WestCoastTime

·Seamaster Cosmic cal 565, c.1970. A "modern" 1970's vibe on the outside with a very traditional watch on the inside. I like the faceted case shape (reminds me a little bit of the modern Seiko Samurai).

It's a nice looking watch, but it has had a long life & seen a lot of use. Case has lots of scuffs, but this is normal wear. Doesn't explain how the dial got marked up, though.

The seconds hand will turn for short spells but then stop, & it feels like something in the winding mechanism is stuck. See how a service helps it out.

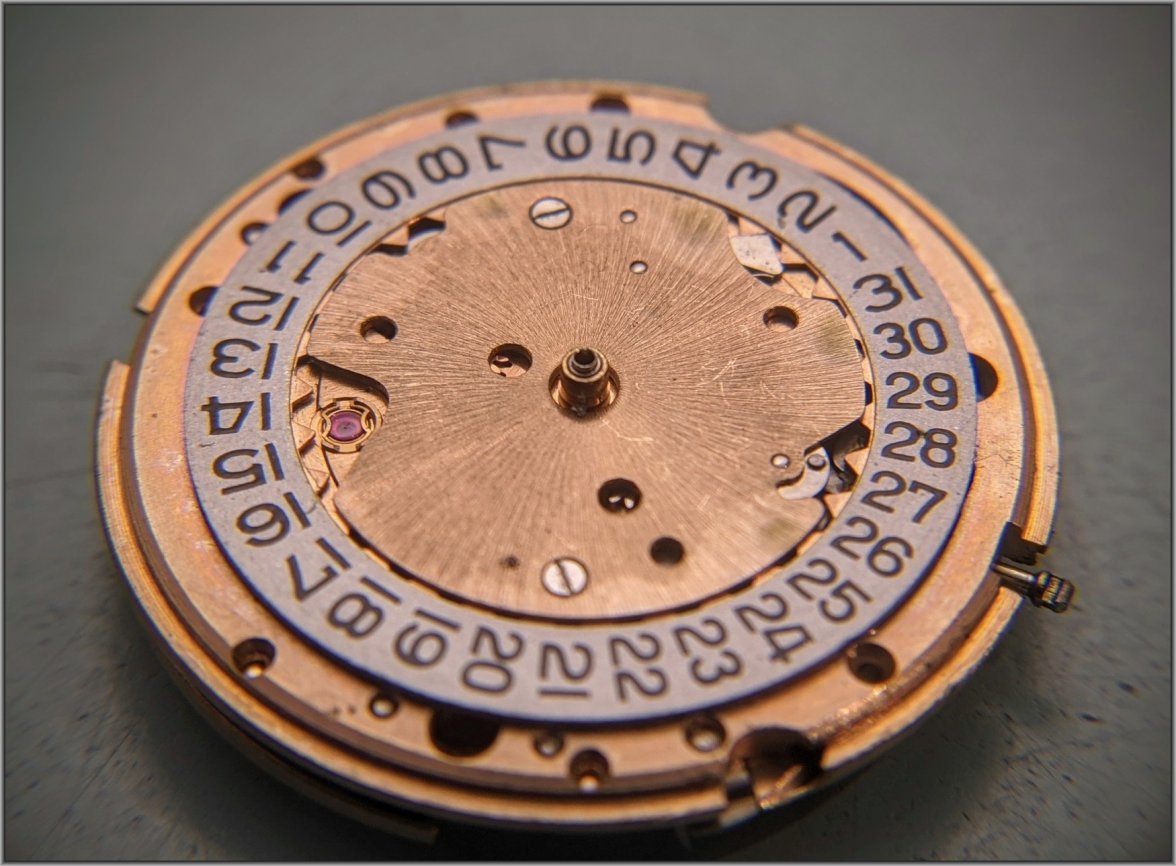

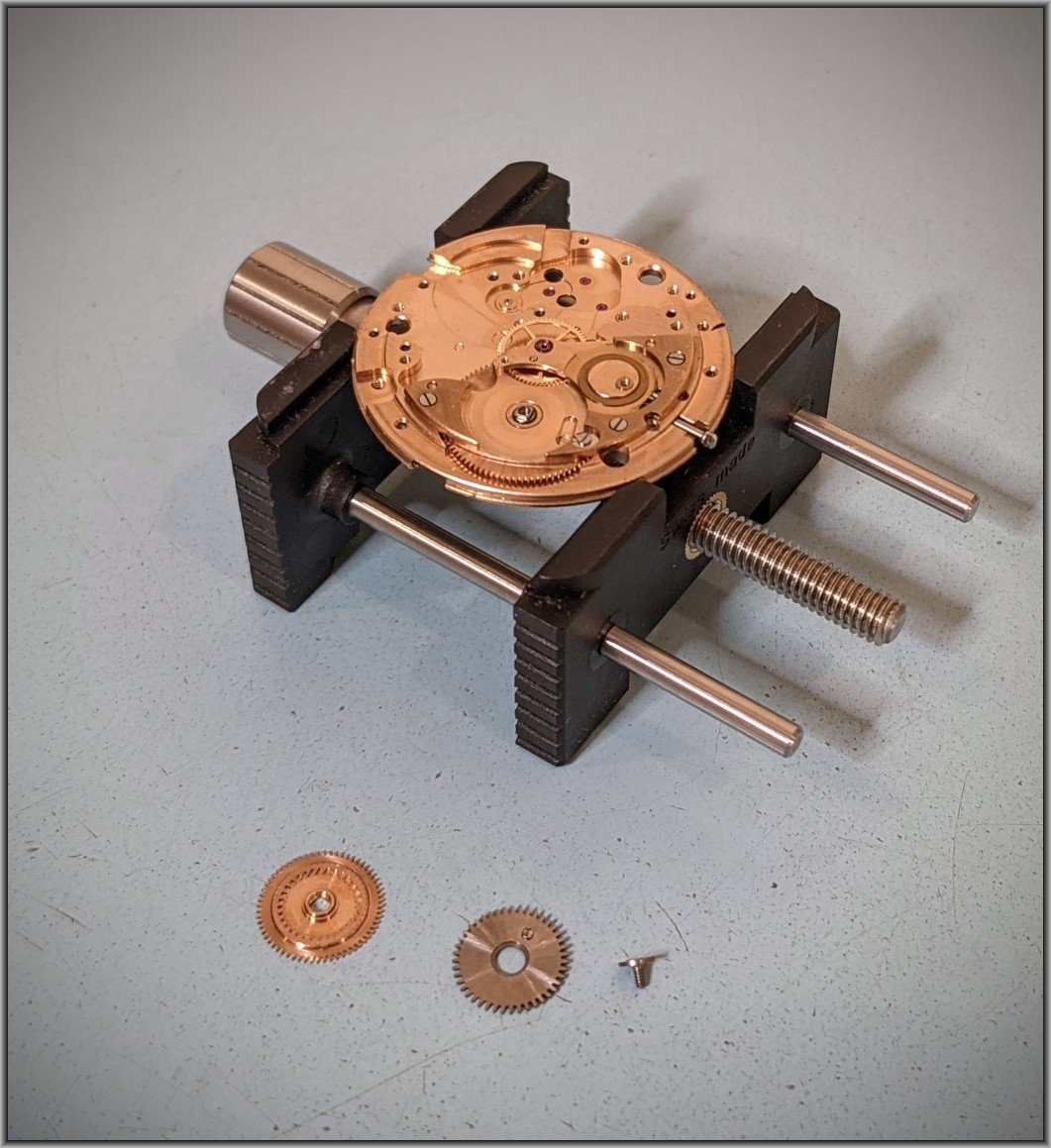

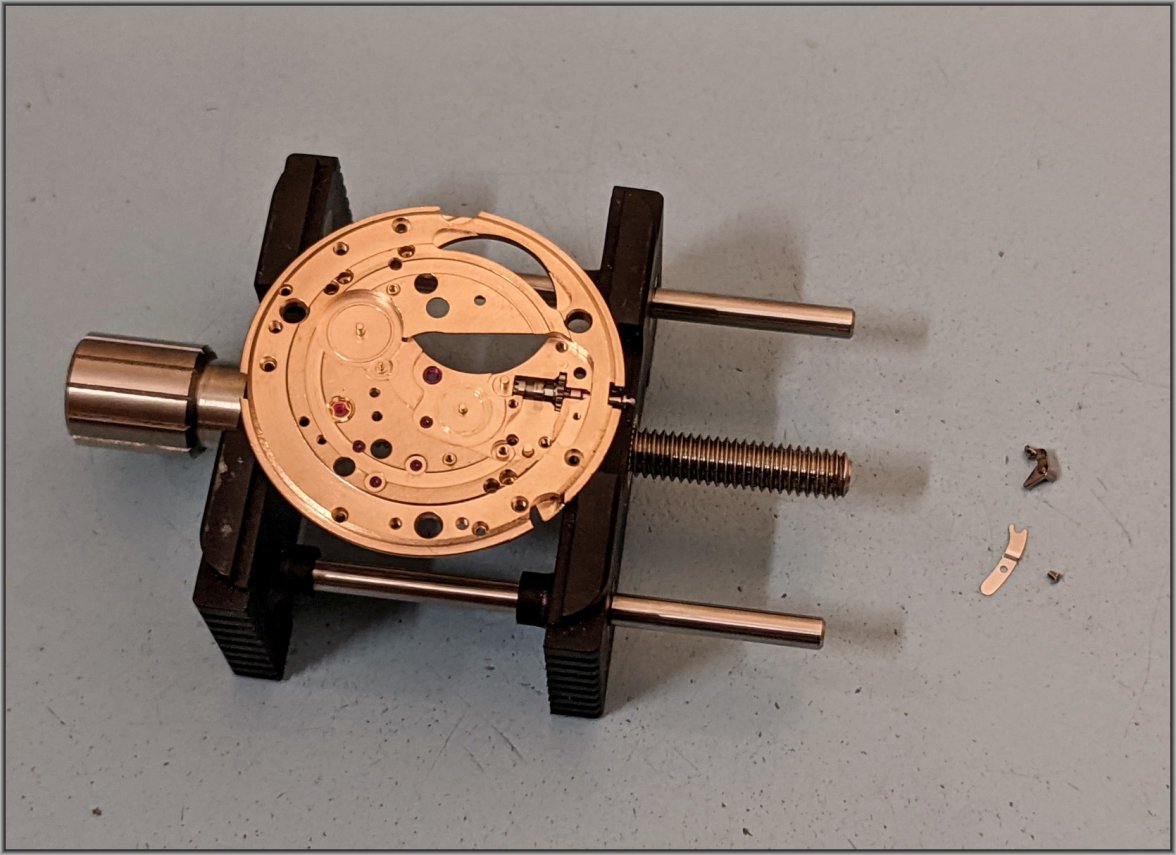

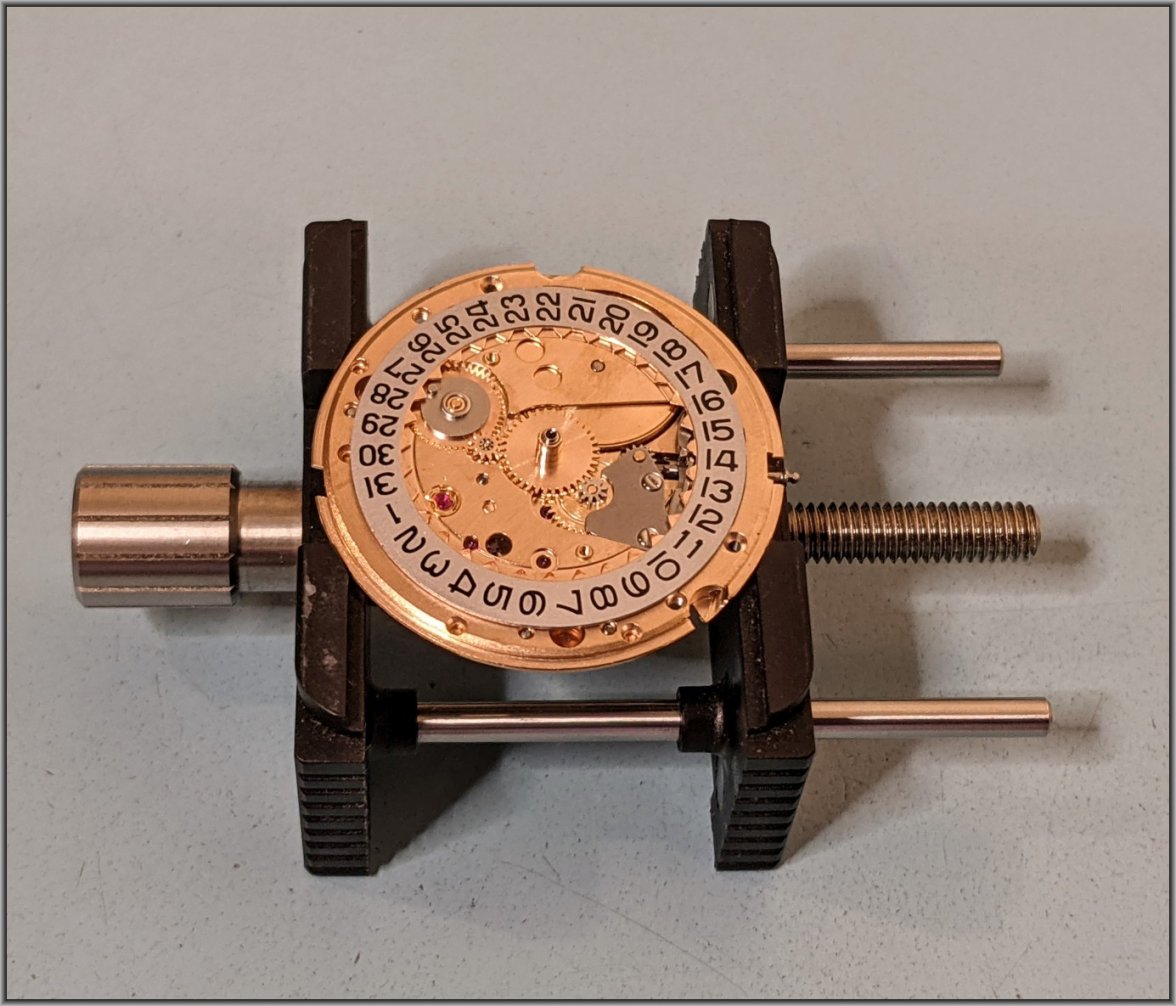

Can see puddles of excess oil on top of the calendar works cap.

