- Posts

- 296

- Likes

- 294

ErichKeane

·I started this thread: https://omegaforums.net/threads/exp...ing-started-with-servicing-for-myself.180073/

I started that thread trying to get into some watch repair, which I've been doing poorly (or at least with poor luck!). I had a ST36 that I screwed up badly, then a ST36 that a build went fine/well. THEN, a NH34 disassembly/reassembly that went without issue.

THEN, an Elgin 293 pocket watch that ended up having a busted balance that I'll be unable to fix.

However, that thread is getting big! SO, this is one for my next step:

I looked at the 3 pocket watches I have left. I have 2 Walthams that are running well, though perhaps lowish amplitude. As much as I want to dive into one, I'm a little tentative to work on those.

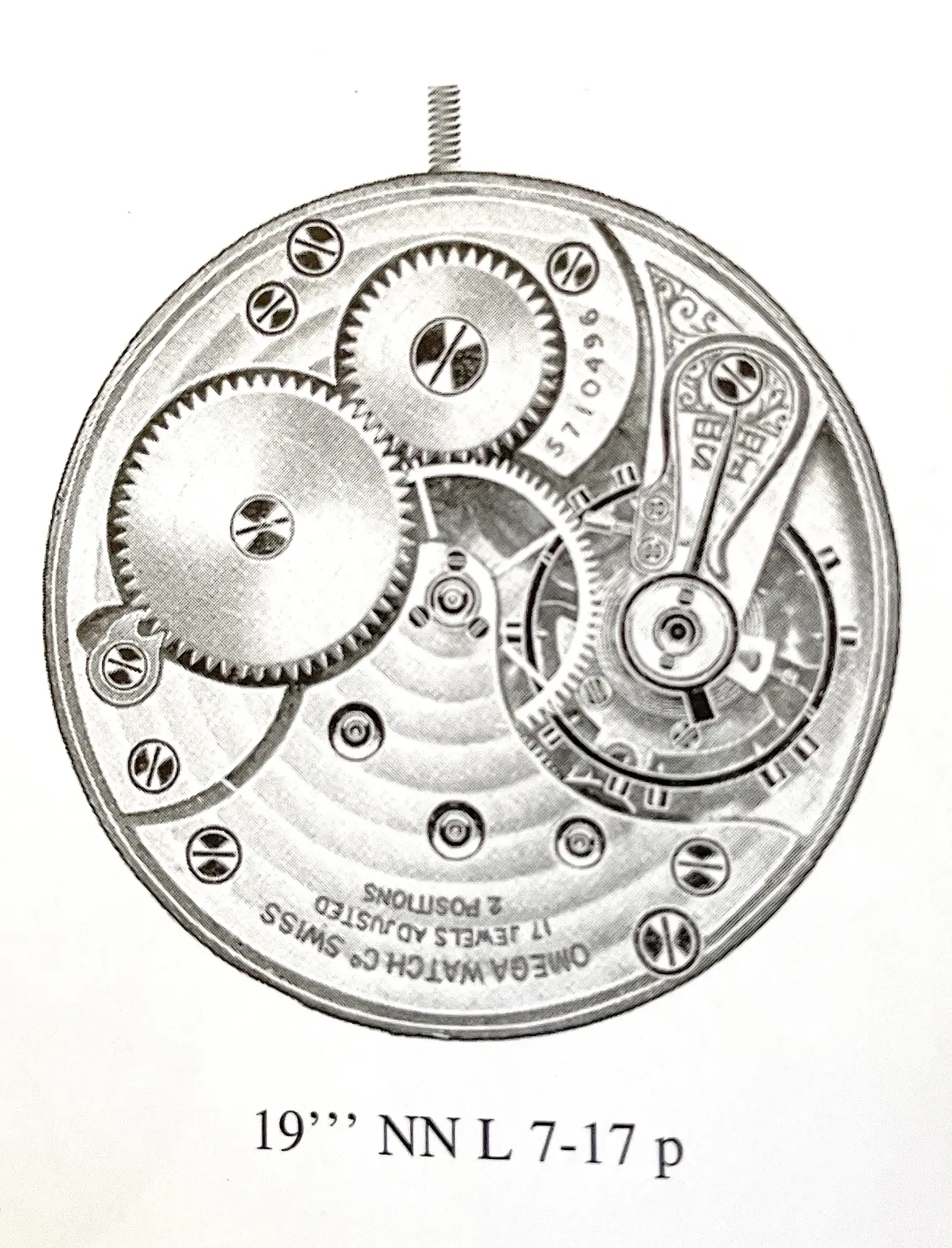

However, I still have this absolutely gorgeous Omega that according to THIS: https://pocketwatchdatabase.com/search/result/omega-watch-co/2433139

is a 1905, but no known movement. It says 16 jewels. OTHERWISE, I know nothing about it. It is absolutely beautiful both in movement and case, so I'm excited to dig into it.

