Anyone else collect knives?

mjb

·Another perfect example of why these forums are so dangerous - reading through the posts made me want to go add to my collection. 😲

Admittedly, it's not much of a collection, just a few folders, but this is my most recent purchase. I discovered the DiamondBlade brand via the "How It's Made" TeeVee show, and thought it was an interesting process called Friction Forging to keep the blade sharp. And they're made in America.

I like automatic knives, it's just so convenient when I'm typically holding something in one hand and need to open the knife one-handed. And they're not illegal in my state.

Admittedly, it's not much of a collection, just a few folders, but this is my most recent purchase. I discovered the DiamondBlade brand via the "How It's Made" TeeVee show, and thought it was an interesting process called Friction Forging to keep the blade sharp. And they're made in America.

I like automatic knives, it's just so convenient when I'm typically holding something in one hand and need to open the knife one-handed. And they're not illegal in my state.

Explorador

·I finally entered the world of serious folders. @STANDY got me real curious about Spyderco in this thread, so I spent the last 2 months cultivating myself in the Spyderco forum. Yes, Standy99, I saw you there too.

So this is my entry folder, a Native Chief in "only" s30v. I am starting to understand the difference. Could not be happier!!!

Happy new year to all of you out there!

So this is my entry folder, a Native Chief in "only" s30v. I am starting to understand the difference. Could not be happier!!!

Happy new year to all of you out there!

mjb

·Brrr, what's that white stuff?

(LOL yes, I live in the south)

(LOL yes, I live in the south)

Wryfox

·Wryfox

·The most critical step in any Japanese sword, the tempering. Watch the flexing. Awesome!

STANDY

··schizophrenic pizza orderer and watch collectorNot a knife but a hammer made by a knife maker

one on left is mine. Video a bit down on December 15th shows him making one. ( uses old school fly press and not a hammer press )

https://www.facebook.com/Ellardblacksmithing/

one on left is mine. Video a bit down on December 15th shows him making one. ( uses old school fly press and not a hammer press )

https://www.facebook.com/Ellardblacksmithing/

Archer

··Omega Qualified WatchmakerJust FYI - that's hardening, rather than tempering. Hardening is done by heating the steel to above critical temperature, then a rapid quench where the microstructure is transformed, hopefully to a very fine grain. Tempering is a lower temperature process done after hardening to draw back some hardness and make the steel tougher. It is often slowly air cooled after tempering, rather than quenched, but it depends on the steel.

Hardening temperatures are in the area of 1400 F, where tempering is more like baking a cake typically - 350 F or so...

Wryfox

·Just FYI - that's hardening, rather than tempering. Hardening is done by heating the steel to above critical temperature, then a rapid quench where the microstructure is transformed, hopefully to a very fine grain. Tempering is a lower temperature process done after hardening to draw back some hardness and make the steel tougher. It is often slowly air cooled after tempering, rather than quenched, but it depends on the steel.

Hardening temperatures are in the area of 1400 F, where tempering is more like baking a cake typically - 350 F or so...

Not in this case, with Japanese swords this IS tempering.

"What is Clay Tempering?

Clay tempering is an art form as well as a science. Pioneered by the Japanese, traditional clay tempering techniques are perhaps the pinnacle of Japanese sword design.

Today, clay tempering techniques are used by many modern smiths on swords as well as knives, both western and eastern.

The principle behind clay tempering is to achieve both hardness and flexibility, which equals strength. A hard cutting edge, and a flexible spine. A harder steel will sharpen better than softer, retain its sharpness longer, and resist denting. The flexible spine allows the blade to resist greater impact, without breaking.

These two things combined, hardness and flexibility, make for a great sword.

Clay tempering is called just that because the smith will use “clay” e.g. mud, to insulate the blades spine. Like a plastic sleeve around a wire. Where the clay is the plastic and the blade is the wire. Though it is just the spine of the sword that is coated in the clay. The edge is left exposed.

Once the clay is applied the blade is heated in the furnace. When it gets to its optimum temperature it will be glowing red. It is then plunged into a cool pool of quenching liquid (water, or oil). There is a rapid cooling of the blade. Due to the clay insulation the spine cools slightly slower than the edge which is exposed.

The differential tempering is now created, hard and flexible. It is this pattern that the Japanese call the “Hamon”. It is revered, studied and admired for its beauty."

Edited:

redpcar

·Archer

··Omega Qualified WatchmakerNot in this case, with Japanese swords this IS tempering.

Yes, I am aware of this process, and how the Hamon is created during hardening. This is a process of preventing a portion of blade from being hardened, and this is called selective hardening in metallurgical terms. Another way of accomplishing this is flame hardening with a torch - you only heat up the cutting edge with the torch and not the spine of the blade, that way when the blade is quenched, the spine stays soft.

Wryfox

·Yes, I am aware of this process, and how the Hamon is created during hardening. This is a process of preventing a portion of blade from being hardened, and this is called selective hardening in metallurgical terms. Another way of accomplishing this is flame hardening with a torch - you only heat up the cutting edge with the torch and not the spine of the blade, that way when the blade is quenched, the spine stays soft.

More specifically, the only part that is hardened is the knife edge, the rest is actually a tempering of the body.

The term Differential Tempering is correct for this process.

Archer

··Omega Qualified WatchmakerMore specifically, the only part that is hardened is the knife edge, the rest is actually a tempering of the body.

