1039 flat link stretch bracelet springs

wsfarrell

·Has anyone tried to source the spring material?

OF member McGyver used .2mm stainless spring steel, and had (or built) the necessary tools for cutting and shaping it. Details here.

ChrisN

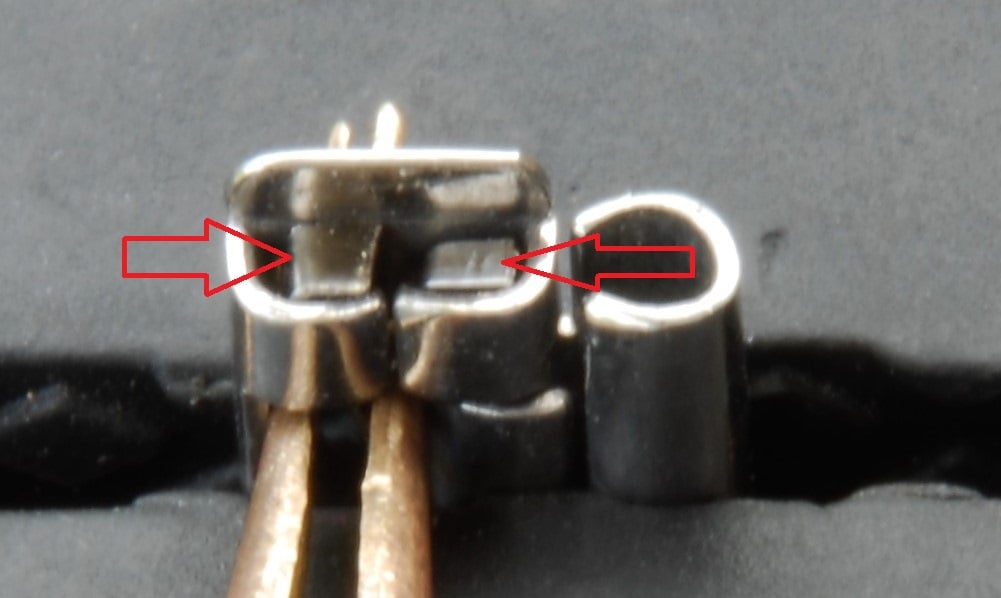

·Hi Chris, great right up. If I understand this correctly, a spring can be installed where the red line is, snugging up the clasp connecting link? Both my 7912 and 1039 look like your picture with gaps at this connection.

The one I did above is the lower one in your picture @stefman - you can see the springs in this shot - one on each side. This snugs everything up. The other one is the same design so a spring should go in but I don't have any left to do it. I did have to slightly trim back the other end of the spring to get it in but that will be clear when you do it.

@kingsrider - I don't know the dimensions/design of a 7912 but I suspect it is similar. I don't know if these springs will work, though.

Cheers, Chris

ChrisN

·Some people use watch mainsprings for this purpose. It's spring steel (obviously), and can be obtained in the right width. I tried this a couple years ago and located the right size mainspring, but I lacked the necessary skills to bend it in the right shape.

OF member McGyver used .2mm stainless spring steel, and had (or built) the necessary tools for cutting and shaping it. Details here.

Nice work by @mcgyver 👍

Unfortunately, it seems that Urdelar are now out of stock as I've bought the last four... I've written to Mikael to see if he is likely to get any more in and if he does, then I will just buy from there as they've gone to the trouble of making these for us.

If he's not interested in having more made:

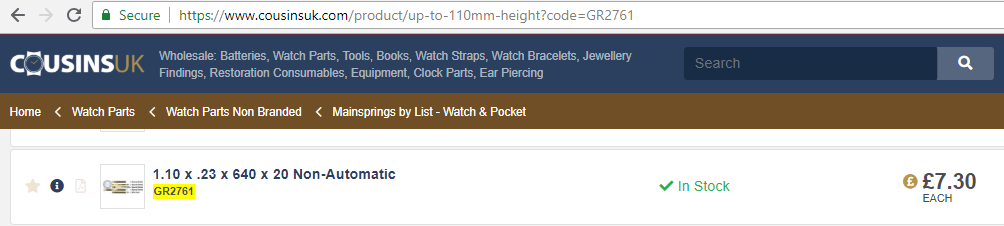

a. If you want to try and make some yourself, the most suitable watch mainspring from GR would be GR2761, which is 1.10 high and 0.23 thick so is very close to the Omega original spec. It's not stainless but at €10 for 640 mm length, it would make a lot of these, probably enough for a complete bracelet refit. The problem will be forming them...