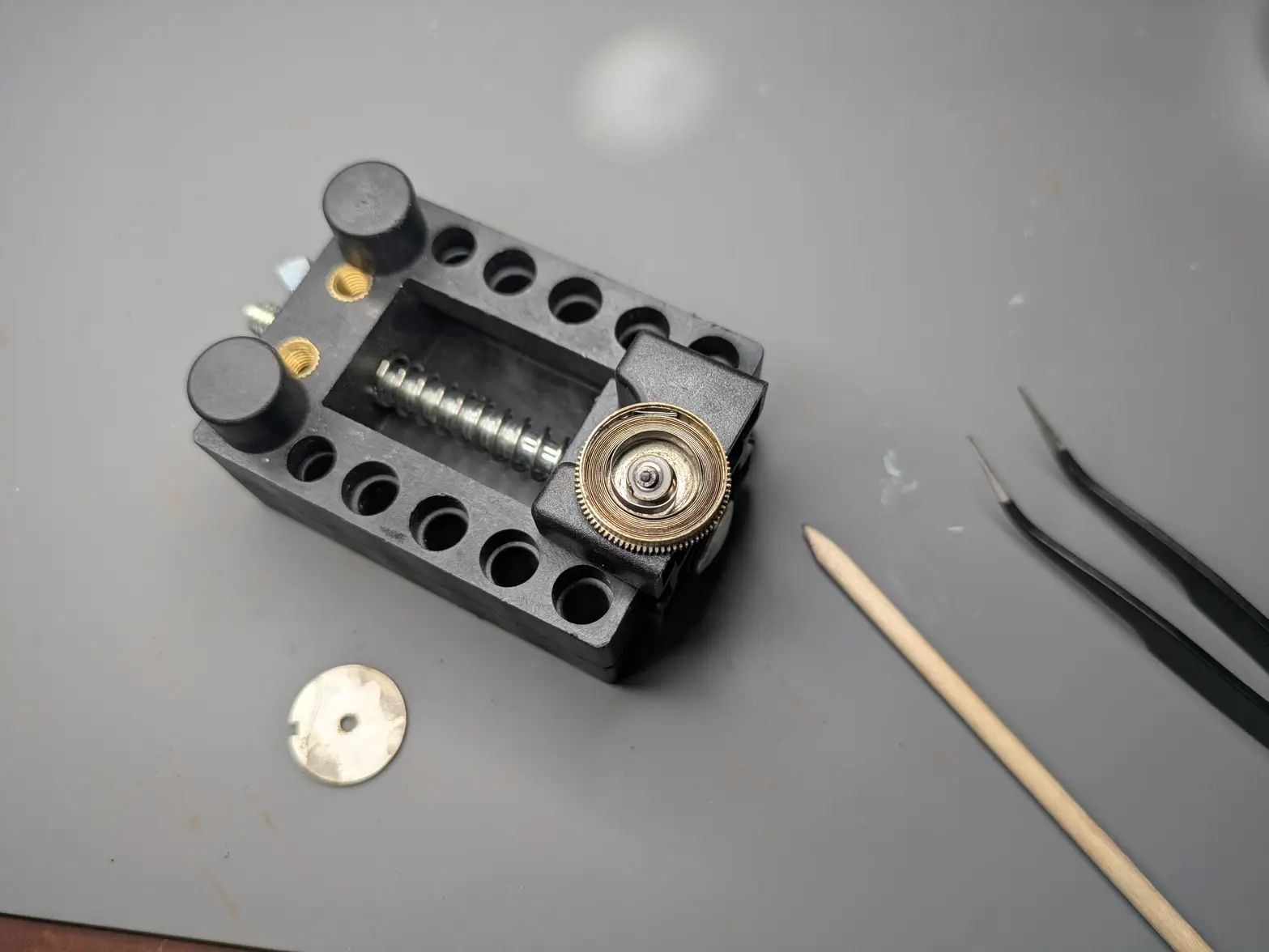

A quick function check shows: It is 'stuck' in wind mode. Pulling the crown works, but it seems to stay in wind mode. We'll see what that means!

WINDING the watch itself actually doesn't work. The click spring doesn't seem to be causing the click to engage the ratchet wheel, so it just spins.

The balance seems to be working 'fine', but I have a feeling I need a hair-spring, it looks a little messy in there, plus the balance wheel doesn't do its 'back and forth' thing.

ANYONE with ideas/help is appreciated, but otherwise feel free to stick around and comment/enjoy the process!

I started that thread trying to get into some watch repair, which I've been doing poorly (or at least with poor luck!). I had a ST36 that I screwed up badly, then a ST36 that a build went fine/well. THEN, a NH34 disassembly/reassembly that went without issue.

THEN, an Elgin 293 pocket watch that ended up having a busted balance that I'll be unable to fix.

However, that thread is getting big! SO, this is one for my next step:

I looked at the 3 pocket watches I have left. I have 2 Walthams that are running well, though perhaps lowish amplitude. As much as I want to dive into one, I'm a little tentative to work on those.

However, I still have this absolutely gorgeous Omega that according to THIS: https://pocketwatchdatabase.com/search/result/omega-watch-co/2433139

is a 1905, but no known movement. It says 16 jewels. OTHERWISE, I know nothing about it. It is absolutely beautiful both in movement and case, so I'm excited to dig into it.

A quick function check shows: It is 'stuck' in wind mode. Pulling the crown works, but it seems to stay in wind mode. We'll see what that means!

WINDING the watch itself actually doesn't work. The click spring doesn't seem to be causing the click to engage the ratchet wheel, so it just spins.

The balance seems to be working 'fine', but I have a feeling I need a hair-spring, it looks a little messy in there, plus the balance wheel doesn't do its 'back and forth' thing.

ANYONE with ideas/help is appreciated, but otherwise feel free to stick around and comment/enjoy the process!