bind. One of the assortment watches would run for 15/20 minutes then stop. I removed the setting wheels and It ran for hours. The cannon pinion needs to be greased. This also needs some backing when assembling as the center wheel is usually jeweled.

I am finding I am learning a lot from assembling random watch parts. The quality of the online stuff is all over the place. So makes for great practice.

I personally like to work from the escapement back up the train. I think most people start with the barrel and center wheel. Checking for bent broken teeth. If the spring breaks or there is a quick rundown, these teeth become damaged. The wheels tend to work in pairs.

Again watchmaking is not one and done.

UNLucky

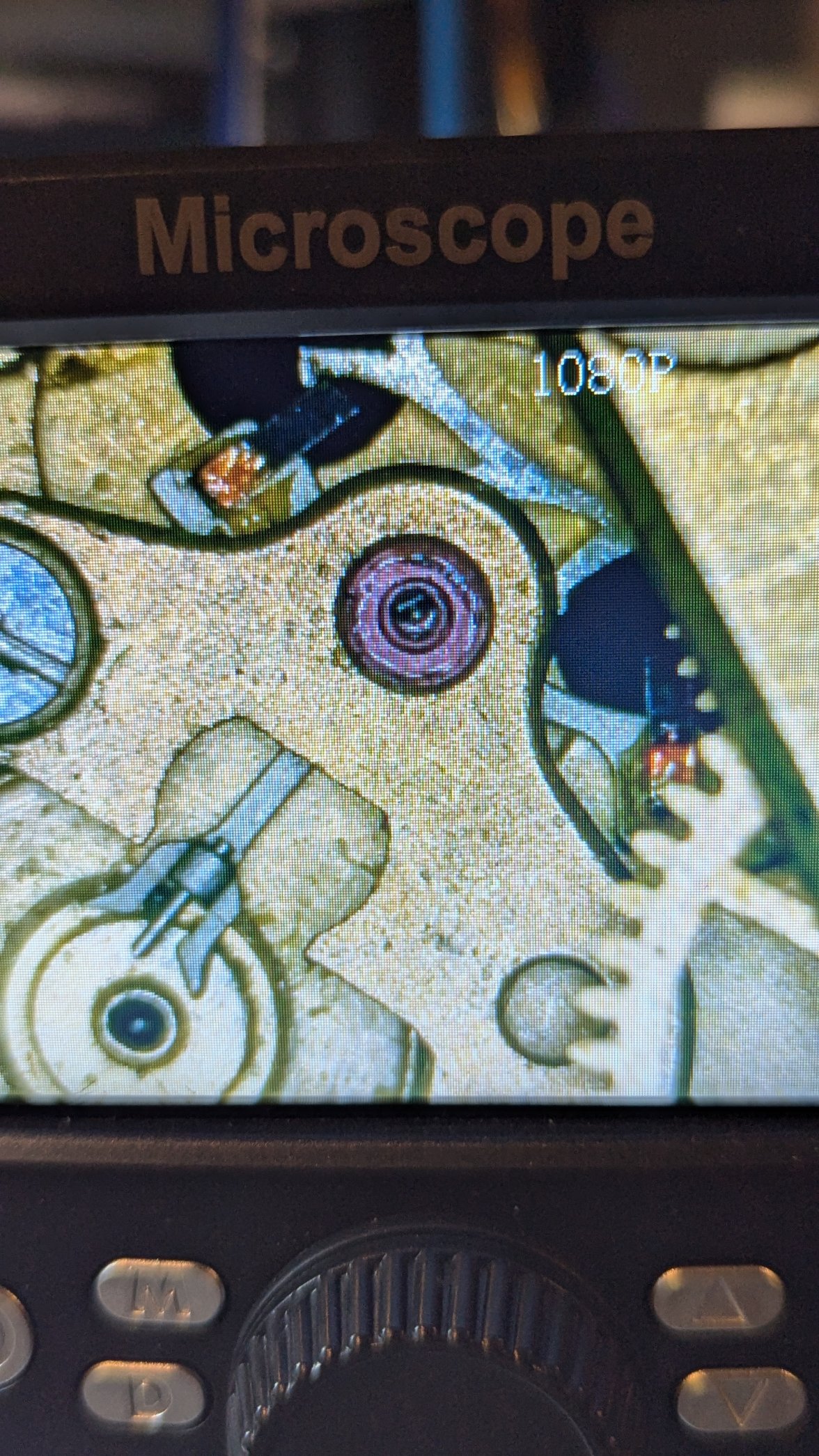

·I used the microscope to verify all the pivots as I disassembled.