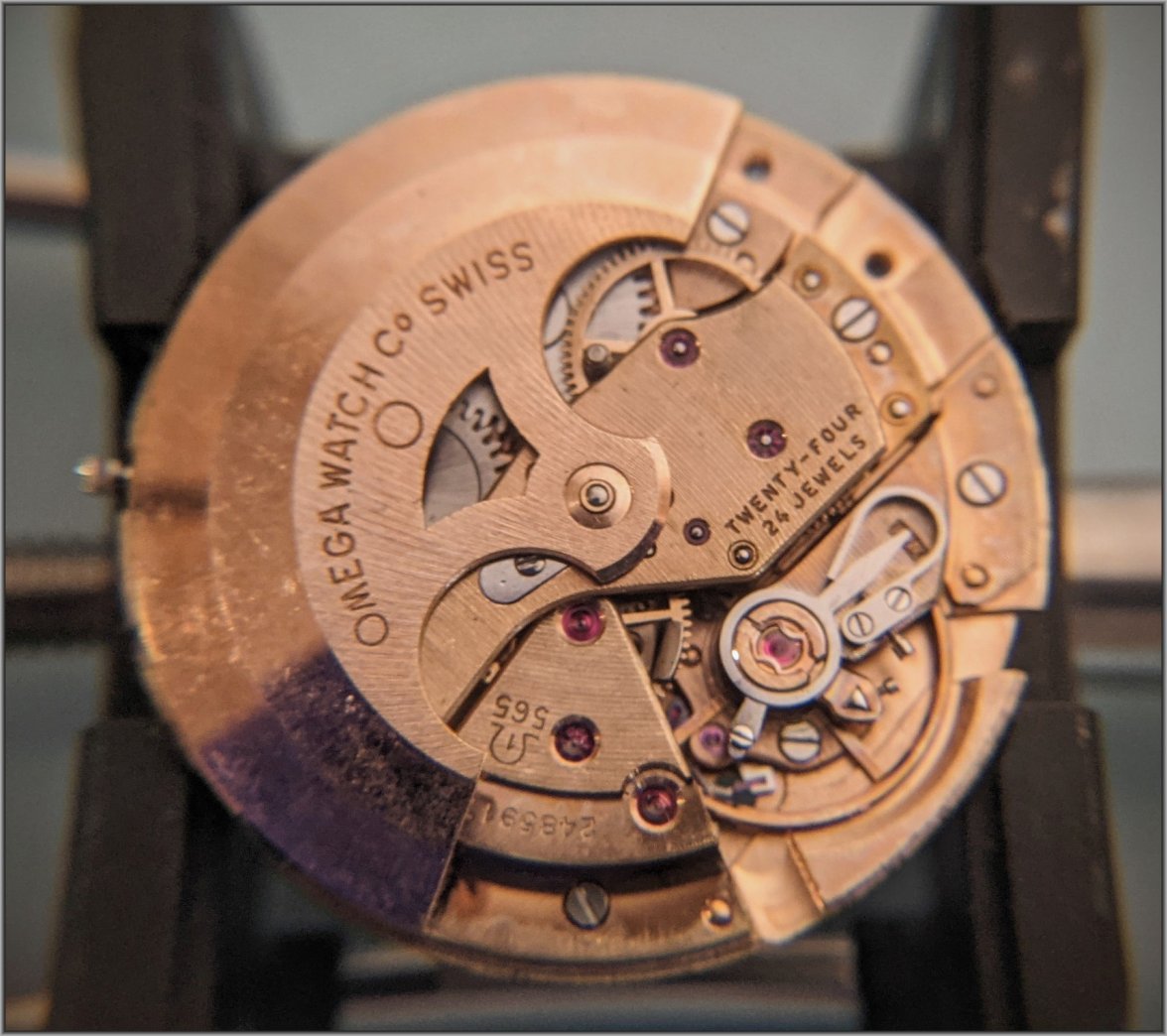

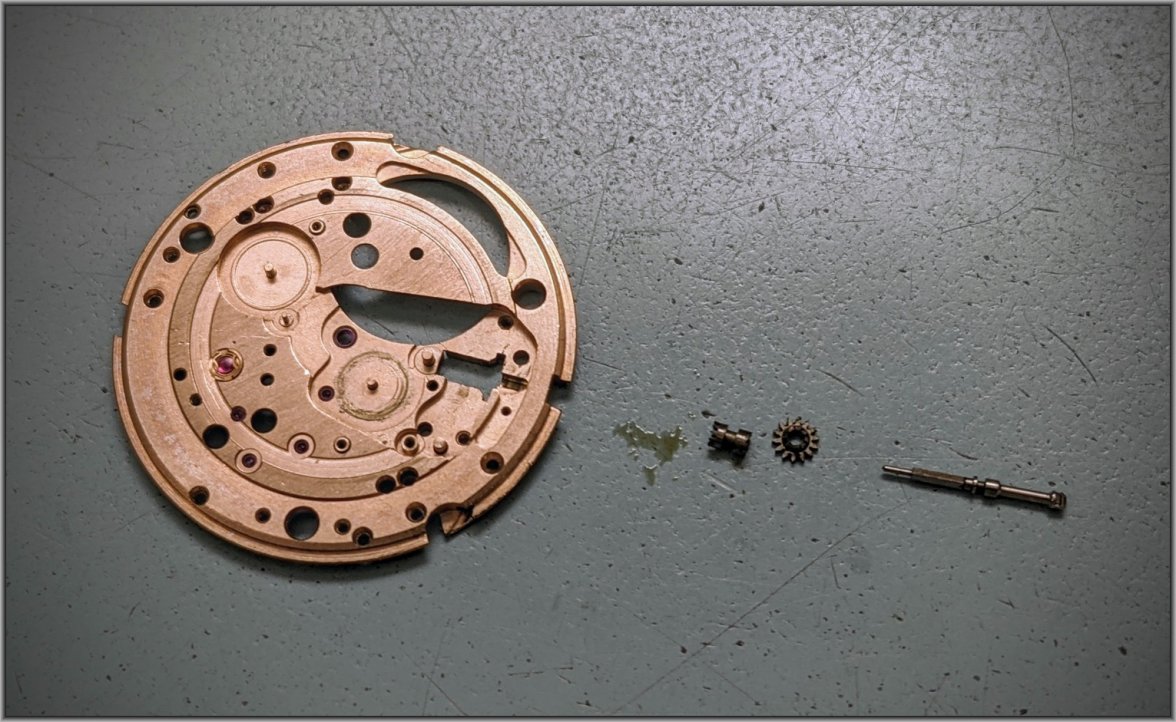

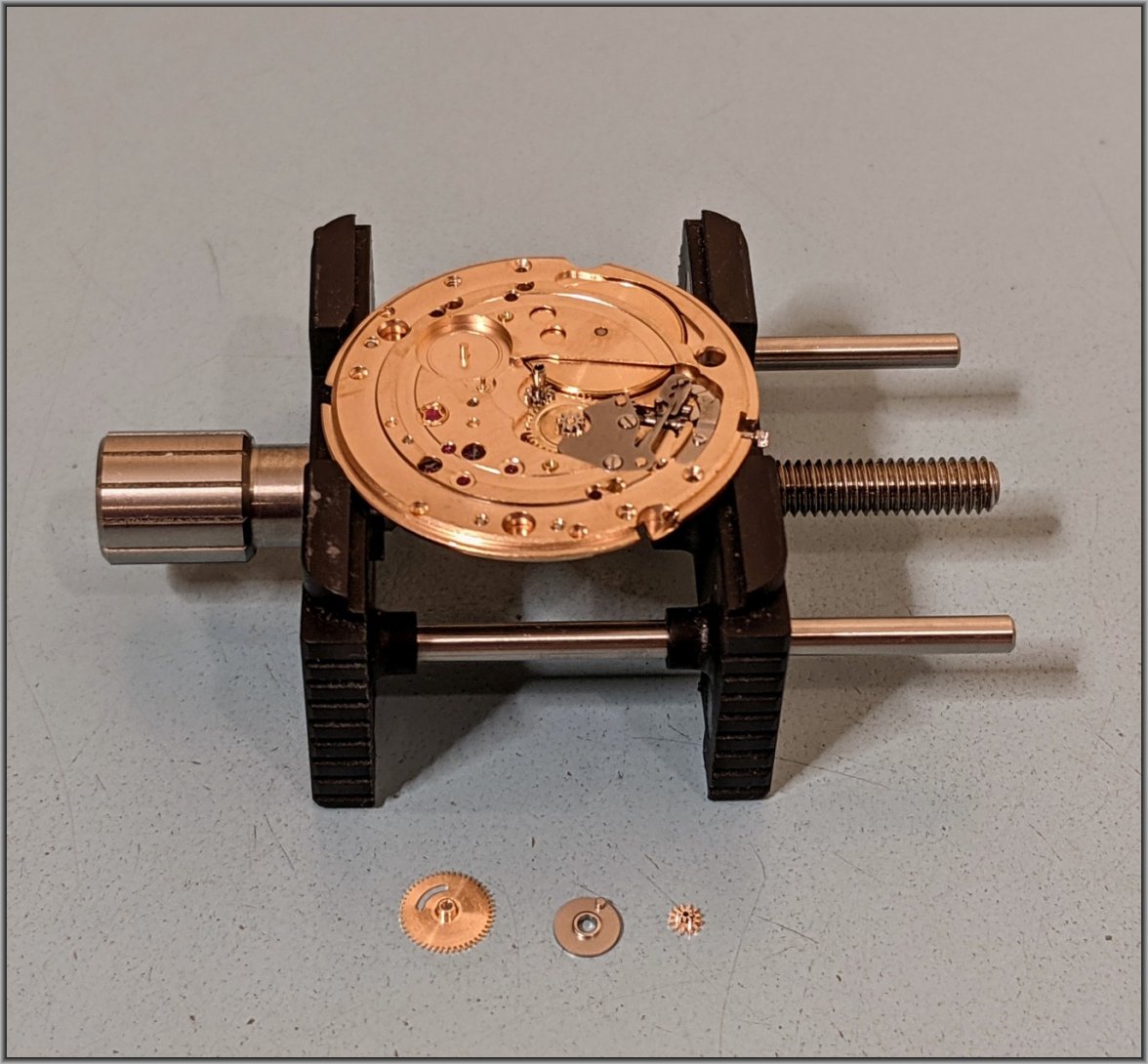

Watchmaker side of the movement (if you have sharp eyes, you can spot the beginnings of the winding / running problems…).

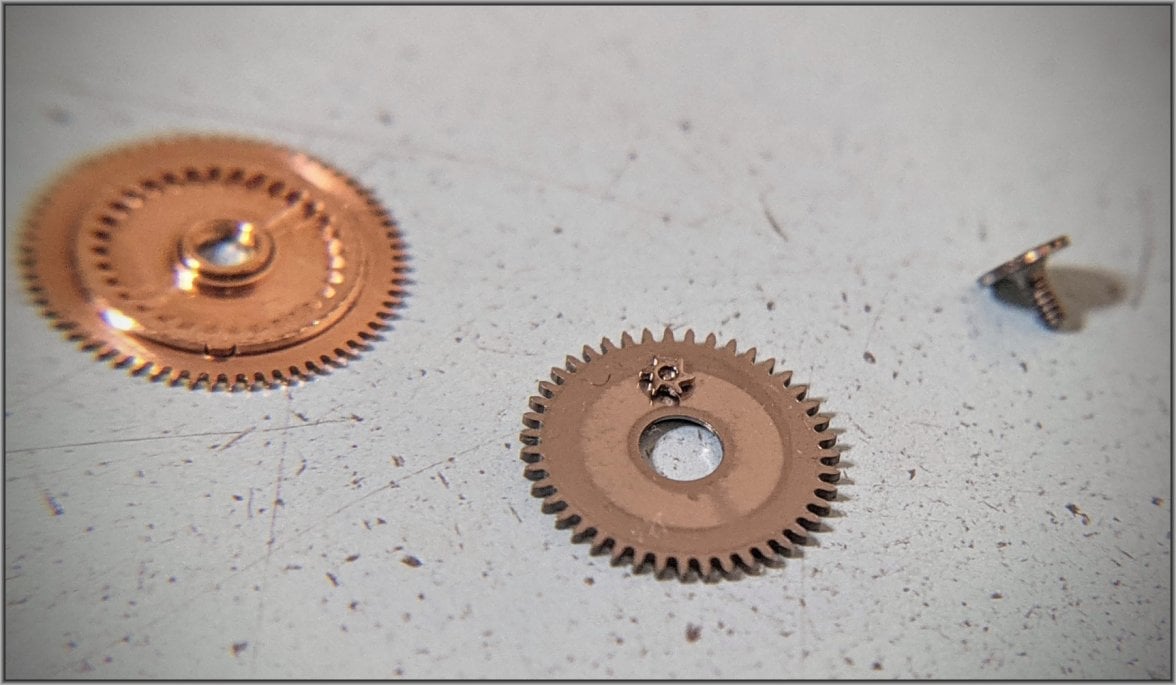

Well that's not good...