b. If there was sufficient interest, I could ask about having some made in UK from stainless spring steel. They might be a little cheaper than Urdelar but, they will sell them in ones and twos if you want and I wouldn't do that. Thinking as I type, I suspect to sell them in a minimum order of ten would probably be the way to go. I'm a watchmaker, not a parts supplier so wouldn't want to get involved in little orders as it would just take up my time plus I'd probably have to make a minimum order in the hundreds with any supplier.

Let's see what reply I get from Urdelar.

Cheers, Chris

stefman

·The one I did above is the lower one in your picture @stefman - you can see the springs in this shot - one on each side. This snugs everything up. The other one is the same design so a spring should go in but I don't have any left to do it. I did have to slightly trim back the other end of the spring to get it in but that will be clear when you do it.

@kingsrider - I don't know the dimensions/design of a 7912 but I suspect it is similar. I don't know if these springs will work, though.

Cheers, Chris

Thanks Chris, I have 2 left, will put them in. I wear my Speedy on a daily basis and quite often on the 1039 bracelet. Will get them in. Thanks for your help, much appreciated!

Archer

··Omega Qualified Watchmakera. If you want to try and make some yourself, the most suitable watch mainspring from GR would be GR2761, which is 1.10 high and 0.23 thick so is very close to the Omega original spec. It's not stainless but at €10 for 640 mm length, it would make a lot of these, probably enough for a complete bracelet refit. The problem will be forming them...

Indeed. Not as easy as some have indicated. Mainsprings don't like being bent at severe angles...

