Explaining how escapements work is not easy without being able to talk face to face, but I'll try....

Let's start with the lever escapement. Yes the top part is the underside of the balance wheel with the impulse pin (roller jewel), then the pallet fork (or lever) and then the escape wheel. Here is a shot of the pallet fork inside a watch (Omega Cal. 861 I believe) and it shows the working surface of the pallet jewel - there is a small drop if oil placed on that jewel.

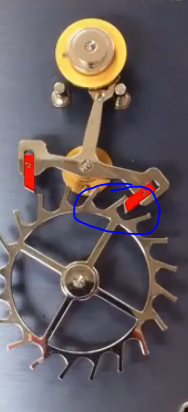

The picture you posted above of the lever escapement shows the escapement in a locked position, and although there is a bit of sliding friction when the escape wheel tooth unlocks from the side of the pallet stone, the major friction I was referring to is during the impulse. This is when the impulse pin (roller jewel on the bottom of the balance wheel) is inside the fork horns of the pallet, and the escape wheel tooth is pushing on the pallet fork. This is what gives the impulse to swing the balance wheel around.

In this photo, you can see the tooth part way across the face of the pallet stone, and this is what it would look like when the tooth is giving the impulse to the pallet fork, Here the wheel is rotating CCW, so the tooth is moving from right to left, pushing on the jewel and causing the lever to flip, and push on the impulse pin on the balance:

Lubrication here is important, and too much or too little can cause problems.

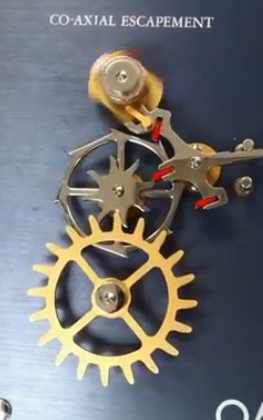

In the photo of the co-axial escapement, the terminology is a little different...

At the top we still have the underside of the balance wheel, but in addition to the impulse pin (roller jewel) there is another jewel in the roller that looks like a pallet stone. Next we have the pallet fork, and it is a different shape that the lever style obviously, and it has 3 jewels instead of 2. Next is the co-axial wheel, with the star thingy on top, to use your terminology. And he last one is the intermediate escape wheel.

There is sliding friction in this escapement between the teeth of the intermediate escape wheel, and the upper co-axial wheel teeth (those are the star shaped thingies). This is actually the trouble spot in the 2-level design, and this can cause issues with the function of the escapement, and what is known on WUS as "the stopping problem."

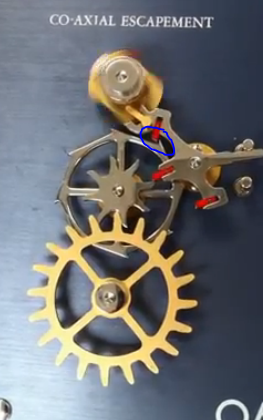

Now the shape of the jewels in the pallet fork and the extra one on the roller are similar to what is in the lever escapement, but the working surfaces of those jewels are all quite different. The angled surface that is the sliding surface on the lever, is merely clearance on these jewels, and it's mostly the sides of the jewel that are in contact with the various parts.

There is a tiny bit of sliding happening at the point you circled, but I can't stress enough how small it is in relation to the lever escapement.

The lower teeth on that co-axial wheel are very small, and very sharp. Just how small? Well here is a little demo for you to show you how small...

Here is a Cal. 2500 mounted in a movement holder that is specifically designed for checking and oiling the co-axial escapement:

Here I have used a regular old straight pin to show the size of the hole that I oil through on the dial side of the movement:

Now moving to the microscope, here is that same pin beside the co-axial wheel:

And finally, here is the wheel under 50X power, showing how I have oiled one of the teeth on the co-axial wheel:

Hopefully you can see the drop of oil I have placed there. I can assure you it is very small, and this is the oil that helps protect the wheel from impact damage. If the wheel is not properly lubricated, you end up with this sort of damage to the teeth:

So the contact between the jewel and this tooth is almost a "point contact" rather than two large areas that are sliding against each other as you have in the lever system.

Anyway, I hope this helps.

Cheers, Al