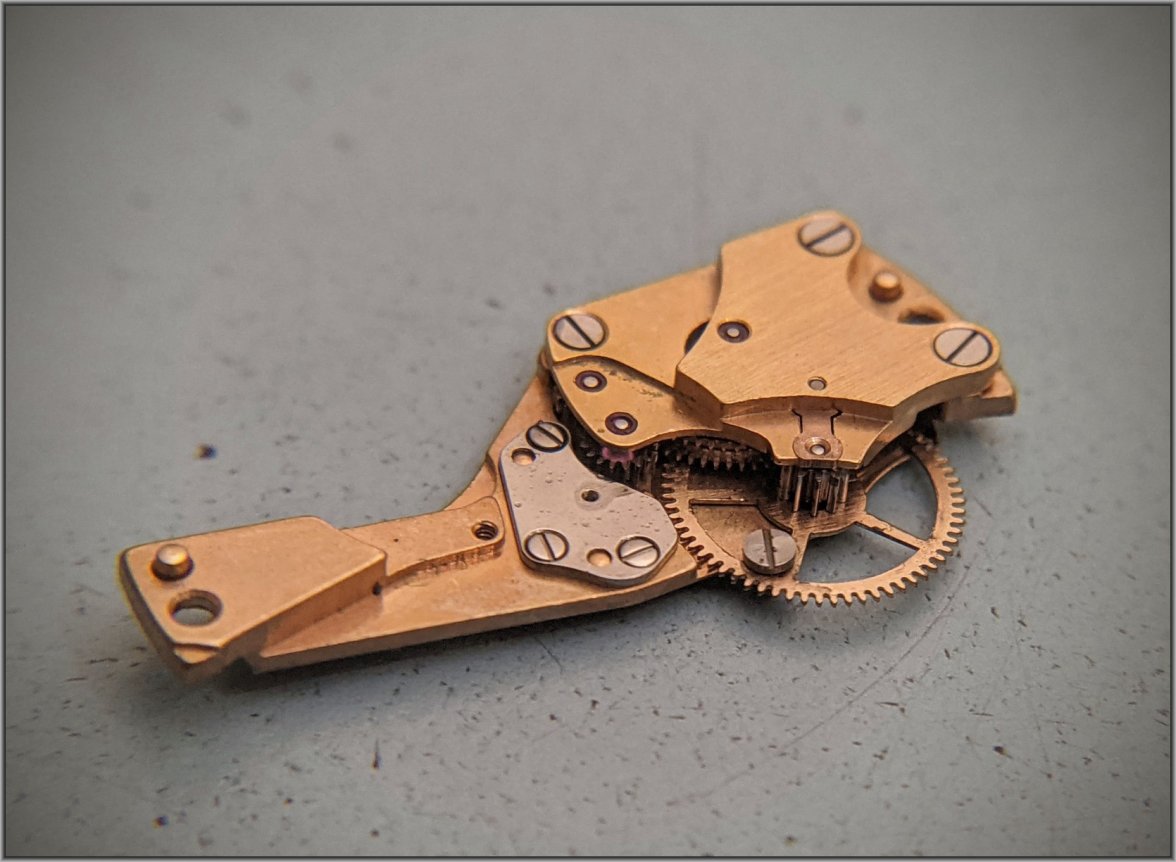

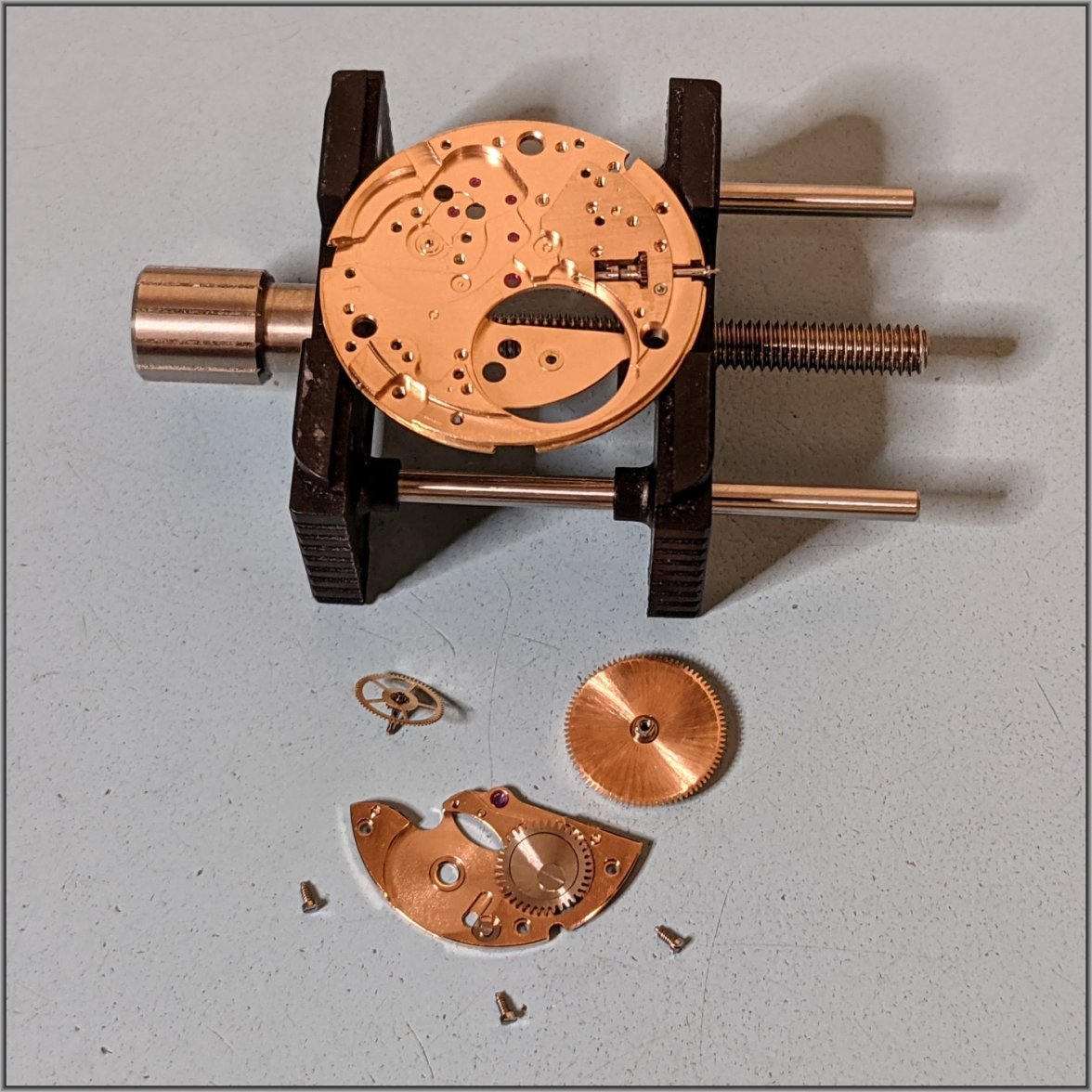

So how much damage has been done by steel pinions turning brass wheels when the brass wheel aren't going to move?... The brass leaves are tiny, & no match for the steel pinions of the automatic winding mechanism. Damage done, let's see how bad.

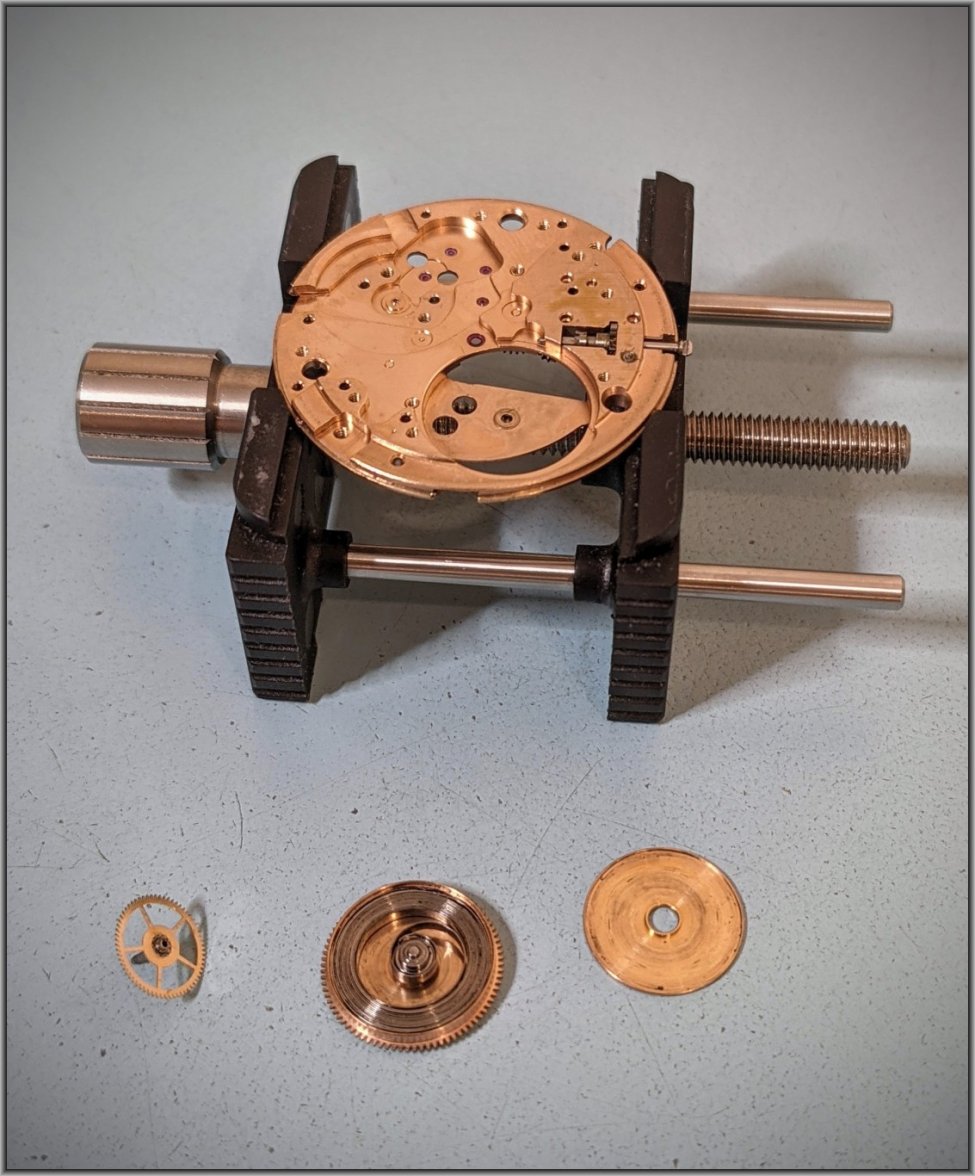

There's that screw (& more puddles of excess oil).

The intermediate winding drive wheel is what took the damage from those stray parts. This part is not salvageable, but was able to find a used whole auto-wind mechanism at a reasonable cost to serve as a parts donor.

On with the disassembly.

