OllieOnTheRocks

·Hi guys, I hope you are well.

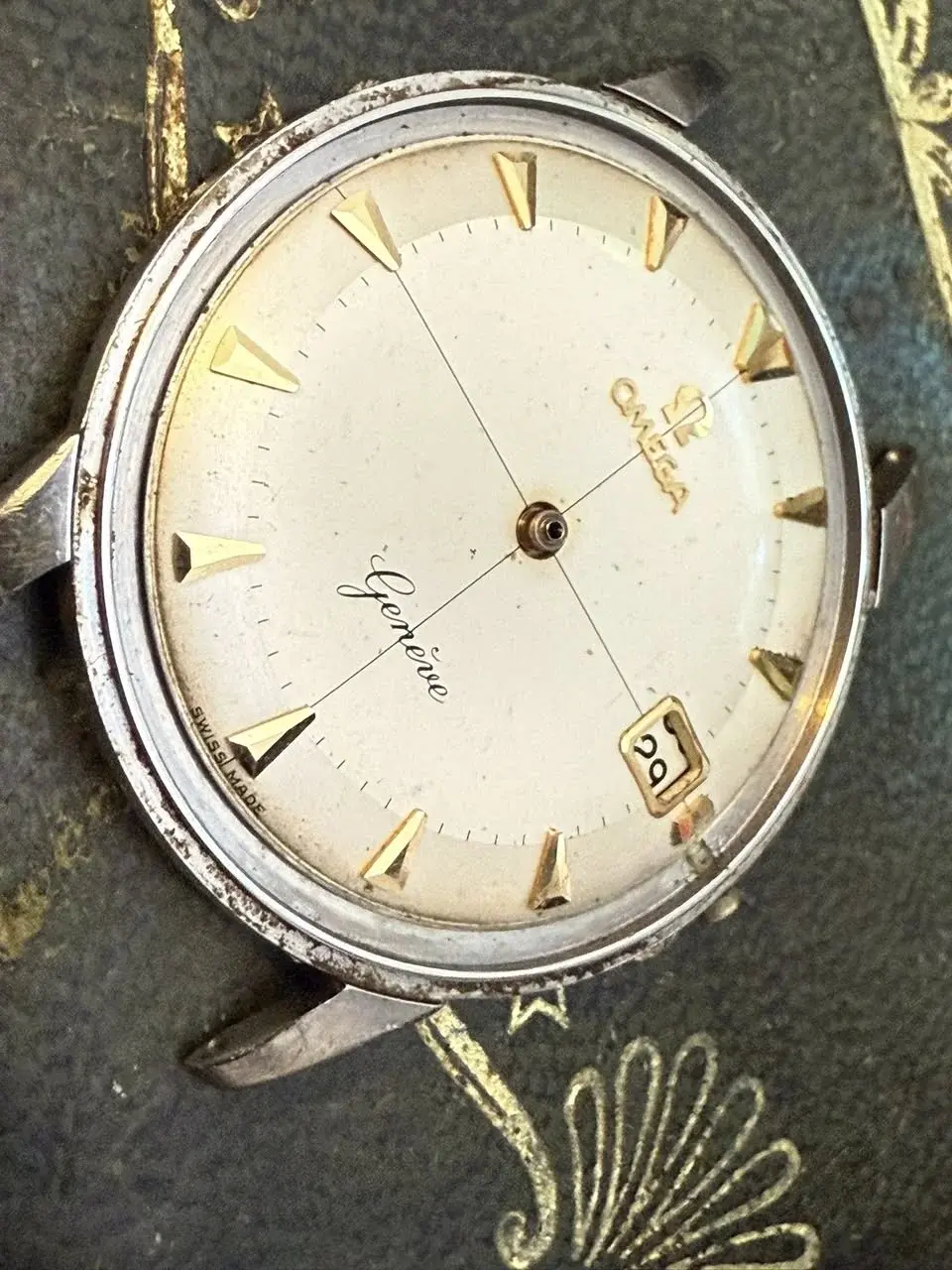

I have this gorgeous cursive Omega geneve that I intend to get working. It's running strong, but the calendar gets stuck at 4 and 29.

