On My Bench - Omega GSTP Pocket Watch - Caliber 38.5 L T1

JimInOz

··Melbourne AustraliaJimInOz

··Melbourne Australia😀

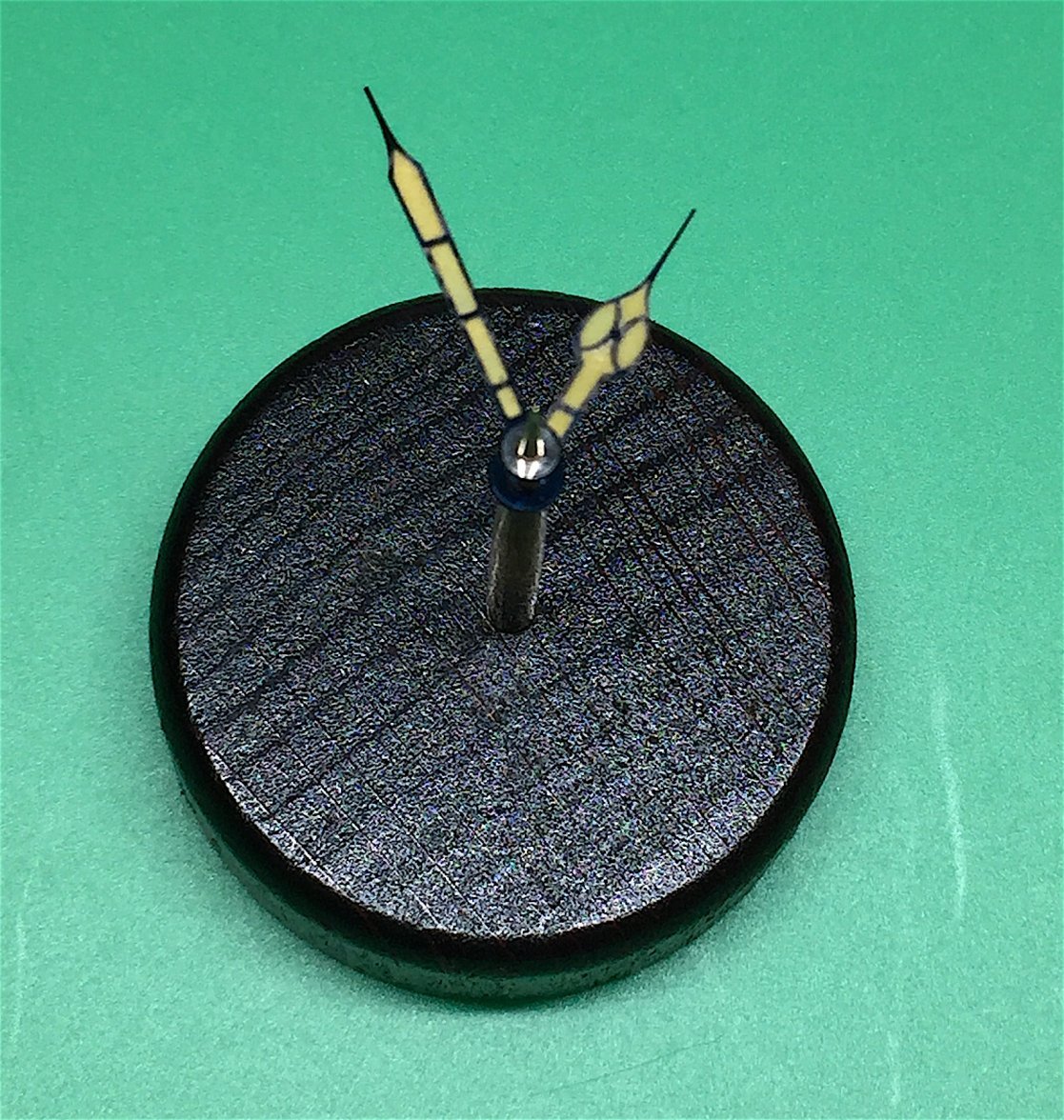

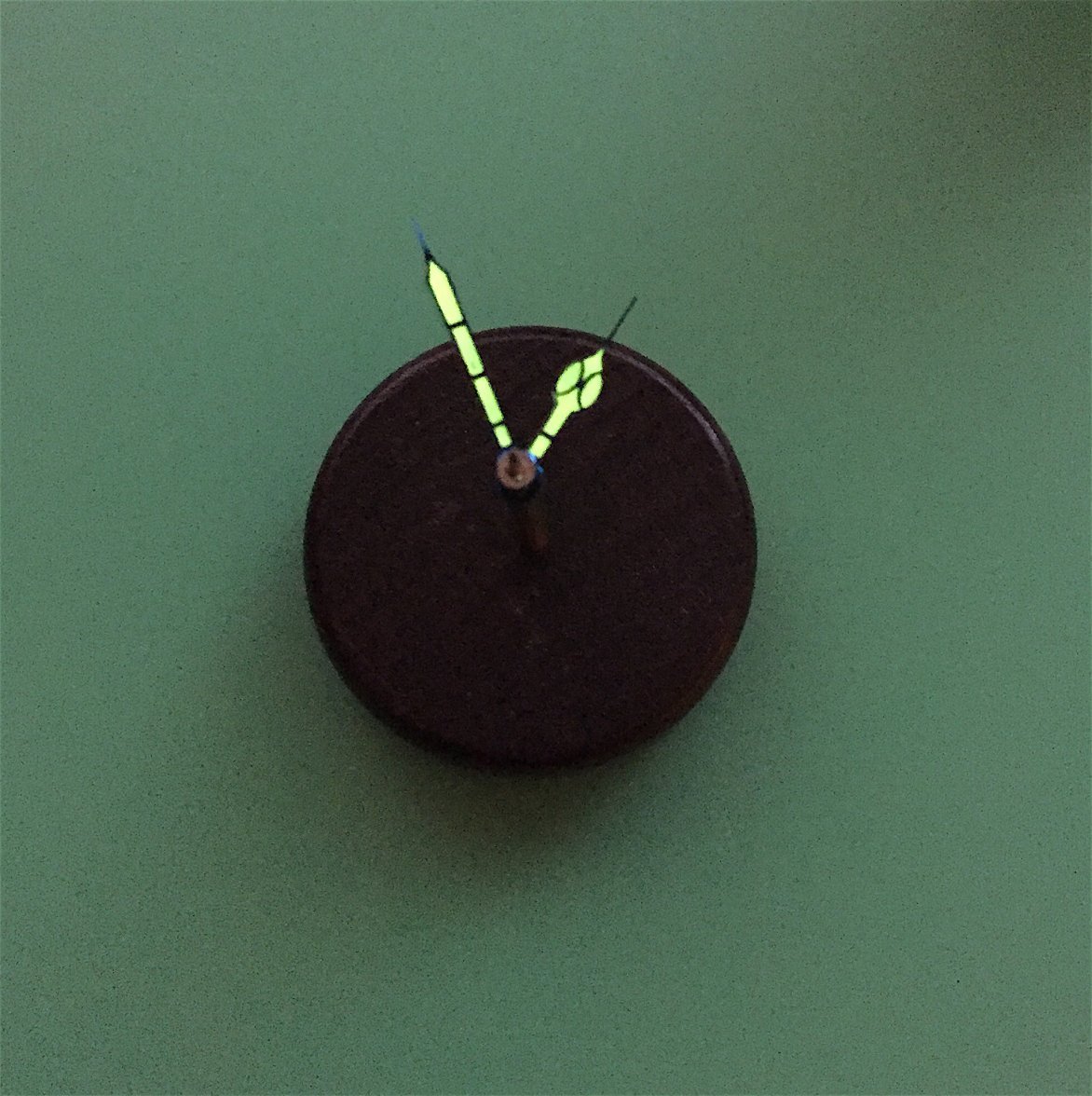

The hour hand was a real PITA, don't know how those radium girls managed to get the big areas filled in so easily. Doing hundreds a day would help though.

I think the colour turned out well for simulated aged radium, 3 drops of Humbrol clear matte, 1/2 a drop of Humbrol 94 Brown Yellow Matt and lume powder to the right consistency.

The numbers on the dial will have to stay clean. I can do dial dots/markers and hands, but I'm not good enough to do numbers yet and I don't want to send you a crap job.