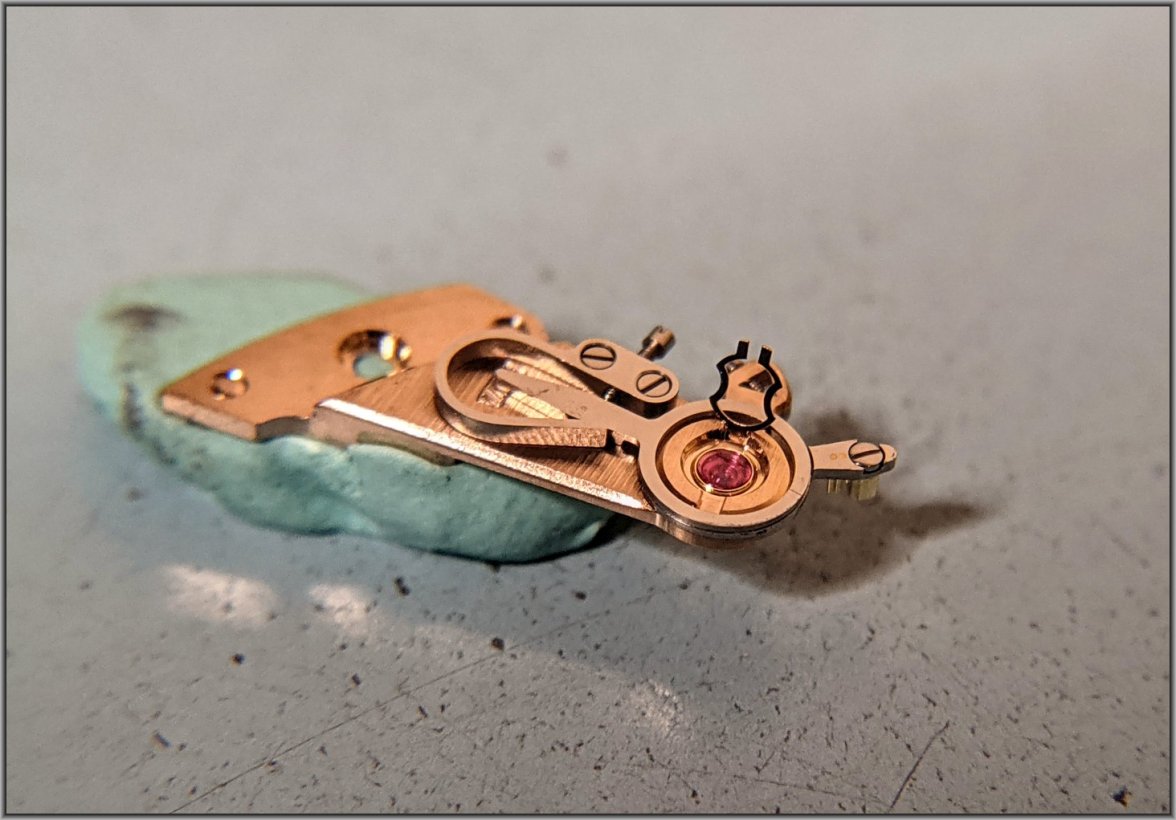

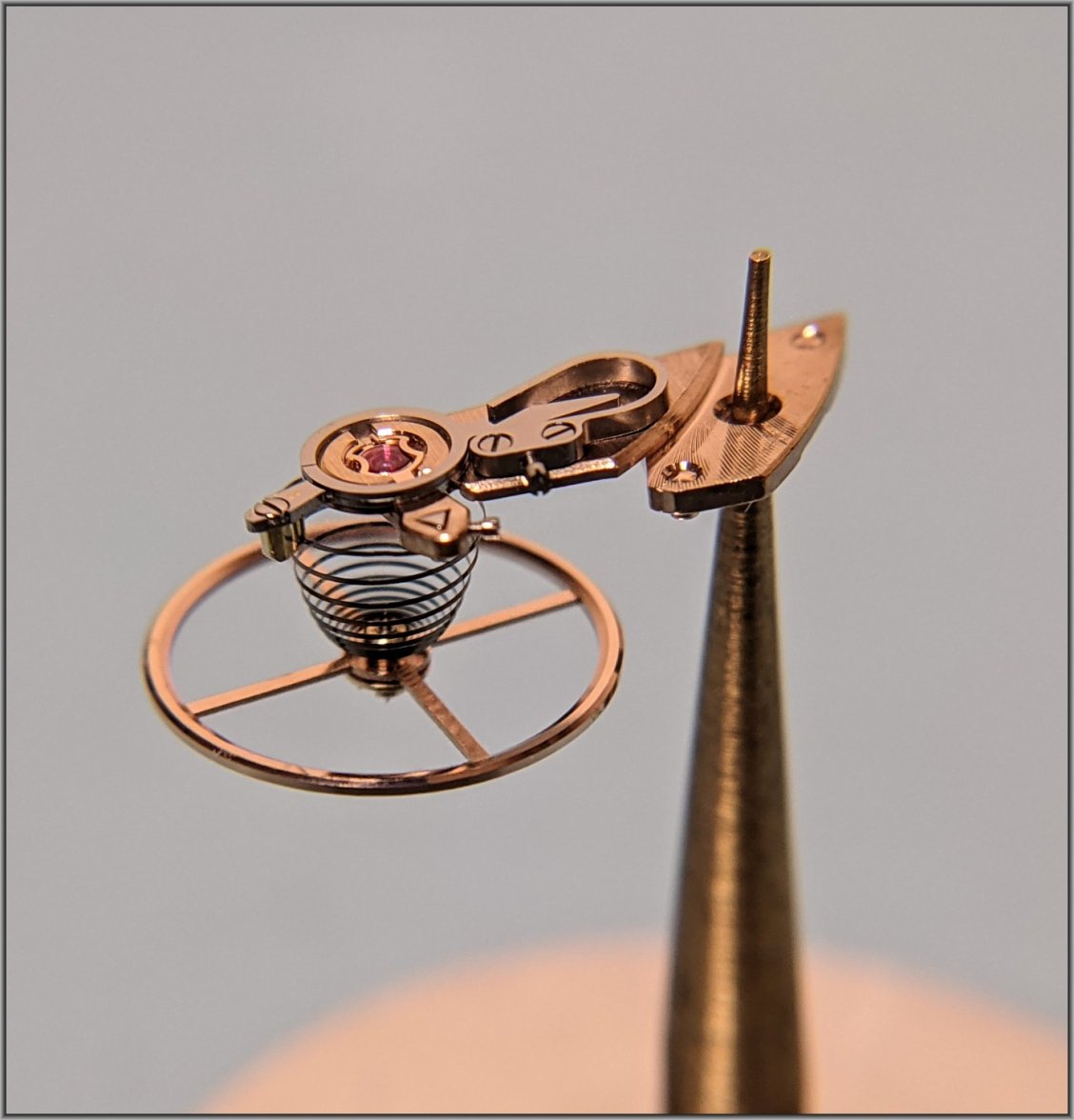

Upper balance hole jewel & upper balance cap jewel.

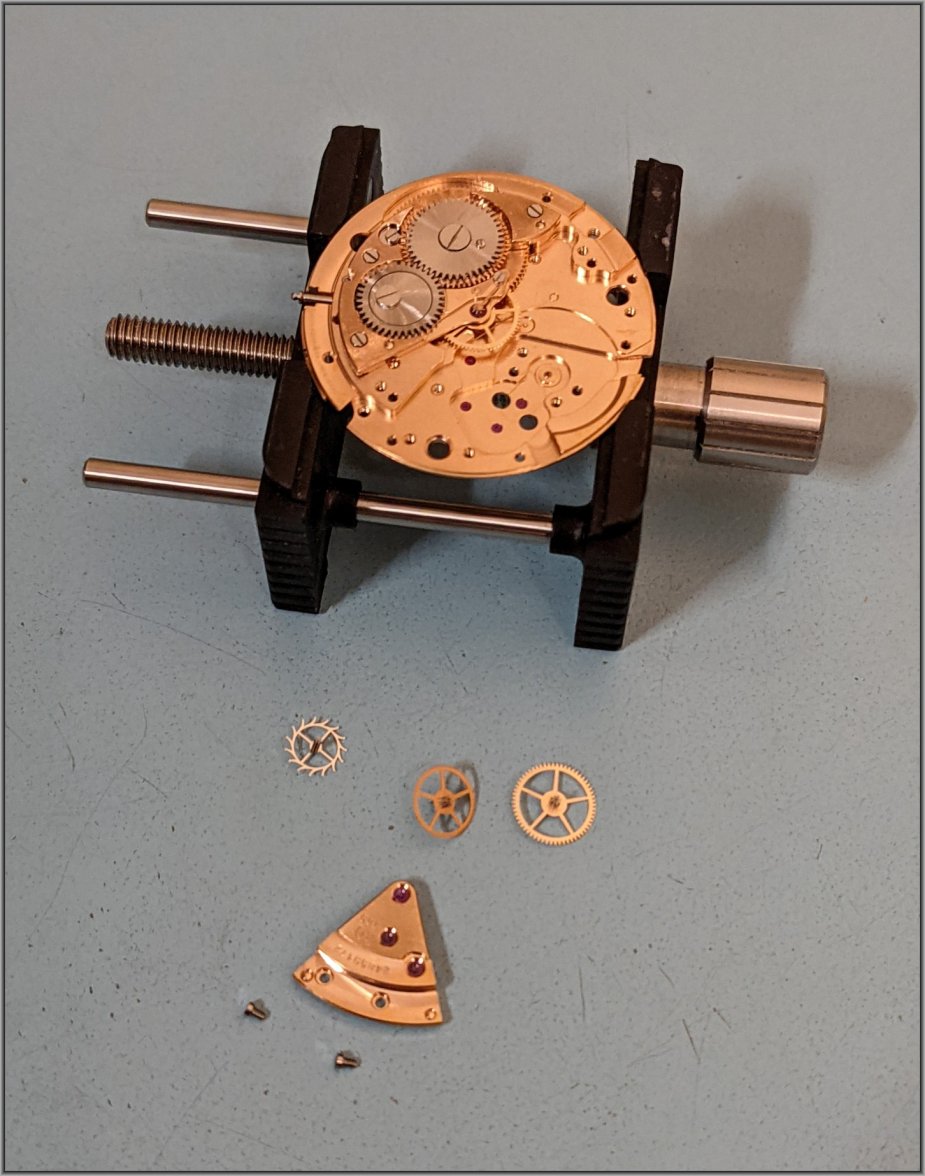

Can see the progression of the going train.

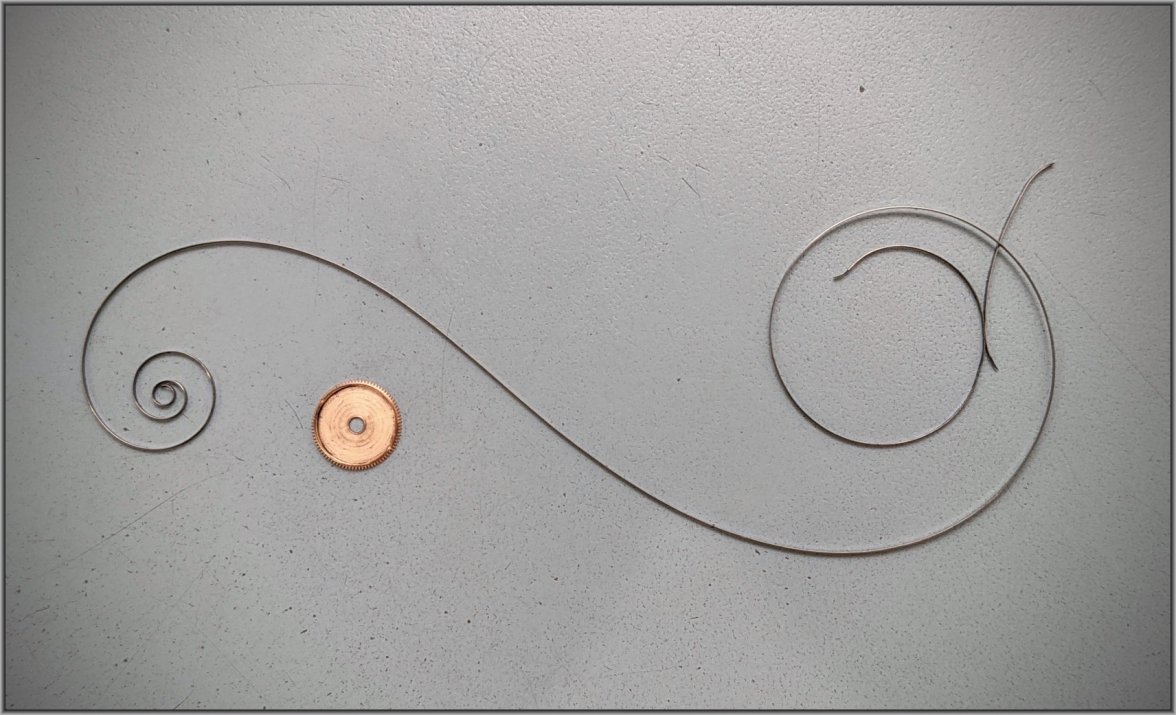

Dual ratchet wheel, allows the mainspring arbor to wind the mainspring by either the auto-wind or via the crown.