The term Differential Tempering is correct for this process.

We can agree to disagree...

Differential heat treatment - Wikipedia

cvalue13

·Never realized this is why katanas' have that distinctive curve! Very cool

cvalue13

·Not a collector, but looking through this post today thought I'd add a few pictures.

First, pictured below, a knife (and sheath) my grandfather made (his 3rd, as noted on the spine) in 1999. I know that (1) this knife and sheath were made in the shop of one of Arkansas' more famous knife makers somewhere in North West Arkansas, (2) my grandfather was good friends with said knifemaker, and (3) somewhere I have a photo of my grandfather in said shop making said knifes (but I've been unable to locate the photo). My faulty memory is that my grandfather's friend was either A.G. Russell or Bob Dozier, but I can't remember which - or be certain it's either. (I wish I'd listened better, and remembered my grandfather wouldn't always be around).

Here are the other two knives my grandfather gifted me, and anything at all interesting about them:

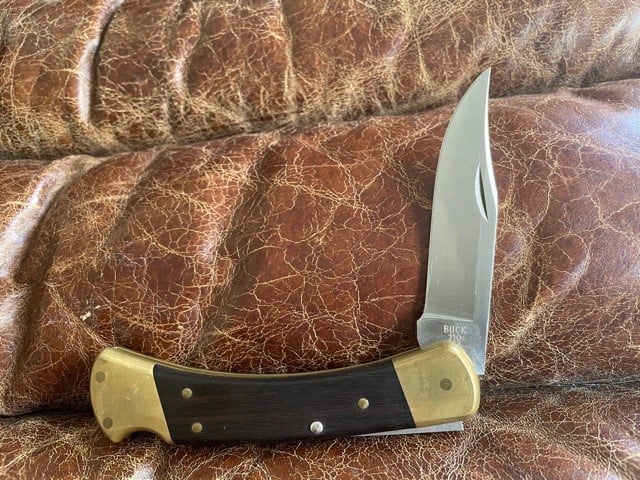

This Buck 110 folding hunter my grandfather gifted me because he used it "to skin [his] first mountain lion."

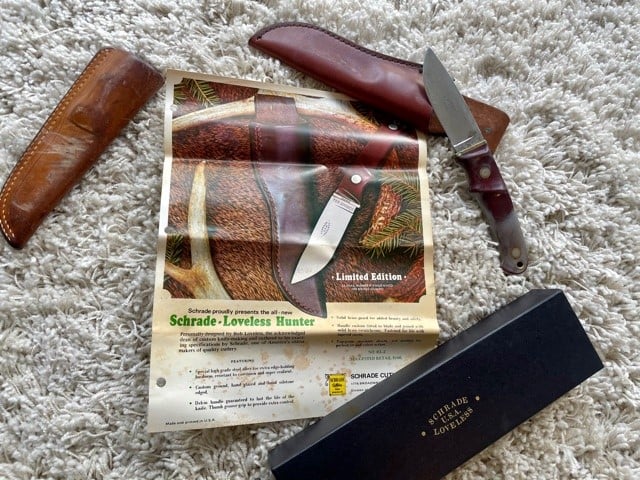

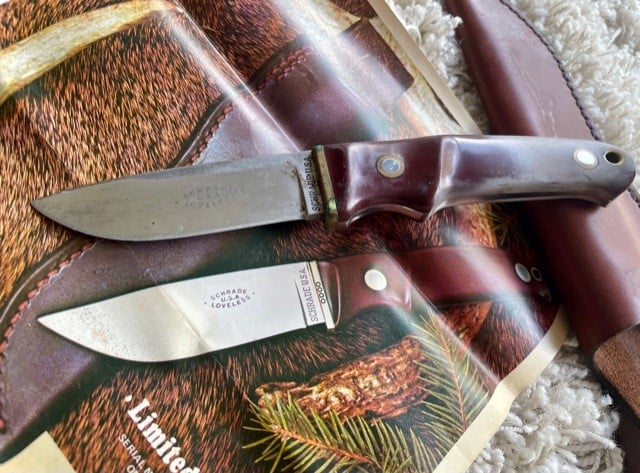

This Schrade-Loveless Hunter, which I wore and used during a 400 mile/30 day ride across Nebraska on a mule.

Taking the Schrade-Loveless out of the box, I'm embarrassed to say it appears I never cleaned it after that mule ride...

First, pictured below, a knife (and sheath) my grandfather made (his 3rd, as noted on the spine) in 1999. I know that (1) this knife and sheath were made in the shop of one of Arkansas' more famous knife makers somewhere in North West Arkansas, (2) my grandfather was good friends with said knifemaker, and (3) somewhere I have a photo of my grandfather in said shop making said knifes (but I've been unable to locate the photo). My faulty memory is that my grandfather's friend was either A.G. Russell or Bob Dozier, but I can't remember which - or be certain it's either. (I wish I'd listened better, and remembered my grandfather wouldn't always be around).

Here are the other two knives my grandfather gifted me, and anything at all interesting about them:

This Buck 110 folding hunter my grandfather gifted me because he used it "to skin [his] first mountain lion."

This Schrade-Loveless Hunter, which I wore and used during a 400 mile/30 day ride across Nebraska on a mule.

Taking the Schrade-Loveless out of the box, I'm embarrassed to say it appears I never cleaned it after that mule ride...