Deafcon

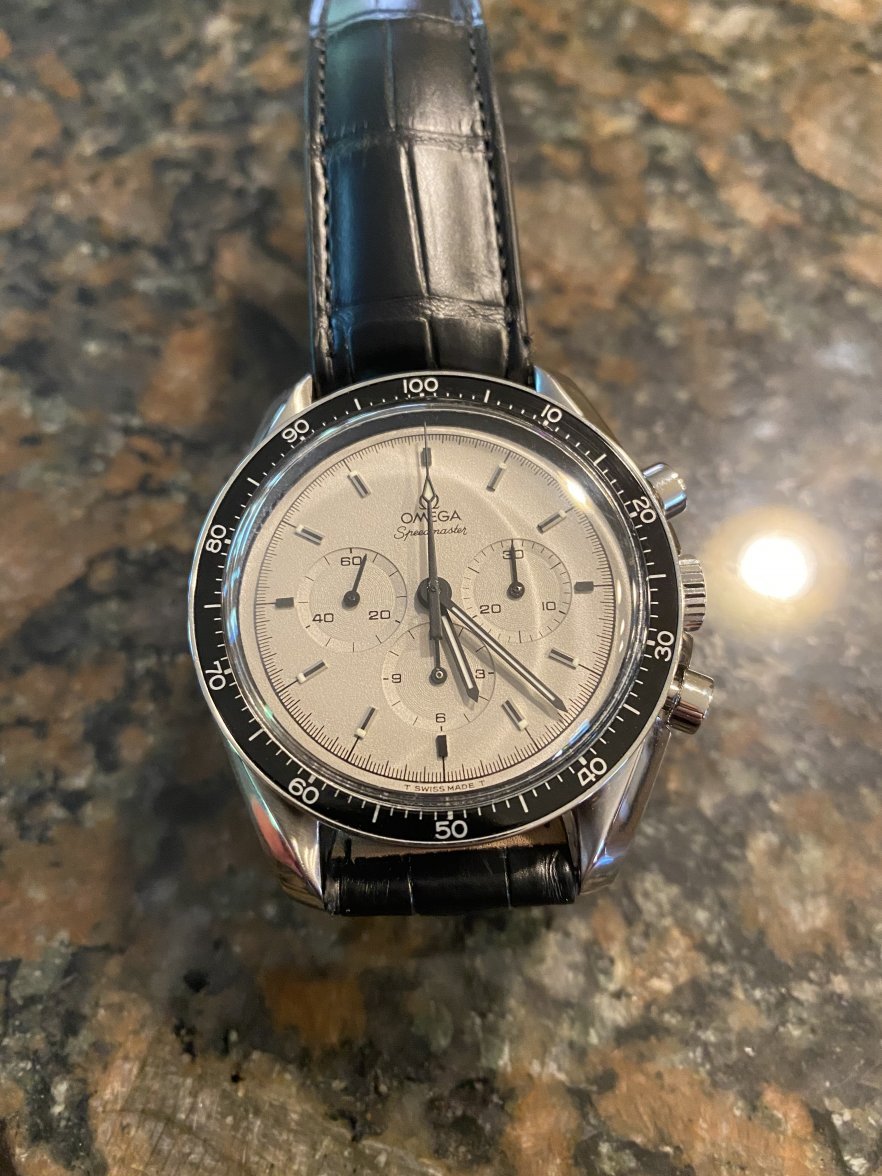

··Omega Certified WatchmakerSome shots from custom project. I had a spare 861 movement out of a 1970’s Mark II that had a junk case. I sourced a NOS case, German market dial, and some hands. The sub dial hands are form the original watch. I went with a Decimeter bezel. I also used a Custom Watch Concepts case back, and a Leather strap on an Omega deployment clasp. Complete service, a little dynamic posing, casing and testing and it was done!

