Sedagive

·Firstly I should say I am a novice watchmaker with fair experience on Seiko movements.

I wanted to service my Omega Constellation cal 564 my grandfather passed to me.

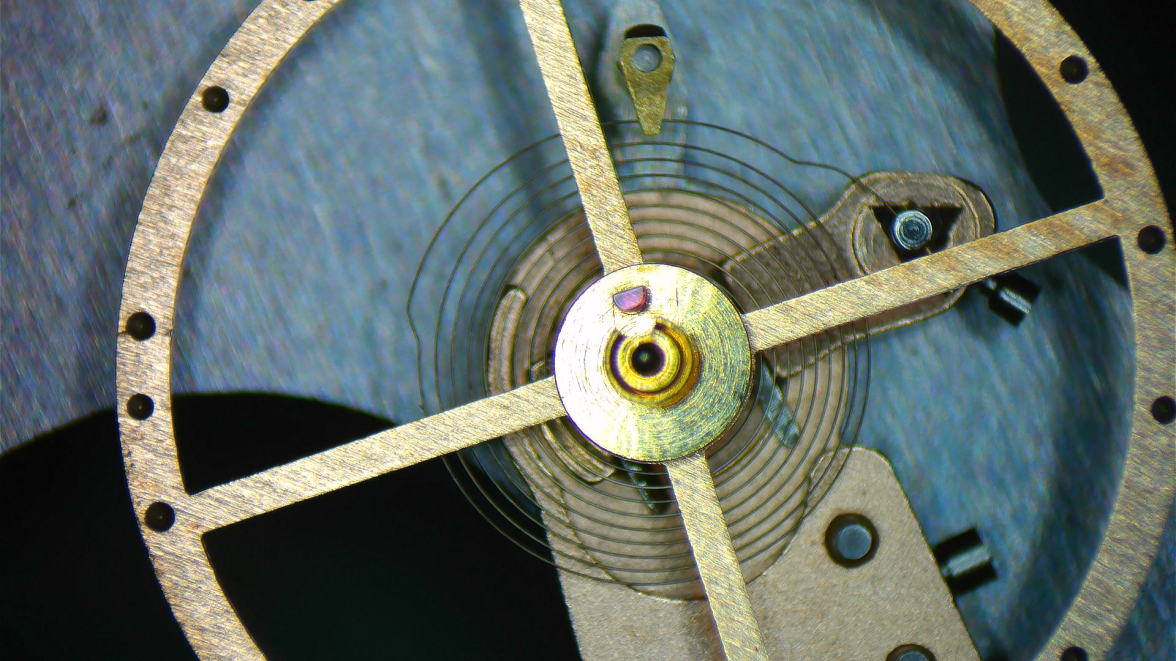

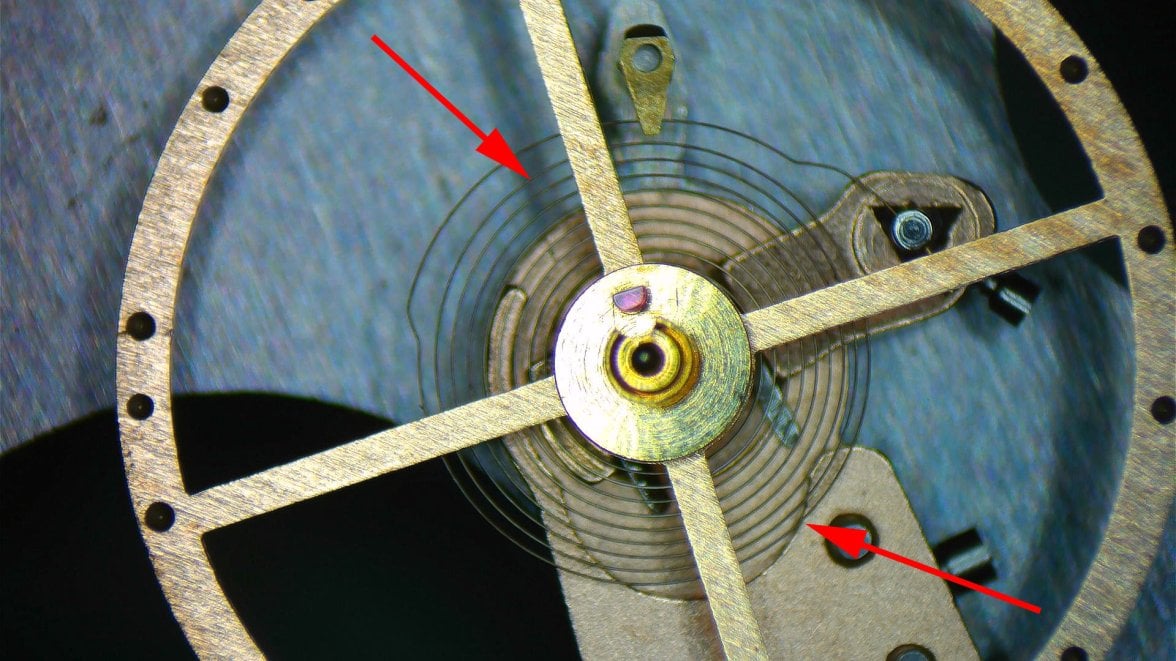

On the 1900 timer it was running very fast +300 with a beat error of 0.6

I can regulate it to its max setting giving +150 at best

I adjusted the beat lever to slow down rate to +4 but of course the beat error has increased to 7.3ms

So how can I get both rate and beat error in harmony?

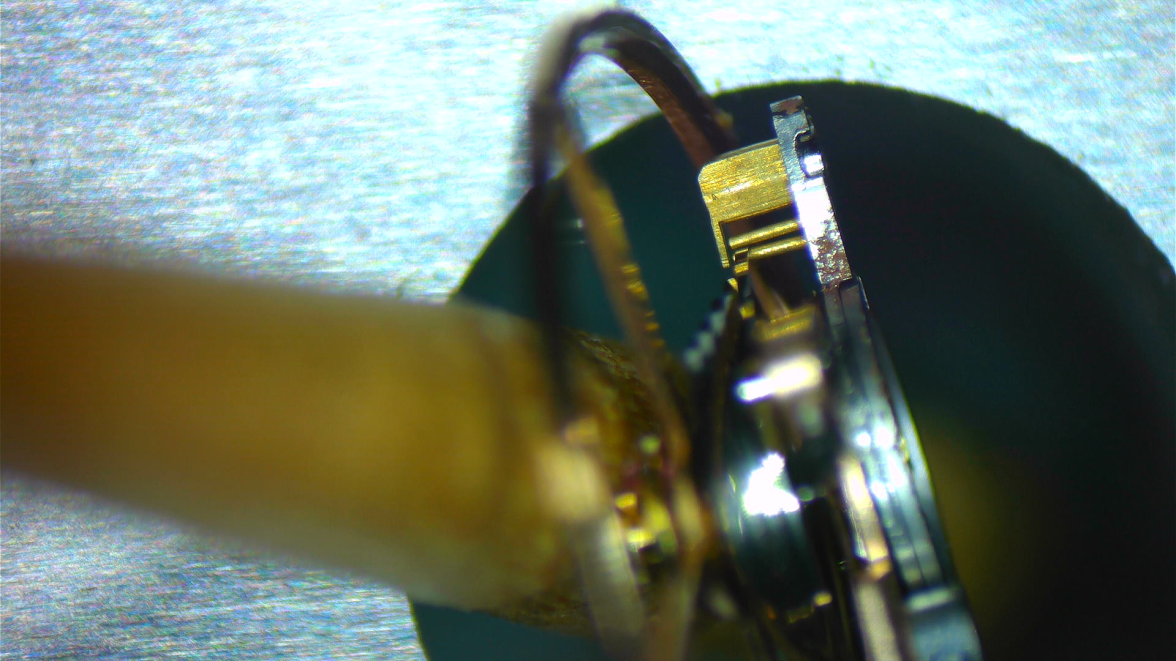

Should I shorten the balance spring by adjusting stud screw or is there a collet to adjust?

Or am I looking at this all wrong? Your thoughts and help would be appreciated before go deeper.

I wanted to service my Omega Constellation cal 564 my grandfather passed to me.

On the 1900 timer it was running very fast +300 with a beat error of 0.6

I can regulate it to its max setting giving +150 at best

I adjusted the beat lever to slow down rate to +4 but of course the beat error has increased to 7.3ms

So how can I get both rate and beat error in harmony?

Should I shorten the balance spring by adjusting stud screw or is there a collet to adjust?

Or am I looking at this all wrong? Your thoughts and help would be appreciated before go deeper.