Deafcon

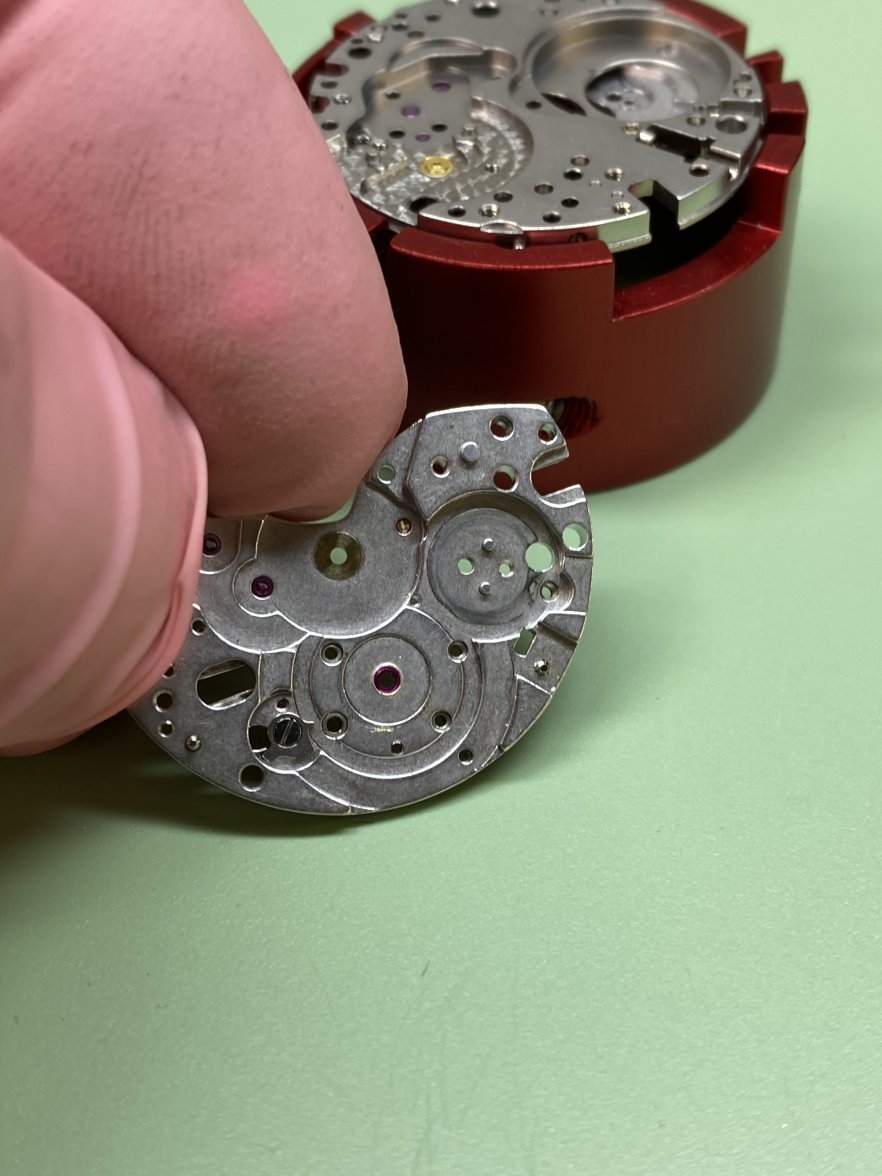

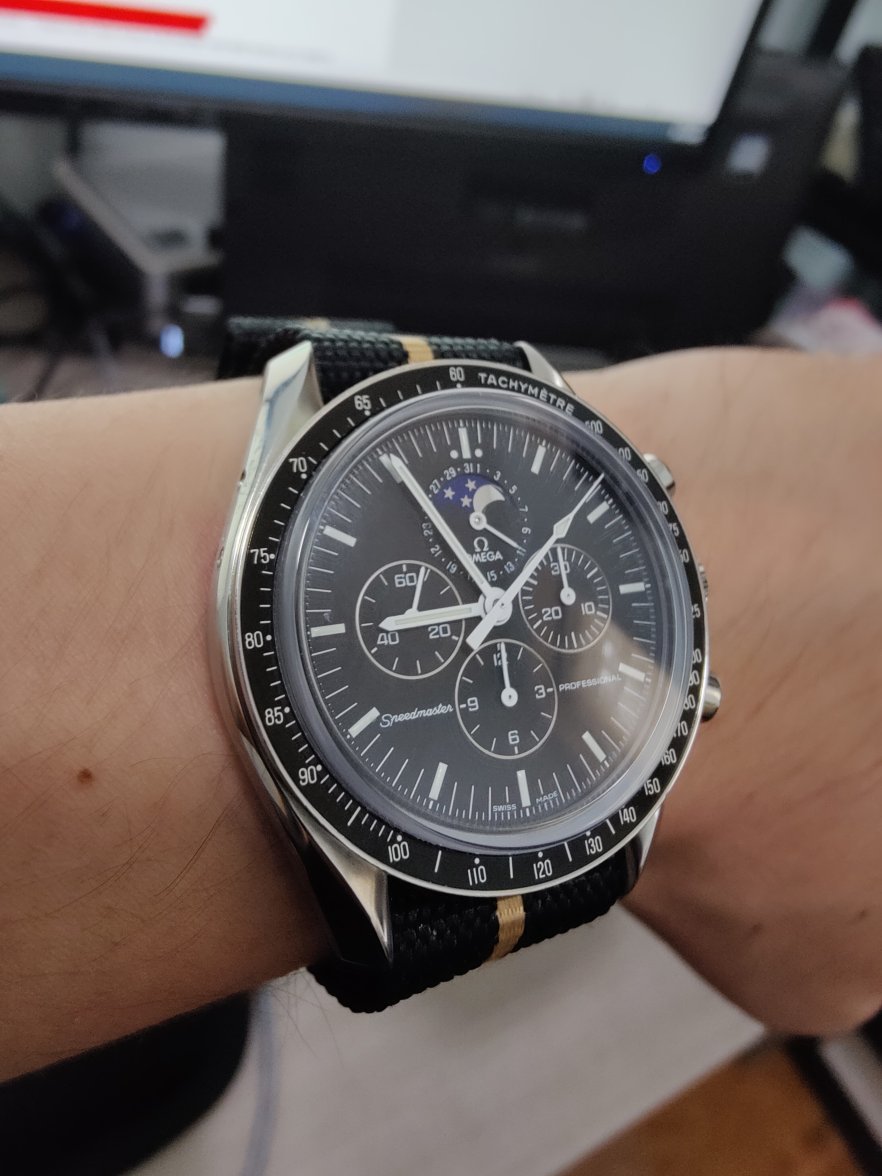

··Omega Certified WatchmakerThis movement had some wear I’m finding to be not too uncommon. The pivot hole for the barrel arbor in the 3/4 plate was worn. The wear wasn’t to the point where the barrel was tipping and causing the ratchet wheel to rub on the 3/4 plate, but it needed to be dealt with.

There are different ways to repair this. Either a jewel or a bushing, ideally bronze, could be used. I had jewels of the correct size, so that is what I used.