I installed a new mainspring and verified the arbor.

I didn't see any noticable wear in any of of the pivots or holes. None of the jewels are damaged that I can see under the scope. No corrosion. The balance spring does not appear to be warped or twisted.

As I said I am just getting started but I verified all the steps up to this moment as I did them. I made sure I had all the tools, research, and even the parts guide from omega before I opened the watch. I really am taking my time as just getting to this point has taken 2 months of slow work. I have disassembled it and reassembled it twice now and can do a 3rd to take pictures and verify one more time.

I'll take it all apart and go piece by piece one more time taking pictures as I go. Thank you all for the help and guidance, we'll get it. 😀

I installed a new mainspring and verified the arbor.

I didn't see any noticable wear in any of of the pivots or holes. None of the jewels are damaged that I can see under the scope. No corrosion. The balance spring does not appear to be warped or twisted.

As I said I am just getting started but I verified all the steps up to this moment as I did them. I made sure I had all the tools, research, and even the parts guide from omega before I opened the watch. I really am taking my time as just getting to this point has taken 2 months of slow work. I have disassembled it and reassembled it twice now and can do a 3rd to take pictures and verify one more time.

I'll take it all apart and go piece by piece one more time taking pictures as I go. Thank you all for the help and guidance, we'll get it. 😀

rendo

··faux legendBefore you completely disassemble the movement one more time, you might want to do these three checks separately (some already mentioned above, but not sure if you followed them):

1. Remove the balance wheel, wind the watch a couple times and manually move the pallet fork right and left using a wooden pick. Record a video of how/if the pallet fork moves.

2. This time, remove the pallet fork (make sure you release power before doing this) and install the balance wheel. Blow air on the balance wheel and record a video of how it moves and stops.

3. With both the pallet fork and balance wheel removed, put a little wind on the watch and record the gear train.

1. Remove the balance wheel, wind the watch a couple times and manually move the pallet fork right and left using a wooden pick. Record a video of how/if the pallet fork moves.

2. This time, remove the pallet fork (make sure you release power before doing this) and install the balance wheel. Blow air on the balance wheel and record a video of how it moves and stops.

3. With both the pallet fork and balance wheel removed, put a little wind on the watch and record the gear train.

UNLucky

·You did just point something out that I'm not positive is happening. I don't think the watch is getting a wind. But I shall do these steps and record them. Maybe I got a defective mainspring. I'll complete tonight. Thank you!

rendo

··faux legendI would check the direction of the mainspring. You may have installed it the wrong way.

Good luck!

Good luck!

UNLucky

·I bought a new mainspring. You're saying there's an upside down!?! Ugh. (I'm only slightly joking. I'm crazy scared to open the mainspring up, I already launched one.) I'll look at that too after doing the above steps.

rendo

··faux legendTypically the colored side of the mainspring faces up when you are installing it. Did you make sure to check if the notch on the arbor was catching the mainspring? You can troubleshoot that before reopening the barrel. If you have to open it, some people do that inside a ziplock bag to be safe.

JimInOz

··Melbourne Australia................. I pull the crown out to wind and only the gears on the bottom move, nothing moves on the face side, to include the mainspring. ...................

Push the crown right in and wind slowly/gently, watch the crown wheel and the ratchet wheel to see that they rotate.

Report back.

Archer

··Omega Qualified WatchmakerI bought a new mainspring. You're saying there's an upside down!?! Ugh. (I'm only slightly joking. I'm crazy scared to open the mainspring up, I already launched one.) I'll look at that too after doing the above steps.

UNLucky

·UNLucky

·All the research I've done shows this is in backwards. Damn it. Was so meticulous! I'll redo it once my tool gets here. I'll update the post once that happens.

UNLucky

·Ok. So here's an update. The mainspring was backwards, so learned quickly how to do a mainspring wind with the tool. My first one! See attached video for the spring actually winding and giving power to the train and escape wheel. So far, so good.

