precisionhrlgy

·I recently had an Omega Cosmic come in for an overhaul from a customer who purchased it on eBay. The seller claimed the watch had recently been serviced and even mentioned he had an affiliation with several respected watchmaking organizations in the United States as if to say that imparted some measure of confidence in the work that had been performed.

Despite this recent overhaul, the watch wasn't running as it should and I thought I would share what I found.

First off, these one-piece cases need to have air run through them to blow the crystal out so that's what I did. They have a split stem that simply comes detached when you pull the crown hard enough. When I pulled it out, the crown tube came out of the case with the stem. Problem number 1.

With the watch out of the case, I was ready to remove the dial and hands.

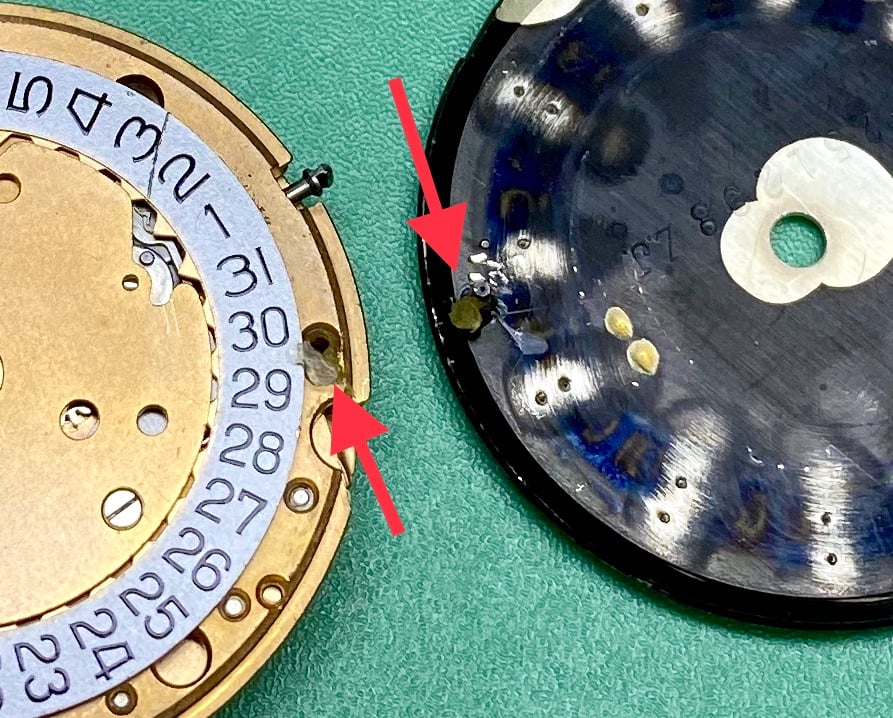

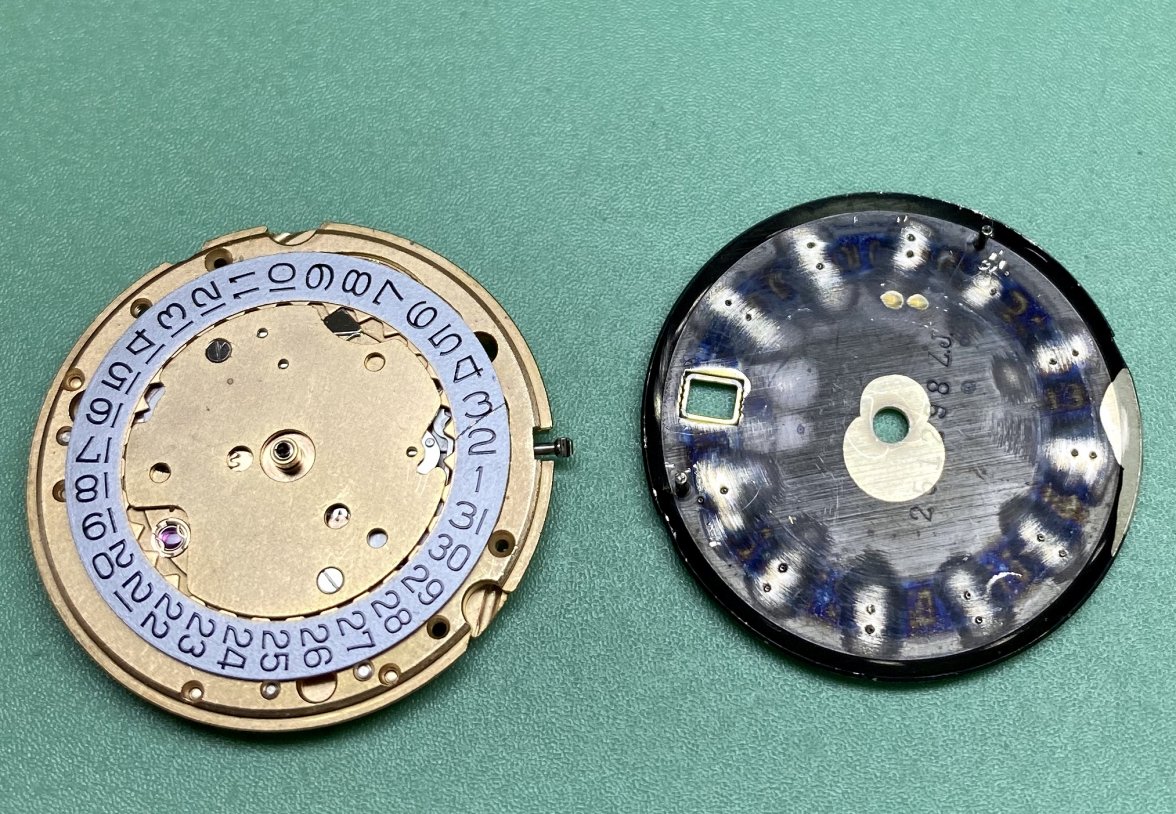

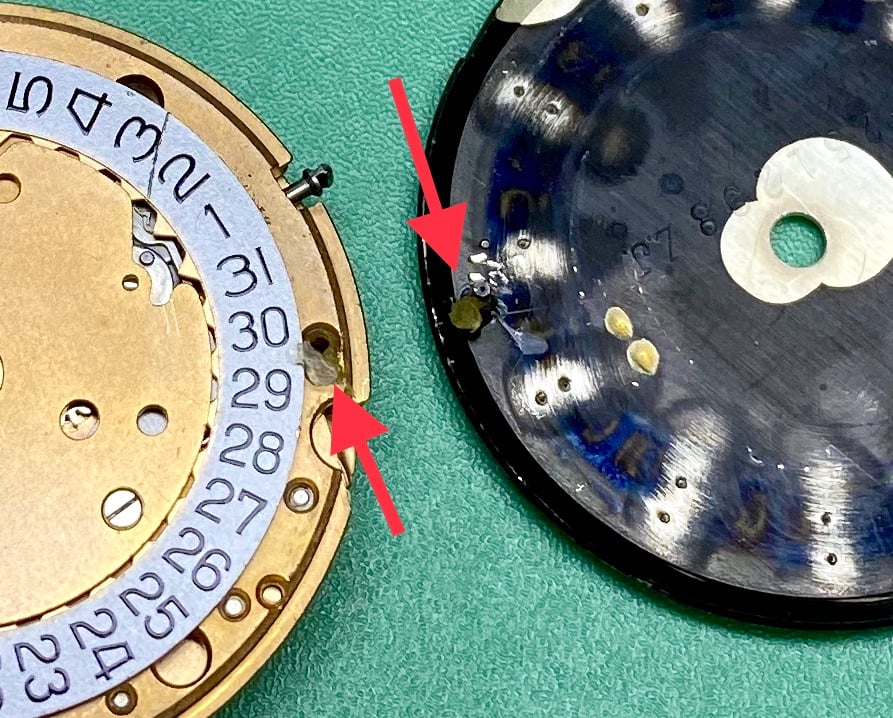

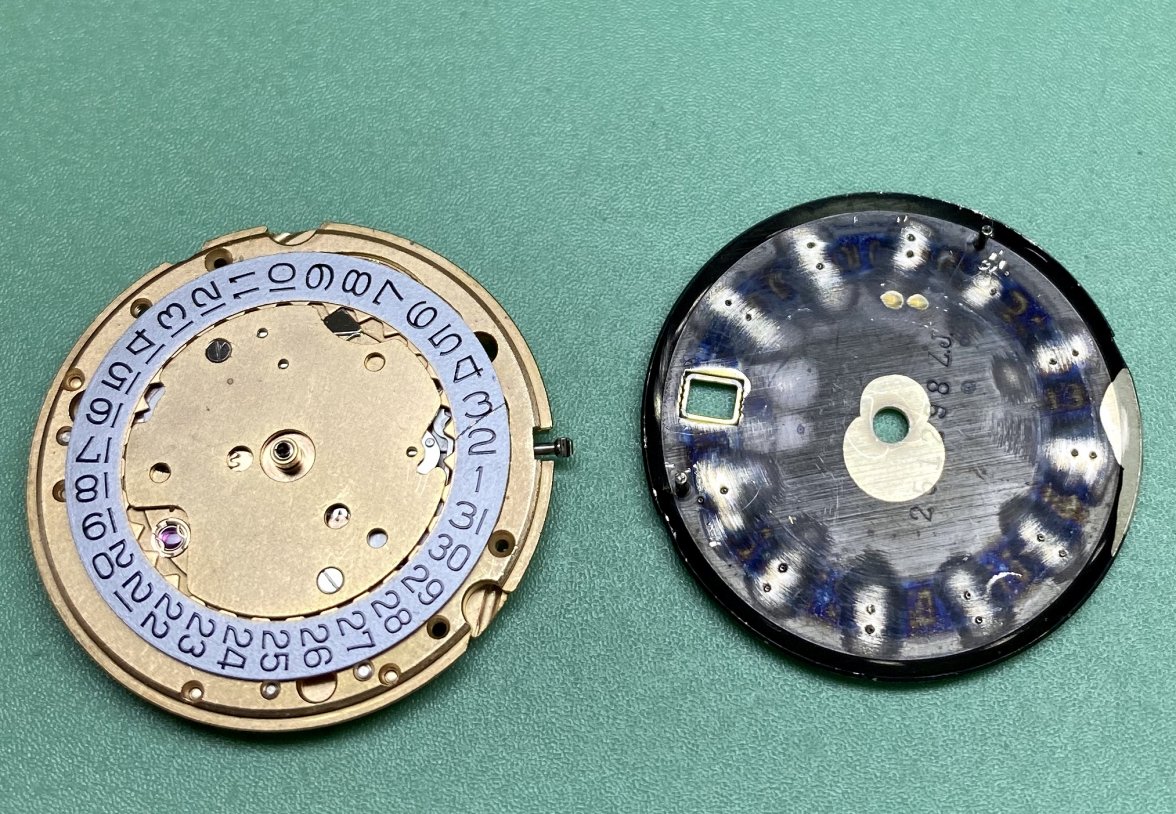

As I removed the dial I noticed the dial feet were intact, but there was one dial screw missing. Instead of procuring a new dial screw the previous watch repairer decided to glue the feet into the holes in the movement. Great move.

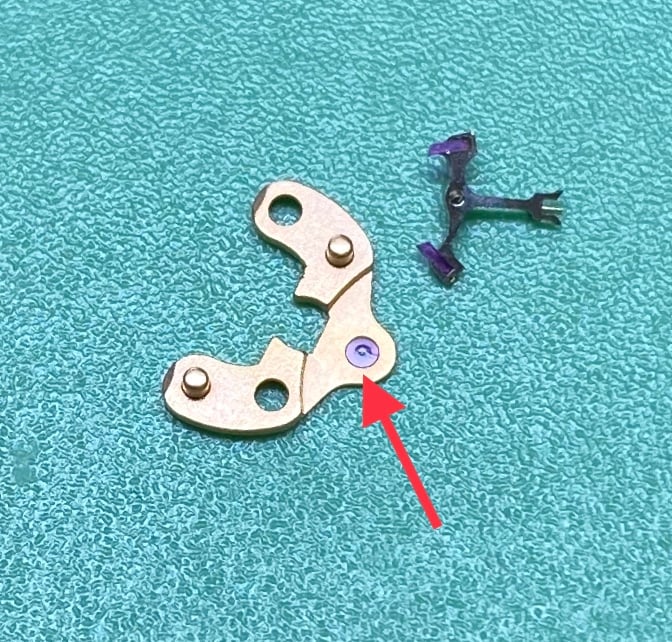

Here we can see some shoddy oiling of the setting lever, it's too much and seems to be very lumpy. It looks like an old oil that we don't use these days.

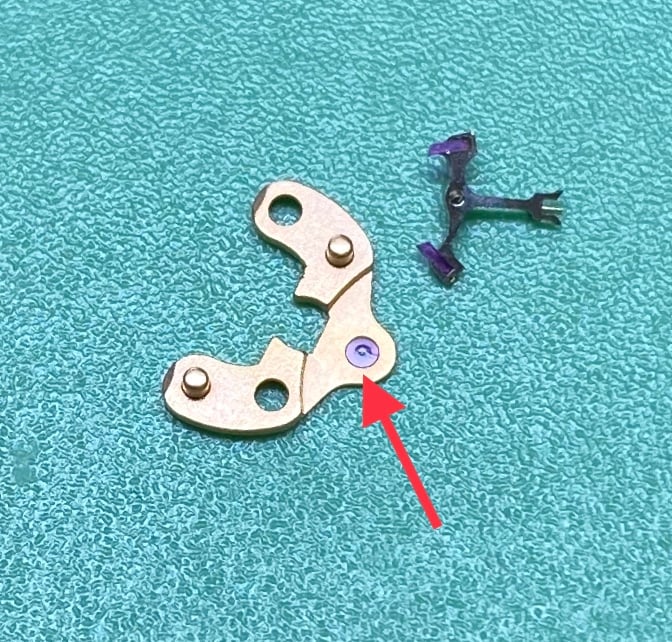

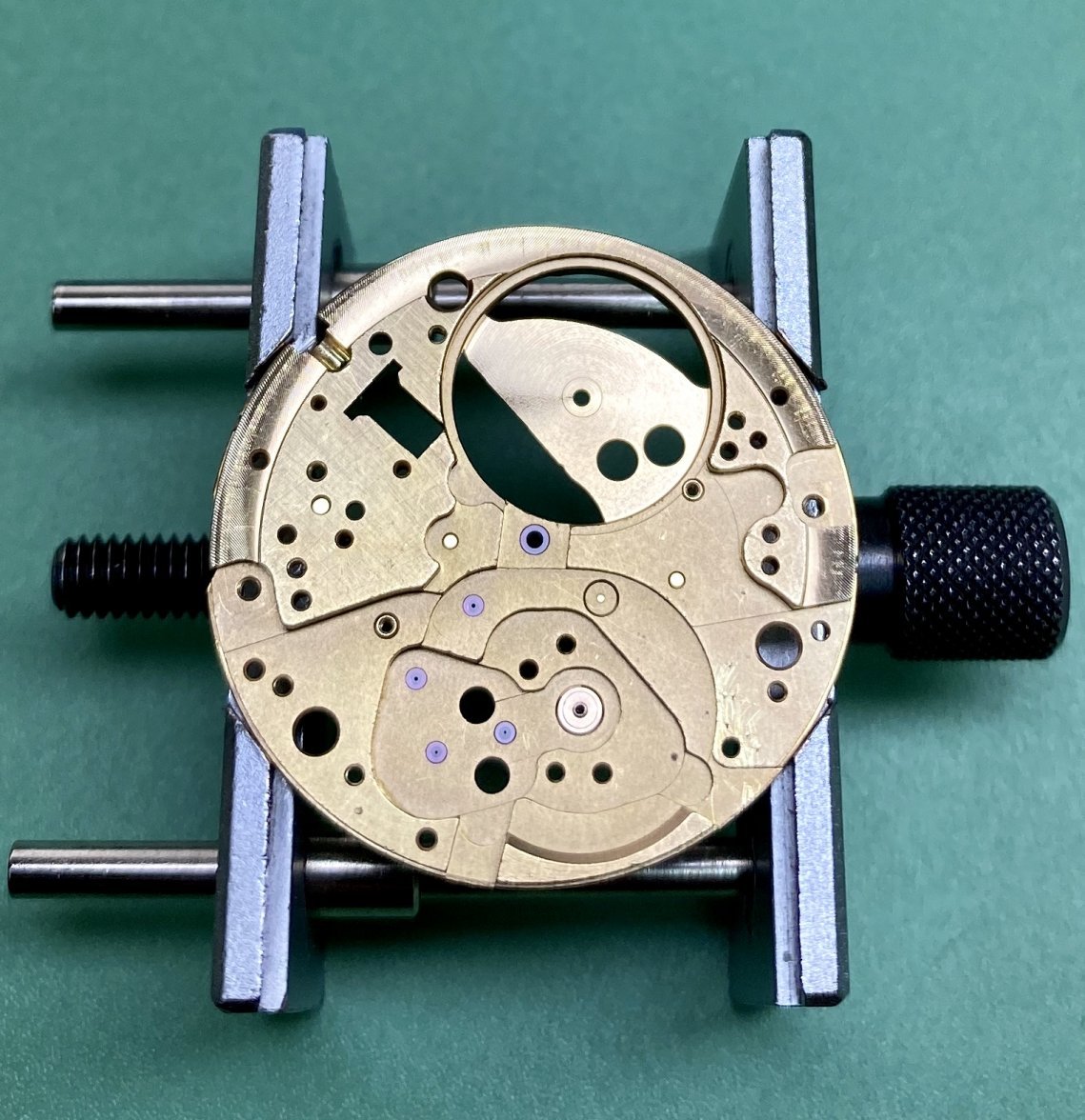

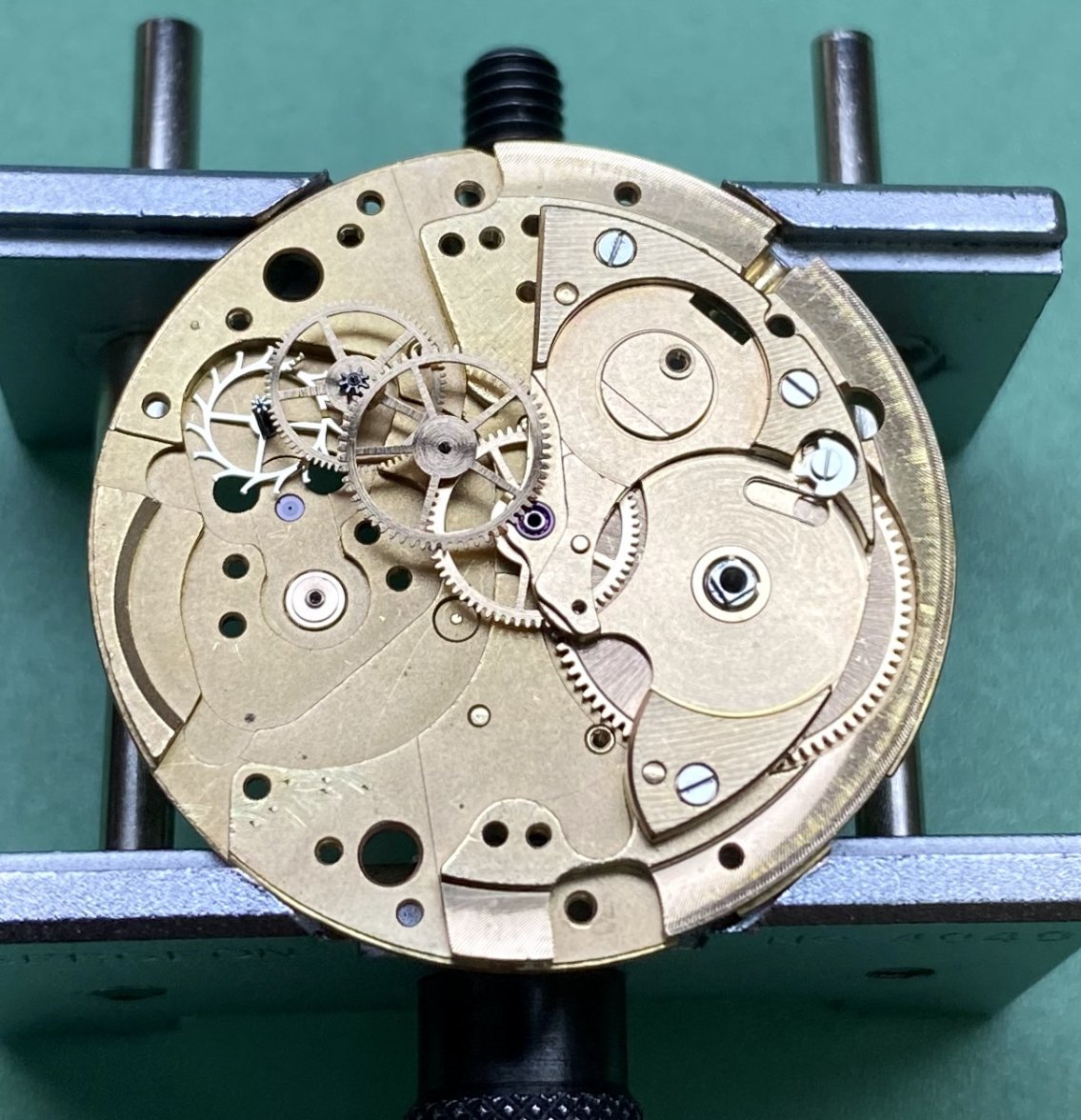

Now the movement side. The first obvious issue was the cap jewel for the incabloc setting. It was seated in place upside down.

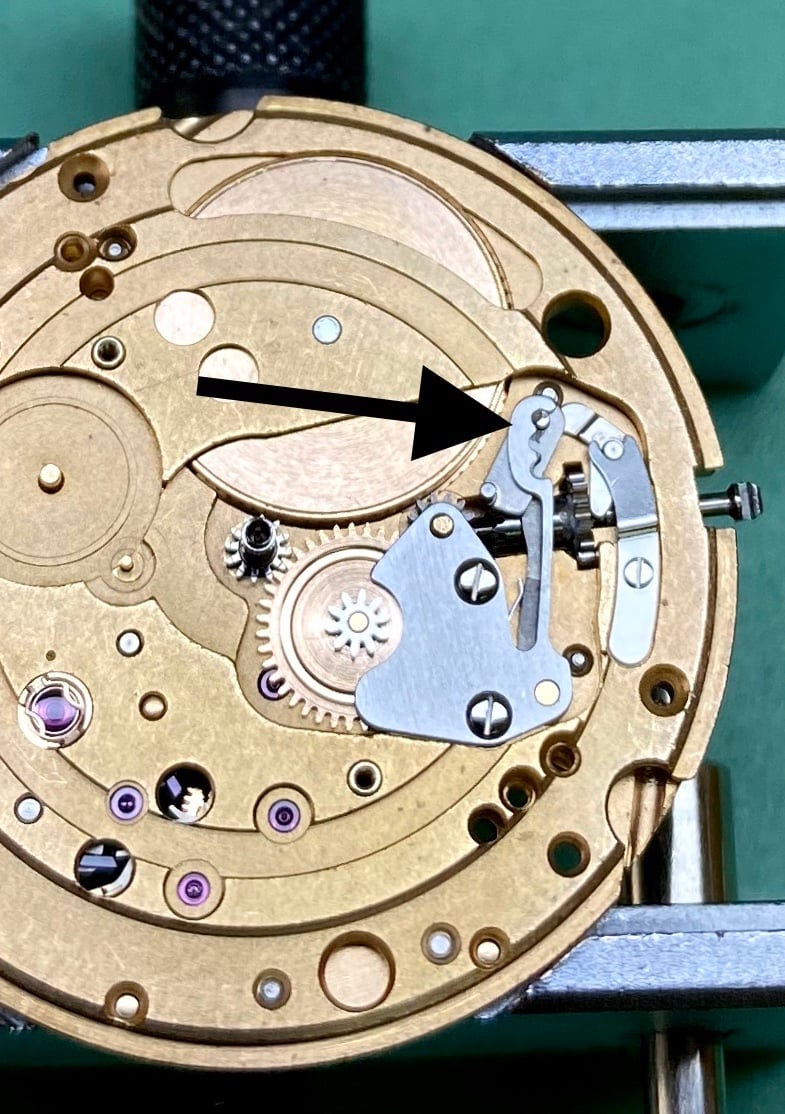

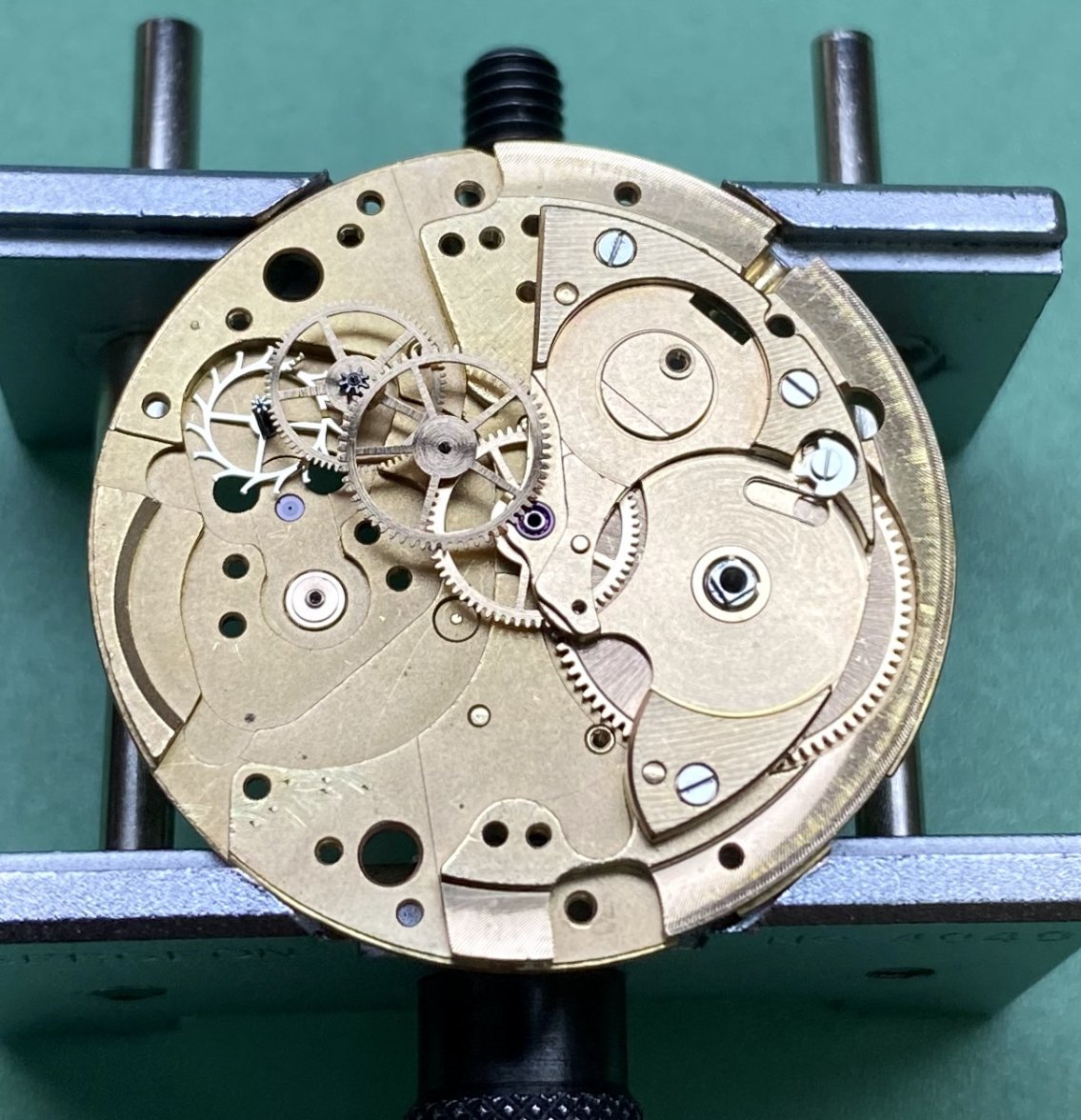

Here you can see the fantastic oiling job that was done. Oil spewing over the sides of the crown wheel.

As I take the movement to pieces I see more bad oiling. This winding stem is just a mess.

I take the pallet bridge off and remove the pallet fork. I see oil on the pallet fork pivots. This is watchmaking 101. Do not lubricate pallet pivots (in most but the extreme of cases).

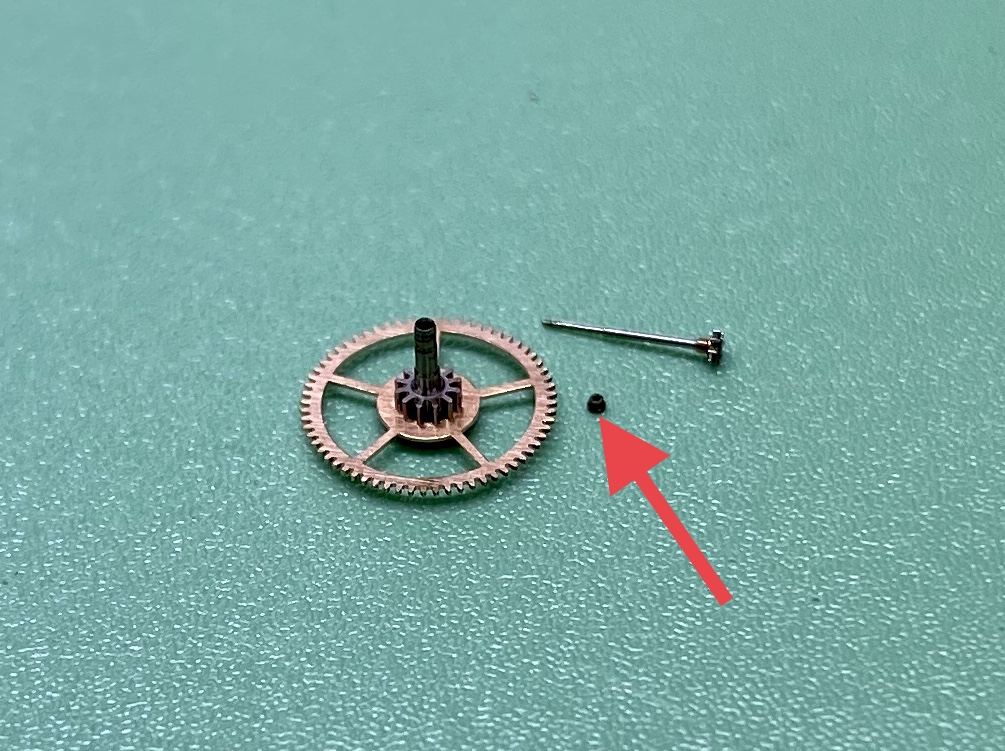

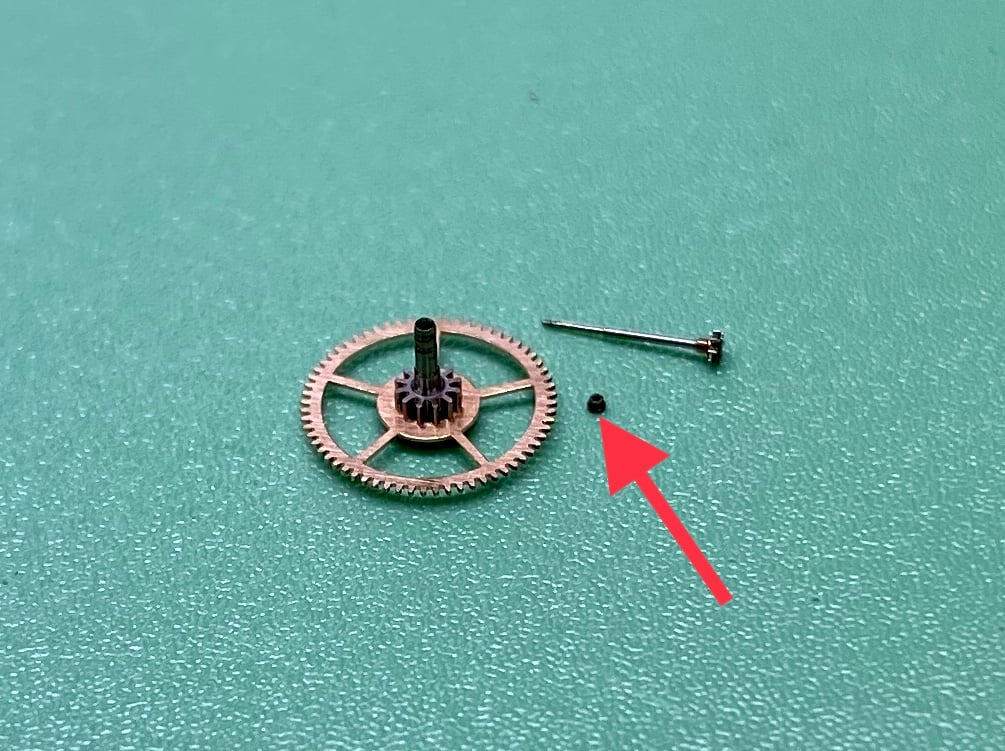

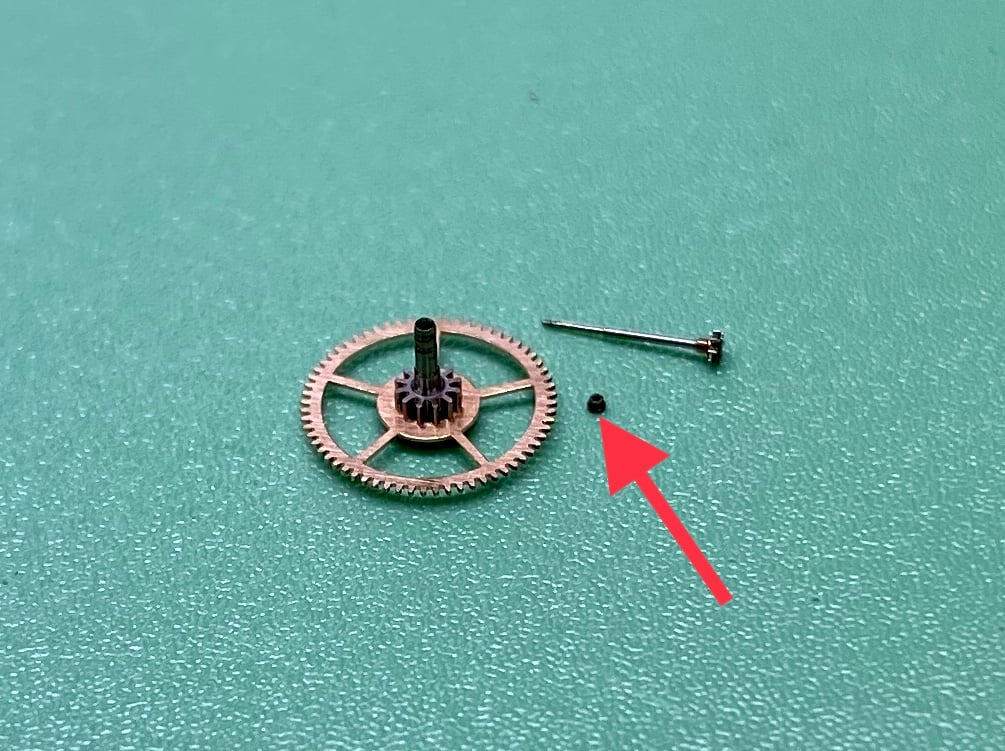

As I take the center wheel out the bushing in the end for the second's pinion comes loose. This was able to be repiared and didn't need to be replaced.

The balance roller was loose causing the watch to behave erratically and keep very bad time amongst other problems.

I sourced a new roller.

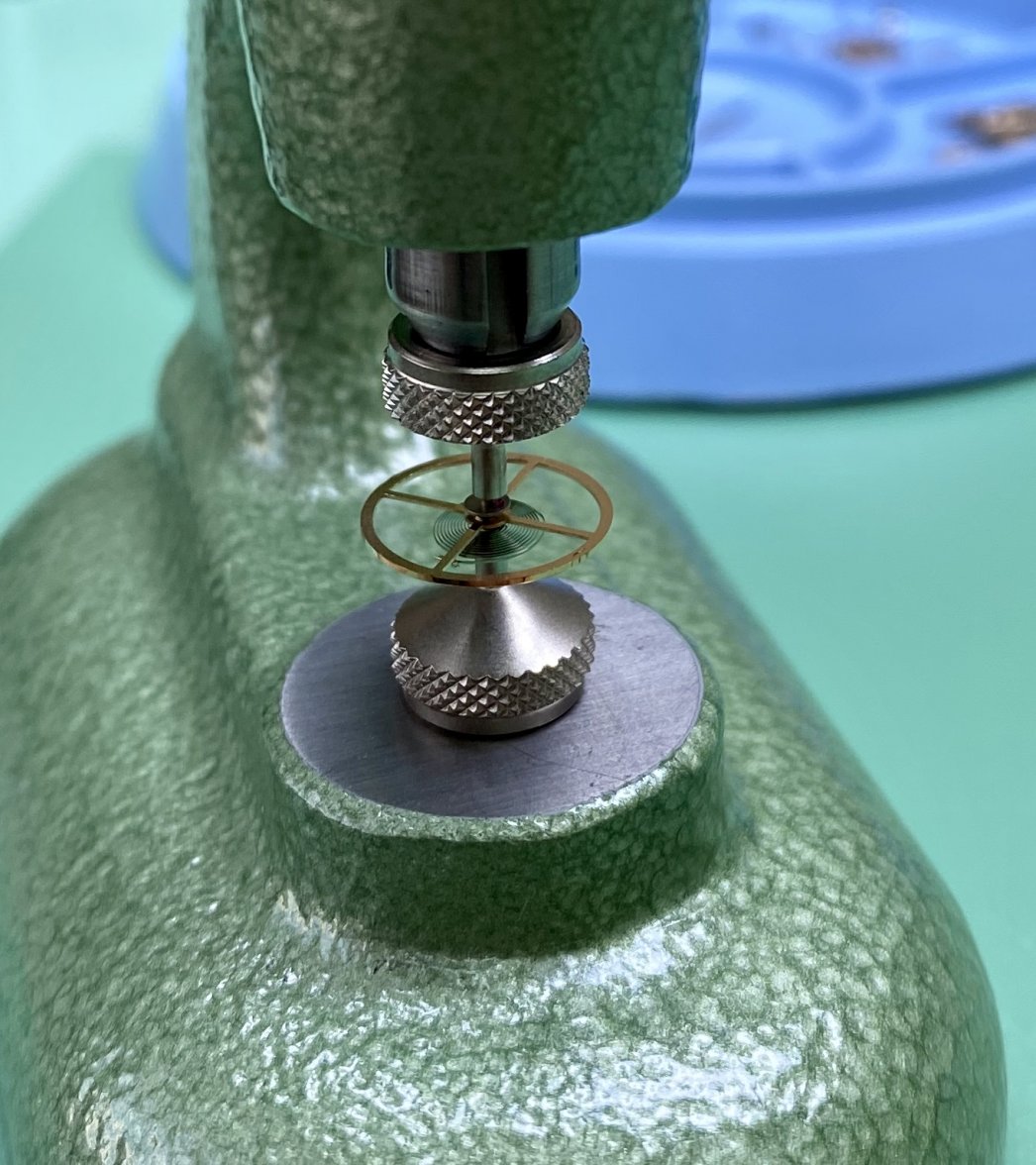

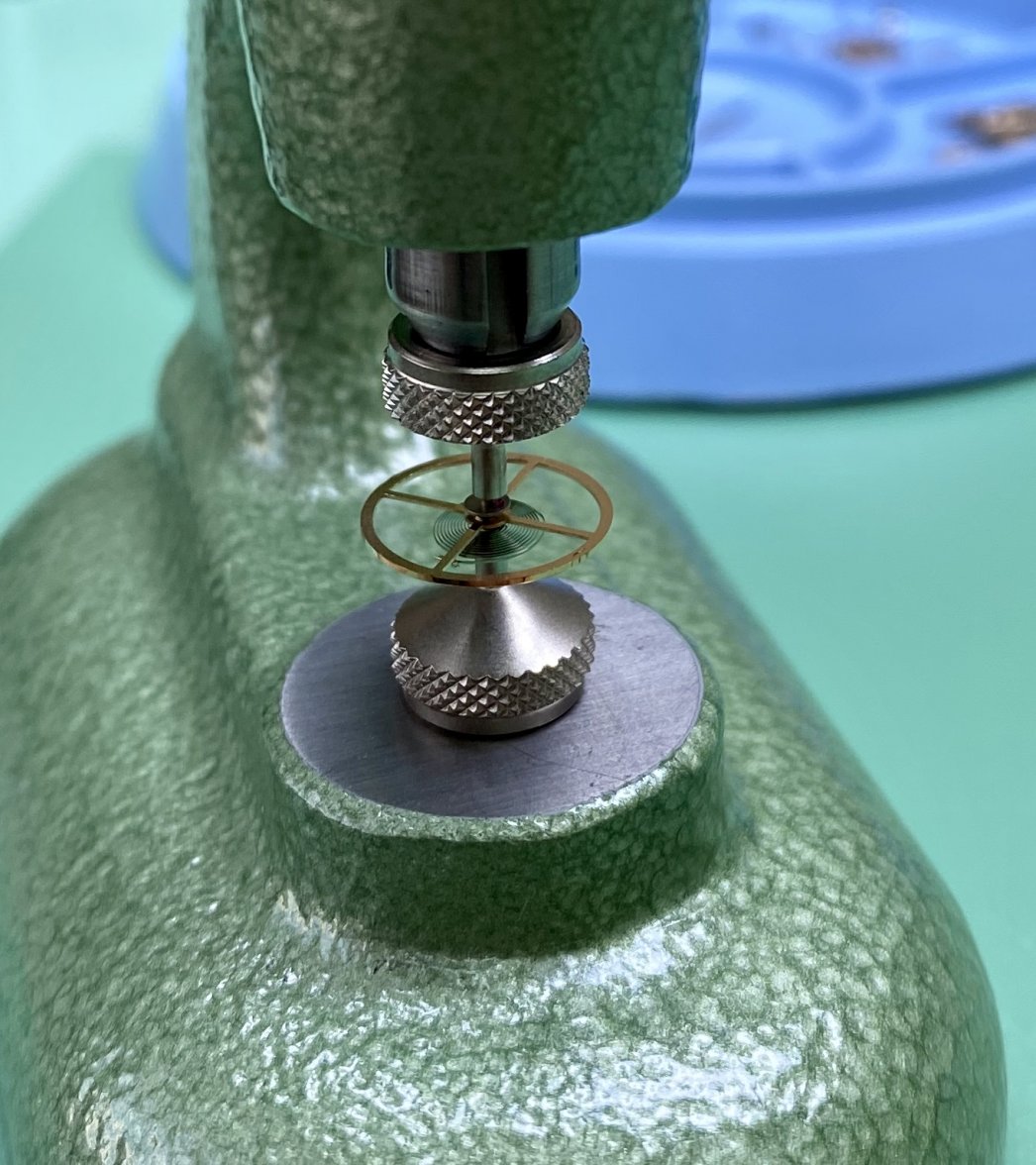

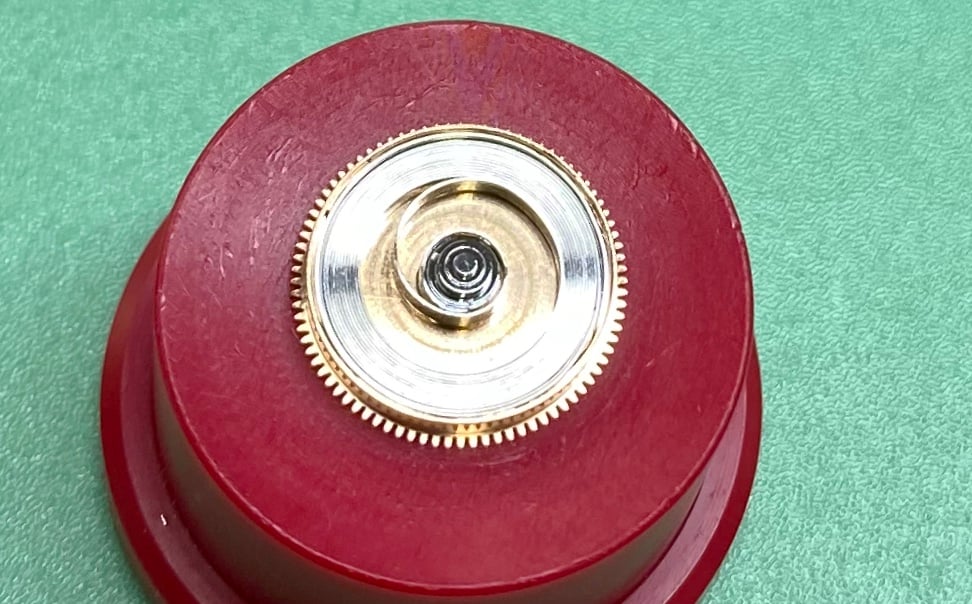

The roller is fitted with my Horia tool.

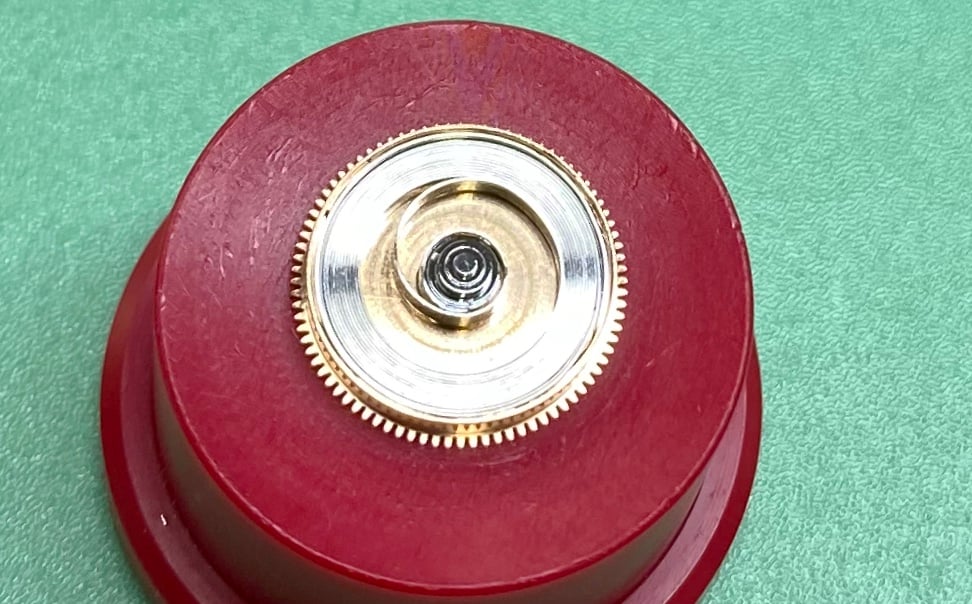

The mainspring didn't appear too dirty, but the barrel arbor seemed to have very old grease on it. I would assume it wasn't removed and cleaned with the last 'service'.

With the issues rectified and spare parts ordered, the movement was ready for cleaning, lubrication, and assembly.

We start by installing a new mainspring in the barrel.

I assemble the barrel bridge, lubricating as I go.

Now the gear train.

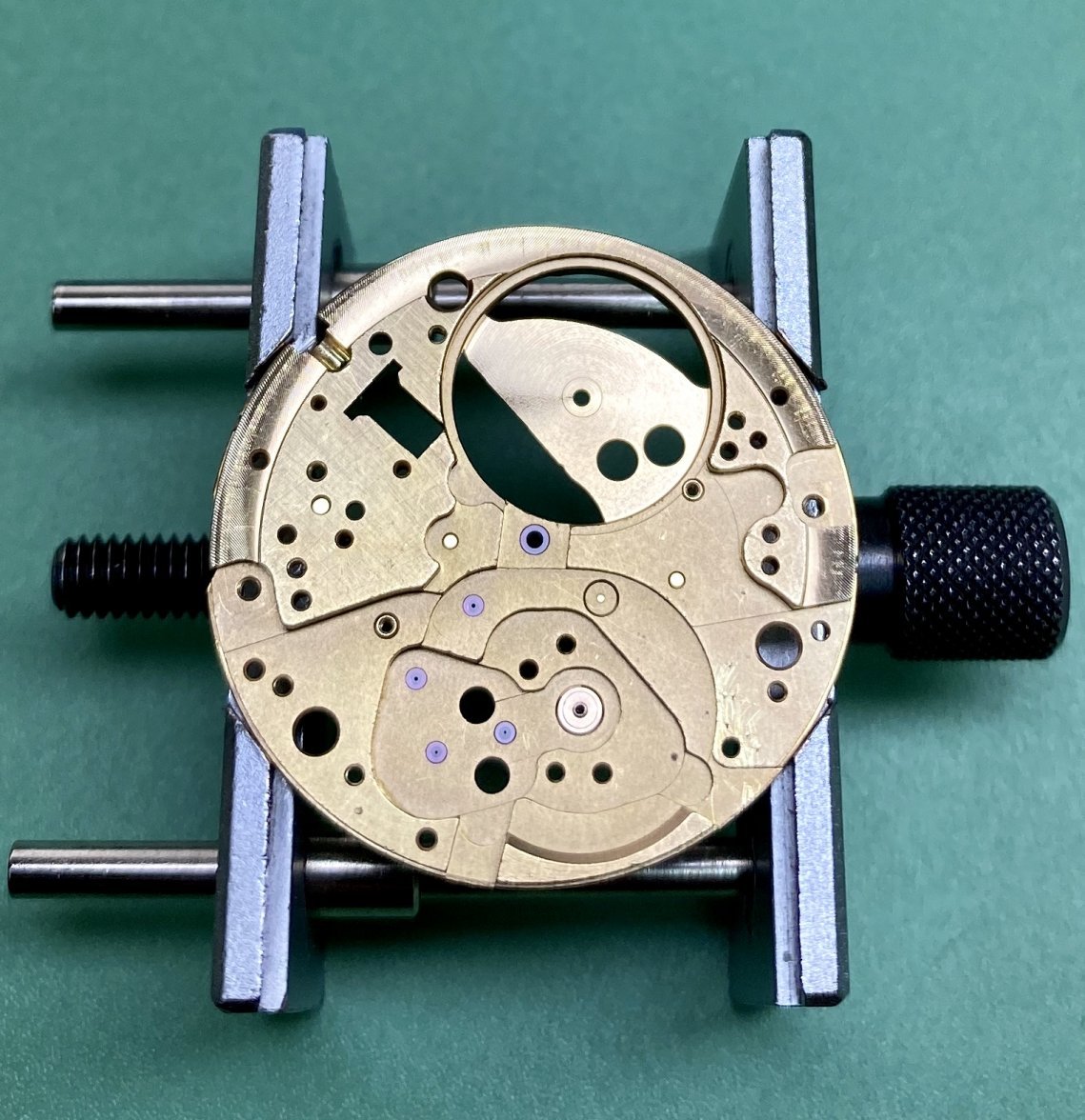

The rest of the movement goes back together correctly, without lubricating the pallet fork pivots! Notice the clean oiling and it's all where it should be.

