It's been an age since I wrote anything here as I've been pretty busy so, thought it might be nice to bring the thread up to date:

My exams are in a month's time but the work is spread from now until the end of June. You work on them in this order:

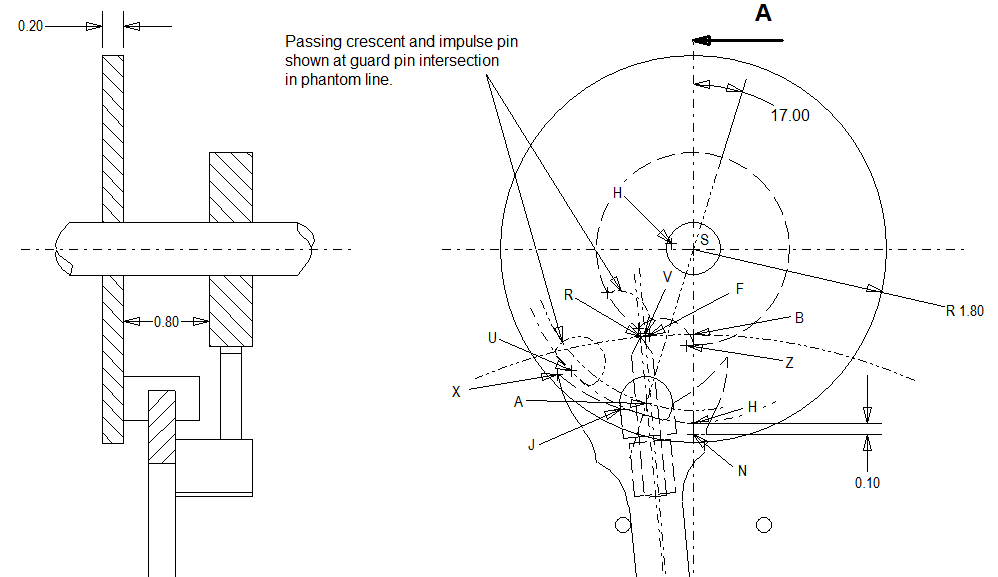

Unit D6: Drawing Clock/Watch Escapements

a. The course work exam arrived a week or so ago and it looks like it's about a days work. I have started it and it's to draw the pallet fork/balance roller interaction. They give you the basic geometry with the pallet fork centered and you have to draw it resting against one banking pin with the balance roller in the correct orientation. It's not really to prove that you can draw but more that you can understand how the parts are working together. This is only 25% of the total mark for this unit as I suppose you could get someone else to do it. I'm doing this in CAD.

b. I sit a 3 hour exam on 17th May at Upton Hall. You can take the explanation booklet of how the escapement geometry is defined so it's not all memory. I'm expecting something slightly simpler in that time but, we'll see. I'm doing this manually with an A3 drawing board as if you want to use CAD, you need to bring your own A3 printer....

Unit D1: Theory of Clock and Watch Servicing

I sit this 3 hour exam on 17th May at Upton Hall. Not much to say on this really as I'm re-reading the notes and just thinking about what is likely to be asked.I suspect this varies from something such as "draw a mainspring in it's relaxed condition" to "calculate the periodic time of a pendulum and the gearing of each wheel in this clock". I feel it shouldn't be an issue as I think I have good knowledge of how a watch works.

Unit D4: Servicing and Correcting Faults in a Quartz Watch

I attended a course at the BHI in March and it was useful but it was with a Ronda 1015 calibre and I'd have preferred an ETA 955. Anyway, that's not a major issue and now that ETA will only supply movements to you if you are running full time courses in your institution, I suspect it'll be a Ronda in the exam. They are just not as nice as an ETA.

The examiner will introduce faults such as a broken stem, dirt in the jewels, bent stop lever (the stop lever usually contacts part of the circuit when the crown is pulled out to ground it and stop the stepper motor). You're expected to analyse the faults, strip the movement, clean, adjust or replace parts, oil and re-test. I'm expecting a cased movement so, it'll also include water resistance testing.

I sit this 6 hour exam on 18th May at Upton Hall. 6 hours seems a very long time for this but allowing for queuing for the testers and cleaning machine and the strange environment, it seems it can be a bit of a push. I'm not allowed to take my own quartz tester as I'd need to leave it because they will all give slightly different results.