Barrel & mainspring

Back to the dial side & disassembly of the keyless works.

Date corrector yolk. This provides the cal 565 date quick-set function via the crown.

Clutch, winding pinion, & winding stem. Grossly excess oil (doesn't smell great, either...).

And that’s it for the breakdown, off to the ultrasonic.

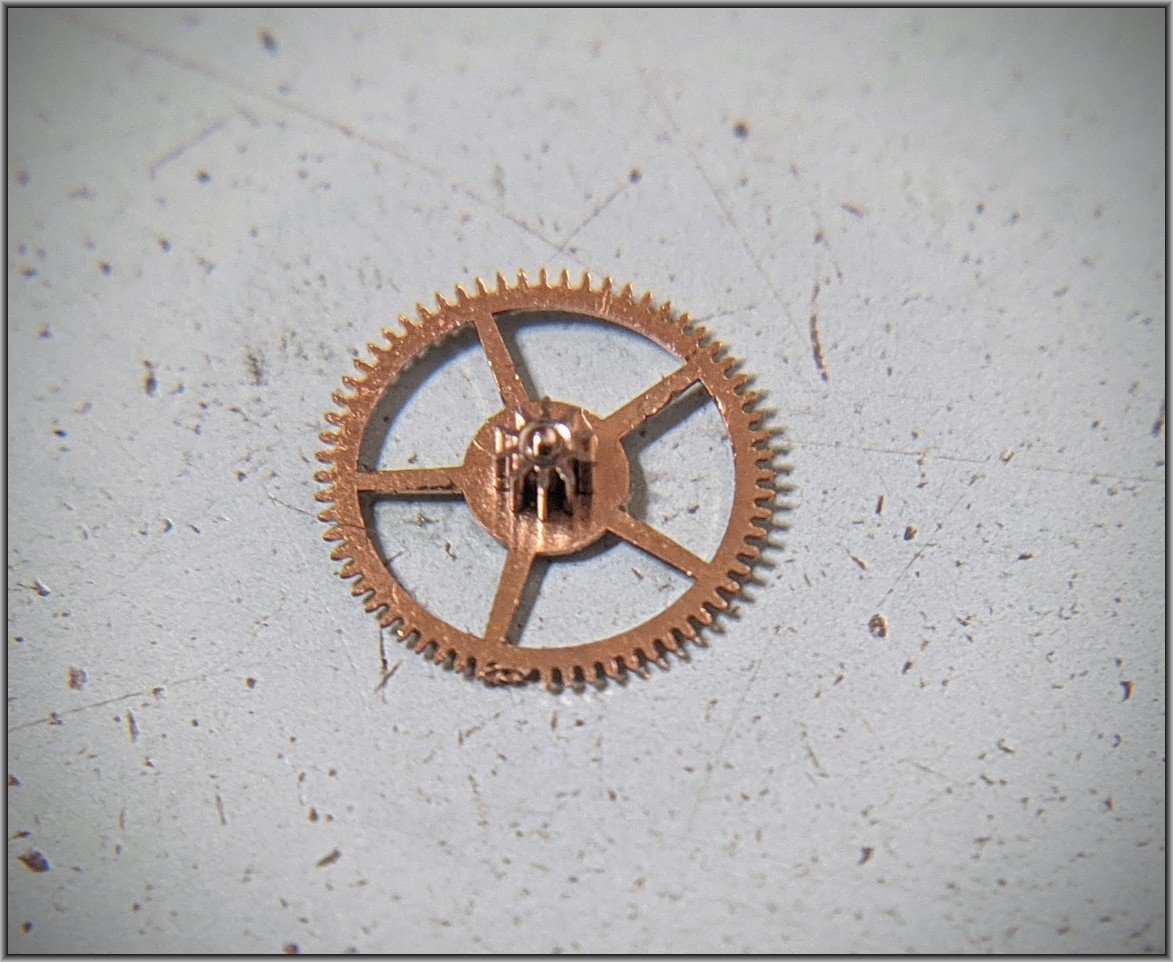

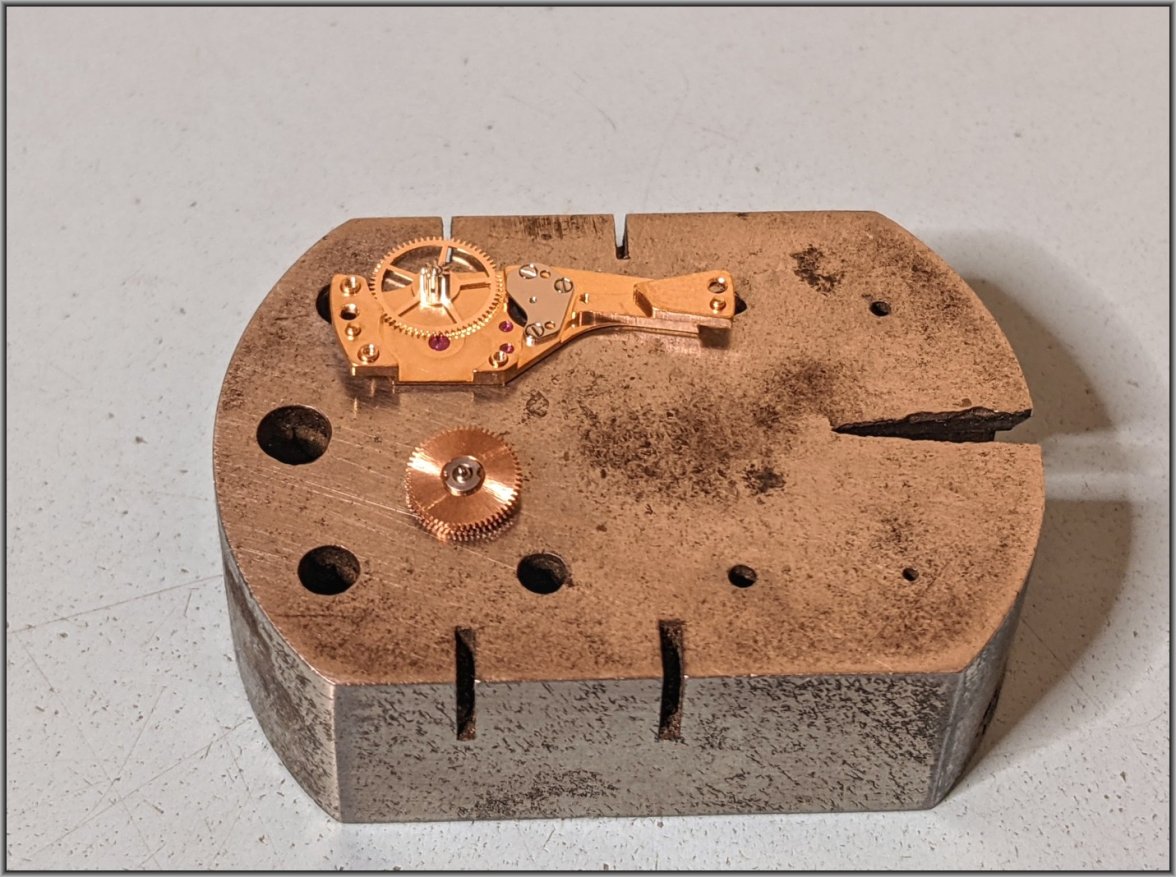

Intermediate winding drive wheel (the new one!) & auto-wind reversing wheel.

Auto-wind cap.

Lower balance jewel assembly.