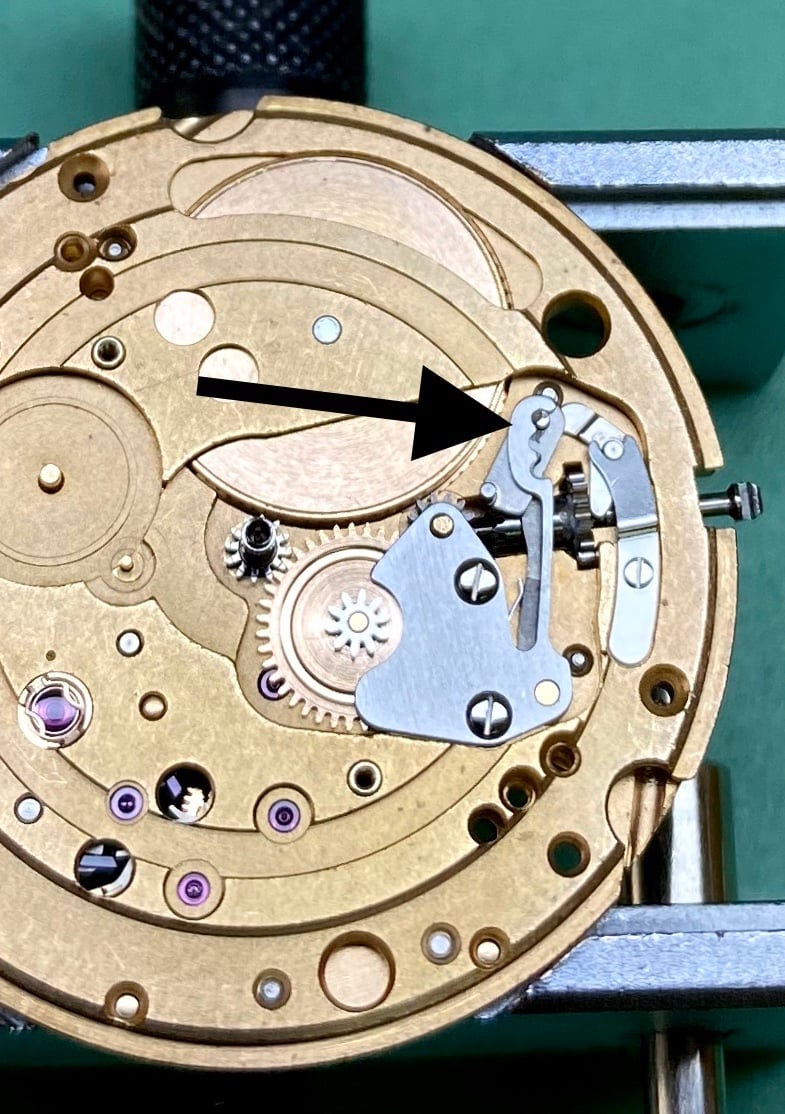

I mount the automatic block to check all the functions before installing the dial and hands.

The dial is now ready to be ut in place. I have removed all the glue and procured a correct replacement dial screw.

The dial and hands are in place, the watch is ready to be cased up and then tested.

The dial and hands are in place, the watch is ready to be cased up and then tested.

It's a strange thing, but oiling and doing clean work is such a simple aspect of watchmaking when it is looked at in a broader context. Manufacturing obsolete components by hand, correctly refinishing cases, refinishing movement components, etc are all vastly more complicated, yet the basics, lubricating a watch in clean and functional manner seem to be s difficult for so many.

This is a cautionary tale to not just trust watchmaker's blindly by reputation alone. Many times, reputation is based on price. Make sure whoever you choose knows what they are doing and they do it well!

Ashton Tracy

Despite this recent overhaul, the watch wasn't running as it should and I thought I would share what I found.

First off, these one-piece cases need to have air run through them to blow the crystal out so that's what I did. They have a split stem that simply comes detached when you pull the crown hard enough. When I pulled it out, the crown tube came out of the case with the stem. Problem number 1.

With the watch out of the case, I was ready to remove the dial and hands.

As I removed the dial I noticed the dial feet were intact, but there was one dial screw missing. Instead of procuring a new dial screw the previous watch repairer decided to glue the feet into the holes in the movement. Great move.

Here we can see some shoddy oiling of the setting lever, it's too much and seems to be very lumpy. It looks like an old oil that we don't use these days.

Now the movement side. The first obvious issue was the cap jewel for the incabloc setting. It was seated in place upside down.

Here you can see the fantastic oiling job that was done. Oil spewing over the sides of the crown wheel.

As I take the movement to pieces I see more bad oiling. This winding stem is just a mess.

I take the pallet bridge off and remove the pallet fork. I see oil on the pallet fork pivots. This is watchmaking 101. Do not lubricate pallet pivots (in most but the extreme of cases).

As I take the center wheel out the bushing in the end for the second's pinion comes loose. This was able to be repiared and didn't need to be replaced.

The balance roller was loose causing the watch to behave erratically and keep very bad time amongst other problems.

I sourced a new roller.

The roller is fitted with my Horia tool.

The mainspring didn't appear too dirty, but the barrel arbor seemed to have very old grease on it. I would assume it wasn't removed and cleaned with the last 'service'.

With the issues rectified and spare parts ordered, the movement was ready for cleaning, lubrication, and assembly.

We start by installing a new mainspring in the barrel.

I assemble the barrel bridge, lubricating as I go.

Now the gear train.

The rest of the movement goes back together correctly, without lubricating the pallet fork pivots! Notice the clean oiling and it's all where it should be.

I mount the automatic block to check all the functions before installing the dial and hands.

The dial is now ready to be ut in place. I have removed all the glue and procured a correct replacement dial screw.

The dial and hands are in place, the watch is ready to be cased up and then tested.

The dial and hands are in place, the watch is ready to be cased up and then tested.It's a strange thing, but oiling and doing clean work is such a simple aspect of watchmaking when it is looked at in a broader context. Manufacturing obsolete components by hand, correctly refinishing cases, refinishing movement components, etc are all vastly more complicated, yet the basics, lubricating a watch in clean and functional manner seem to be s difficult for so many.

This is a cautionary tale to not just trust watchmaker's blindly by reputation alone. Many times, reputation is based on price. Make sure whoever you choose knows what they are doing and they do it well!

Ashton Tracy