I have some notes. I come from advanced manufacturing in aerospace and have a background in quality control and fabrication. I have no affiliation with any watch brand, but this kind of discussion is right up my alley.

1. I don’t think these differences should be considered quality rejects or rejections or sub-par quality as others have indicated. I will expand on this in punch point #3.

2. I believe Omega is using multiple dies. I have seen a few examples posted that are nearly identical to mine and near the same collection time (24Q3). It would make sense that Omega has 3-4 dies with 1 master die they use as a function tool or test/QA control that is NOT used for production. These may have all been made at the same time, of they (more likely) they have made more dies recently as they decided to continue production past the “assumed” 5yr run. The market is dictating this run, and I think they only initially planned to make 4-5k of these pieces and only planned to have a few dies execute this release. I don’t think they would have more than a handful of these snoopy dies made, and I think it is next to zero likelihood they use a single stamp. These are obviously batch made. Maybe 20x at a time. Maybe 50x. Maybe 100x. I can’t imagine batches being larger than this.

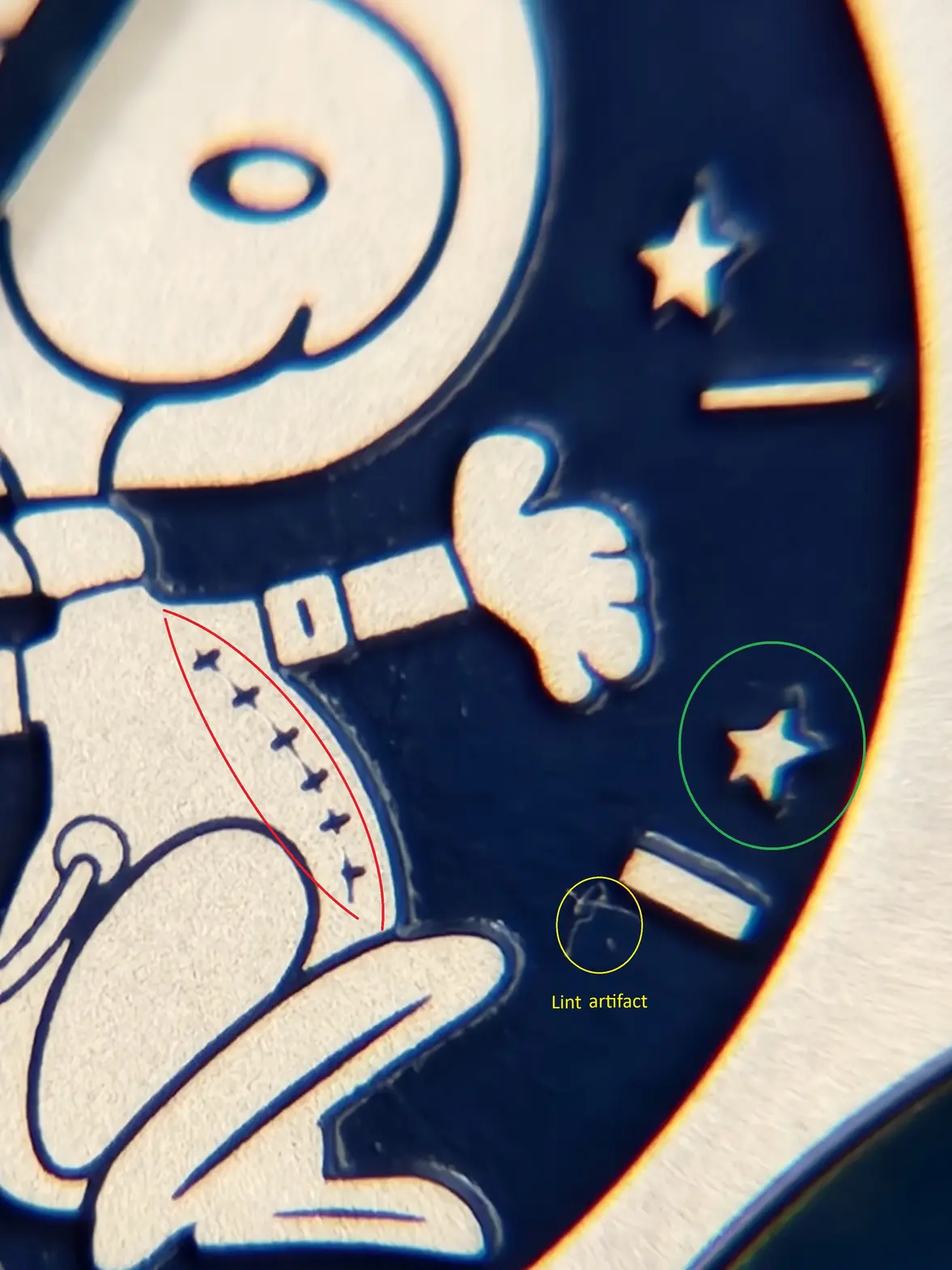

If you look at the differences illustrated above. The "50th" text is wildly different in thickness. and the star pattern doesn’t look exact.

3. Quality Control. As with everything with tight tolerances, it is impossible to make two identical things. Let alone tens of thousands. There are tolerances and acceptance criteria. Yes, Omega has a quality control or quality assurance program, it would be impossible to be as successful as they are without a QA Dept. Is any QA dept 100% no. But again, I don’t view these quality rejects. I will explain why:

