- Posts

- 10

- Likes

- 0

deloid

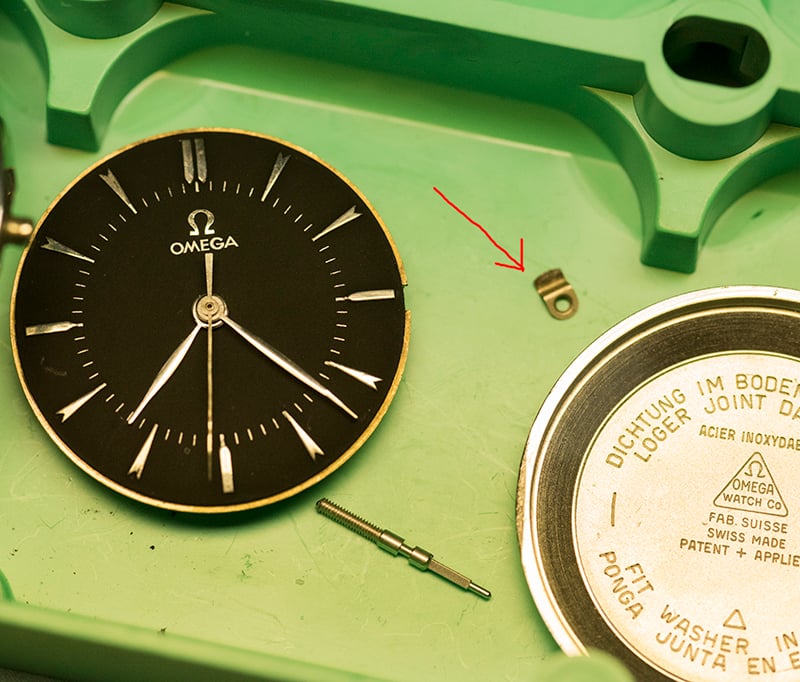

·I almost finished this Omega 284 and in testing the stem I tried to fix the mvt in the case and they are a bit shy of the slot so the mvt can move just a bit when tested.

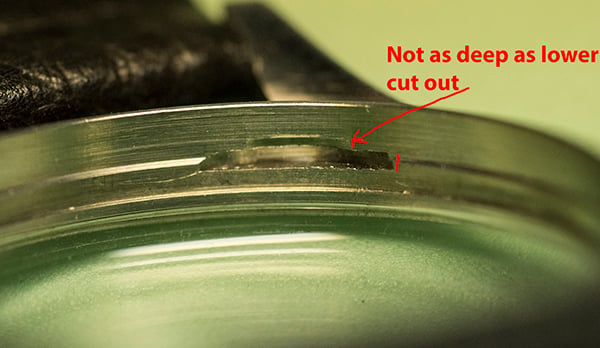

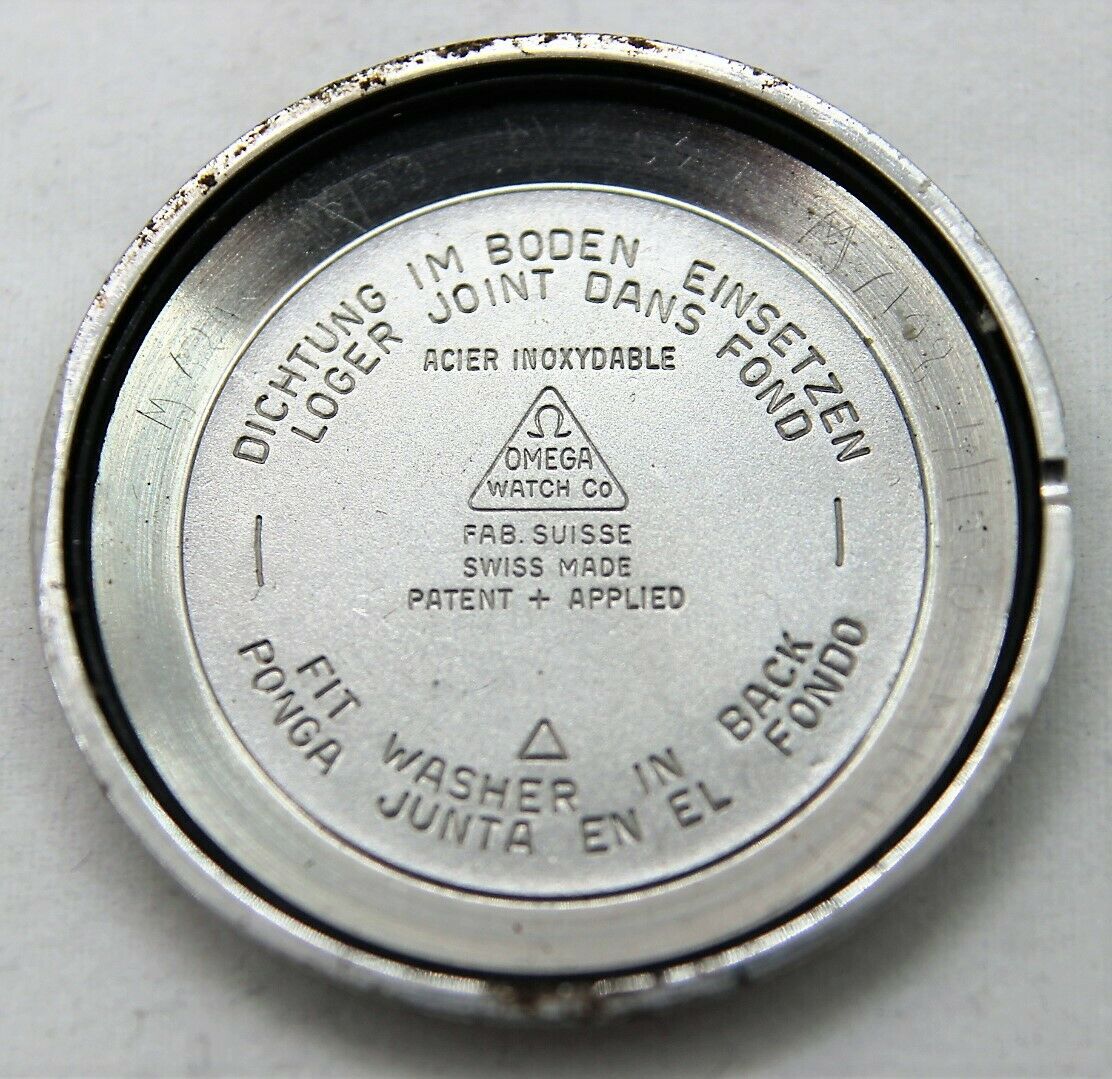

The case looks right , the case back is Omega and in a style I have seen before. I don't think this is the wrong case for this movement. When looking at the slot it looks like it was modified by raising the height with a more shallow slot. I don't have another similar mvt/case to compare it to.

I could add a spacer under the case clamp/spring but I'd like to understand what may have happened.

Thanks for your thoughts.

Dean

The case looks right , the case back is Omega and in a style I have seen before. I don't think this is the wrong case for this movement. When looking at the slot it looks like it was modified by raising the height with a more shallow slot. I don't have another similar mvt/case to compare it to.

I could add a spacer under the case clamp/spring but I'd like to understand what may have happened.

Thanks for your thoughts.

Dean