A day away from the bench tomorrow as I've got to do some gardening for my mate and his wife so the lume will have time to dry properly.

The hour hand was a real PITA, don't know how those radium girls managed to get the big areas filled in so easily. Doing hundreds a day would help though.

I think the colour turned out well for simulated aged radium, 3 drops of Humbrol clear matte, 1/2 a drop of Humbrol 94 Brown Yellow Matt and lume powder to the right consistency.

The numbers on the dial will have to stay clean. I can do dial dots/markers and hands, but I'm not good enough to do numbers yet and I don't want to send you a crap job.

A day away from the bench tomorrow as I've got to do some gardening for my mate and his wife so the lume will have time to dry properly.

JimInOz

··Melbourne AustraliaGetting towards the end now.

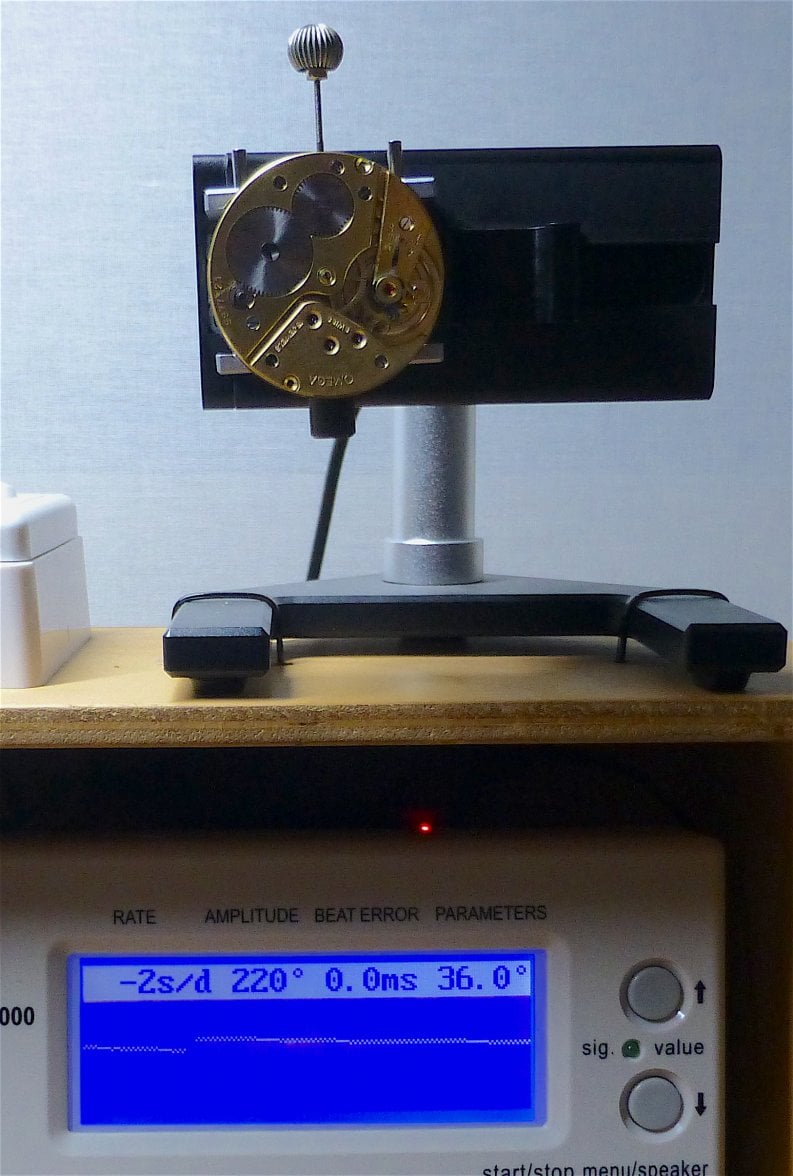

After the third adjustment I had the beat error down to 0.2 m/s.

"I can do better than that!" I thought, so off with the balance again for a tiny weeny adjustment.

Back on the timing machine and "Damn!!!!!! I must have looked at it the wrong way, and I don't remember sneezing when I did it.

Time to walk away. I'll do it again tomorrow.