stefman

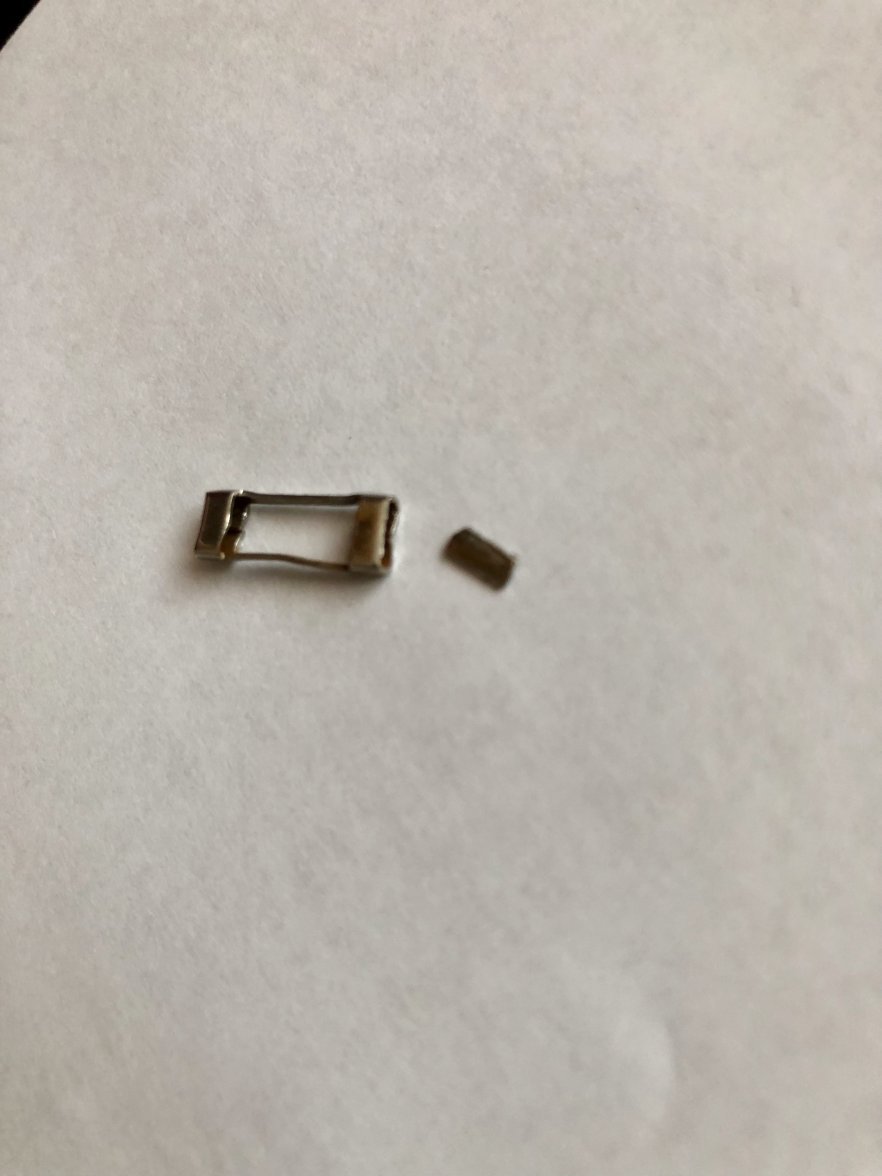

·Just finished trying to fix my bracelet and it was a disaster. Broke a bracelet link, broke the tip to my bergon spring bar tool, lost two springs. Obviously, I’m not meant to be a watchmaker.

ChrisN

·What do you mean by "broke a bracelet link"? Do you have a picture of it?

The springs won't be far away and you shouldn't have needed the spring bar tool but, you can buy replacement ends for them.

Cheers, Chris

The springs won't be far away and you shouldn't have needed the spring bar tool but, you can buy replacement ends for them.

Cheers, Chris

mozambique

·Hi Chris, great right up. If I understand this correctly, a spring can be installed where the red line is, snugging up the clasp connecting link? Both my 7912 and 1039 look like your picture with gaps at this connection.

A spring is located in the link to the right which then snugs it against the red line

mozambique

·Awesome link!

Good to know which pocket watch mainspring to order. Gotta give it a go, Archer's heads up notwithstanding

Good to know which pocket watch mainspring to order. Gotta give it a go, Archer's heads up notwithstanding

mozambique

·Nice work by @mcgyver 👍

Unfortunately, it seems that Urdelar are now out of stock as I've bought the last four... I've written to Mikael to see if he is likely to get any more in and if he does, then I will just buy from there as they've gone to the trouble of making these for us.

If he's not interested in having more made:

a. If you want to try and make some yourself, the most suitable watch mainspring from GR would be GR2761, which is 1.10 high and 0.23 thick so is very close to the Omega original spec. It's not stainless but at €10 for 640 mm length, it would make a lot of these, probably enough for a complete bracelet refit. The problem will be forming them...

b. If there was sufficient interest, I could ask about having some made in UK from stainless spring steel. They might be a little cheaper than Urdelar but, they will sell them in ones and twos if you want and I wouldn't do that. Thinking as I type, I suspect to sell them in a minimum order of ten would probably be the way to go. I'm a watchmaker, not a parts supplier so wouldn't want to get involved in little orders as it would just take up my time plus I'd probably have to make a minimum order in the hundreds with any supplier.

Let's see what reply I get from Urdelar.

Cheers, Chris

GR?

As in GR2761.......please can you elaborate......google not giving me much.......thanks!

ChrisN

·The side broke off, guess I could find someone to weld it back maybe.

I started this thread to show my experience with the springs that are commercially available and to see if they are fit for purpose. In the first post, I deliberately didn't explain how I worked on the links but as it was clear people would have a go, I thought it safest to at least show my method rather than having people pry with pliers and so on. In that post, I said "This is hardly watchmaking but, the parts are fairly small and expensive to replace so please, don't do this and damage your bracelet if you are concerned.". I'm a bit concerned now that I'm assuming a level of delicate touch that people don't necessarily have so please, if in any doubt, please give the bracelet to your watchmaker as I really don't want to be responsible for lots of broken bracelets.

Regards, Chris

ChrisN

·Chris,

GR?