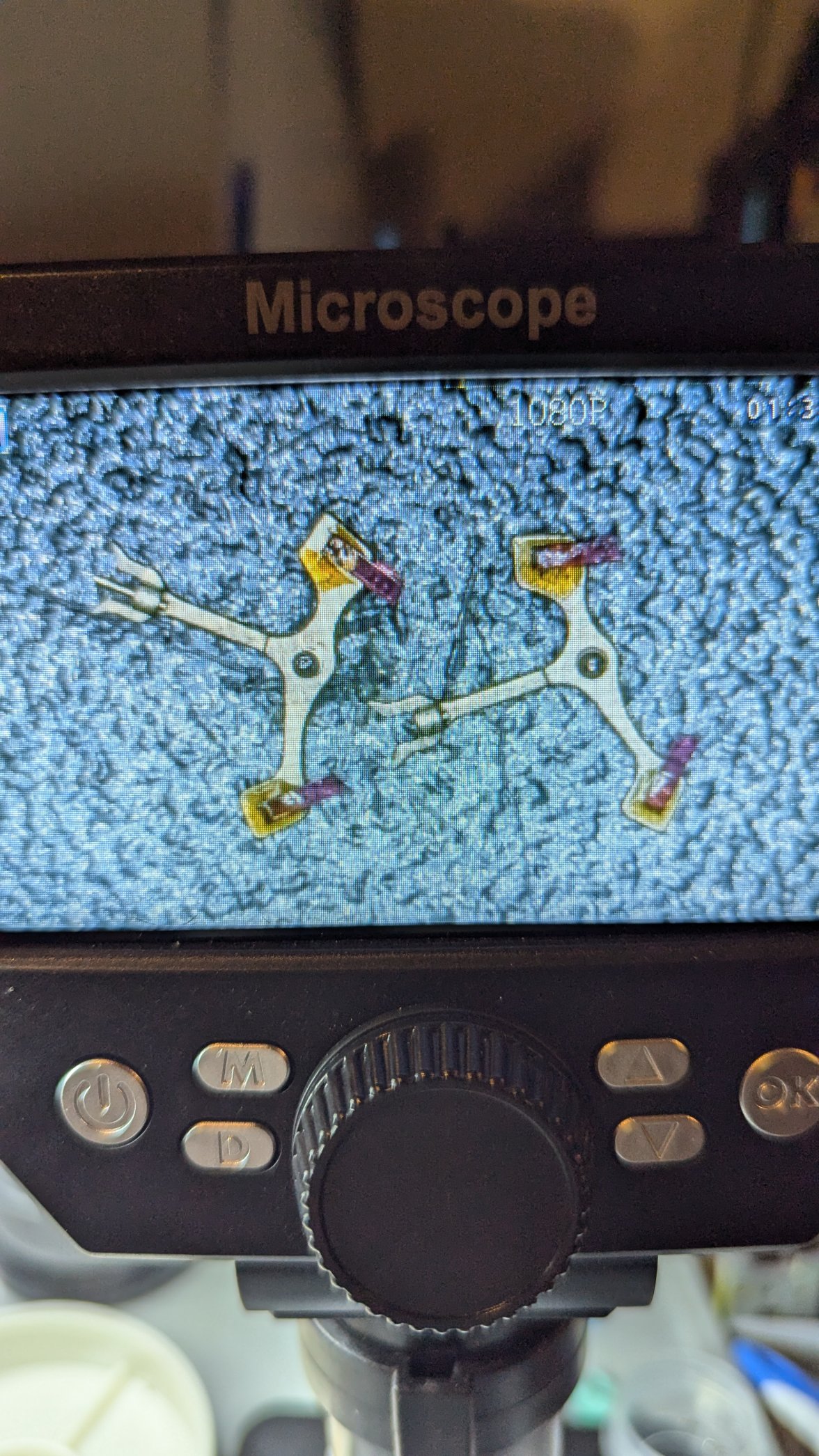

I have 2 replacement forks. One came damaged, the other has an extra time in the center of the catch, I legit do not know if my old one was broken or if it's supposed to have three. I'm also unsure where the post should be when I install the balance? Center left or right? I also believe I was using the wrong screws for the pallet support, which was providing too much tension. So, got the right screws, got the new pallet fork, actually have tension from the main spring. Install it all....same thing. Pallet fork will not move. I'm going to get a video of it attempting, the balance does rotate back and forth and looks great, but soon does down without the pallet moving either way. I'm open to ideas.

I have 2 replacement forks. One came damaged, the other has an extra time in the center of the catch, I legit do not know if my old one was broken or if it's supposed to have three. I'm also unsure where the post should be when I install the balance? Center left or right? I also believe I was using the wrong screws for the pallet support, which was providing too much tension. So, got the right screws, got the new pallet fork, actually have tension from the main spring. Install it all....same thing. Pallet fork will not move. I'm going to get a video of it attempting, the balance does rotate back and forth and looks great, but soon does down without the pallet moving either way. I'm open to ideas.