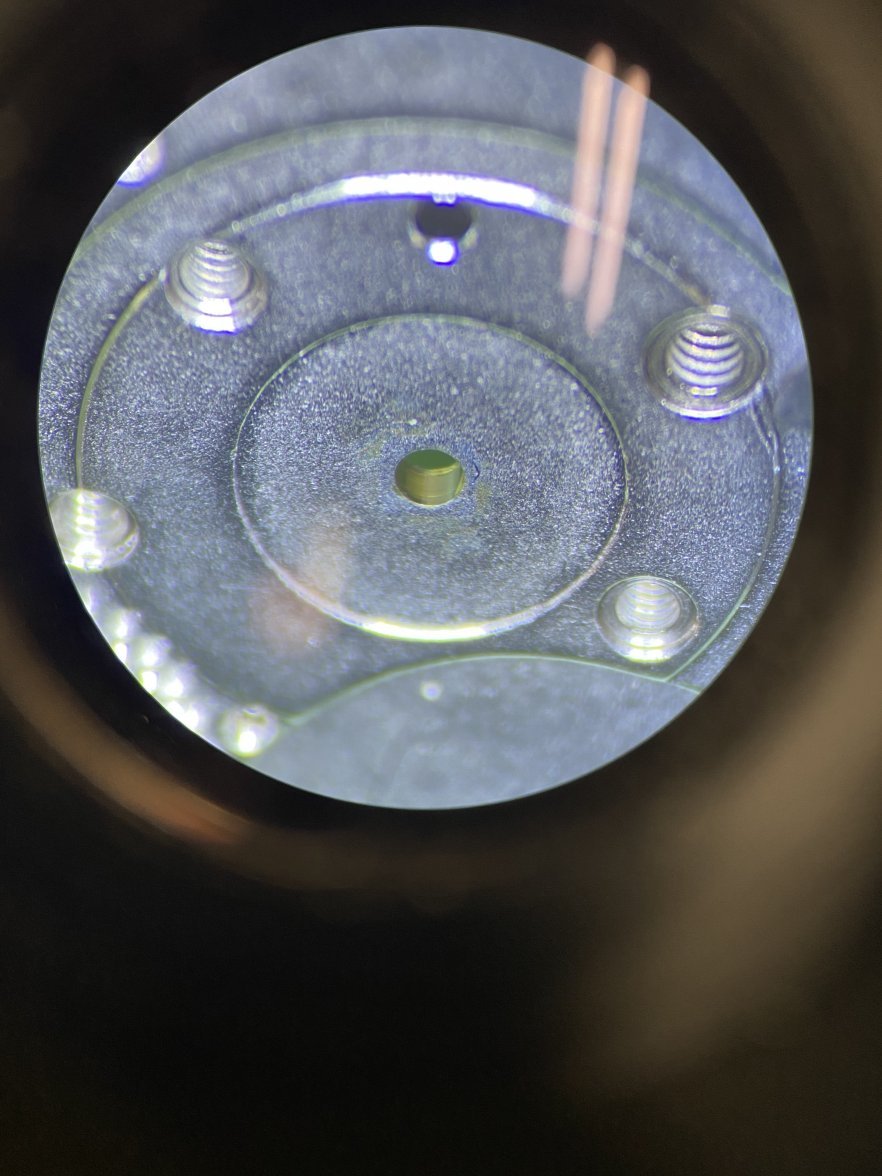

When performing this type of repair you don’t want to lose the center. There is no wear on the top side of the pivot hole in the 3/4 plate, so it can safely be reamed from that side without loosing the center. I have to thank @Archer for his advice on this.

The traditional method is using a lathe with a faceplate and a wobble stick to center things. I performed this repair at a lathe class on a 7750 as that bridge is not as deep and the entire barrel arbor pivot hole was worn.

