UNLucky

·I posted this in the Vintage forum as well, but it was recommended I post here as well. So here it is. Sorry for the dupe.

Good afternoon all.

I'm writing this from work, so pictures to follow, but this is my first attempt. I took a big bite and I love it, but I've had a few missed steps and I'm learning as I go.

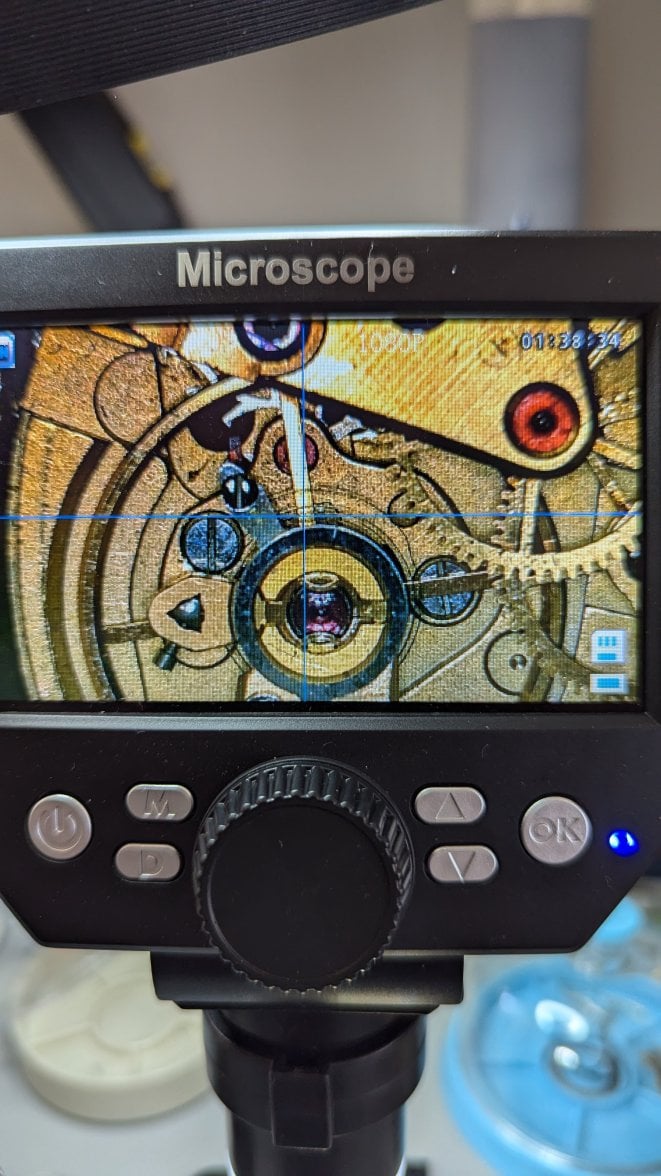

Here's where I'm at. I have the train of wheels installed and everything is working beautifully, flip it over and install the crown and the gears and go to install the pallet fork and THAT'S where everything goes wrong. before the pallet fork I can use the crown to wind everything up and all the wheels move and it is smooth, once I install the pallet fork, the escape wheel stops moving. I cannot figure out what would be the cause. I will update a picture and maybe a video if I can when I get home tonight, just trying to create the post now to get the ideas flowing.

BLUF: Installed everything up to the pallet fork and works well, pallet fork installed, hangs on the escape wheel.

Look forward to learning with you all! Thank you!

Good afternoon all.

I'm writing this from work, so pictures to follow, but this is my first attempt. I took a big bite and I love it, but I've had a few missed steps and I'm learning as I go.

Here's where I'm at. I have the train of wheels installed and everything is working beautifully, flip it over and install the crown and the gears and go to install the pallet fork and THAT'S where everything goes wrong. before the pallet fork I can use the crown to wind everything up and all the wheels move and it is smooth, once I install the pallet fork, the escape wheel stops moving. I cannot figure out what would be the cause. I will update a picture and maybe a video if I can when I get home tonight, just trying to create the post now to get the ideas flowing.

BLUF: Installed everything up to the pallet fork and works well, pallet fork installed, hangs on the escape wheel.

Look forward to learning with you all! Thank you!