To be honest, I have found it very difficult to work at Upton Hall. Not because they don't have the equipment or the conditions are particularly bad but, I'm not used to it and where the various tools are. I'm also used to working in my own room with my own tools and without disruptions. I'll take a lot of my own tools with me including my microscope but, there is a limit to what you can reasonably take. I am not looking forward to this or the next one because of that.

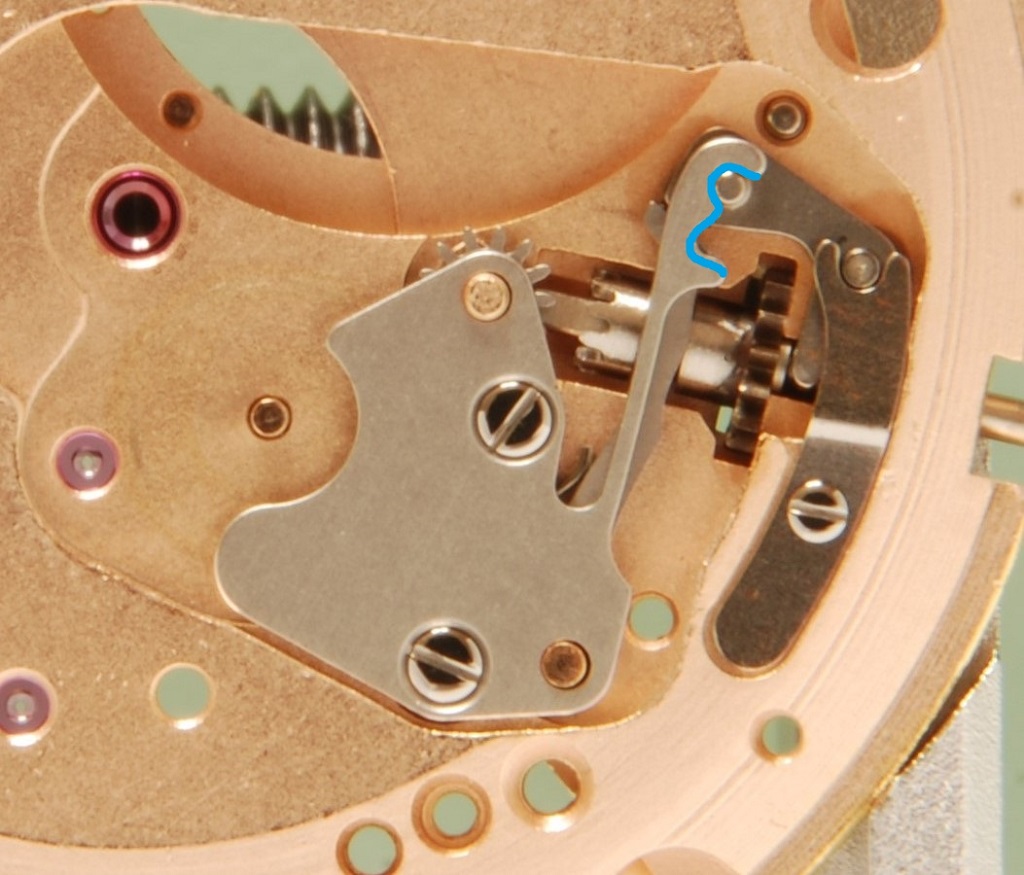

Unit D15: Servicing and Correcting Faults in a Manual Winding Watch Movement

On the mechanical course, they use an ETA 6497 but again because of the latest moves by Swatch, I'm expecting a clone in the exam and it's likely to be an Alpina AL-435. Both have ETACHRON adjustment and here is no real difference unless they are using the new Novodiac shock system in the Alpina. I've not seen this particular shock system up close but, it looks like the KIF or many Russian systems so it should not be an issue for anyone.

The examiner will introduce faults such as a broken stem, dirt in the jewels, excessive end shake in a wheel, deformed hairspring and so on - the list can be huge, obviously. You're expected to analyse the faults and so on in the same way as the quartz exam.

I sit this 7 hour exam on 19th May at Upton Hall. Again, this seems like a huge amount of time but, bear in mind my comments above...

Unit D5: Constructing Clock and Watch Components

This is performed in early June and I have confidence in this now I've spent more time with my lathe, files and so on. It's all done at home and you're given three weeks to construct some parts. I'll explain a little more closer to the time.

