- Posts

- 2

- Likes

- 0

Hitcher

·I am working on an Omega 1012.

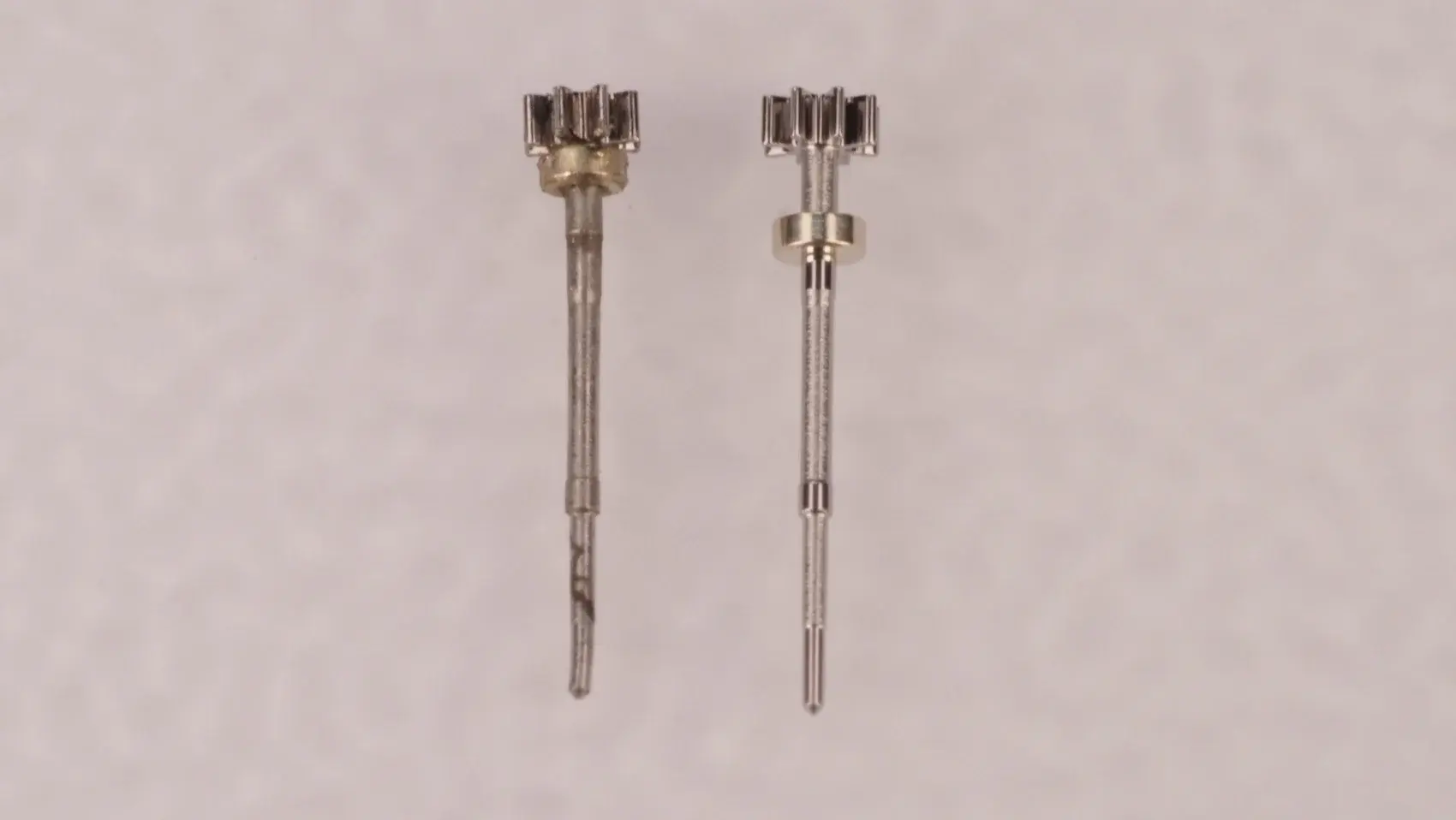

The friction spring for the seconds pinion did not look great so I bought a replacement from Gleave.

After installing the train, not the barrel or keyless yet, the action of the train, it’s stiff, very stiff, I literally have to force the centre wheel for the train to move.

It runs well without the friction spring.

I will have to bend the spring which I would not expect to do with a new spring.

I have seen a post explaining the ‘rule of thumb’ the third wheel should turn 1.5 times after lifting the friction spring.

I will do that when I have the barrel and keyless in as I don’t think there is a way of telling when only the train is installed?

The seconds pinion, according to the Omega technical guide from 1972, the seconds pinion is not lubricated. Is that right?

And they specify lubrication between the friction spring and the collar on the pinion which is generally not lubricated. Is this also right?

The friction spring for the seconds pinion did not look great so I bought a replacement from Gleave.

After installing the train, not the barrel or keyless yet, the action of the train, it’s stiff, very stiff, I literally have to force the centre wheel for the train to move.

It runs well without the friction spring.

I will have to bend the spring which I would not expect to do with a new spring.

I have seen a post explaining the ‘rule of thumb’ the third wheel should turn 1.5 times after lifting the friction spring.

I will do that when I have the barrel and keyless in as I don’t think there is a way of telling when only the train is installed?

The seconds pinion, according to the Omega technical guide from 1972, the seconds pinion is not lubricated. Is that right?

And they specify lubrication between the friction spring and the collar on the pinion which is generally not lubricated. Is this also right?