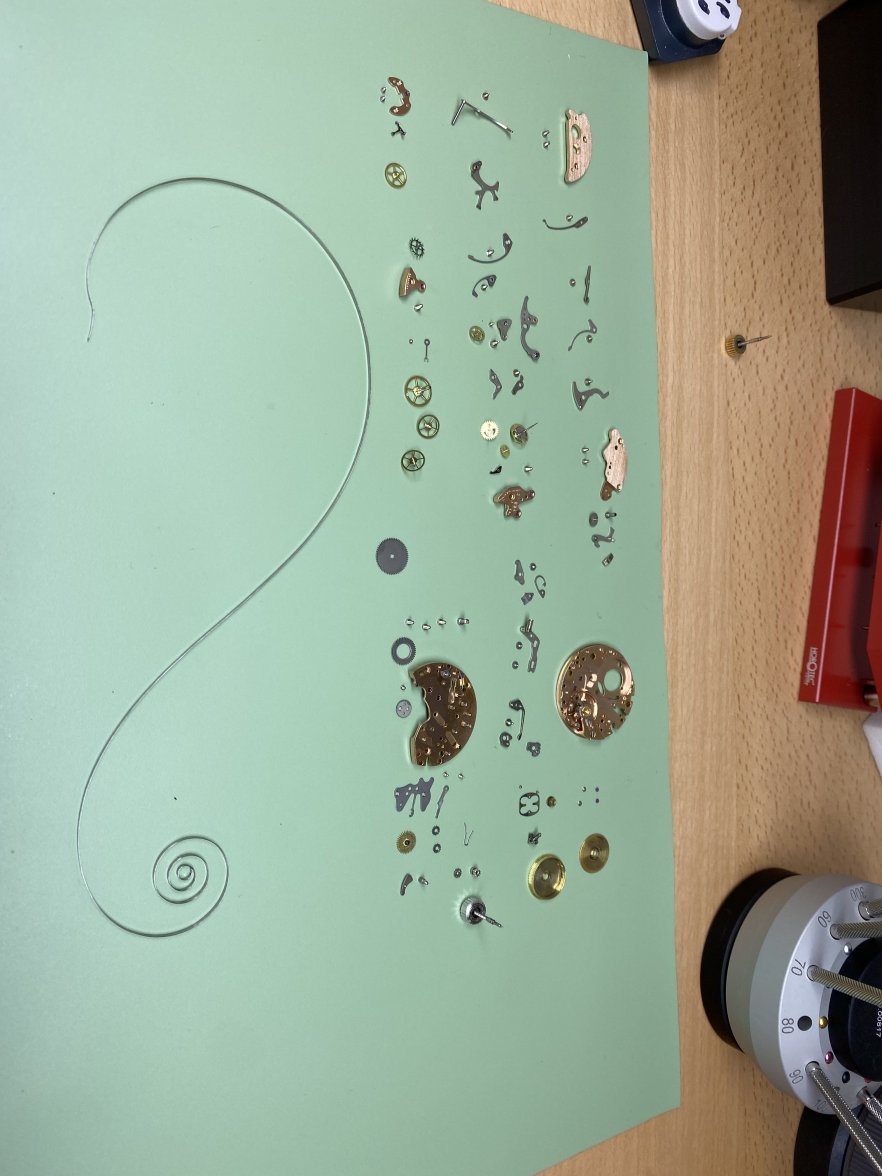

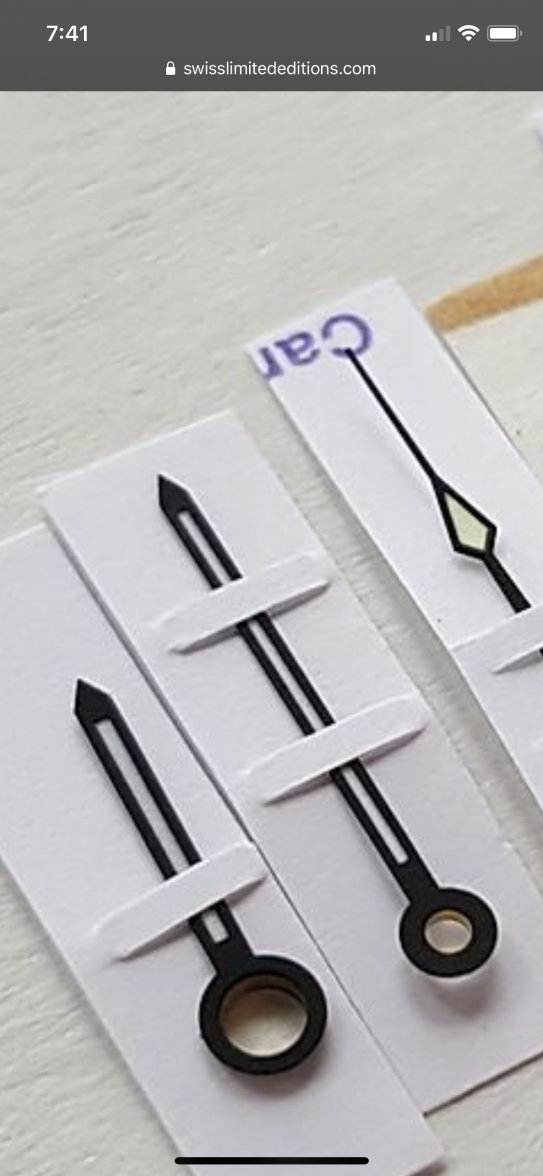

Various shots during disassembly:View attachment 1020637

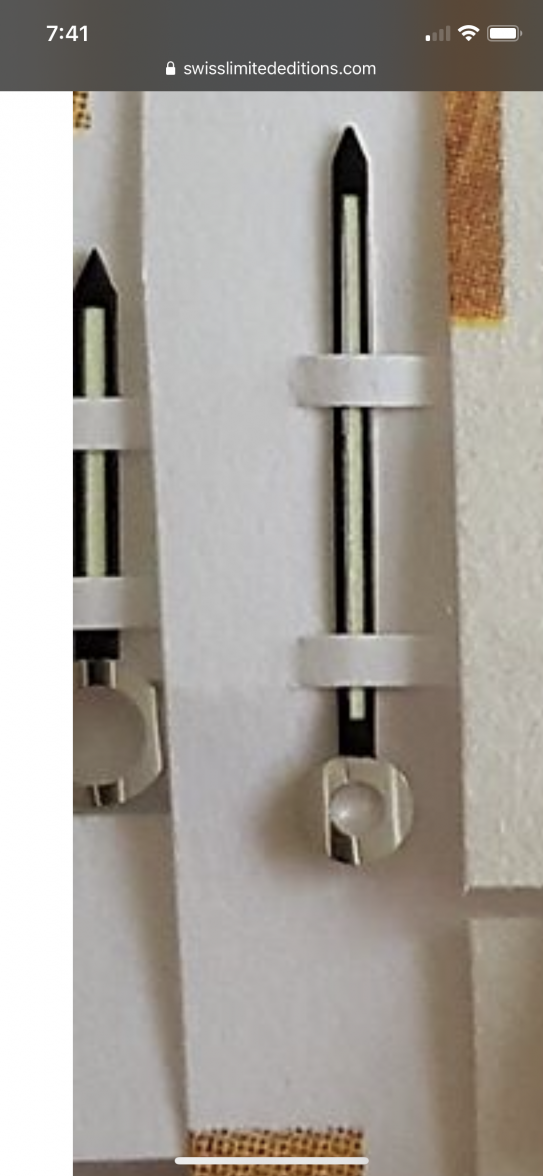

View attachment 1020639

One cap jewel had a divot worn into. The end of the balance staff needs to be slightly burnished. I’m going to do that when I’m at the staffing and timing class next month at the AWCI.