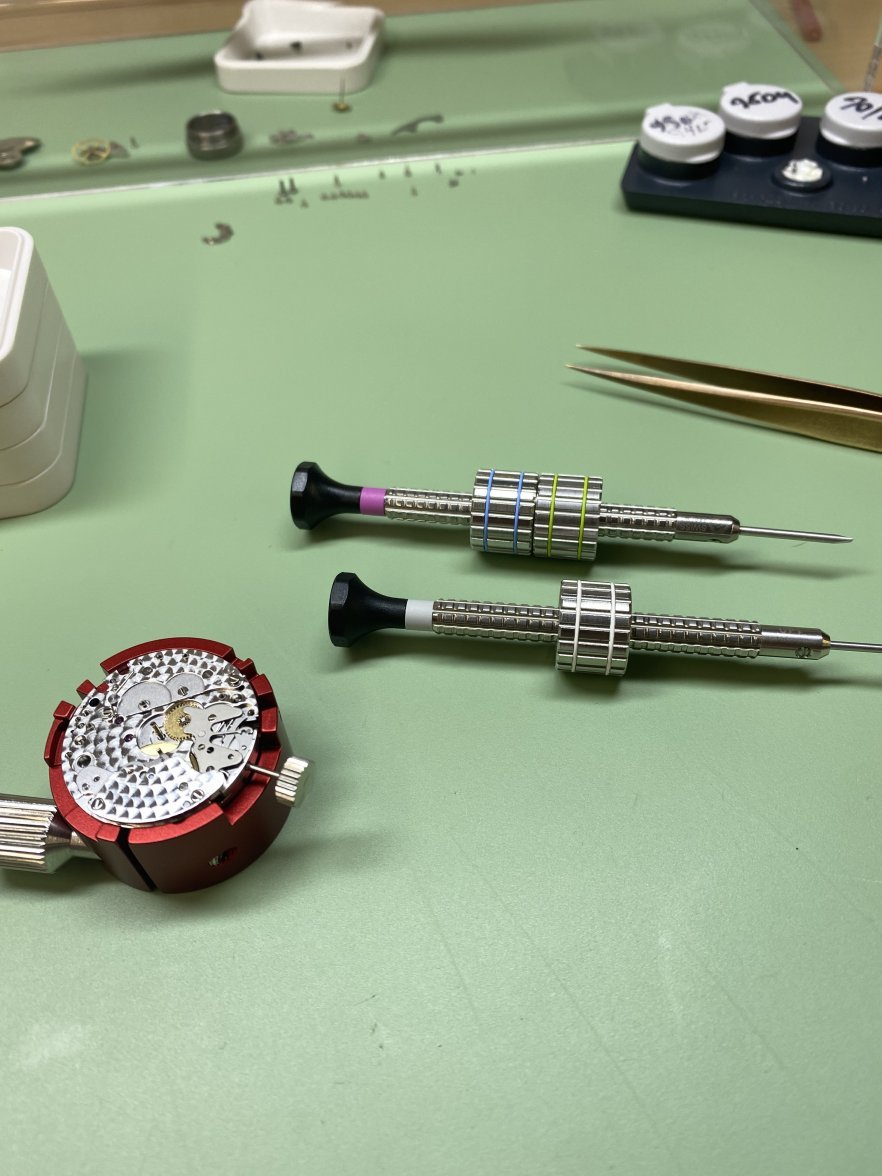

Reaming operation.

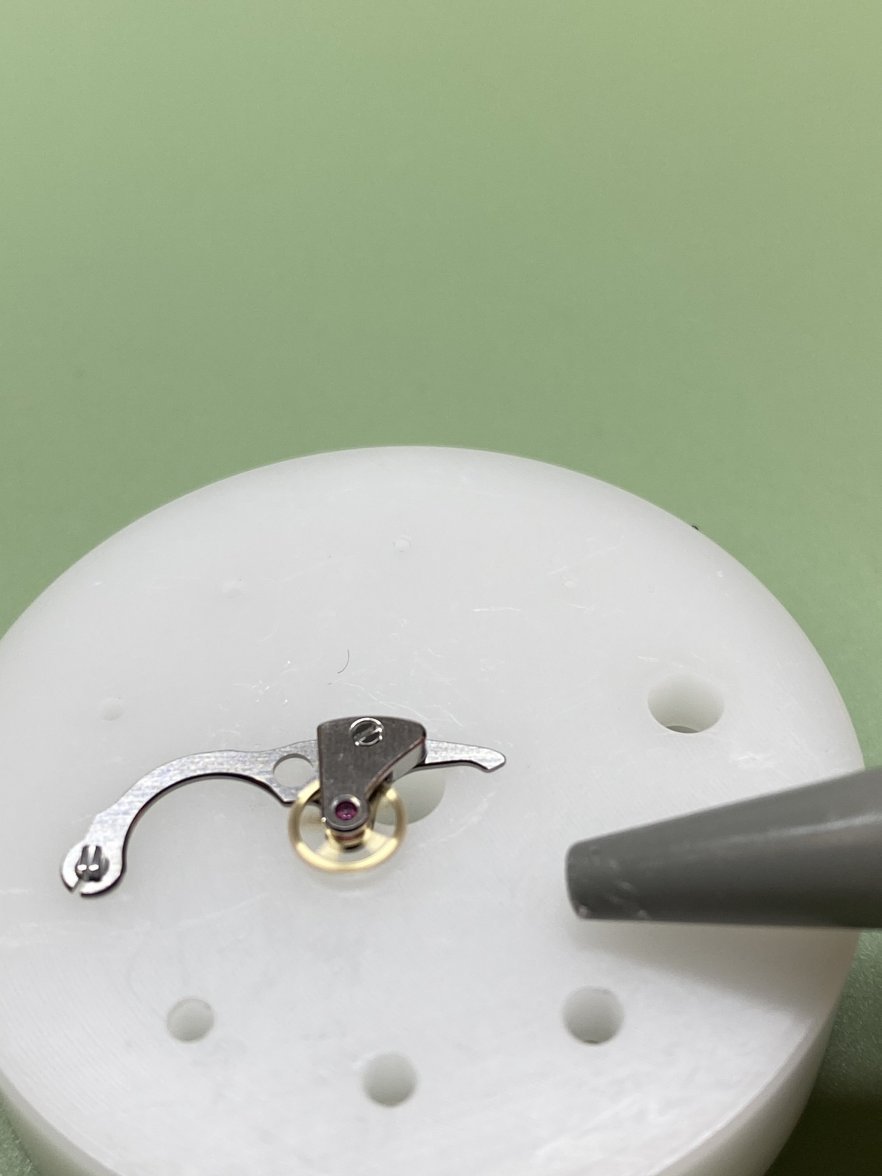

Horia tool used to press the jewel in.