I'm going to have a beer.

After the third adjustment I had the beat error down to 0.2 m/s.

"I can do better than that!" I thought, so off with the balance again for a tiny weeny adjustment.

Back on the timing machine and "Damn!!!!!! I must have looked at it the wrong way, and I don't remember sneezing when I did it.

Time to walk away. I'll do it again tomorrow.

I'm going to have a beer.

verithingeoff

·Hi Jim

I was an engineer in the print industry for many years and I learnt when to walk away, take a deep breath.......and have a beer!😎

I was an engineer in the print industry for many years and I learnt when to walk away, take a deep breath.......and have a beer!😎

JimInOz

··Melbourne Australiatdn-dk

·Nice 😀

I can se you use 36 dg. Lift Angel. I have been looking lift angel for Omega pocketes and older watch calibers without any luck, most charts starts at cal. 161 (I guess a later version of the 38.5?) Have you found older charts or asume it is like the 161?

I can se you use 36 dg. Lift Angel. I have been looking lift angel for Omega pocketes and older watch calibers without any luck, most charts starts at cal. 161 (I guess a later version of the 38.5?) Have you found older charts or asume it is like the 161?

JimInOz

··Melbourne AustraliaIt was a matter of working forwards. Cal 38.5 was later re-designated 160/161/162/163, so I just used the lift angle for Cal 160.

If I can't find an original technical guide for the caliber I use this excellent lift angle chart (Thanks to Christian Dannemann).

Unfortunately I haven't found any charts/guides for older calibers in Omega.

If I can't find an original technical guide for the caliber I use this excellent lift angle chart (Thanks to Christian Dannemann).

Unfortunately I haven't found any charts/guides for older calibers in Omega.

tdn-dk

·It was a matter of working forwards. Cal 38.5 was later re-designated 160/161/162/163, so I just used the lift angle for Cal 160.

If I can't find an original technical guide for the caliber I use this excellent lift angle chart (Thanks to Christian Dannemann).

Unfortunately I haven't found any charts/guides for older calibers in Omega.

Looks similar to this one 😀

https://longines30l.com/wordpress/?page_id=597

verithingeoff

·Looks like you hit the sweet spot there Jim😎

Archer

··Omega Qualified WatchmakerNice 😀

I can se you use 36 dg. Lift Angel. I have been looking lift angel for Omega pocketes and older watch calibers without any luck, most charts starts at cal. 161 (I guess a later version of the 38.5?) Have you found older charts or asume it is like the 161?

If you don't know the lift angle of a particular watch, it's easy to find it. Starting with the watch fully run down, wind it until the balance amplitude can be seen visually to be 180 degrees. I use the "slo mo" video on my iPhone to verify this, and if required a marker can be used to place a small mark on the balance as a reference point for easier visualization. Once you know the amplitude is 180, put the watch on your timing machine and adjust the lift angle until the machine reads 180, and now you know the lift angle.

Cheers, Al

JimInOz

··Melbourne AustraliaThanks Al, i remember you explaining it some time ago but I never bookmarked it, will now though.

Next question.

