MoclovFlop

·Took a gamble and bought this uncommon Omega Electroquartz desk clock in nonworking condition (not the one from ebay). Based on what I've found online and from other similar posts here from other members (paging @Tom Dick ) Very few of these are still out there out of the 1000 that were originally made.

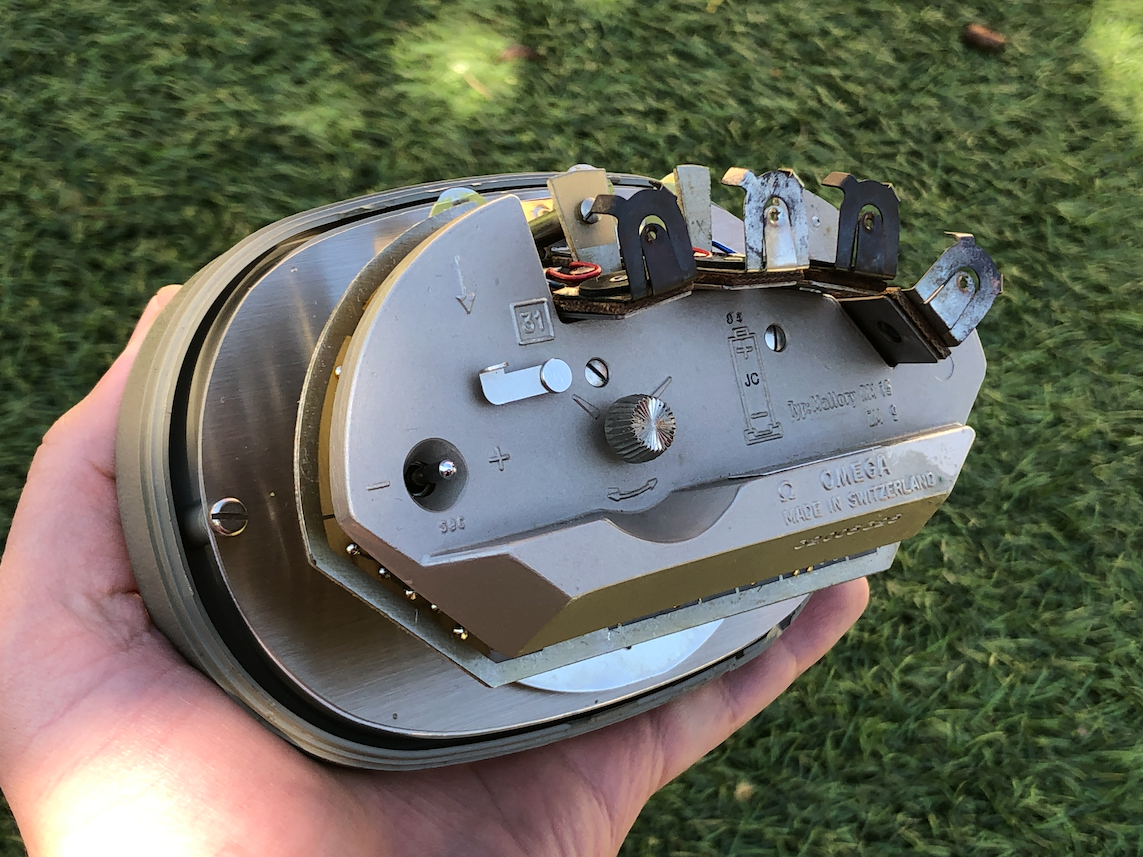

Anyways. Cleaned up some corrosion on the battery terminals, put in some fresh batteries and.... it fired up! ... Sort of. 😵💫

Seems the stepper motor is on its last legs. It ticks on the second without issue, so at the very least the quartz system is good. But the hand staggers or will stay in one spot just ticking.

