This idea of using Face Time when dealing with problems with clocks from remote locations is becoming a regular occurrence with me.

A friend who is a clock collector, and managing director of the Revelstoke (British Columbia) Railroad Museum, collects Seth Thomas railroad standard wall clocks. He has three spring driven Seth Thomas World (15-day) clocks, a Seth Thomas # 17 weight driven regulator, and several other miscellaneous clocks. The four Seth Thomas clocks are all ex-CPR. I have serviced all of these clocks over the years.

He has been gradually re-locating from his house in Calgary to Revelstoke, the recent move including a Seth Thomas World that I last serviced in 2005. 19 years ago. When he set it up at his home in Revelstoke, it wouldn’t run. He phoned me. I had some questions, and asked him to take some pictures from within the cabinet, to determine if I could see anything. Nothing conclusive, as it happens.

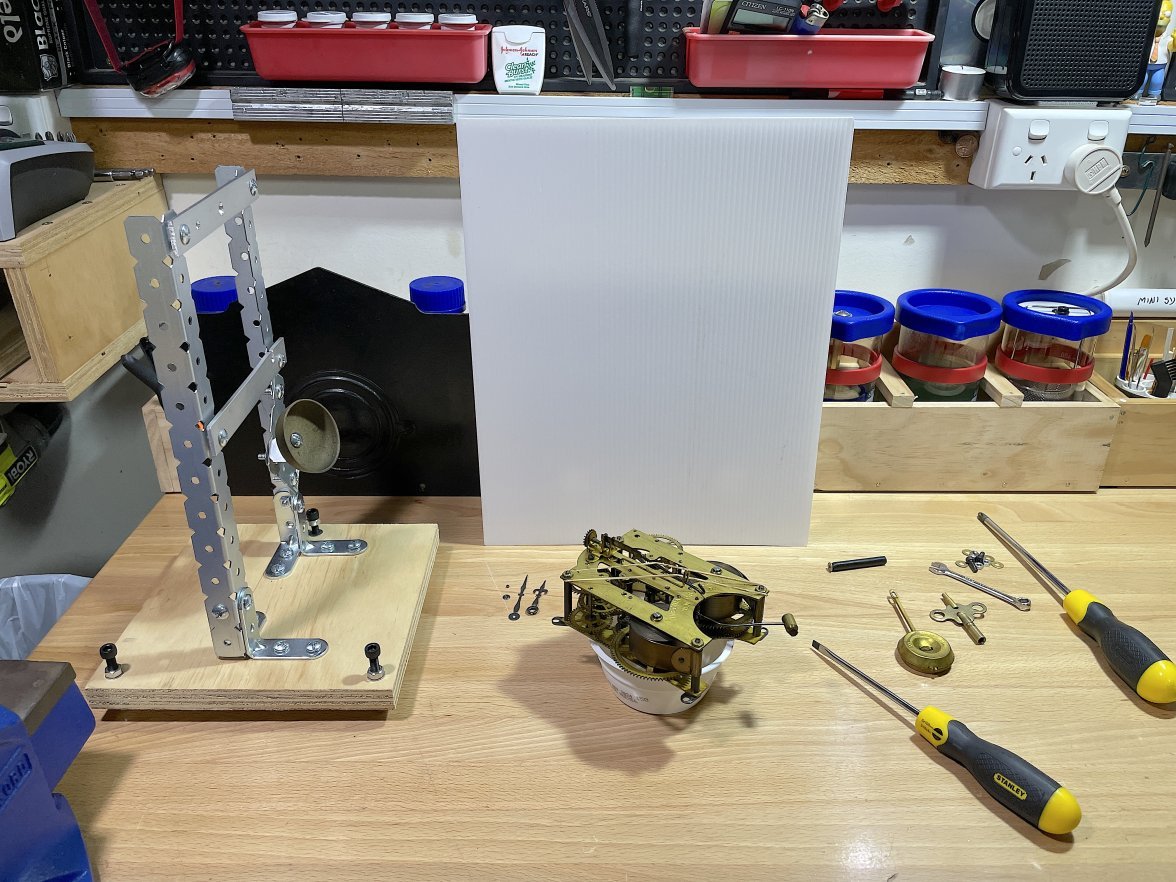

So, we had a Face Time session this morning (Sunday), and I tutored him as to removing hands, and dial, and to remove the movement from the case. Nothing major stood out, as it happens. However, we two came to the conclusion that, after 19-years, it was overdue to be gone through, again. It proved to be very sluggish when out of the case. I’ll strip it, clean it, lubricate it etc.

Shipping the movement by itself is a whole lot different process than having to ship the whole clock. I’ll service the movement in due time, and ship it back. When the time comes, we’ll establish the Face Time connection again, and he now has the confidence to put it all back together.