Jewel installed. The jewel was pressed in flush with the underside of the plate. I test fitted the barrel arbor to verify proper endshake and proper freedom of movement. After final cleaning, assembly and lubrication can begin.

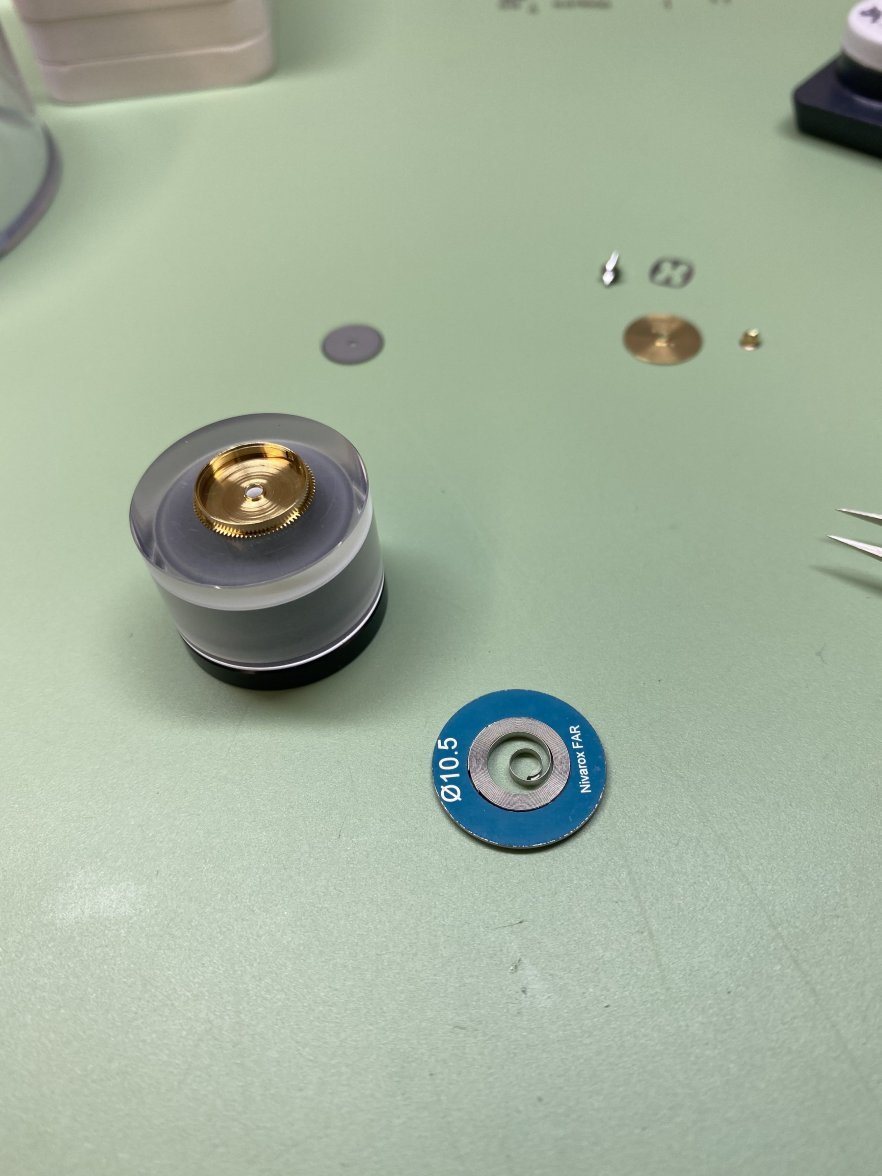

new mainspring. It is installed dry, no braking grease on the barrel wall being manual wind. The springs have a dry lubricant applied at the factory, so the spring itself also does not to be lubricated.

A small puff of air is used for a freedom check of the coupling clutch before lubricating it. I have 6 different torque cylinders that work with one of my sets of screwdrivers. Omega has both tightening torque as well as the minimum loosing torque for all the screws in the movement.