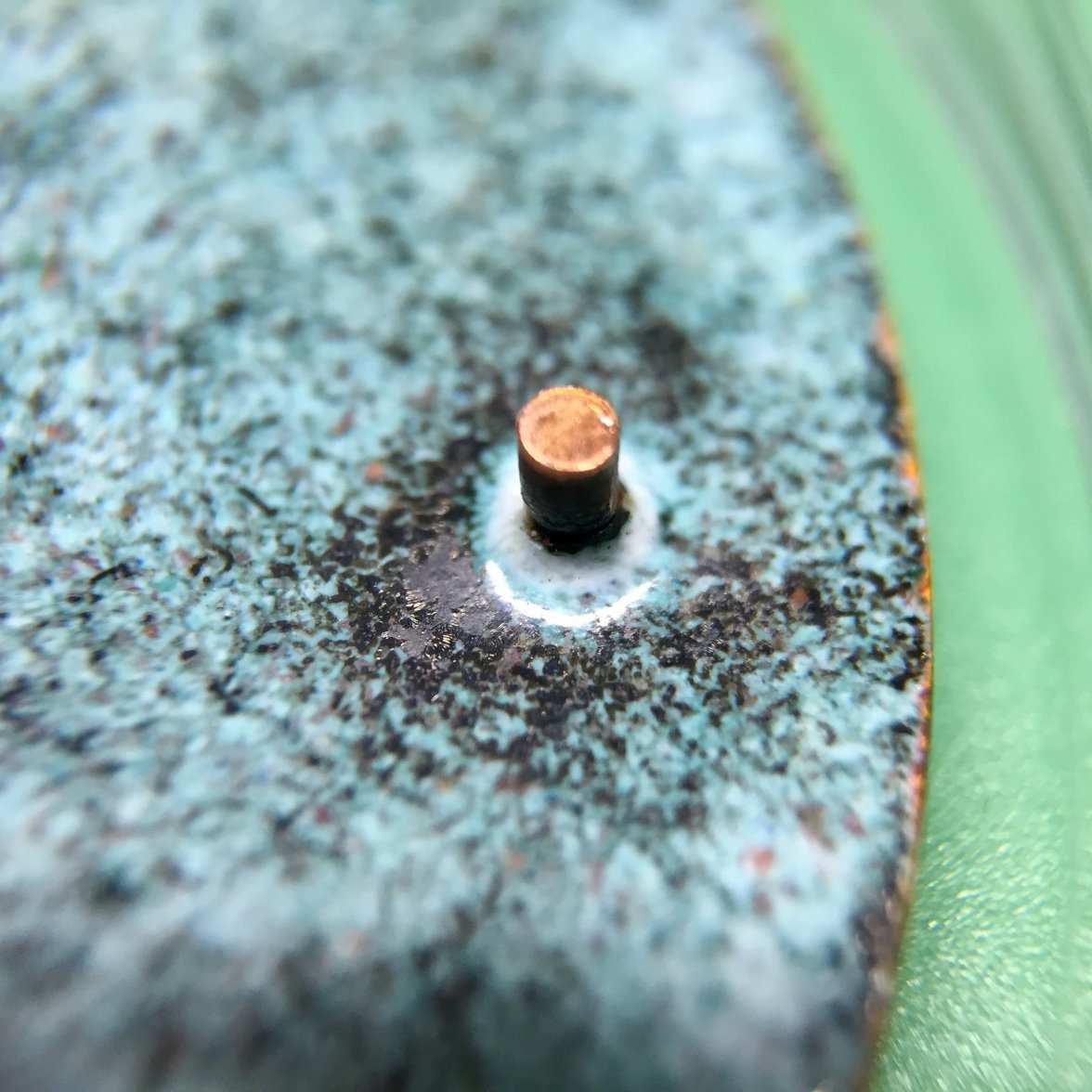

One of the feet on the enamel dial has broken off.

Two causes I think. First, it may not have been a good weld and second, I think it may have been heavily over tightened at some stage.

The good one:

The bad one:

As much as I’m reluctant to use a dial dot, I think it may be my only option .

Not being my own watch I’d rather not try to re-weld or solder it in case it causes the enamel to crack.

Any suggestions?

Next question.

One of the feet on the enamel dial has broken off.

Two causes I think. First, it may not have been a good weld and second, I think it may have been heavily over tightened at some stage.

The good one:

The bad one:

As much as I’m reluctant to use a dial dot, I think it may be my only option .

Not being my own watch I’d rather not try to re-weld or solder it in case it causes the enamel to crack.

Any suggestions?

verithingeoff

·What's a dial dot?

Geoff

Geoff

JimInOz

··Melbourne Australiahttps://www.ebay.com/itm/250-Dial-f...of-vintage-watches-spares-parts-/191336126581

250 x dial feet stickers.

These are great if your dial feet have broken from the dial, or if you are swapping a dial on a movement and the feet are not present or do not line up. The pads have been designed for this job.

The pads hold the dial firmly but can be removed for future repairs.

This website may earn commission from Ebay sales.

JimInOz

··Melbourne AustraliaJimInOz

··Melbourne Australiaverithingeoff

·That looks fantastic Jim, now to find the right chain and fob

Geoff

Geoff

verithingeoff

·Good idea Jim, I have some suitable leather cord

Geoff

Geoff