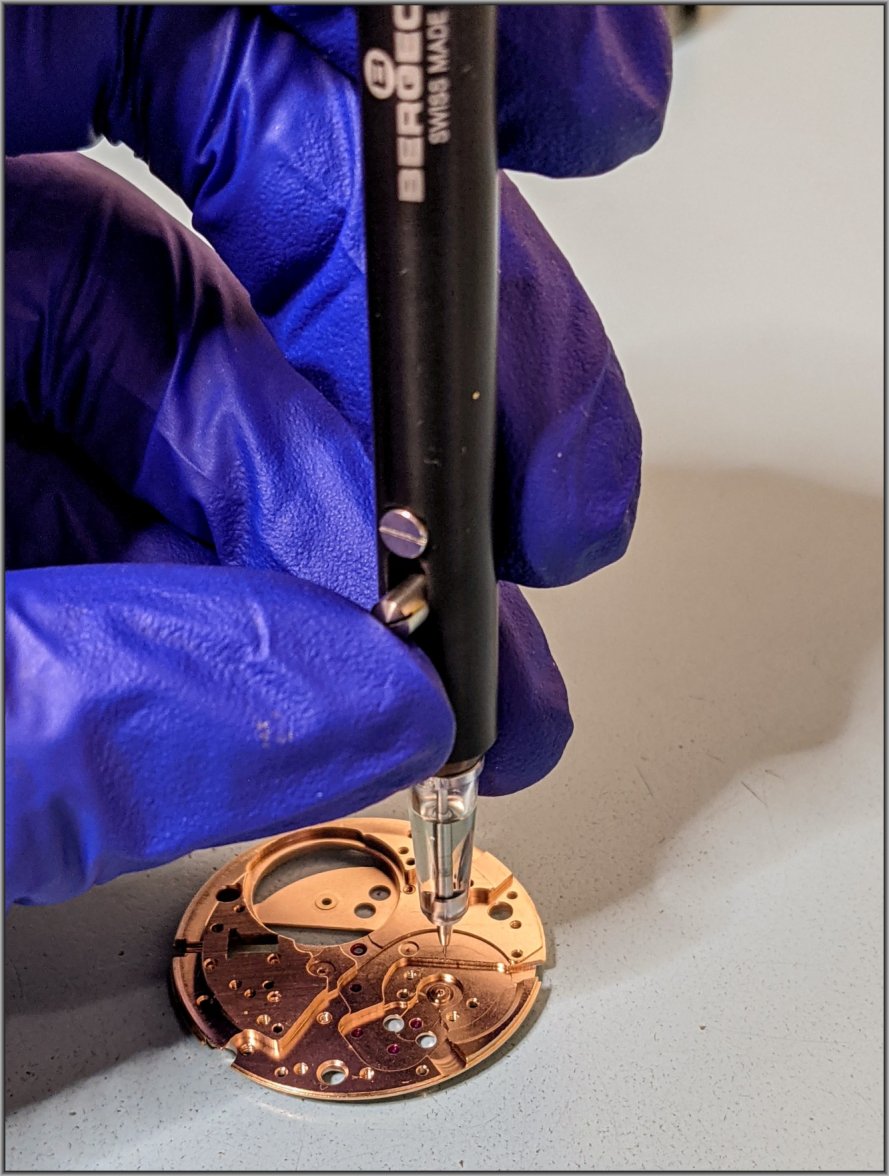

Automatic oiler. Handy, but very easy (& expensive) to bend up that fine dispensing needle.

Same treatment for the upper balance jewel assembly.

Dial side of the movement & the setting lever assembly.

Keyless works.

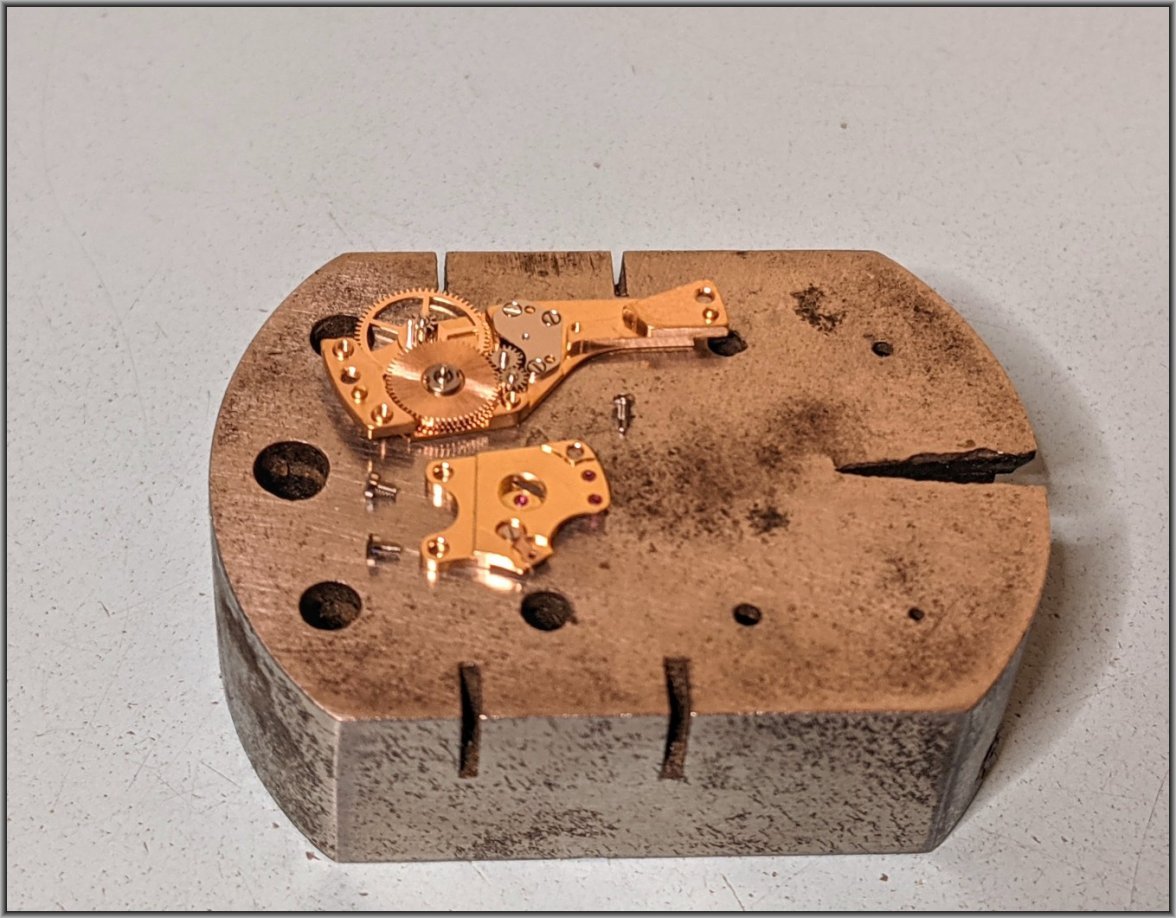

Over to the Watchmaker side once more. Click & crown wheel assembly.

Second wheel & mainspring barrel.

Barrel bridge assembly complete.

Going train & bridge.

If you look close, can see how the pallet stones interact with the escape wheel.

Moment of truth… Time for the balance to go back in, see if this old movement has some life left in it.

And off she goes… 😀

Always a good feeling for a watchmaker.

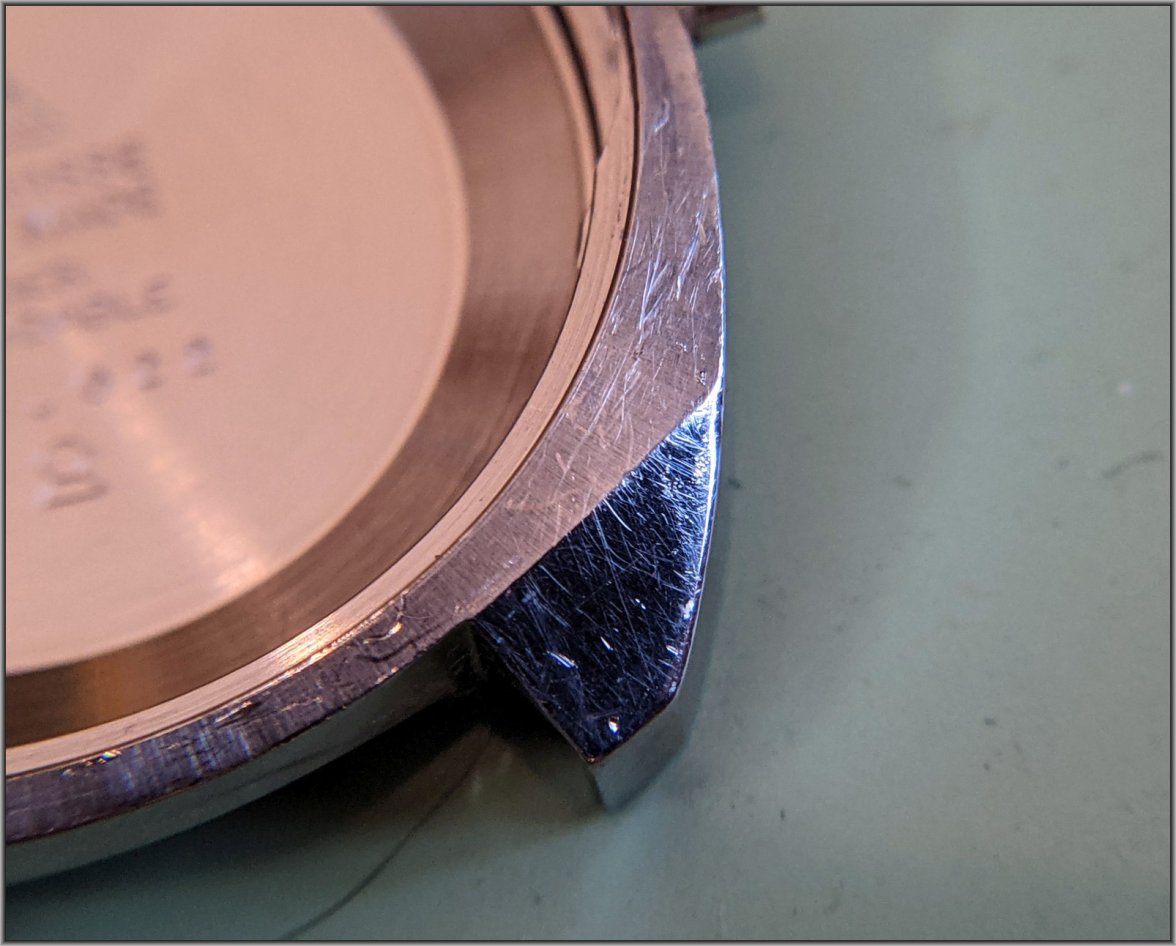

Now on to the case. Heavy scratches throughout. If you look close, can see what looks like the radially striped graining on the top surface from the original factory finish. Pretty well obscured now by a lifetime of battle scars.