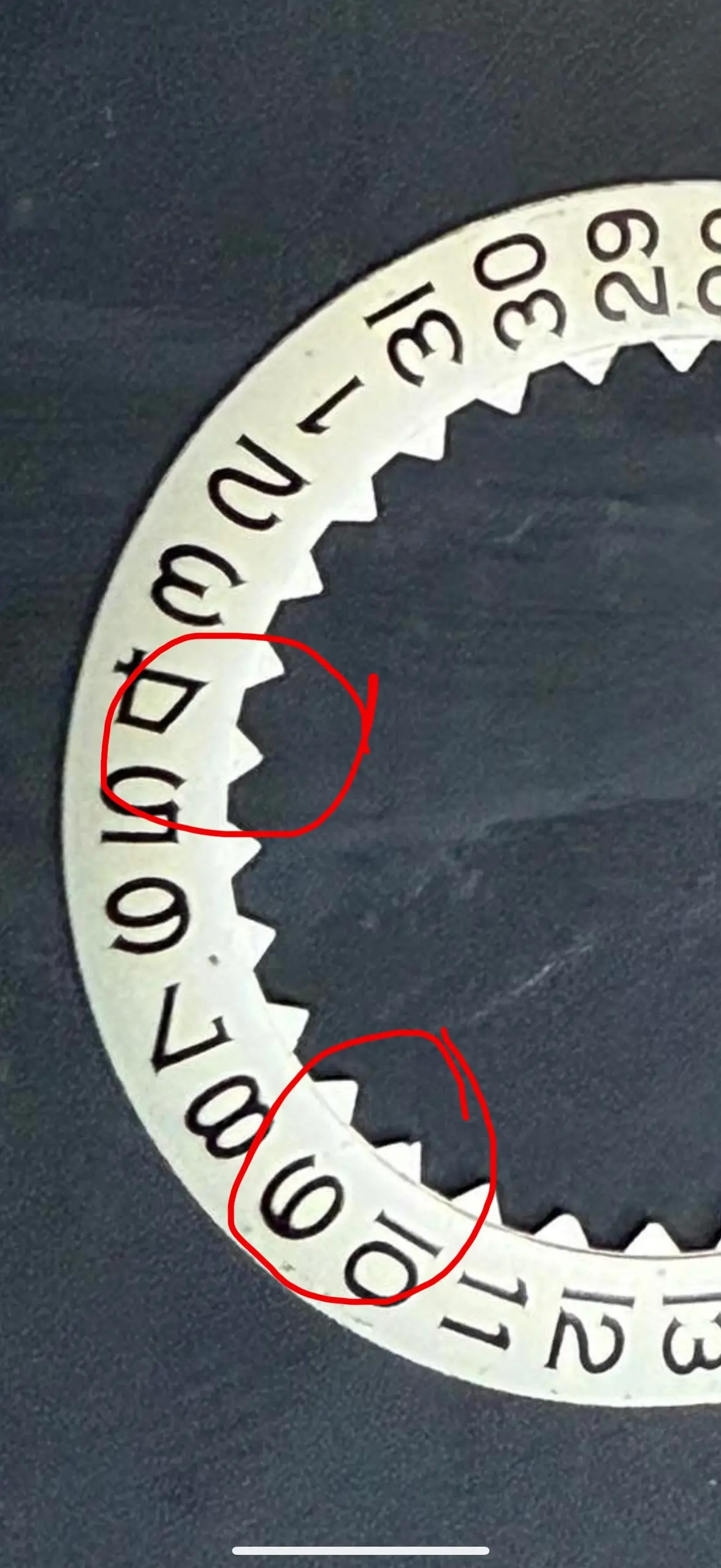

Having disassembled the watch, it would appear the teeth that engage when on those dates are worn, so despite it's deceivingly good condition, I think it will need to be replaced (unless anyone else can advise otherwise).