As in GR2761.......please can you elaborate......google not giving me much.......thanks!

You need to be very careful if you're not used to dealing with such things. The spring comes coiled inside a "washer" ready to press directly into the barrel. You will need to uncoil it from the washer but, this is a strong spring and if it flies out, it could very well hurt you - it could easily cut you but be very careful of your eyes as this could blind you. Certainly wear safety goggles when uncoiling it and protect your fingers and arms. I'm a bit wary of describing how to get it out in detail bearing in mind the link problem that @stefman had above.

As Al said, these tight bends are a pain and you'll probably just break the spring. There is an equivalent in watchmaking where we need to bend a mainspring back on itself for very old watches - it's explained in Figure 141 of Practical Watch repairing by De Carle which is available on Kindle for about the same price as the mainspring above. With that method, you would be able to form the shape required. Good luck!

Cheers, Chris

OMTOM

·Very interesting Chris. Can you break into safes as well?

Tom

Tom

stefman

·That's upsetting. I am very surprised that you managed to break this by following my post above. You're holding the link down to the bench with your fingers so it limits the forces you can apply and encourages you to be gentle - many small taps being preferable to one heavy hit. At least you started with an intermediate stretch link and you clearly have lots of those within the clasp so, definitely don't have a go at the bracelet end pieces.

I started this thread to show my experience with the springs that are commercially available and to see if they are fit for purpose. In the first post, I deliberately didn't explain how I worked on the links but as it was clear people would have a go, I thought it safest to at least show my method rather than having people pry with pliers and so on. In that post, I said "This is hardly watchmaking but, the parts are fairly small and expensive to replace so please, don't do this and damage your bracelet if you are concerned.". I'm a bit concerned now that I'm assuming a level of delicate touch that people don't necessarily have so please, if in any doubt, please give the bracelet to your watchmaker as I really don't want to be responsible for lots of broken bracelets.

Regards, Chris

ChrisN

·Thanks Chris, I’m still happy to have added springs to the sections that were missing them. I have lots of links on the bracelet so it’s ok. Maybe I was going at it with too much brute force. I do appreciate you having shared here and I’m glad I gave it a try, but I think next time I go to this local guy that restores bracelets LOL! Thanks again!

Cheers, Chris

stefman

·Well done for finishing the others and I'm really pleased that those went well.👍 Who is the local bracelet restorer?

Cheers, Chris

mcgyver

·Nice work by @mcgyver 👍

Unfortunately, it seems that Urdelar are now out of stock as I've bought the last four... I've written to Mikael to see if he is likely to get any more in and if he does, then I will just buy from there as they've gone to the trouble of making these for us.

If he's not interested in having more made:

a. If you want to try and make some yourself, the most suitable watch mainspring from GR would be GR2761, which is 1.10 high and 0.23 thick so is very close to the Omega original spec. It's not stainless but at €10 for 640 mm length, it would make a lot of these, probably enough for a complete bracelet refit. The problem will be forming them...

b. If there was sufficient interest, I could ask about having some made in UK from stainless spring steel. They might be a little cheaper than Urdelar but, they will sell them in ones and twos if you want and I wouldn't do that. Thinking as I type, I suspect to sell them in a minimum order of ten would probably be the way to go. I'm a watchmaker, not a parts supplier so wouldn't want to get involved in little orders as it would just take up my time plus I'd probably have to make a minimum order in the hundreds with any supplier.

Let's see what reply I get from Urdelar.

Cheers, Chris

Mikael at Urdelar will soon have new springs in stock! 😉

I make them for him from stainless spring steel (0.2 mm thick - passed on to me from my father's company, the link mentioned above).

They are made to perform as the original Omega springs, but with a geometry so they can be fitted without having to bend out the sides of the link pieces - and risk breakage or at least stress the material.

I'm setting up a new shop right now and good contractors are as easy to find as a cheap 321-Speedy = I have to do much of the work myself so I'm not online as frequently as I would like and my time is very, very limited! (-Sorry, but having a hard time answering PM's right now!)

If you would like springs, please contact Mikael at Urdelar.se and if you have any input regarding the design, please contact me directly at info(at)urvintage.se

Best regards

Roger