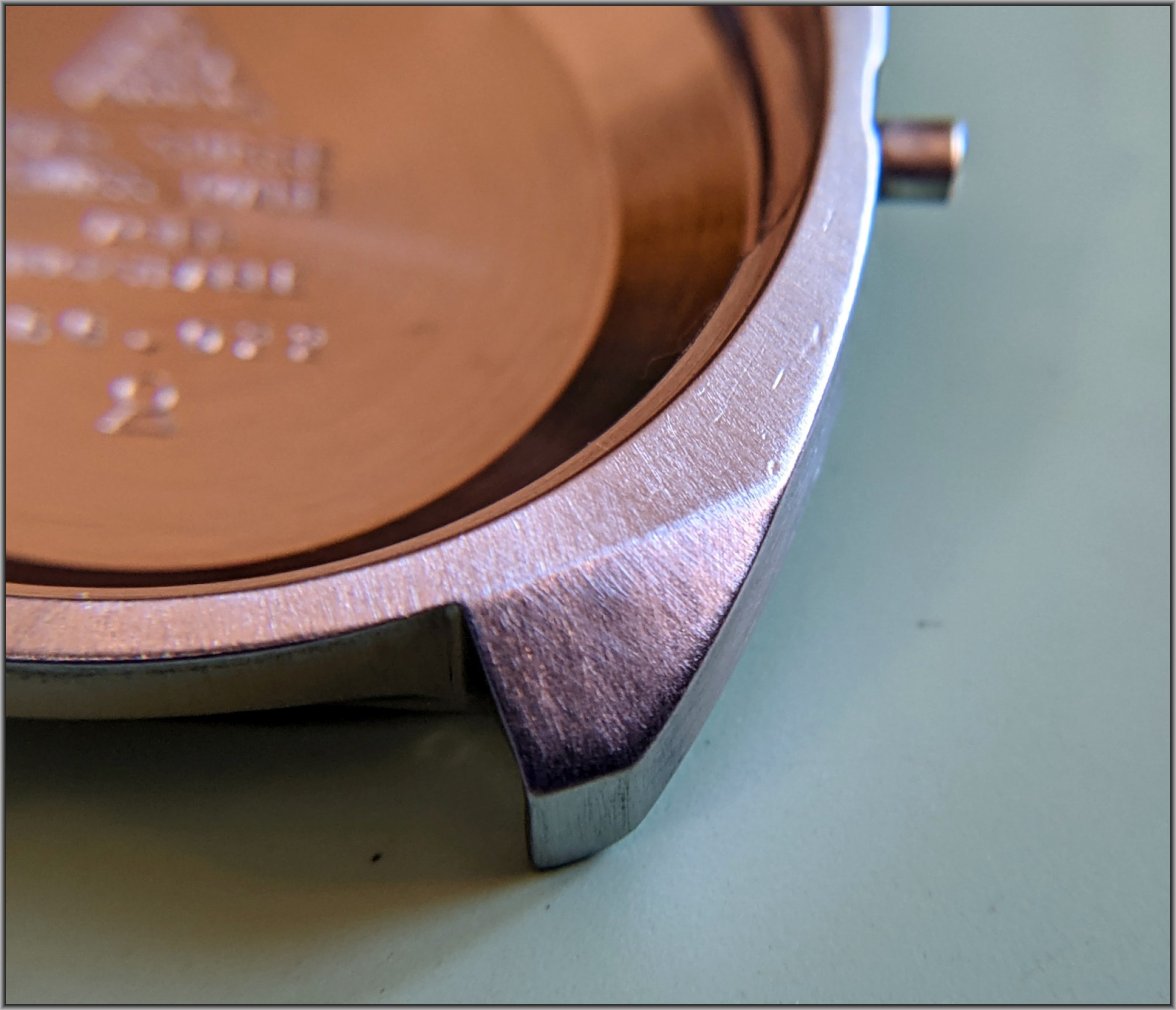

Coarse brushing all over to give a uniform foundation for the surface finishing to follow.

Medium brushing, & beginning to reintroduce the outward radial grain on the top surface.

Fine radial brushing for the top surface, mirror polish for the sides & lugs. That’s good for the case, now back to finish up on the movement.

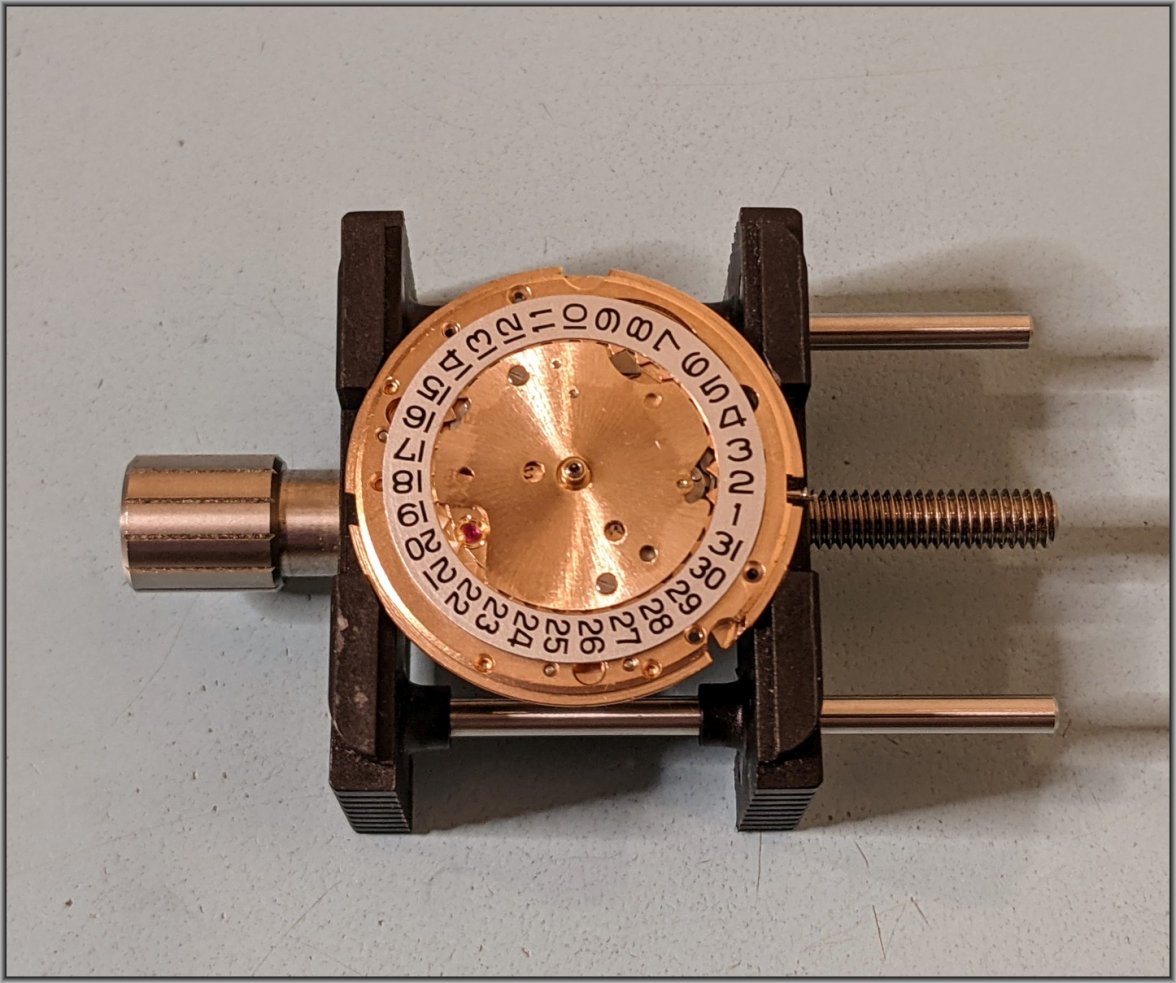

Calendar works to finish up the movement.

Date disc.

Auto-wind mechanism.

Completed movement.

Dial & hands.

Cased up.

Complete.

Hope everyone is enjoying the weekend, & hopefully it's a long weekend for you, too 😀

It's a nice looking watch, but it has had a long life & seen a lot of use. Case has lots of scuffs, but this is normal wear. Doesn't explain how the dial got marked up, though.

The seconds hand will turn for short spells but then stop, & it feels like something in the winding mechanism is stuck. See how a service helps it out.

Can see puddles of excess oil on top of the calendar works cap.

Watchmaker side of the movement (if you have sharp eyes, you can spot the beginnings of the winding / running problems…).

Well that's not good...

So how much damage has been done by steel pinions turning brass wheels when the brass wheel aren't going to move?... The brass leaves are tiny, & no match for the steel pinions of the automatic winding mechanism. Damage done, let's see how bad.

There's that screw (& more puddles of excess oil).

The intermediate winding drive wheel is what took the damage from those stray parts. This part is not salvageable, but was able to find a used whole auto-wind mechanism at a reasonable cost to serve as a parts donor.

On with the disassembly.

Upper balance hole jewel & upper balance cap jewel.

Can see the progression of the going train.

Dual ratchet wheel, allows the mainspring arbor to wind the mainspring by either the auto-wind or via the crown.

Barrel & mainspring

Back to the dial side & disassembly of the keyless works.

Date corrector yolk. This provides the cal 565 date quick-set function via the crown.

Clutch, winding pinion, & winding stem. Grossly excess oil (doesn't smell great, either...).

And that’s it for the breakdown, off to the ultrasonic.

Intermediate winding drive wheel (the new one!) & auto-wind reversing wheel.

Auto-wind cap.

Lower balance jewel assembly.

Automatic oiler. Handy, but very easy (& expensive) to bend up that fine dispensing needle.

Same treatment for the upper balance jewel assembly.

Dial side of the movement & the setting lever assembly.

Keyless works.

Over to the Watchmaker side once more. Click & crown wheel assembly.

Second wheel & mainspring barrel.

Barrel bridge assembly complete.

Going train & bridge.

If you look close, can see how the pallet stones interact with the escape wheel.

Moment of truth… Time for the balance to go back in, see if this old movement has some life left in it.

And off she goes… 😀

Always a good feeling for a watchmaker.

Now on to the case. Heavy scratches throughout. If you look close, can see what looks like the radially striped graining on the top surface from the original factory finish. Pretty well obscured now by a lifetime of battle scars.

Coarse brushing all over to give a uniform foundation for the surface finishing to follow.

Medium brushing, & beginning to reintroduce the outward radial grain on the top surface.

Fine radial brushing for the top surface, mirror polish for the sides & lugs. That’s good for the case, now back to finish up on the movement.

Calendar works to finish up the movement.

Date disc.

Auto-wind mechanism.

Completed movement.

Dial & hands.

Cased up.

Complete.

Hope everyone is enjoying the weekend, & hopefully it's a long weekend for you, too 😀

Edited: