noless

·A few months back I found what I looked like a project watch rage quit on the bay, so took a gamble on 2 non running 1012 movements.

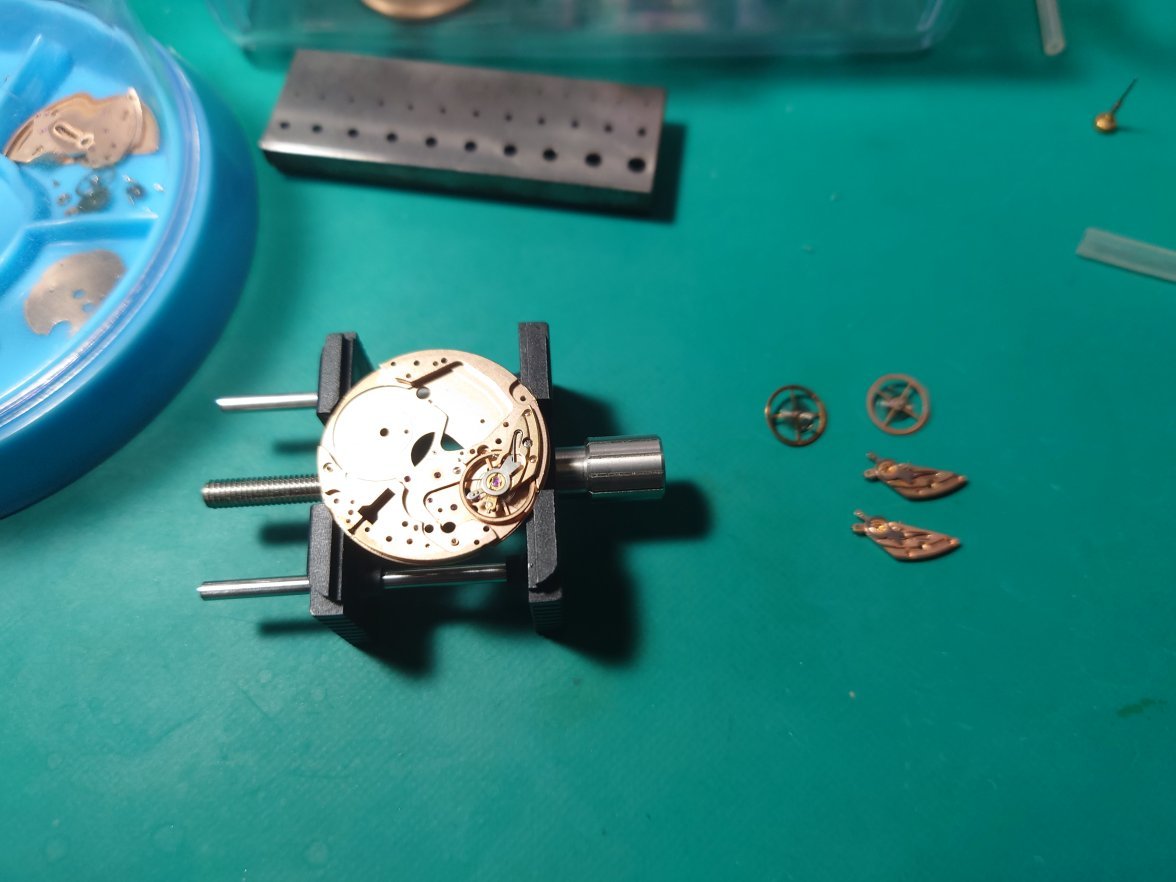

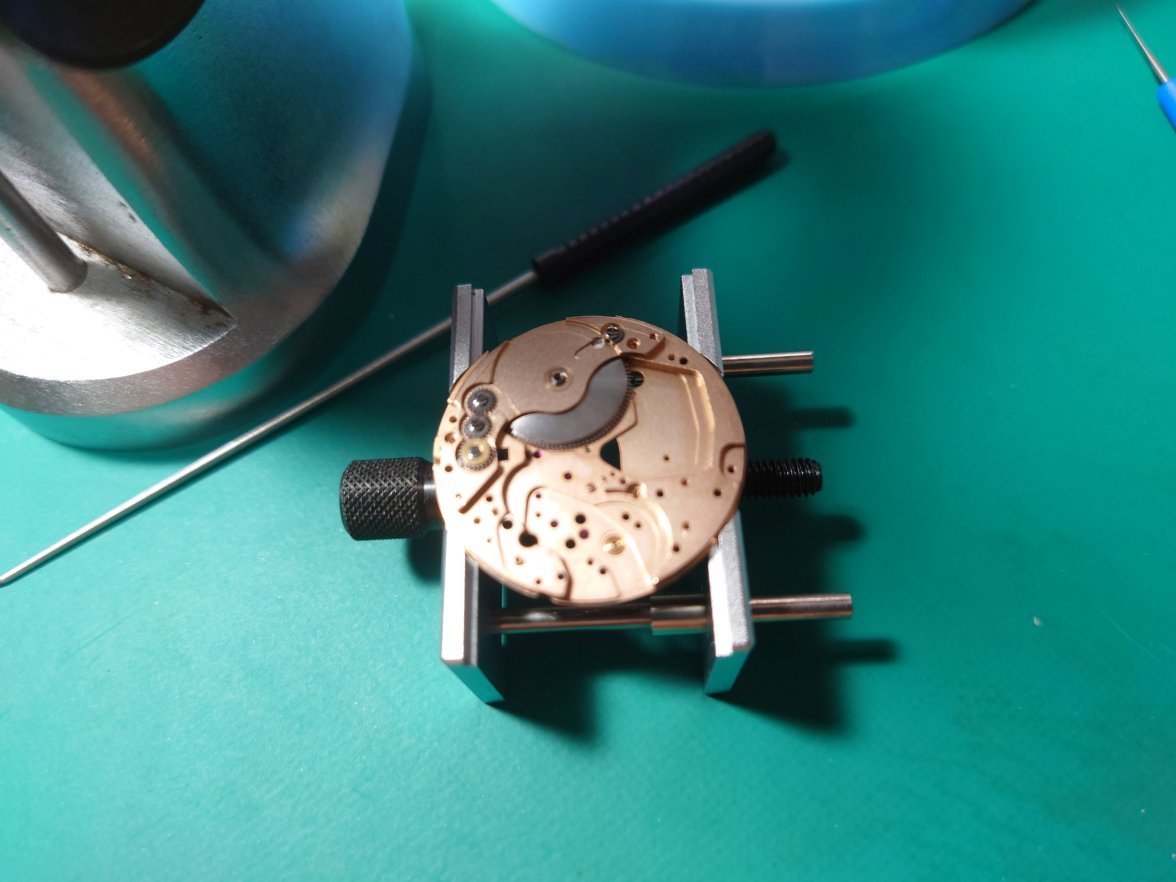

Stripped both of them down, and discovered a broken balance pivot stopping on one, and the tube that holds the seconds pinion loose on the other. Along with broken incablock springs on BOTH balance cocks...

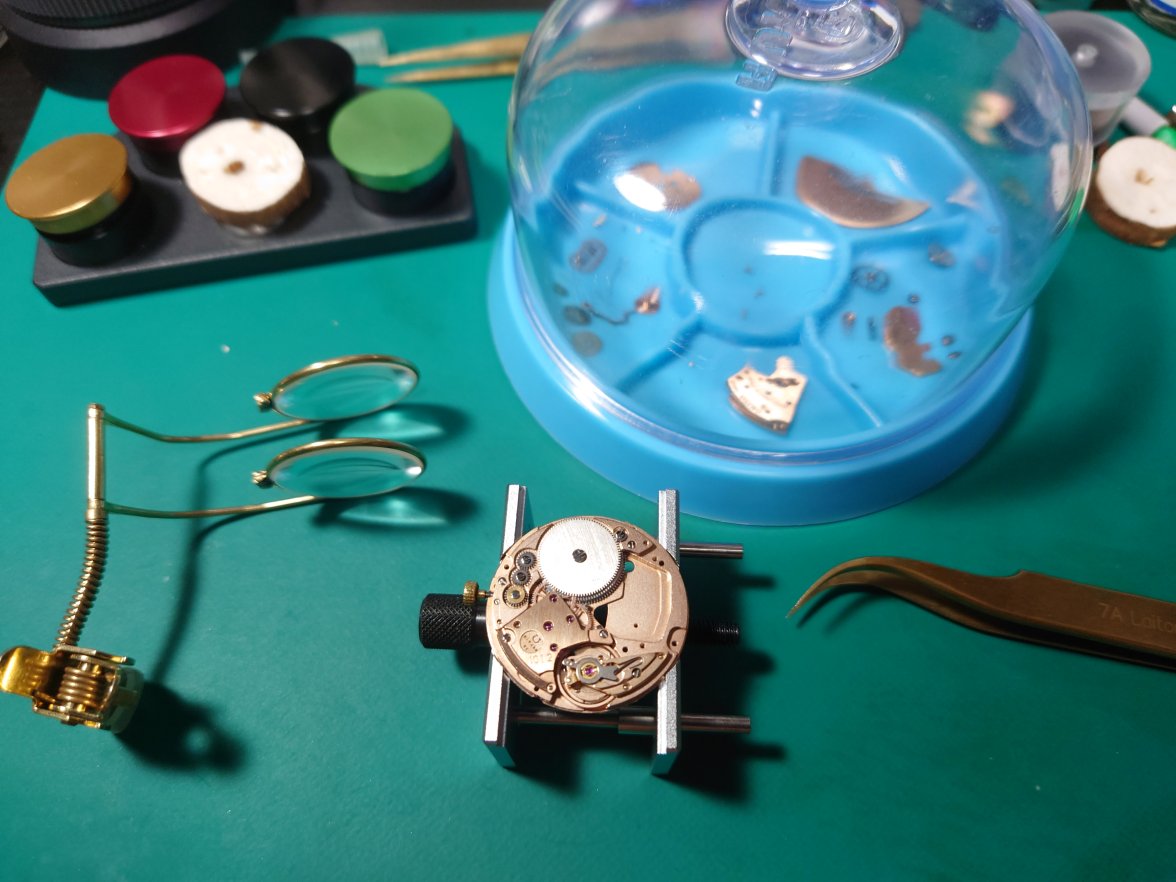

Needed to move some balance wheels around, and dig a balance cock from the parts box, but managed to get a seemingly functional balance cock assembly together.

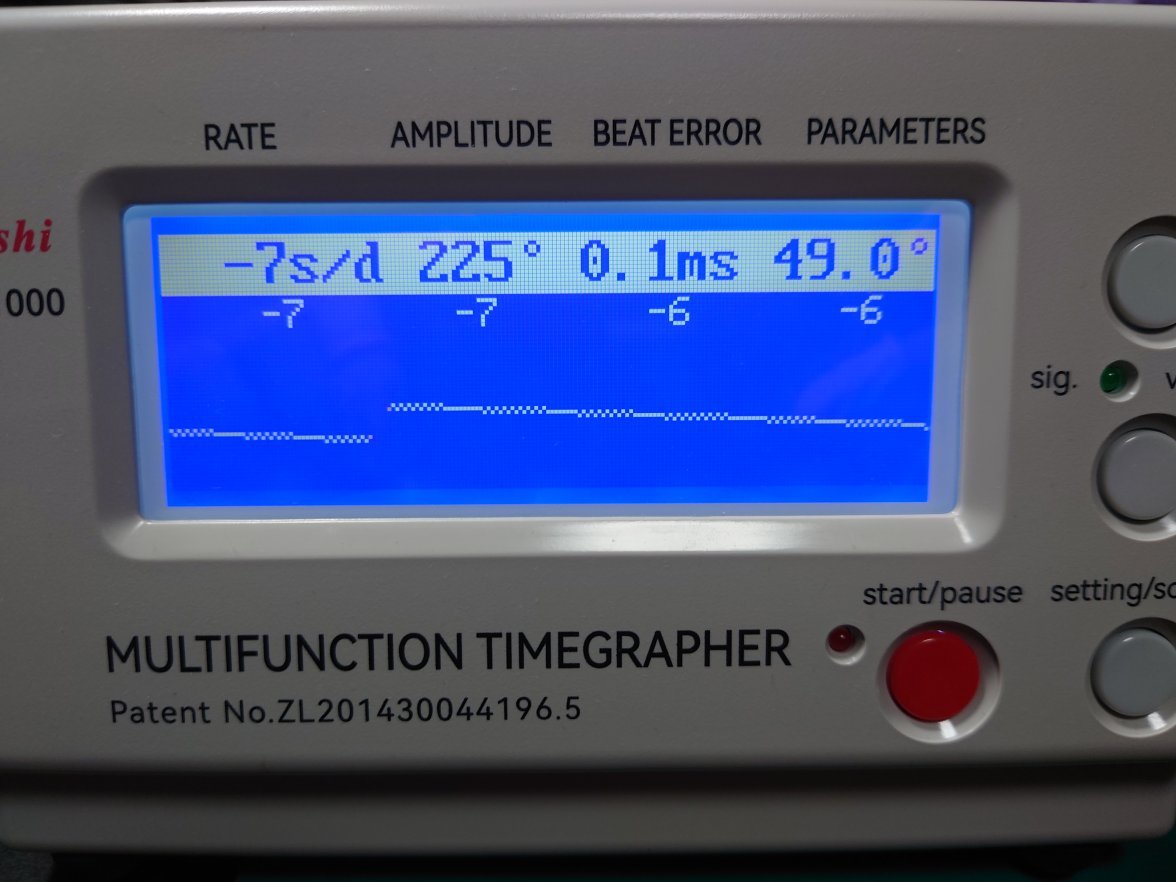

lets see if I can't make a runner out of these 2 movements yet.

Stripped both of them down, and discovered a broken balance pivot stopping on one, and the tube that holds the seconds pinion loose on the other. Along with broken incablock springs on BOTH balance cocks...

Needed to move some balance wheels around, and dig a balance cock from the parts box, but managed to get a seemingly functional balance cock assembly together.

lets see if I can't make a runner out of these 2 movements yet.