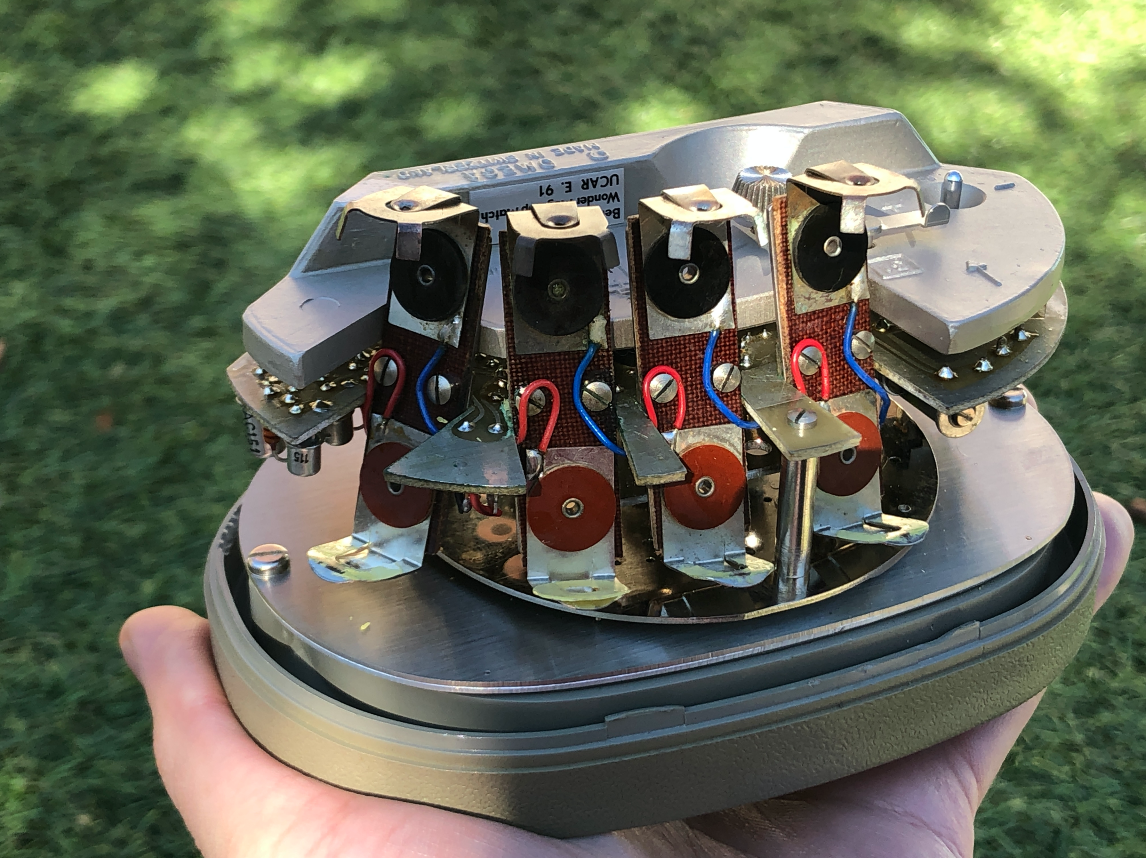

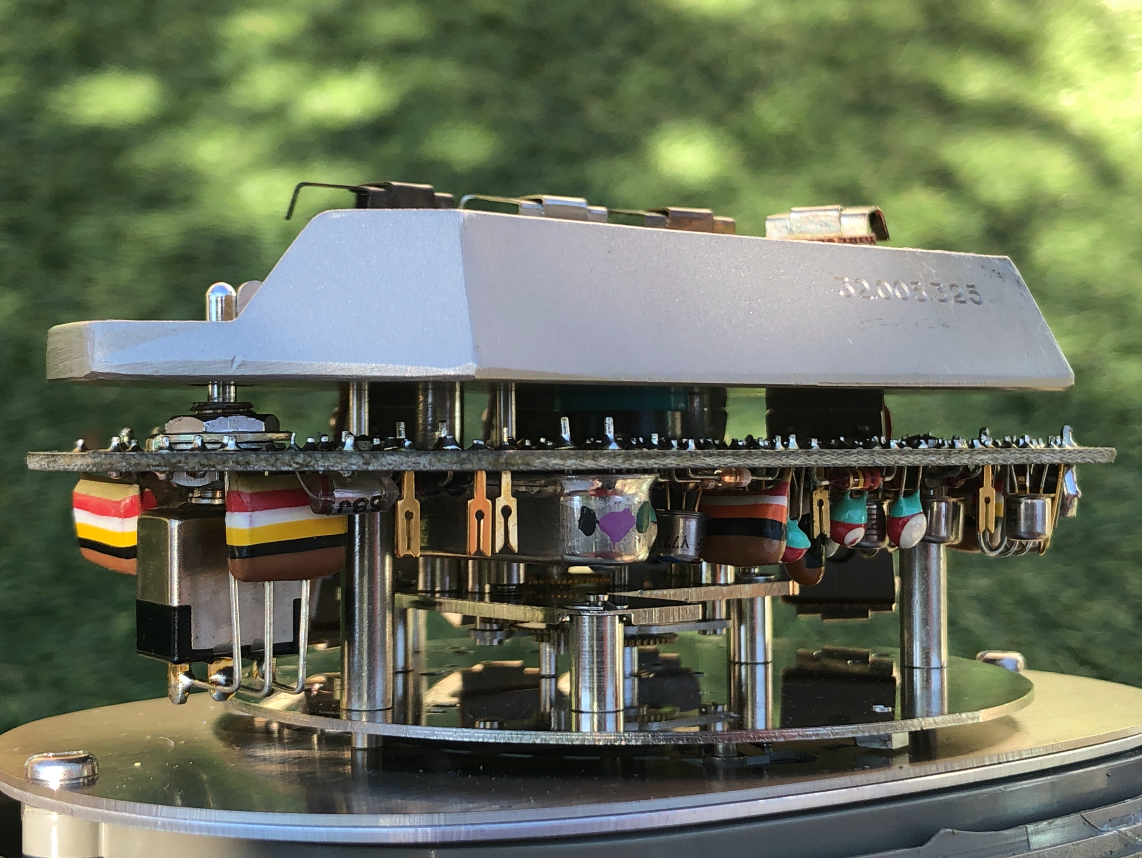

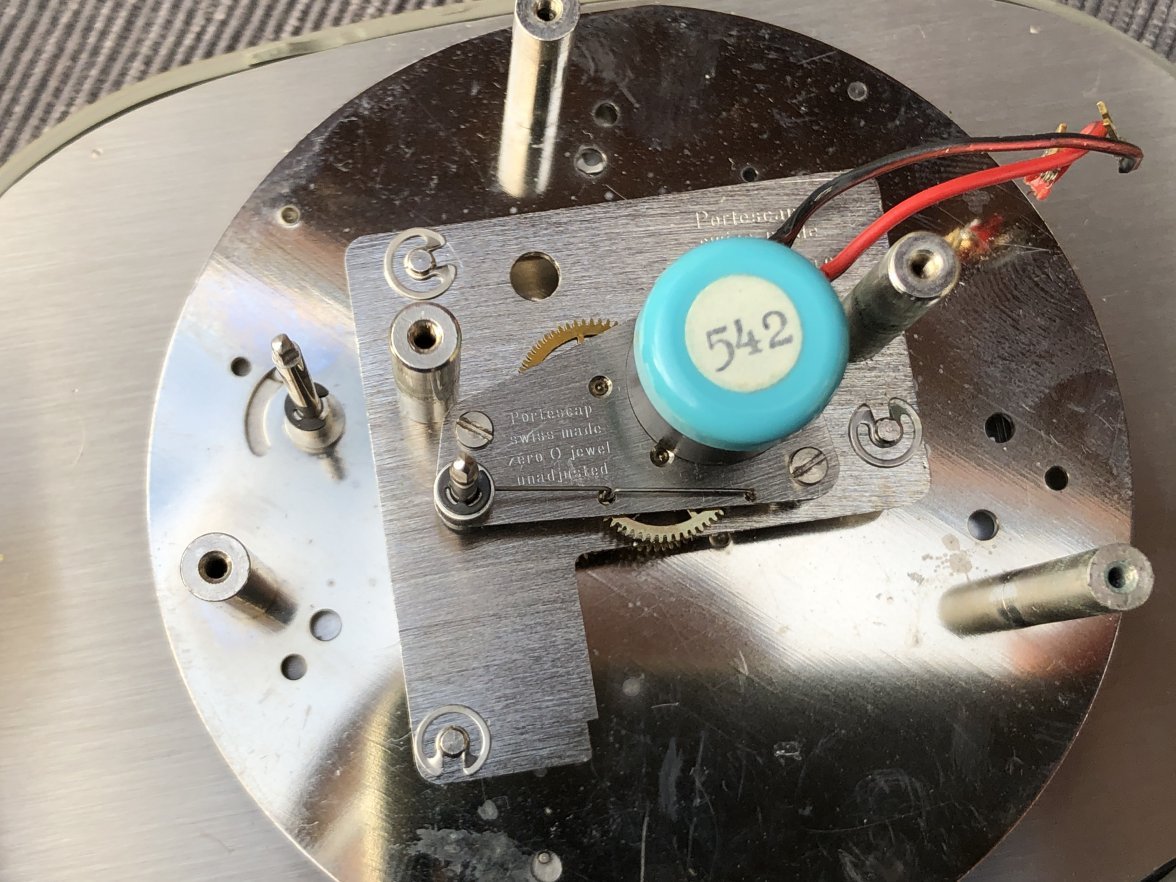

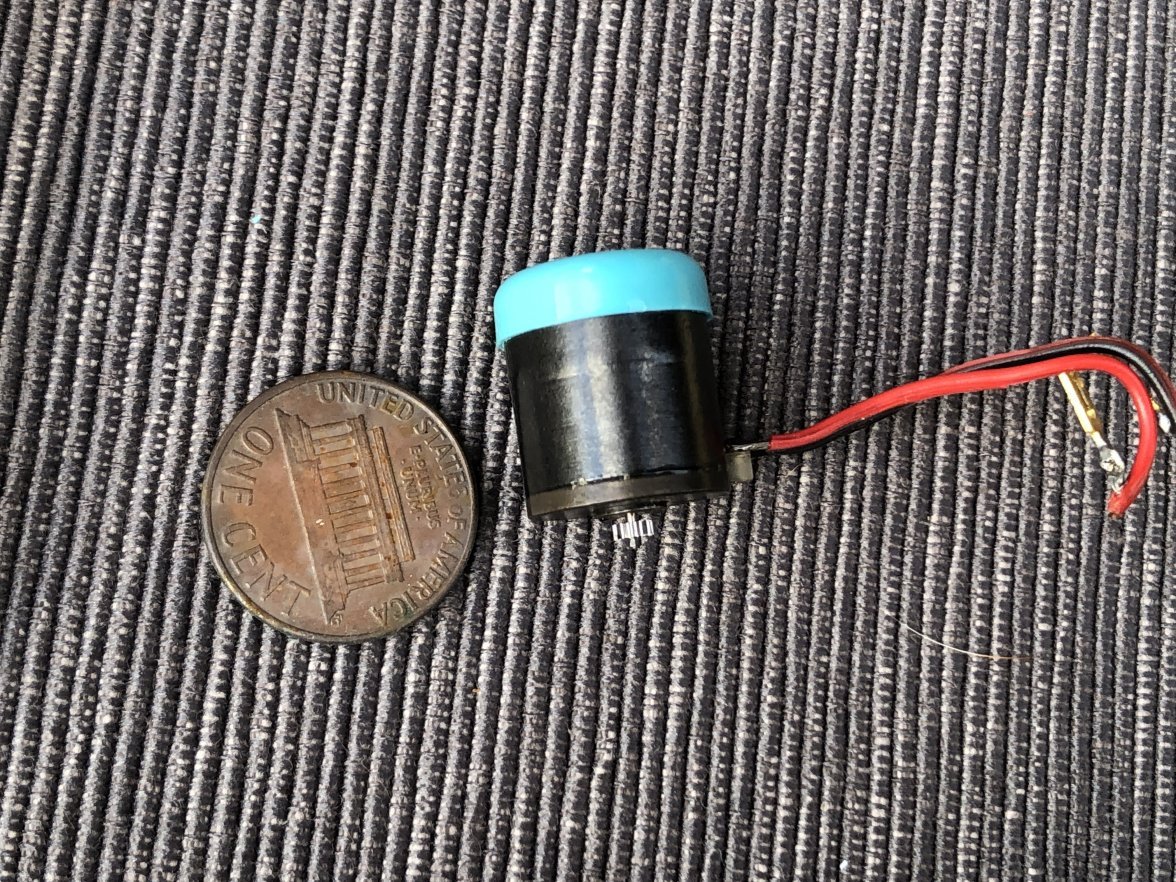

Took it apart (Modular sandwich), checked the geartrain for interference, cleaned the grounds, etc and took a look at the stepper. Everything is clean, but it seems like it has more front to back play than it should. When face down, it'll tick better, so I'm betting either a bushing in the motor is bad or some other interference between the coils and the rotor. It's pretty well contained, and not obviously serviceable. But there is probably a way.

Marking on the motor plate say it's made by Portescap, and they still make other steppers, but nothing even close to this. I'll be reaching out to them to see if they have any service centers who might be able to figure it out.