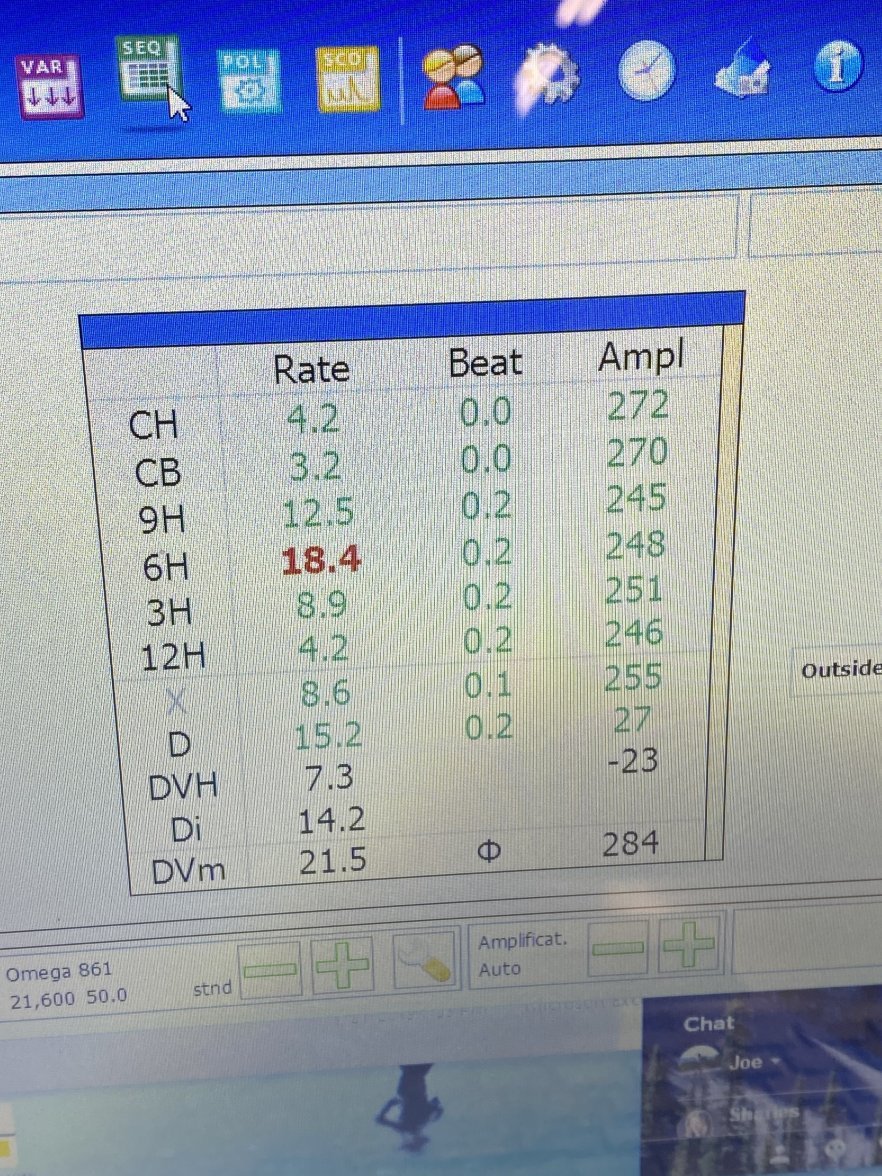

Some dynamic posing was needed to correct a high delta in the verticals.

