mcgyver

·I got a request to make a new insert for a 166.0177 a while ago.

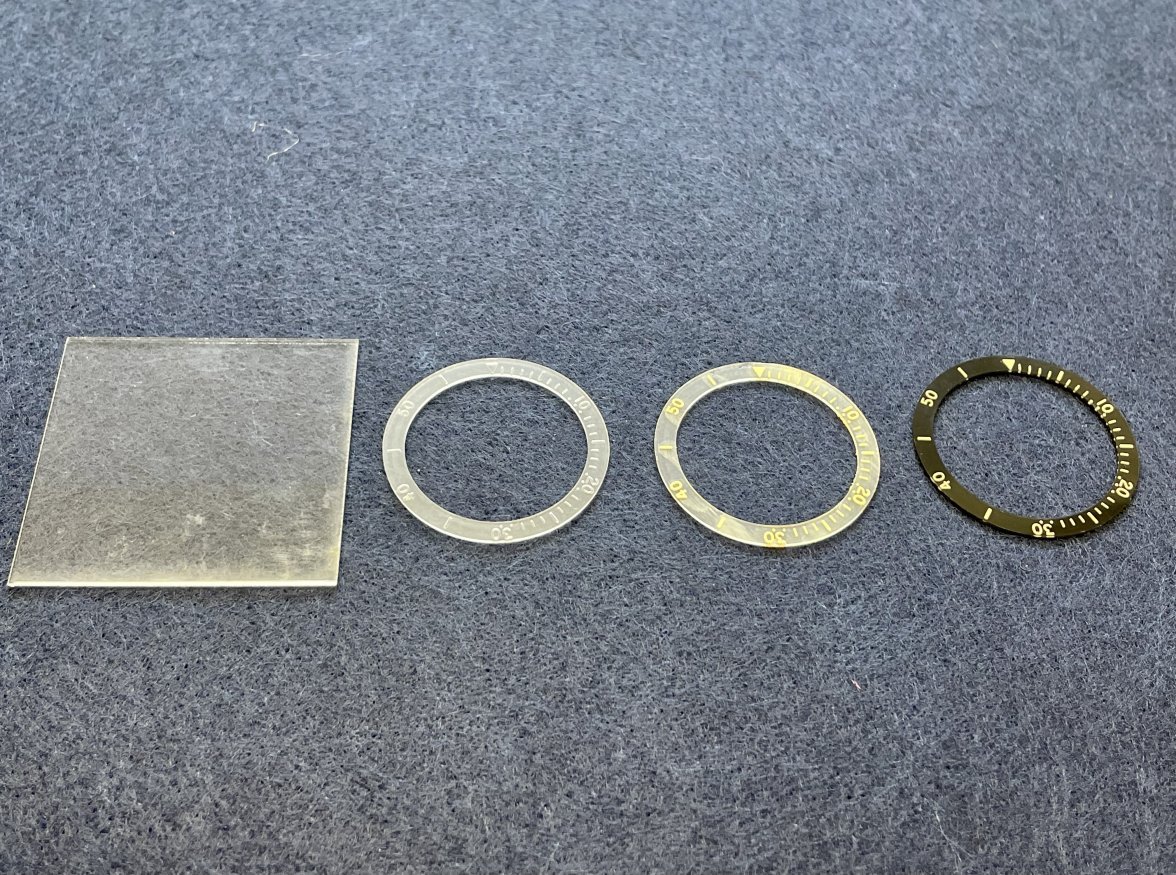

The original insert is 0.8mm thick so I started with a piece if 1mm acrylic sheet, machined it using a 0.2mm mill.

After milling the piece is deburred, cleaned and then the numbers/indexes are filled with a lume/paint mixture.

Finally the back gets four coats of black paint and the front a buff.

The different stages shown.

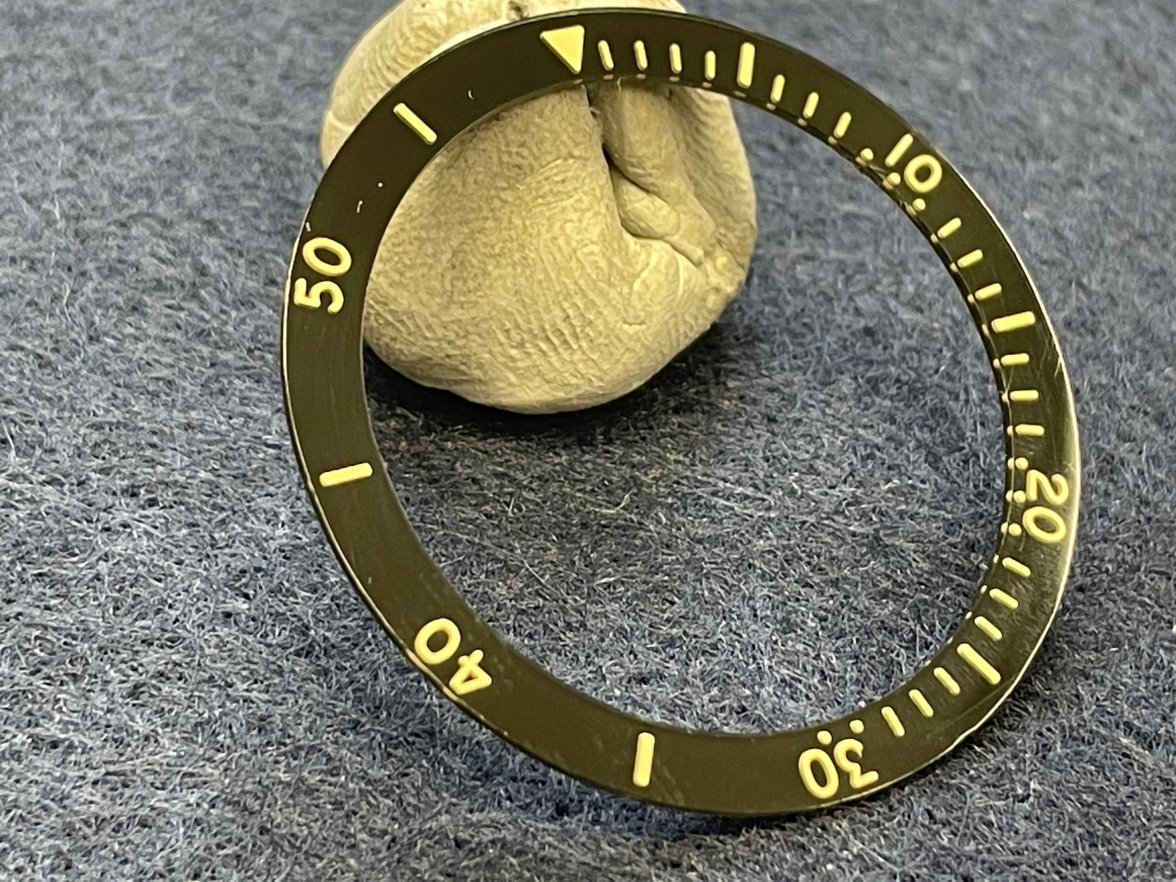

Final result

Now I just need to cut some dubble sided tape and tjey are ready for instalation.

The original insert is 0.8mm thick so I started with a piece if 1mm acrylic sheet, machined it using a 0.2mm mill.

After milling the piece is deburred, cleaned and then the numbers/indexes are filled with a lume/paint mixture.

Finally the back gets four coats of black paint and the front a buff.

The different stages shown.

Final result

Now I just need to cut some dubble sided tape and tjey are ready for instalation.