Technology is great, and things like CNC machines can be very useful in the watch production business. I’ve seen it used many times in factories, and one example comes to mind.

I was in the Patek factory and came to a CNC station where bridges were being engraved. They were held in a very expensive to make vacuum fixture, and then all the text was engraved. Here’s the fixture…you can see bridges in there as well:

There were two ladies unloading the parts and they mentioned to me that the bridges were all scrap, because the engraving that had just finished was too deep. I asked if I could have one, and they obliged. Here it is:

So, they had cut the bridge out, bored all the holes, installed the jewels, chamfered the edges, added countersinks on the holes. All that work on 25 bridges and they were all scrap likely because someone put in an incorrect Z axis offset. Having programmed CNC machines and run them, it’s easy make such a mistake on a run of parts like this.

Computer controls do not eliminate human error. Again to me this is far more likely a machining issue than a little used die wearing out.

By the way I’ve posted about this factory before, and have mentioned that they ran some of the CNC operations “lights out” meaning that they pushed the start button at the end of the day, then turned the lights out and let it run unattended. Watch production is very unglamorous in real life.

By the way, rejection rates are an interesting topic. Back before I became a watchmaker I was a full time engineer for an automotive parts supplier, tier 1 if you know what that means. I went through the introduction of quality systems, such as ISO 9000, TS 16909, etc. In all the watch factories I’ve been through, there was a dearth of quality information posted in the factories. I was used to seeing it on information boards all over the shop floor. The exception was at Patek, as

they had quality information on several boards. When I looked at the numbers, they were atrocious compared to the types of numbers that would be barely acceptable in the automotive world.

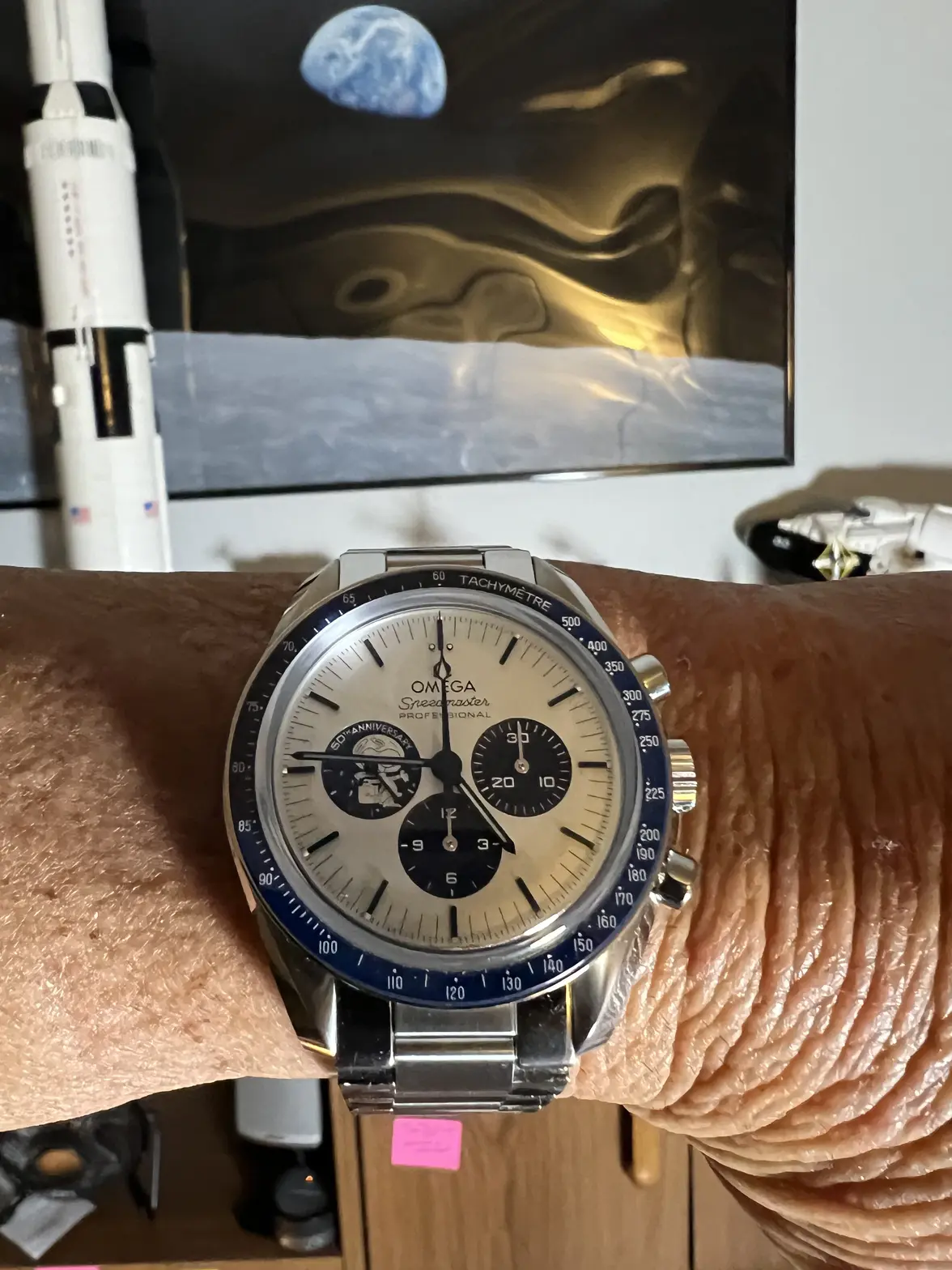

I know you have mentioned that these are Veblen goods, and you expect tight tolerances and top quality at least in part because of that. In my experience the reality doesn’t match that expectation, unless you get to a much higher tier than Omega sits at.

These are made in factories, and those factories are not much different than any other factory making some other widget. People there are factory workers just like those who assemble your cars, washing machines, TV’s, etc.