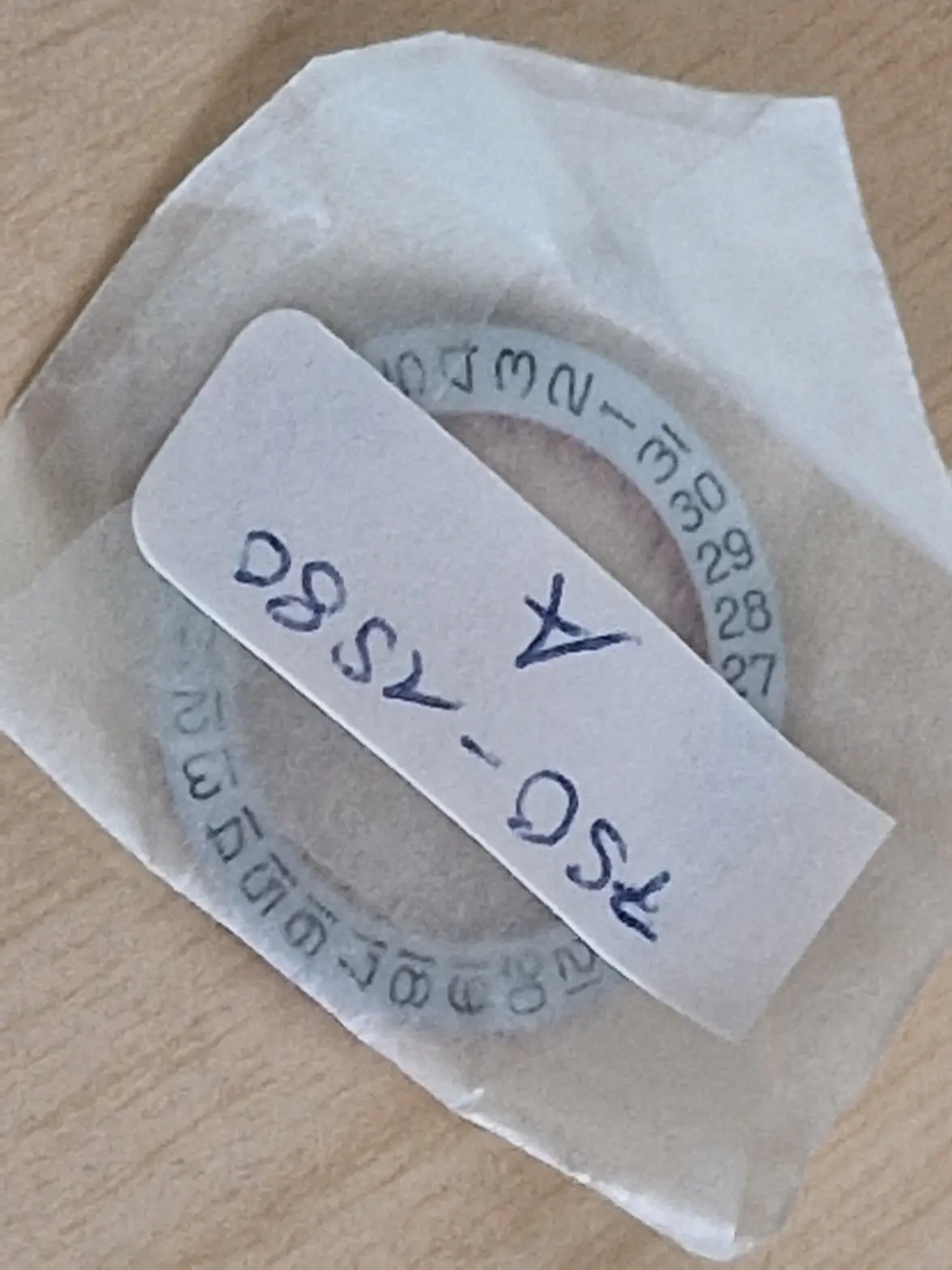

I've looked into the parts, and it would appear I require Omega part number 1500 A , which is the silver calendar disc with black date numbers.

Unfortuantely I missed a NOS one on ebay just last week at a reasonable price. I wondered if anyone here has one I could purchase?

Hope you are all well.

Oliver

I have this gorgeous cursive Omega geneve that I intend to get working. It's running strong, but the calendar gets stuck at 4 and 29.

Having disassembled the watch, it would appear the teeth that engage when on those dates are worn, so despite it's deceivingly good condition, I think it will need to be replaced (unless anyone else can advise otherwise).

I've looked into the parts, and it would appear I require Omega part number 1500 A , which is the silver calendar disc with black date numbers.

Unfortuantely I missed a NOS one on ebay just last week at a reasonable price. I wondered if anyone here has one I could purchase?

Hope you are all well.

Oliver