But otherwise, anyone have a friend who has a collection of Caliber 1390 parts laying around somewhere? Maybe some old clockmakers in Switzerland?

Or more realistically, any recommendations on someone who can service unique quartz clocks?

Otherwise, I have a nice sounding display piece 😟

Anyways. Cleaned up some corrosion on the battery terminals, put in some fresh batteries and.... it fired up! ... Sort of. 😵💫

Seems the stepper motor is on its last legs. It ticks on the second without issue, so at the very least the quartz system is good. But the hand staggers or will stay in one spot just ticking.

Took it apart (Modular sandwich), checked the geartrain for interference, cleaned the grounds, etc and took a look at the stepper. Everything is clean, but it seems like it has more front to back play than it should. When face down, it'll tick better, so I'm betting either a bushing in the motor is bad or some other interference between the coils and the rotor. It's pretty well contained, and not obviously serviceable. But there is probably a way.

Marking on the motor plate say it's made by Portescap, and they still make other steppers, but nothing even close to this. I'll be reaching out to them to see if they have any service centers who might be able to figure it out.

But otherwise, anyone have a friend who has a collection of Caliber 1390 parts laying around somewhere? Maybe some old clockmakers in Switzerland?

Or more realistically, any recommendations on someone who can service unique quartz clocks?

Otherwise, I have a nice sounding display piece 😟