Unit D14: The Practical Servicing of Quartz and Mechanical Watches

This, in my opinion, is the most important of them all. It shows the sort of work that you'll be doing in your own workshop for the customer.

It's not easy to get an assessor but, I've been very lucky to have that help from an MBHI who is interested in bringing people on - many are not or just don't have the time. The submission is to be six mechanical and four quartz with a minimum series of faults introduced and they need to be complete for the end of June. I work on them in my workshop, submit them and receive feedback plus a pass/fail mark. They have to be full services and not just a partial job. I submitted five cased movements to my assessor last month to get his initial feedback and he has been excellent at helping me. It's always a bit worrying to show your work to anyone else in case the comments come back in an unfavourable manner - anyone can call themselves a Watchmaker and you don't need any qualifications or to have attended any course to say that, however, I think to get this feedback can only improve your ways of working and processes.

I gave my assessor five mechanical watches and spread them over the years and types - essentially, you don't need to do this and can just supply for example, six ETA 6497 (manual wind, no complications) and four ETA 955 (quartz with central second and date complication). These can all be brand new and you can introduce some faults and correct them. You can leave any mechanical complications (central seconds, date, automatic mechanism etc) to the second year of the course as this year is to get you through the basics but, I thought it best to submit the sort of movements I intend to work on. I chose the following, going back in time:

1. A cased ETA 6498, circa 2014 - manual wind with no complications - cased in generic case. This was brand new a few years ago but I use it to try various things out so it's not perfect now. This watch has Incabloc shock protection and ETACHRON which is a nice system for adjusting the hairspring.

2. A cased ETA 2892-2, circa 2000. This is an Oris with display back and is in quite nice condition. This watch also has Incabloc and ETACHRON and has central seconds, date and automatic mechanism. The Omega 1120 is based on this but I baulked at submitting one of those.

3. A cased Poljot 2614.2H, probably 1990s - manual wind and date and has a different shock protection (manufacturer specific). I put this in as it's very different to the ETAs and Omegas. A bit agricultural as well.

4. A cased Omega 601 "Admiralty" manual from the 1960s. This is typical of the sixties Omegas and has similarities to the 550 series (561, 565 etc). Incabloc but again no clever hairspring system. Central seconds complication.

5. A cased Omega 354 automatic from the 1950s. This is the most complex of any that I submitted and is also the oldest. Incabloc and no trick hairspring system with a central seconds and an automatic system. This is a bumper and really employs a lot of old technology but, I do work on these. I thought I might regret putting this in as it has some acceptable wear and is a trickier movement to assemble and oil correctly but, it wasn't the case.

My Assessor had a long chat with me after spending time reviewing every watch. His list of checks is comprehensive - everything from water resistance of the case to end shake of the balance and so on. It really is huge and I am making it very clear that, although he is a working watchmaker, he has spent a significant time on these reviews for which, I am very grateful. So, after going through the huge list, he went through his comments on my watches and they were very small which pleased me enormously.

Primarily, some of his requirements are slightly different to the BHI instructors and this may be because he is more involved nowadays than they are. I adjusted some of my greasing, for example in the keyless works to be that shown by the BHI instructor but, he would like a little more grease there and that's fine as he's spent the time to review them so, he sets the standard. The great thing is that he was happy with all the movement adjustments so, I just need a few tweaks to meet his way of working in one or two places. What he is saying is very similar to what I was doing before the BHI courses and I thought it best to change rather than risk any issues. I used to base a lot of oiling/greasing on discussions with Al and it appears that if I'd continued in that vein, I would have kept my assessor happier. Ah well, everyone has a slightly different way of working.

---------------------------------------------------------------------------------------

All coming together and I'm feeling happy with the way it's going to the extent that I have now started taking some work on. Not much as I don't need to but I have a few happy customers already😁.I now need to learn how to run a small business but I'll enlist my wife's help with that.😉

Just a general note here as I know I've gone on a lot but my feelings about this change in direction are that if you can put the effort in and spend a lot of time at the bench, it's a rewarding job to do and you can build the knowledge as you go. I would certainly not try to put anyone off who has the desire to change to be a watchmaker and would recommend people try it if they think it's for them - I know there are a few people already doing that. There is an issue with spare parts at the moment and a lot of people will be interested to see how that works out however, there is certainly room for further watchmakers in the world based on the many enquiries I've already had and bearing in mind I'm not advertising....

Cheers, Chris