EauTerre

·Hi, I was not sure where to post this so I chose the Open discussion section.

In relation to a thread on the co-axial movement over at the Modern watches section, and specially as a follow up to Horlogerie's post :

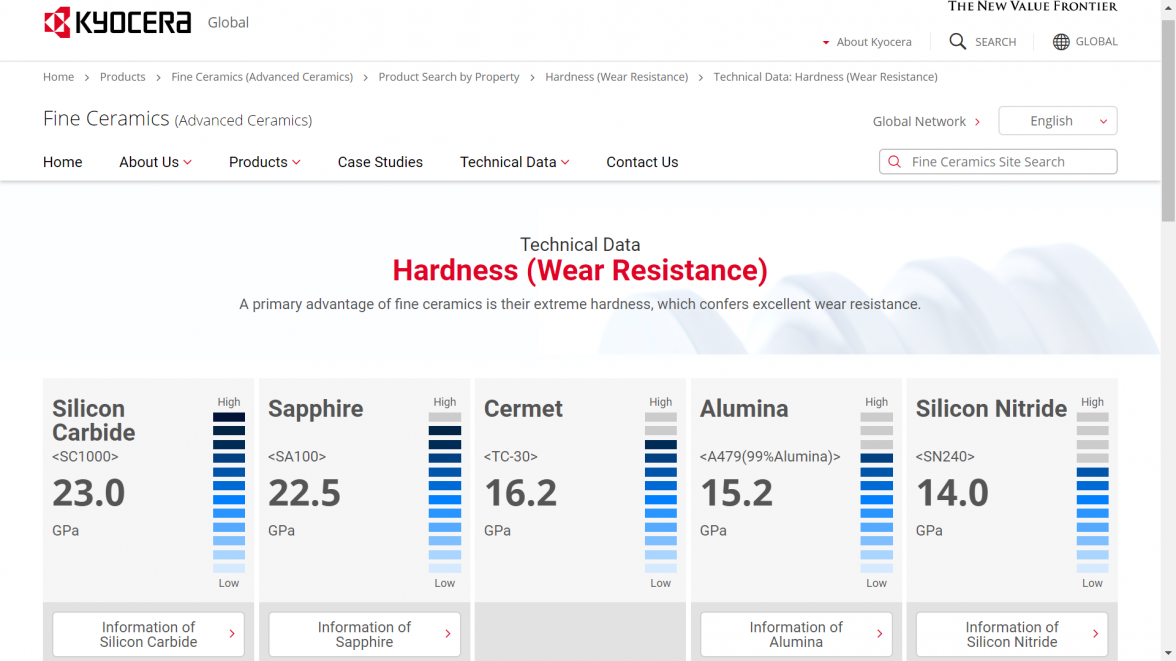

I'm wondering which new materials could be used to make watch parts which are more resistant to wear and require less to no oil.

Would it be possible to make an extensive use of, say, silicon carbide or sapphire ? Or even the mighty graphene ?

Given these materials seem to be very resistant to wear :

Source : https://global.kyocera.com/prdct/fc/list/tokusei/koudo/index.html

What prevents the adoption of such materials in watch parts ? Is it the lack of ability to cost-efficiently manufacture them at minute scales ? Or are there undesirable aspects about their mechanical properties ?

Are major manufacturers such as Rolex and Swatch even working on this ?

Cheers.

In relation to a thread on the co-axial movement over at the Modern watches section, and specially as a follow up to Horlogerie's post :

I struggle to wonder where the advantage is between a Coaxial and Swiss Lever escapement, and if the same problems exist on the Daniels Coaxial movements and those made by Roger Smith.

If having to replace escape wheels becomes part of the servicing routine due to wear, that cost has to be factored into the cost of ownership.

I guess a new material for the escape wheels would be in order to eliminate the wear issues, maybe silicone? or carbon?

In the end the service interval is still dependent on the qualities of the lubricants and their deteriation over time.

I'm wondering which new materials could be used to make watch parts which are more resistant to wear and require less to no oil.

Would it be possible to make an extensive use of, say, silicon carbide or sapphire ? Or even the mighty graphene ?

Given these materials seem to be very resistant to wear :

Source : https://global.kyocera.com/prdct/fc/list/tokusei/koudo/index.html

What prevents the adoption of such materials in watch parts ? Is it the lack of ability to cost-efficiently manufacture them at minute scales ? Or are there undesirable aspects about their mechanical properties ?

Are major manufacturers such as Rolex and Swatch even working on this ?

Cheers.