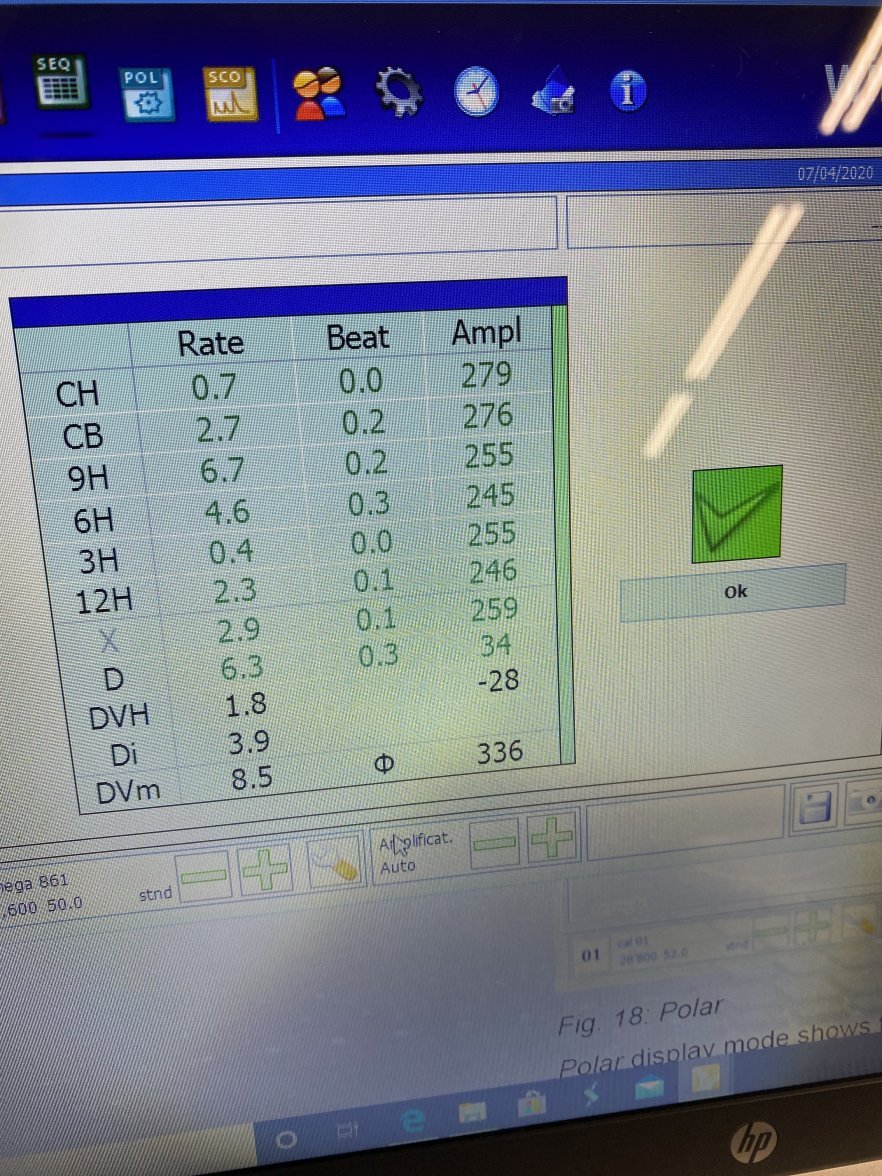

The results after removing a very small amount of weight from the underside of the balance.

The Pac-Man tool and tiny hand drill use while removing weight for the heavy spot