What is a tolerance range: If I design a block of cheese in CAD with the dimensions of 1.00” x 2.00” x 3.00”. When I cut the cheese using a tape measure and a sharp knife, I can probably get close with say 1.24” x 1.91” x 3.05. Does it look like 1x2x3” block of cheese? Yes. But if I cut 10x or 100x of these cheese blocks the same way, you will start to notice dramatic dimensional variations between all of my cheese blocks. Let’s reject this lot of cheese because I think my customer that ordered these will not be happy with the precision. Let’s try to control the allowable tolerances (new acceptance criteria) by closing the delta on allowable dimensional deviation to +-0.010”. Ten thou is tricky to hit with a carving knife, so let’s change our manufacturing process to cut these cheese blocks with an endmill on a manual mill. We measure with dial calipers and make as precise as possible cutting paths. But due to the clamping loads from the vise holding the block in place, we deform the blocks slightly to make clean cuts. Our new precision machined cheese blocks are as follows:

SN 001 : x=1.05” y=1.99” z=3.00

SN 002 : x=1.02” y=2.03” z=3.01

SN 003 : x=0.98” y=2.01” z=2.95

SN 004 : x=1.00” y=2.07” z=3.05

SN 005 : x=1.09” y=2.01” z=

2.85

We managed to hit decent precision and accuracy to tolerance allowance but SN005 is just a little too out of spec and cannot be corrected. It is scrapped by my pooch (head of QA), Fez.

The takeaway from this exercise is to understand that none of our actual blocks are perfectly 1.000000 x 2.000000 x 3.000000, nor would any reasonable person expect them to be. Our blocks live in a realm of acceptability that are both larger AND smaller than nominal. This is where our snoopy sub-dial medallions live as well.

4. The production process and added complexity with “stack up tolerancing”. This involves stamping a silver plate. Which is a soft metal and unless they are precision ground, are not all going to be perfectly flat or the same exact thickness. This is our 1st tolerance to consider. They are not all the same identical thickness even if they vary by 0.00001”. This will have an effect stamping depth. In the die striking, a prescribed amount of stamping pressure is needed to stamp the silver baseplate. Tolerance #2 is press pressure, this can vary by quite a bit even between first and last striking in a batch as hydraulic fluid heats and the die itself heats up for work. Tolerance #3 is die wearing. Everything wears out, especially things in high pressure applications. A brand-new die will strike deeper than every subsequent strike if all other variables are the same. When a die no longer produces acceptable stamping, it is pulled from service and a new die is swapped into service. Now that we have our stamped snoopy medallions, they need to be blue coated with some type of paint or enamel. The thickness of this coating can vary as well across a single batch depending on how heavy or light handed the application process is. This may be automated, it may not. But even in an automated process, it still will have lighter coated and thicker coated areas across the batch. This is tolerance #4, paint/coating thickness. Lastly, we have a grinding or lapping step. Tolerance #5, lapping depth. We abrade the medallion to remove the highpoints and paint/enamel from the medallion until the silver features start to show through. IF WE KEEP ABRADING, MORE MATERIAL WILL BE REMOVED. We will see certain features such as the zipper and the shoe trace lines start to become less prominent. The inverse is true about the stars in the background, the more the medallion is abraded, the more definition is achieved. This is very easily visible between examples shown. Dials that have diminished snoopy line characteristics appear to have better definition on the stars. And visa-versa. Lightly abraded medallions have better contrasting line work on Snoopy, but the stars look a mess and are barely recognizable as such.

It is important to understand the die geometry for this concept to make sense. Every edge of a feature of the die, any die, must have a positive angle or it will cause damage and undercutting. A die with perpendicular feature edges will not last long and wear out almost immediately. Because of this, when the medallion is abraded deeply, the flat plane of the star features INCREASE in size and definition and the internal Snoopy features DECREASE in size and definition. The three-dimensional structure is more of a pyramid than a block with straight sides. It is wider at its base than it is at its peak. So, the more you abrade, the larger the plane or slice of the projection gets. The same is true with all other features of this stamping.

So, in this production of making these, there is at least 5 easily recognizable manufacturing tolerances that CAN and likely DO have an impact on final presentation. A die that is worn out, that had lower than nominal press pressure, on a medallion that was thinner than normal, than had a heavy coat of paint, that was only deeply abraded will likely yield a snoopy with less defined features. On the other extreme, we can have a medallion that is thicker than nominal, struck with a brand-new die, with a warmed up machine yielding higher press pressure, that gets a thinner than nominal paint coating, that is then lightly abraded yielding an well defined snoopy.

5. Here is my takeaway. None of this really matters to me as an owner and it shouldn’t matter to anyone else really IMO. We are all looking at these under loupes. I have taken hundreds of photos of my snoopy and stared at mine endlessly and NEVER noticed this until people started talking about it. I look down at it and can’t visibly discern any issues with the naked eye. I think this is just standard manufacturing variation. I don’t think these should be graded or thought of as less than. Take a look at Omega Speedies from the past. The Moon to Mars release has WILD variation between sub-dials based on UV exposure and which sub vendor made the printings. Or any of the mission patch releases from the 80’s. Do you think owners ever noticed printing differences and shared high-res macro images to compare and complain about the quality? Absolutely not. You still have a wonderful engineered and executed special release on your wrist. It’s not a FP Journe, relax. Try to keep things in perspective. The distance between the surface of the snoopy and blue painted background is less than a sheet of paper, or 0.0025”. Two and a half thousands of an inch. With all these variables and stack up tolerances involved, I’m surprised they look as good as they do. And it took 5 years for anyone to notice. I would say this is NOT a quality issue. Furthermore. I think the MOST LIKELY explanation is that early on in production, people complained about the definition of the stars, so they started grinding more the image down to get the star resolution up. But sacrificing image definition on internal features to get there. It’s a balancing act. And it all comes down to these stack up tolerances to best case/best image quality. We haven’t seen any examples with NO zipper buttons. And no examples with pinpoint stars (no star point definition) so I believe the acceptance criteria lies between these two features and their depths.

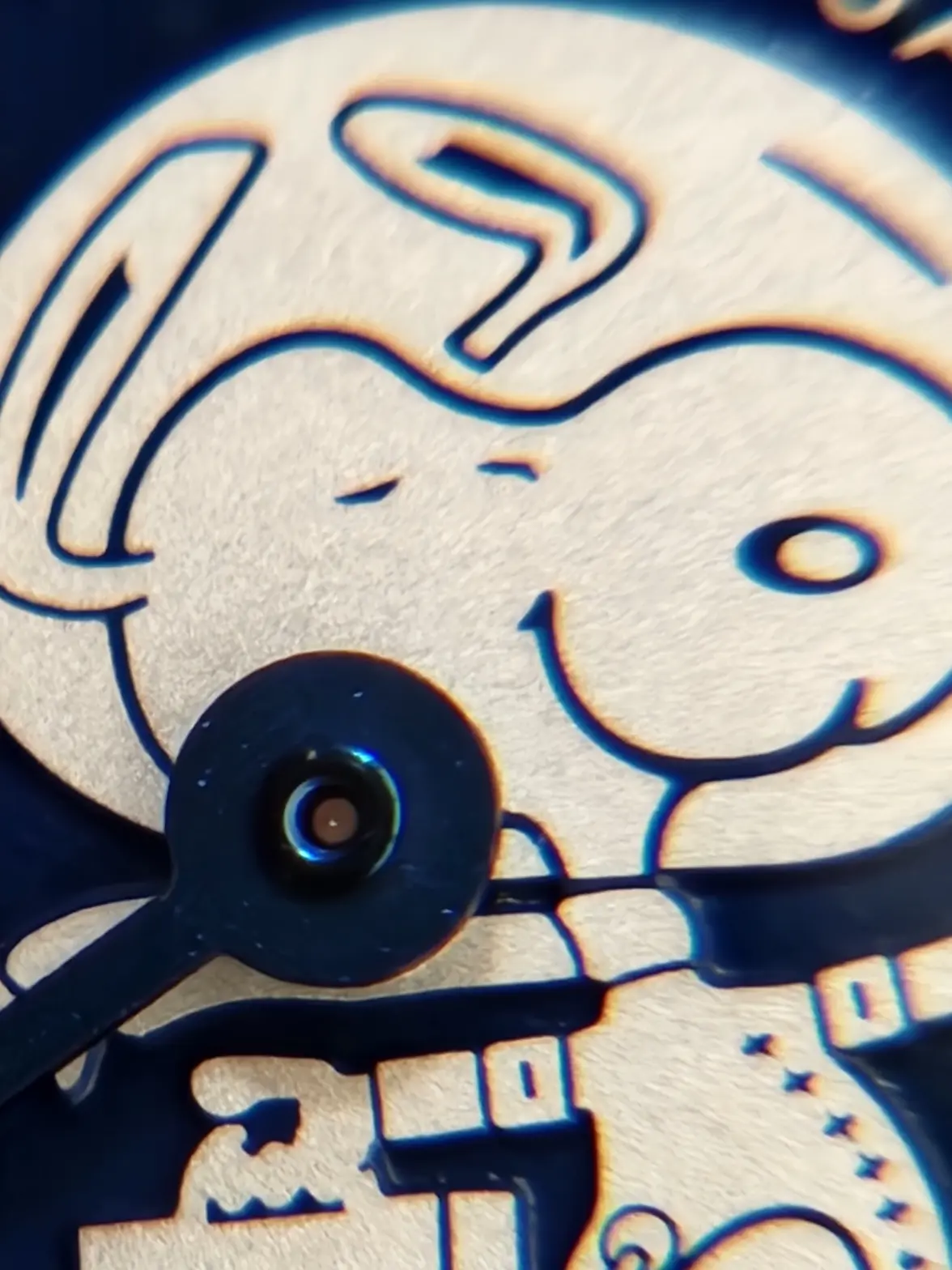

Please see a couple pictures of mine using a 10x loupe on my S22+, collected in Sept 2024 at NYC OB. A serial. I would classify mine as having a "half zipper". Love it still the same. I won’t be complaining to the boutique. This is a non-issue to my eye.