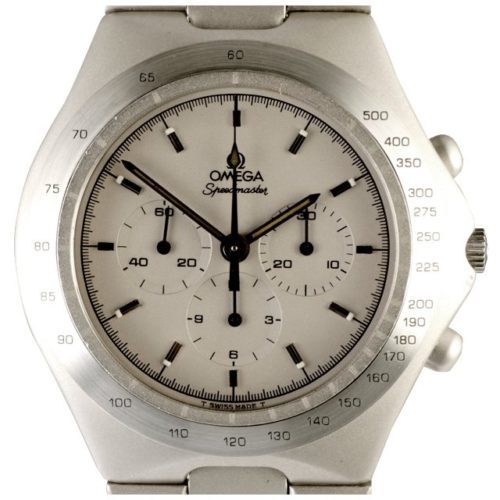

The end results: I call it the “Speedmaster Engineer” View attachment 1020645

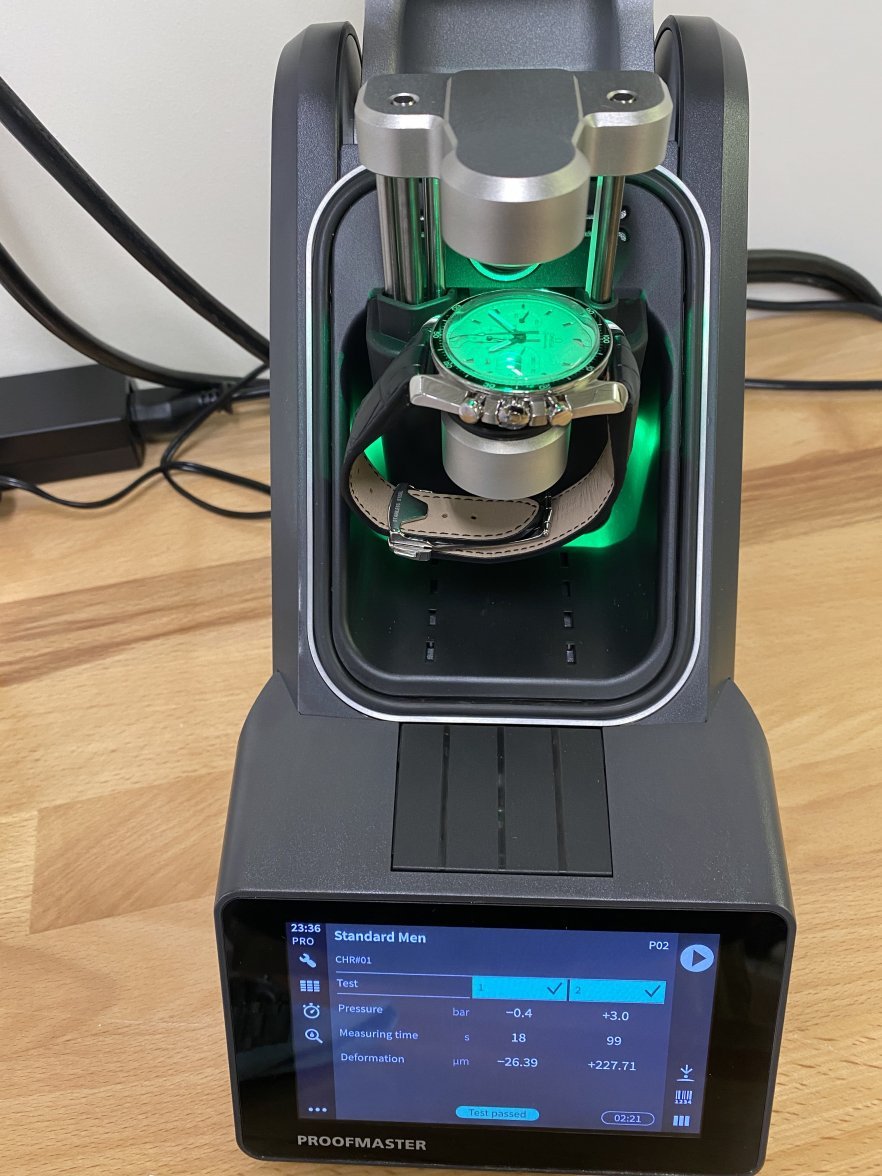

Watet resistance testing passed:

Various shots during disassembly:View attachment 1020637

View attachment 1020639

One cap jewel had a divot worn into. The end of the balance staff needs to be slightly burnished. I’m going to do that when I’m at the staffing and timing class next month at the AWCI.

Some dynamic posing was needed to correct a high delta in the verticals.

The results after removing a very small amount of weight from the underside of the balance.

The Pac-Man tool and tiny hand drill use while removing weight for the heavy spot

The end results: I call it the “Speedmaster Engineer” View attachment 1020645

Watet resistance testing passed: